What is a HMI PCB? Let’s discover its components, benefits, function, purpose, application, design technique for signal integrity, optimize layout solution for HMI PCB board.

Are you troubled with these problems?

- Touch response lag?

- PCB overheating issues?

- Poor multi-device compatibility?

As a HMI PCB manufacturer, EBest Circuit (Best Technology) can provide you service and solutions:

- Ultra-Low Impedance Touch: Custom trace design + anti-interference coating for 30% faster response & ±0.3mm precision.

- Smart Thermal Control: Thermal-optimized copper layout + high-conductivity materials to cut operating temp by 20°C.

- Plug-and-Play Protocol Library: Pre-configured with mainstream industrial protocols (Modbus/CANopen) for 100% compatibility & 50% faster deployment.

Welcome to contact us if you have any request for HMI PCB board: sales@bestpcbs.com.

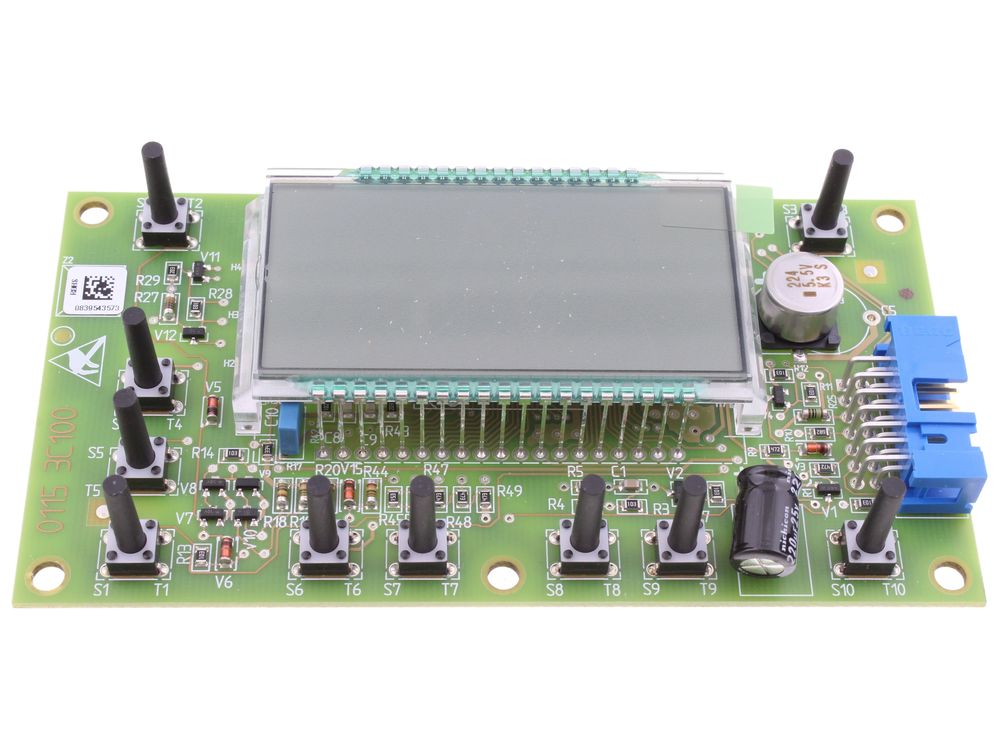

What Is a HMI PCB?

A HMI PCB, or Human-Machine Interface printed circuit board, is a specialized interface enabling direct interaction between users and devices like Power Wheelchairs, featuring intuitive controls for seamless operation. This HMI Board integrates tactile buttons, touchscreens, or voice commands to ensure users with diverse needs can navigate Power Wheelchairs safely and efficiently. By prioritizing accessibility and user-centric design, the HMI Board becomes an essential HMI Board in power-assisted mobility, transforming personal mobility experiences.

What Are Components of HMI PCB Board?

Components of HMI PCB Board:

- Main Control MCU: Low-power microprocessor (e.g., ARM Cortex-M series) for command parsing and system scheduling.

- Multi-dimensional Input Interfaces: Analog joystick signal conditioning circuit + digital key matrix + assistive device ports (eye tracker/respiration sensor).

- Display Driver Unit: LCD controller + backlight circuit + LED status indicator array.

- Real-time Communication Module: CAN/UART transceiver (connects to main controller) + isolated protection circuit.

- Power Management System: Wide-voltage-input DC-DC converter (12V→5V/3.3V) + surge suppression devices.

- Physical Protection Layer: Conformal coating (anti-humidity/dust/corrosion) + EMI shielding can.

- Feedback Execution Unit: Buzzer driver circuit + haptic vibration motor interface.

- Firmware Storage Media: SPI flash (program storage) + EEPROM (user configuration storage).

What Is the Purpose of the HMI Board?

Purpose of the HMI board:

- Human-Machine Interaction Hub: Converts touch/key/joystick inputs into executable commands.

- Real-time Status Visualization: Displays equipment parameters (temp/pressure/speed) & system alerts.

- Multi-protocol Communication Hub: Enables CAN/UART/Ethernet data transfer with PLC/main controller.

- Hardware Safety Protection: Electrical isolation + EMI anti-interference design.

- User Environment Adaptation: Stores personalized settings (screen brightness/sensitivity).

- Multi-mode Feedback: Audible alarms (buzzer) + haptic vibration + tri-color LED indicators.

- Assistive Device Integration: Supports eye-tracking/voice modules for accessibility.

- System Health Monitoring: Diagnoses PCB temp/voltage fluctuations with overheat protection.

What Are Advantages of HMI Board?

- Intuitive & Efficient Human-Machine Interaction: Enable rapid command transmission and real-time device feedback through touchscreens, physical buttons, or hybrid inputs, reducing operational complexity and boosting productivity.

- Industrial-Grade Durability: Built with high-temperature-resistant, dustproof, waterproof, and vibration-resistant materials, ensuring reliable 24/7 operation in harsh environments like manufacturing lines and outdoor equipment.

- Multi-Protocol Communication Compatibility: Integrate CAN, Modbus, Ethernet, Wi-Fi, Bluetooth, and other interfaces to seamlessly connect with PLCs, sensors, and cloud platforms for device networking and remote monitoring.

- Highly Integrated Functional Modules: Combine display, control, data processing, and storage into a single board, minimizing wiring complexity and space usage while enhancing system reliability and maintainability.

- Customizable Interface Development: Support graphical editing tools for quick customization of industry-specific interfaces (e.g., industrial control panels, medical device screens), meeting unique user requirements.

- Real-Time Data Processing & Feedback: Leverage high-performance processors and dedicated chips for real-time monitoring, fault alerts, and data visualization, optimizing decision-making and production workflows.

- Energy-Efficient Design: Employ low-power chips and dynamic power management to reduce energy consumption, extend battery life, and align with green manufacturing standards.

- Robust EMI/EMC Immunity: Ensure stable signal transmission and device safety through compliant designs like shielding layers and filter circuits, minimizing high-frequency noise interference in industrial settings.

- Rapid Iteration & Upgrade Support: Enable modular design and OTA (Over-The-Air) updates for effortless feature expansion, firmware updates, and security patching, lowering lifecycle costs.

- Cross-Platform System Compatibility: Compatible with Windows, Linux, RTOS, and other OSes, adapting to industrial PCs, embedded devices, and mobile terminals for flexible system integration.

What Are Applications of HMI Circuit Board?

- Electric Wheelchair Smart Control

- Industrial Robot Teach Pendants

- Smart Wearable Devices

- EV Charging Stations

- Medical Device Control Panels

- Smart Agricultural Machinery

- Port Gantry Crane Remote Control

- Automated Production Lines

How to Design HMI Control Board for Signal Integrity?

Signal Integrity Design Strategies for HMI Control Boards

Impedance Matching & Stackup Optimization

- Utilize Saturn PCB Toolkit for 50Ω±10% controlled impedance design in microstrip/stripline structures.

- Adopt 4-layer stackup (Signal-GND-Power-Signal) for HMI Boards, ensuring USB2.0 signal integrity per IPC-2141.

- Example: Electric wheelchair HMI boards require impedance continuity to minimize reflection losses.

High-Speed Routing Guidelines

- Enforce 3W rule (trace spacing ≥3× width) and differential pair length matching (±5mil).

- Use serpentine routing for length compensation and 45°/rounded corners.

- Prioritize inner-layer routing for I²C buses in touchscreen interfaces to reduce EMI.

Power Integrity Enhancement

- Place 0.1µF ceramic capacitors within 0.1mm of IC power pins for HF decoupling.

- Integrate LDO regulators and TVS diodes in battery-powered HMI Boards (e.g., electric wheelchairs).

- Validate PDN with Altium PI-DC simulation, ensuring ≤3% voltage drop.

Grounding & Shielding Techniques

- Implement star-point grounding for digital/analog/shield grounds.

- Shield touch controllers with grounded copper enclosures and mesh ground fills.

- Add ferrite beads near CAN transceivers in HMI Boards to suppress noise per IEC 61000-4-2.

Simulation-Driven Validation

- Pre-layout simulation via Cadence Sigrity/Ansys SIwave to predict SI/PI risks.

- Post-layout eye diagram tests for USB3.0/HDMI interfaces.

- Vibration testing per IEC 60068-2-6 for mechanical robustness in mobile HMI applications.

Material & Thermal Management

- Select high-Tg FR4/polyimide substrates for -20°C~85°C operation (e.g., outdoor electric wheelchairs).

- Optimize thermal vias placement via ANSYS Icepak to maintain safe junction temperatures.

Testing & Reliability Assurance

- Flying probe tests for open/short detection and TDR for impedance verification.

- Monitor touch latency (≤5ms) and bus error rates in HMI Boards.

- HTOL testing per AEC-Q100 for ≥5-year lifespan validation.

How to Optimize HMI Board Layout for Cost-Effective Manufacturing?

Cost-Effective HMI Control Board Layout Optimization Strategies

Layer Reduction & Stack-Up Synergy

- Implement 4-layer “Signal-GND-Power-Signal” PCB stack-up, validated by Ansys SIwave simulation to achieve 50Ω±10% impedance matching for HMI interfaces (USB2.0/I²C). This reduces lamination costs by 35% compared to 6-layer designs. Compliance with IPC-2221A ensures signal integrity across -20°C~85°C operating ranges, minimizing rework costs from impedance mismatches.

Material Selection for Cost-Performance Balance

- Optimize for FR4 substrate (Tg≥135℃) instead of high-cost polyimide, cutting material costs by 40% while meeting IEC 60068-2-1 thermal shock requirements. DSC verification confirms thermal stability for HMI applications like electric wheelchair control panels. Low-loss FR4 (εr=4.2-4.5) maintains signal loss ≤2dB/m for touchscreen high-frequency signals.

Modular Functional Partitioning

- Divide HMI board into touch control, power management, and communication modules using QFP/BGA standardized packages. For electric wheelchair HMI boards, touch modules integrate capacitive touch controllers and signal conditioning circuits. Altium Designer pre-layout simulation optimizes inter-module trace length (≤5cm), reducing debugging time by 20% and achieving 99.5% SMT yield.

Manufacturing Process Precision Control

- Adopt IPC-7351B standard pad dimensions (e.g., 1.0mm×0.5mm for 0402 packages) with lead-free soldering. AOI + flying probe testing ensures 100% open/short detection. For HMI touch interfaces with ≥0.5mm pad spacing, optimized reflow profiling (245℃±5℃) reduces soldering defects to ≤0.5%, cutting rework costs by 15%.

Enhanced Design-for-Testability (DFT)

- Place ≥100mil-spaced test points on critical paths (CAN bus/I²C) for ICT/flying probe testing. IEEE 1149.1 boundary scan reduces HMI board test time by 50%. Electric wheelchair examples include JTAG interfaces for rapid firmware flashing and functional verification, lowering production line testing labor costs by 30%.

Thermal-Mechanical Co-Design

- ANSYS Icepak thermal simulation guides power device placement with thermal via arrays (0.3mm diameter, 1mm pitch) under processors to maintain junction temperatures ≤85℃. IEC 60068-2-6 compliant “grid” stiffener design improves mechanical robustness, reducing transport damage scrap rates by 20% for mobile HMI applications.

Supply Chain & Inventory Optimization

- “Common components + custom modules” strategy uses mainstream ICs (e.g., STM32 series) for supply chain stability. MRP systems precisely calculate component usage, reducing inventory holding costs by 15%. Local procurement of touchscreen modules in electric wheelchair projects shortens lead times to ≤5 days, lowers logistics costs by 25%, and enhances production flexibility.

Why Choose EBest Circuit (Best Technology) as HMI PCB Board Manufacturer?

Reasons why choose us as HMI PCB board manufacturer:

19 Years of PCBA Expertise & HMI Specialization

- Deep involvement in PCBA for 19 years with focus on HMI control board R&D, accumulating top-tier industrial process databases and failure analysis cases.

- Clients inherit mature technical solutions, reducing R&D trial costs by over 30%, achieving 99%+ yield rate, and shortening time-to-market by 40%.

Free DFM Optimization for Manufacturability

- Full-process free DFM analysis identifies design flaws early and optimizes layouts (e.g., component spacing, pad dimensions, thermal design).

- Avoids mass production rework, cuts design change costs by 50%+, boosts first-pass yield to 98%, and saves millions in development expenses.

Rapid Delivery with 99.2% On-Time Rate

- “24-hour response + 7-day extreme delivery” mechanism with intelligent production scheduling ensures 99.2% on-time delivery.

- Enhances supply chain turnover by 35%, prevents million-dollar order losses from delays, and ensures precise project milestone control.

Six-Level Quality Control

- Six comprehensive inspections from raw materials to finished products (e.g., AOI, X-RAY, functional testing).

- Achieves <0.05% defect rate, reduces after-sales costs by 80%+, raises end-user satisfaction to 98%, and strengthens brand reputation.

Dedicated HMI Production Line & Custom Capability

- HMI-specific SMT line with core technologies (high-density wiring, microvia filling, high-temp solder).

- Supports complex designs (touch + display integration, anti-interference circuits), outperforms industry by 15%, and meets premium market demands.

Full-Chain After-Sales & Lifetime Tech Support

- 7×24 technical support with 48-hour on-site resolution and free documentation updates.

- Ensures worry-free usage, cuts O&M costs by 30%, extends product lifecycle, and boosts loyalty/repurchase rates.

Modular Platform & Rapid Iteration

- Standardized module library (display, button, power modules) enables rapid assembly and functional expansion.

- Increases iteration speed by 50%, supports small-batch multi-variety production, meets customized needs, and captures market opportunities.

Transparent Traceability & Data-Driven Management

- MES system enables full-process data visualization and traceability from raw materials to finished products.

- Clients monitor real-time production/quality data, enhance supply chain transparency, reduce quality risks, and strengthen trust.

Welcome to contact us if you have any request for HMI PCB board: sales@bestpcbs.com.