PCBA France is a vital part of the European electronics manufacturing industry, specializing in providing high-quality PCB assembly and custom PCBA solutions for various sectors, including medical, industrial, and aerospace. Due to stringent quality standards and advanced manufacturing requirements, PCBA France demands expertise in precision assembly, supply chain stability, and compliance with local regulations. With our 20 years of experience, we have become a trusted partner for businesses seeking efficient, compliant, and cost-effective PCBA France services.

Top 10 Best PCBA France Manufacturer List

| Company Name | Main Business | Core Advantages | PCBA Capabilities | Lead Time |

| EBest Circuit Co., Limited (Best Technology Circuit Co., Limited) | Turnkey PCBA, PCB fabrication, component sourcing, quality testing, after-sales service | 20 years of experience, 5-year warranty, MES traceability, 99.2% on-time delivery, ISO certified | SMT, THT, mixed assembly, HDI PCBA, medical PCBA, industrial PCBA, prototype to mass production | Prototype: 3-5 days; Small batch: 7-10 days; Mass production: 10-20 days |

| Eolane France | EMS, ODM, PCBA assembly, full-system integration for medical, automotive and aerospace | Founded in 1975, 6 French production bases, industrial 4.0 transformation, ISO 13485 certified | High-precision SMT, rigid-flex PCBA, military-grade PCBA, large-volume assembly | Prototype: 5-7 days; Small batch: 10-12 days; Mass production: 15-25 days |

| INGELEC GROUPE (Kabelec) | PCBA assembly, electronic manufacturing, quality inspection, custom electronic solutions | IPC A-610 certified staff, local French support, strict quality control, industrial focus | SMT, THT, through-hole assembly, industrial control PCBA, small to medium batch production | Prototype: 4-6 days; Small batch: 8-10 days; Mass production: 12-20 days |

| Eurocircuits France | PCB fabrication, PCBA assembly, prototype production, quick-turn services | Fast turnaround, online quotation, transparent process, RoHS compliant, French local production base | Prototype PCBA, small-batch assembly, standard SMT/THT, single/double-sided PCBA | Prototype: 2-4 days; Small batch: 6-8 days; Mass production: 14-22 days |

| NTI France | PCBA assembly, electronic sub-assemblies, contract manufacturing for industrial and medical | Specialized in high-reliability PCBA, ISO 9001/13485, French local supply chain, 30+ years industry experience | Medical grade PCBA, industrial PCBA, mixed assembly, functional testing | Prototype: 5-7 days; Small batch: 9-11 days; Mass production: 16-24 days |

| Electronic Systems France (ESF) | PCBA assembly, electronic manufacturing services, custom PCB solutions, small-batch customization | Flexible production, personalized service, competitive pricing, RoHS/REACH compliant, Frenchśú¨Śúü team support | SMT assembly, THT assembly, small-batch production, prototype development | Prototype: 4-6 days; Small batch: 7-9 days; Mass production: 13-21 days |

| Sofelec France | PCBA assembly, electronic integration, maintenance and repair services, industrial electronic solutions | Long-term industry experience (founded in 1982), technical expertise, quick problem-solving, French local after-sales | Industrial PCBA, automotive PCBA, SMT/THT assembly, small to large batch | Prototype: 6-8 days; Small batch: 10-13 days; Mass production: 17-26 days |

| Elproma France | PCBA assembly, PCB design, component sourcing, functional testing, one-stop manufacturing | One-stop service, design-manufacture integration, strict quality control, ISO 9001 certified, French local factory | Prototype PCBA, HDI PCBA, mixed assembly, consumer electronics PCBA | Prototype: 3-5 days; Small batch: 7-10 days; Mass production: 12-20 days |

| C2M Electronics France | PCBA assembly, contract manufacturing, electronic sub-assemblies, industrial PCBA customization | Flexible production capacity, competitive lead time, ISO certified, French local production and logistics | SMT assembly, THT assembly, medium to large batch production, industrial PCBA | Prototype: 5-7 days; Small batch: 8-11 days; Mass production: 14-23 days |

| Proelectronics France | PCBA assembly, prototype development, small-batch production, quality inspection, rapid iteration | Focus on small-batch and prototype, quick response (24h technical support), high precision, French local workshop | Prototype PCBA, small-batch SMT/THT assembly, custom PCBA solutions | Prototype: 2-3 days; Small batch: 5-7 days; Mass production: 15-22 days |

Pain Point of PCB Assembly in France

- Supply chain instability: Global component shortages and delays in cross-border imports within Europe disrupt production schedules and increase project uncertainty.

- Equipment limitations: Insufficient local high-precision assembly equipment restricts the ability to undertake complex projects and meet the technical requirements of high-end sectors such as aerospace and medical electronics.

- Quality consistency issues: Variations in process control or component quality across multiple production batches can lead to rework, product failures, and associated cost losses.

- Component procurement risks: Long lead times for customized/rare components delay project delivery; furthermore, component verification is time-consuming and critical, as counterfeit parts can lead to reliability issues, safety risks, and recall costs.

Our PCBA Services with Turnkey Solution: From Prototyping to Mass Production

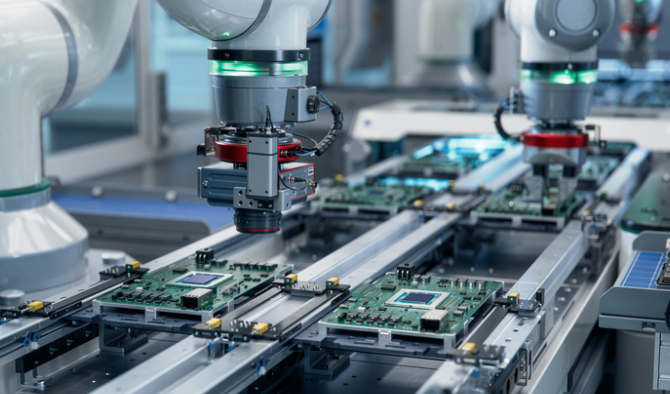

Our tailored one-stop PCBA services for the French market directly address core pain points by eliminating supply chain instability, limited high-precision capabilities, inconsistent batch quality, long lead times for custom components, and time-consuming component authentication. We deliver seamless efficiency from prototype design (1-100 units rapid high-quality prototyping aligned with mass production standards) to mass production, minimizing costly rework. Advanced SMT/THT assembly lines with 28,900 m² monthly capacity overcome local equipment limitations, enabling complex projects. A 99.2% on-time delivery rate resolves delays from custom component sourcing, while global supply chains and French partner networks ensure competitive pricing for reliable genuine components.

With 20 years of expertise, we provide a closed-loop end-to-end solution covering every stage from initial prototype design to final delivery and after-sales support. Comprehensive post-production testing (ICT, FCT, X-ray) and MES traceability ensure consistent quality across batches. Unlike fragmented providers requiring multi-partner coordination, our single streamlined service saves time, reduces costs, and guarantees compliance with France’s strict industry standards, positioning us as the optimal partner for reliability, efficiency, and results in PCBA projects.

Why Choose EBest(Best Technology) for PCBA France Manufacturer?

Reasons why choose EBest(Best Technology) for PCBA France manufacturer:

- One-stop PCBA service integrates prototyping, sourcing, assembly and testing to cover the entire production process for local projects, eliminating the need to coordinate multiple suppliers and cutting coordination time by 60% while ensuring process consistency and cost savings.‚Äč

- A 5-year warranty covers all PCBA products, backed by strict quality control to ensure 99.8% long-term reliability for local projects and cut maintenance costs by 35% through reducing post-delivery failures and repairs.‚Äč

- MES full production traceability tracks every step of the assembly process, from material incoming to final delivery, ensuring 100% batch quality consistency and easy oversight for any quality concerns.‚Äč

- A 99.2% on-time delivery rate is supported by optimized production scheduling and stable component supply, achieving zero delays for local projects and ensuring on-schedule project launch.‚Äč

- Two decades of experience with local industrial and environmental regulations brings deep familiarity with norms like RoHS and ISO standards, achieving 100% compliance and zero regulatory risks for local clients.‚Äč

- Advanced high-precision assembly equipment handles HDI, BGA and other complex PCB processes, delivering a 99.7% pass rate for local complex projects and meeting high-end industry requirements.‚Äč

- Flexible design change support offers rapid evaluation and adjustment for modifications, with prototype validation to avoid rework, cutting rework costs by 40% and minimizing production disruptions by 70%.‚Äč

- Local partnerships paired with a global supply chain combine rapid local delivery advantages with global component sourcing capabilities, achieving 99.9% stable component supply and eliminating uncertainties for local PCB production.

Types of France PCB Assembly Service We Offered

- SMT Assembly: Surface mount technology for small, high-density components, ideal for compact electronic devices common in PCBA France projects.

- THT Assembly: Through-hole technology for larger, high-power components, suitable for industrial and medical equipment requiring durability.

- Mixed Technology Assembly: Combined SMT and THT assembly to meet diverse component needs for complex PCBA France applications.

Our Quality Control Process for France PCB Assembly

Below are quality control process for PCBA France:

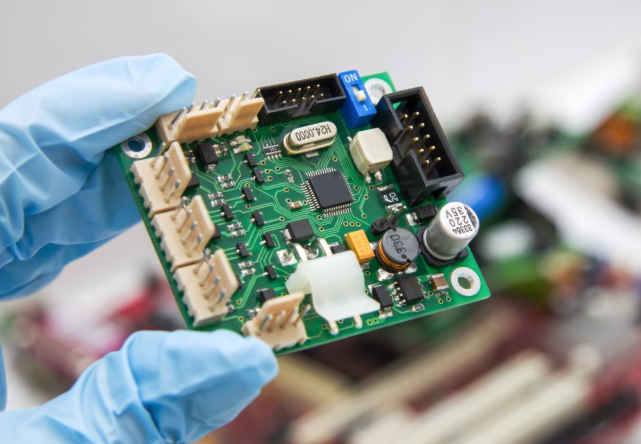

- Incoming Material Inspection: Conduct strict multi-dimensional testing of PCBs and electronic components, including component authenticity verification, PCB dimensional checks, and electrical performance sampling, to eliminate counterfeit or defective materials before they enter the production line.

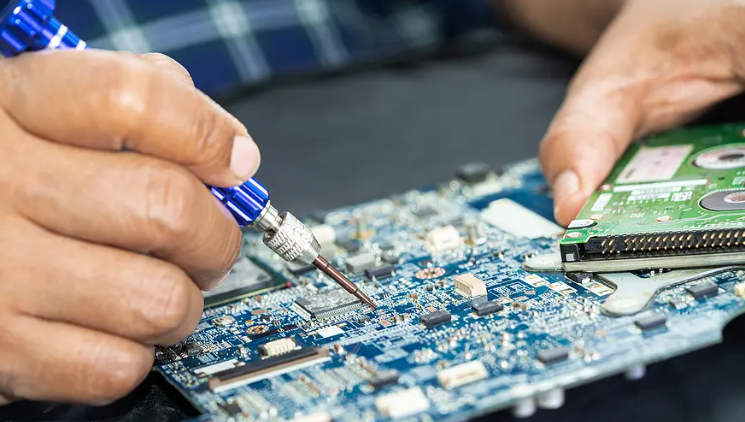

- Solder Paste Inspection: Use automatic solder paste inspection equipment to perform precision checks on printing thickness, area and offset, ensuring uniform solder paste application and effectively reducing common welding defects such as bridging and cold soldering.

- SMT Placement Inspection: Leverage advanced equipment with real-time detection capabilities to check component placement coordinates, angles and pressure, avoiding misalignment, missing components or reverse polarity that could affect subsequent welding quality.

- Reflow and Wave Soldering Control: Customize temperature and time curves based on component types, maintaining strict control during reflow and wave soldering to ensure strong, bubble-free solder joints and long-term reliability.

- AOI and X-Ray Inspection: Combine automated optical scanning (AOI) for surface defects and X-ray testing for hidden issues, such as BGA solder voids or internal component cracks, to achieve comprehensive quality coverage without missing defects.

- ICT and FCT Testing: Perform ICT testing to verify circuit connectivity and component parameters, followed by FCT testing to simulate actual working conditions, ensuring each PCBA meets preset performance and connectivity specifications.

- Final Visual Inspection: Conduct dual checks by professional inspectors and automated equipment, focusing on solder joint appearance, component integrity and marking clarity, ensuring no cosmetic or functional defects before delivery.

- Batch Traceability Review: Utilize the MES system to track every detail of each production batch, from raw material batches to testing results, ensuring quality consistency and enabling quick recall if any issues arise.

Our France PCBA Capabilities

| Item | Capabilities |

| Placer Speed | 13,200,000 chips/day |

| Bare Board Size | 0.2 x 0.2 inches – 20 x 20 inches/ 22*47.5 inches |

| Minimum SMD Component | 01005 |

| Minimum BGA Pitch | 0.25mm |

| Maximum Components | 50*150mm |

| Assembly Type | SMT, THT, Mixed assembly |

| Component Package | Reels, Cut Tape, Tube, Tray, Loose Parts |

| Lead Time | 1 – 5 days |

Case Studies of Our France Medical PCB Assembly

Project Background: A French medical device company specializing in clinical diagnostic equipment was seeking a reliable PCBA partner to support the development of its new portable diagnostic device, which needed to meet the rigorous standards of PCBA France and comply with local medical regulations for safe clinical application. The device required high stability and precision to ensure accurate test results, making the choice of a professional PCBA partner critical to its market success.‚Äč

Project Requirements: The project required full compliance with ISO 13485 certification, high-precision SMT assembly capable of handling miniaturized components as small as 0201 package, a compact PCB layout to fit the device‚Äôs portable form factor, low power consumption to ensure long battery life for on-site use, 100% functional testing to eliminate any defective units, and a tight 6-week lead time for the initial production batch.‚Äč

Project Difficulties: The 6-week lead time for initial production left little room for delays or rework; strict medical compliance demanded full alignment with ISO 13485 standards and local regulatory requirements, with no tolerance for non-compliance. Additionally, miniaturized components (down to 0201 package) required ultra-high precision placement to avoid soldering defects or functional failures, while the device‚Äôs clinical use required strict quality control to ensure zero safety risks.‚Äč

Project Solutions: A one-stop service system was adopted to integrate prototyping, component sourcing and assembly seamlessly, eliminating the inefficiencies of coordinating multiple suppliers. Strict ISO 13485 quality control protocols were implemented throughout the production process, with dedicated inspectors assigned to each stage. High-precision SMT placement equipment with real-time detection capabilities was deployed to handle miniaturized components, and production scheduling was optimized via the MES system to streamline workflows and ensure the 6-week lead time was met.‚Äč

Output Results: The initial 500 PCBA units were delivered on schedule, achieving a 100% pass rate in both functional and compliance testing. A full MES production traceability report was provided, detailing every step from component sourcing to final inspection, and each unit was backed by a 5-year warranty. The client successfully launched its portable diagnostic device in the local market, with positive feedback from clinical users, and has maintained long-term cooperative relations for subsequent batch productions.

FAQs of PCB Assembly in France

Q1: How to ensure PCBA components are authentic and not counterfeit in France?‚Äč

A1: We source components from authorized distributors and conduct strict incoming material inspections, including component labeling, packaging and electrical testing. Our MES system tracks component origins, providing full traceability to ensure authenticity for PCBA France projects.‚Äč

Q2: What lead times can be expected for PCBA prototyping and mass production in France?‚Äč

A2: Prototyping lead times are 4-7 working days for standard orders and 24 hours for urgent requests. Mass production lead times range from 5-20 working days, depending on order size, with our 99.2% on-time delivery rate ensuring consistency for PCBA France.‚Äč

Q3: How to ensure PCBA compliance with French environmental and medical regulations?‚Äč

A3: We stay updated on all French regulations, including RoHS and ISO 13485 for medical devices. Our quality control process includes compliance checks at every stage, and we provide detailed compliance reports for all PCBA France orders.‚Äč

Q4: What can be done to reduce rework costs when design changes are needed for PCBA projects?‚Äč

A4: Our one-stop service includes flexible design change support. We review design changes quickly, adjust production schedules and component sourcing promptly, and use prototyping to validate changes before mass production, minimizing rework costs for PCBA France clients.‚Äč

Q5: How to ensure consistent quality across large PCBA production batches in France?‚Äč

A5: We use our MES system for full production traceability, maintain strict quality control at every stage, and conduct regular equipment calibration. We also test samples from each batch to ensure consistency, with our 5-year warranty backing all PCBA products.