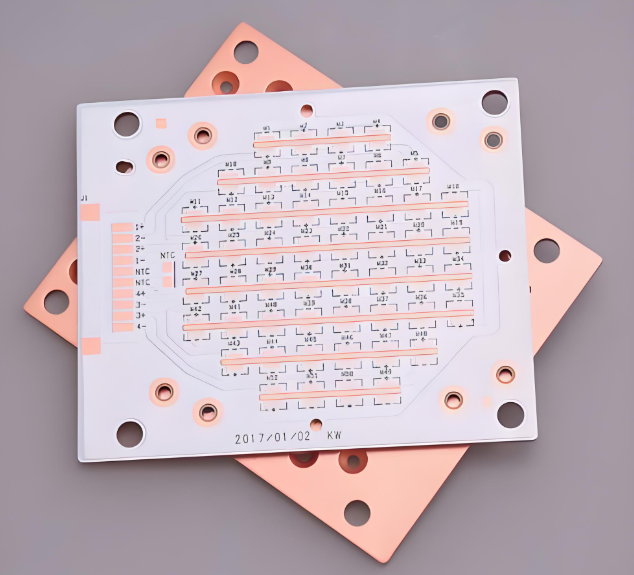

IMS PCB full form is Insulated Metal Substrate PCBâa type of printed circuit board built to manage high heat and maintain strong mechanical support. Itâs a popular choice for LED lighting, power supplies, and automotive electronics, where heat control is critical.

At EBest Circuit (Best Technology), weâre a trusted IMS PCB manufacturer in China, providing custom thermal management solutions with high precision, reliable materials, and a full range of engineering support. But letâs dig deeper into what makes insulated metal substrate PCBs uniqueâand why theyâre so important in modern electronics.

What Is IMS Insulated Metal Substrate PCB?

An IMS (Insulated Metal Substrate) PCB is a type of circuit board that uses a thermally conductive dielectric layer bonded between a metal base (often aluminum or copper) and a copper circuit layer. The metal base helps dissipate heat more efficiently, especially compared to traditional FR4 boards.

When it comes to IMS PCB thermal conductivity, this is the most valuable feature. The dielectric layer in IMS boards typically offers a thermal conductivity range from 1.0 W/mK to over 8.0 W/mK, depending on the application. The metal base, like aluminum or copper, works as a built-in heat sinkâpulling heat away from active components like LEDs, power transistors, or ICs. Thatâs why IMS PCBs are commonly used in LED modules, power converters, automotive lighting, and solar invertersâwhere both heat and performance need to be tightly controlled.

IMS PCB Material

Choosing the right material for an IMS board is essential. Three layers make up a standard IMS PCB: the metal base, the dielectric layer, and the copper foil. And for the metal base, there are two options: copper base and aluminum base.

- Copper IMS PCB

Copper IMS PCBs offer superior heat transfer capabilities. Copper has a thermal conductivity of nearly 400 W/mK, much higher than aluminum. This means copper is ideal for applications with extreme power densities or where space is limited but heat is a concern.

However, copper is also more expensive and heavier than aluminum, so it’s generally reserved for high-performance needs like laser modules, RF circuits, or military-grade devices.

- IMS Aluminum PCB

The IMS aluminum PCB is the most common choice. Aluminum provides good thermal conductivity (typically around 200 W/mK), excellent mechanical strength, and lower cost compared to copper.

Aluminum IMS PCBs are often used in LED lighting systems, electric vehicle chargers, power control modules, and industrial automation systems. They provide a balanced solution between cost and thermal management, which is why theyâre the industry standard. Some common aluminum grades used include:

- 5052 aluminum: Strong, corrosion-resistant, and suitable for structural use.

- 6061 aluminum: Versatile, high-strength alloy.

- 1060 aluminum: Excellent thermal conductivity, ideal for cost-sensitive applications.

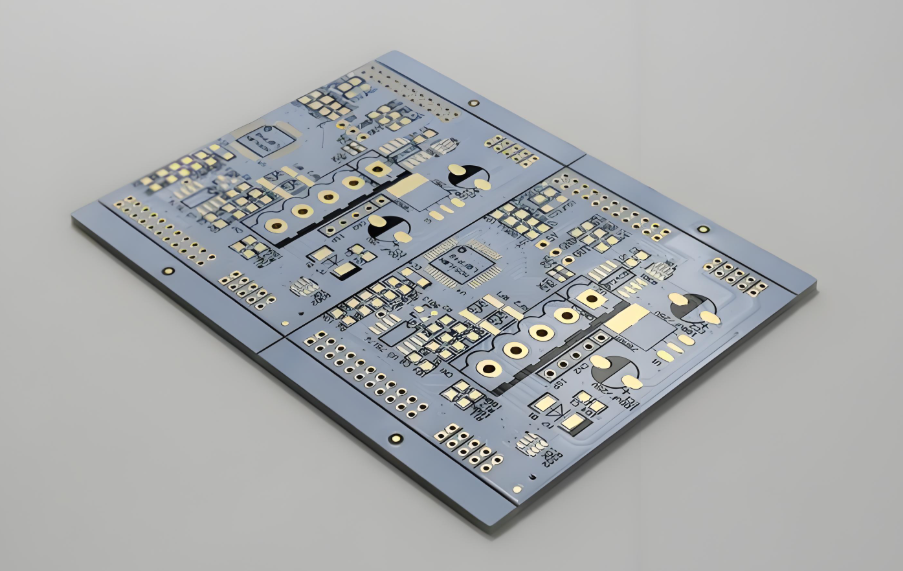

IMS PCB Stackup

The stack-up of an IMS PCB refers to how the layers are arranged. A typical IMS PCB stackup includes:

- Top copper trace layer â for routing signals and power.

- Thermal dielectric layer â usually made of epoxy resin filled with ceramic for heat transfer.

- Metal base â usually aluminum or copper.

For more advanced applications, 2 layer IMS PCBs are often used. In a 2 layer IMS PCB, an additional copper circuit layer is placed above the dielectric, and interconnections are formed using plated through-holes. These are useful when you need more complex routing or higher power density.

Multilayer IMS stackups are possible but require special lamination techniques. These are often customized depending on the mechanical, electrical, and thermal needs of the application.

IMS PCB Applications

Thanks to their excellent thermal performance and mechanical strength, IMS PCBs are widely used in demanding environments. Here are some key application areas:

- LED lighting: Street lights, high-bay lights, grow lights, automotive headlights.

- Power electronics: DC-DC converters, voltage regulators, motor drivers.

- Automotive systems: Electric vehicle controllers, battery management units.

- Industrial equipment: Robotics, welding machines, servo drivers.

- Telecommunication: 5G base stations, power amplifiers.

- Renewable energy: Solar panel inverters, wind turbine converters.

IMS PCB HS Codes

For companies that export or import IMS PCBs, understanding HS codes (Harmonized System codes) is essential for customs clearance and compliance.

The general HS Code for IMS PCB falls under:

8534.00 â Printed Circuits

Subcategories can vary depending on whether the board is populated (assembled) or bare.

To be more precise:

a. Bare IMS PCBs (unassembled):

- HS Code 8534.00.90 (for 1-4 layer ims pcb)

- HS Code 8534.00.10 (4 or above layer ims pcb)

b. Assembled IMS PCBs:

HS Code 8537.10 or others depending on final product classification and applications.

Always check with your local customs authority or logistics provider for the exact code applicable to your product type and destination country.

IMS PCB Assembly

IMS PCB assembly involves more care than standard FR4 boards due to thermal management and mechanical rigidity. Special attention must be given to soldering profiles and thermal expansion to prevent cracking or delamination.

Key points during assembly:

- Use low-stress soldering methods (e.g., vapor phase or controlled reflow).

- Ensure proper thermal profile during reflow to avoid damage to the metal base or insulation.

- Choose high-Tg solder masks and components to handle high power density applications.

For high-volume needs, automated SMT lines should be optimized for heat dissipation and tight placement tolerances.

EBest Circuit (Best Technology) offers one-stop IMS PCB assembly, including:

- DFM (design for manufacturability) & DFA (design for assembly) checks

- SMT and through-hole soldering

- AOI, X-ray inspection

- Functional testing

- Box building assembly

- Final inspection

Our strict quality control ensures your boards are built to meet thermal and mechanical demands.

Best IMS PCB Manufacturer â EBest Circuit (Best Technology)

When choosing an IMS PCB manufacturer, experience, quality, and customization capabilities matter most. Thatâs where EBest Circuit (Best Technology) stands out.

We specialize in insulated metal substrate PCBs with over a decade of industry focus. Our strength lies in advanced thermal management PCBs, from aluminum IMS boards to copper-core multilayer solutions.

Why Choose EBest Circuit (Best Technology) for IMS PCBs?

✅ Technical Support Before & After Sales

✅ 99% Customer Satisfaction ISO9001, ISO13485, IATF16949, UL

✅ Material options: Wide range of metal bases (Al, Cu, Stainless Steel), dielectric materials with 1â8 W/mK.

✅ Full-stack service: From DFM support to final assembly and testing.

✅ MES traceability: Real-time tracking and control throughout production.

✅ Engineering support: Custom stackups, prototyping, thermal analysis, and layout review.

Whether you need a 2 layer IMS PCB for automotive lighting or a high-power copper IMS board for industrial drives, we can tailor the solution to fit your needs. With our strong supply chain and experienced team, we help customers worldwide bring their designs to life.

EBest Circuit (Best Technology) is your go-to partner for custom IMS PCB fabrication and assembly. We combine deep technical knowledge, certified quality, and flexible manufacturing to deliver solutions that workâevery time.

Ready to upgrade your thermal management? Contact EBest Circuit (Best Technology) today for a quick quote or technical consultation.

FAQs

1. What is the difference between IMS PCB and FR4 PCB?

IMS PCBs use a metal base for better heat dissipation, while FR4 boards use fiberglass, which has low thermal conductivity.

2. Can IMS PCBs be multilayered?

Yes, multilayer IMS PCBs are possible but require special lamination techniques and are more complex to manufacture.

3. What are typical thermal conductivity values for IMS PCBs?

The dielectric layer in IMS boards usually ranges from 1 to 8 W/mK. Copper and aluminum also contribute to heat dissipation.

4. What is the HS code for an assembled IMS PCB?

Typically, 8537.10, but check with local customs authorities as codes can vary by region.

5. How can I request a custom IMS PCB quote from EBest Circuit (Best Technology)?

Simply email us your Gerber files, BOM, and design requirements, or use our online quote form. Our engineers will get back to you quickly.