FR 4 Copper Clad Laminate: Core Definition & Key Applications

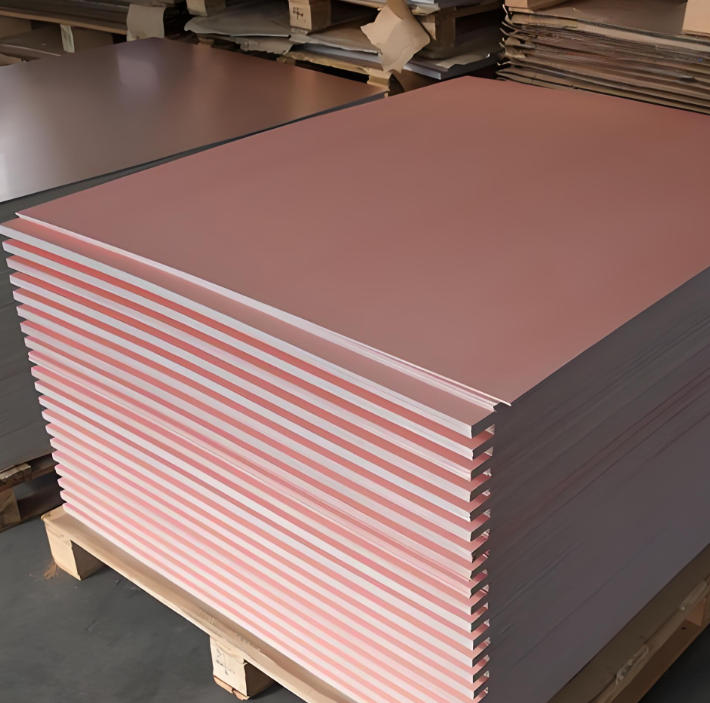

The FR 4 Copper Clad Laminate is a flame-retardant epoxy glass cloth composite, widely used as the core substrate for printed circuit boards (PCBs). This material bonds woven fiberglass cloth with epoxy resin and a copper foil layer, offering balanced mechanical strength, electrical insulation, and flame resistance. The FR 4 Copper Clad Laminate dominates electronics manufacturing due to its compatibility with most soldering processes and stability in humid/dry environments, making it ideal for consumer electronics, industrial controls, and automotive components.

What Are the Main Classifications of FR 4 Copper Clad Laminate?

Classifications are based on Tg value, flame retardant type, dielectric performance, and thickness, each targeting specific use cases:

- By Tg Value: Regular Tg (120-130℃) for low-temperature applications (e.g., chargers); High Tg (≥150℃) for high-heat scenarios (e.g., automotive electronics).

- By Flame Retardant: Brominated FR 4 (cost-effective, stable) and Halogen-Free FR 4 (RoHS/REACH compliant, for medical/consumer electronics).

- By Dielectric Performance: Regular Dk (4.2-4.7) for low-frequency circuits; Low Dk (3.5-4.0) for mid-high frequency devices (e.g., routers).

- By Thickness: 0.2-3.0mm substrate with 1-3oz copper foil, matching thin (mobile) and thick (industrial) PCB needs.

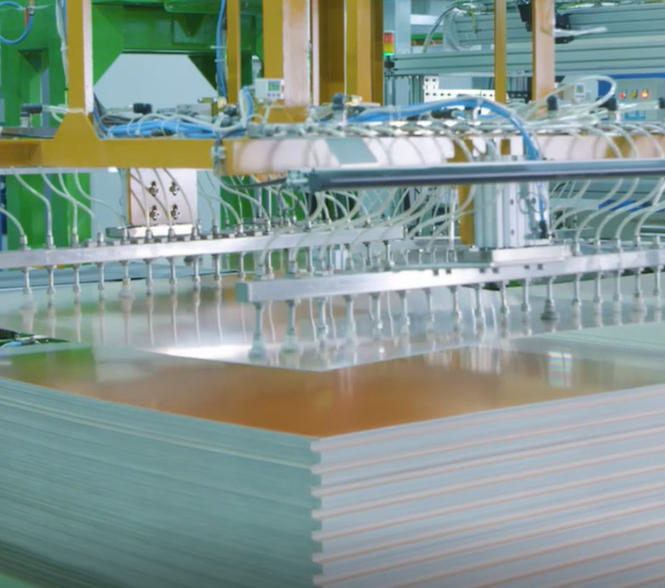

How Is FR 4 Copper Clad Laminate Manufactured?

The production process follows strict standards to ensure consistency, with 6 core steps: raw material preparation, resin varnish mixing, impregnation, B-staging, lamination, and post-processing. Each step controls critical parameters to avoid defects like delamination or bubble formation.

Key Manufacturing Steps & Quality Controls

- Raw Material Prep: Select E-Glass cloth, modified epoxy resin, and electrolytic/rolled copper foil (rough surface for better adhesion).

- Resin Varnish Mixing: Blend resin with curing agents, flame retardants, and fillers at controlled temperature/velocity.

- Impregnation: Immerse glass cloth in varnish, adjusting speed/scrapers to ensure full resin penetration.

- B-Staging: Cure impregnated cloth in a tunnel oven to form semi-solid prepreg (PrePreg) with stable gel time.

- Lamination: Stack copper foil and prepreg, then hot-press (high temp/pressure/vacuum) to form a solid board.

- Post-Processing: Trim edges, inspect for warpage, and age-treat to stabilize dimensions and performance.

FR 4 Copper Clad Laminate vs. Other CCL Materials: A Comparison

FR 4 outperforms alternatives in cost-performance, but choosing the right CCL depends on application requirements. Below is a comparison with common substitutes:

| Material | Key Advantage | Limitation | Best For |

|---|---|---|---|

| FR 4 Copper Clad Laminate | Balanced strength, flame resistance, low cost | Not for >5GHz high-frequency use | General electronics, industrial controls |

| G-10 CCL | High mechanical strength | Non-flame retardant | Non-critical insulation parts |

| PTFE CCL | Ultra-low Dk/Df for high frequency | High cost, poor machinability | RF/microwave devices |

Critical Performance Standards for FR 4 Copper Clad Laminate

Compliance with international standards ensures reliability. The top benchmarks for FR 4 Copper Clad Laminate are IPC-4101 (global) and IEC 61249-2-7 (halogen-free), with A1 grade as the highest performance tier.

A1 Grade FR 4 Key Performance Requirements (IPC-4101)

- Tg ≥ 140℃ (up to 170℃ for enhanced models)

- Td ≥ 310℃, T288 delamination time ≥ 60 mins

- Dk (1GHz): 4.2-4.5, Df (1GHz) ≤ 0.020

- Water absorption ≤ 0.10%, peel strength ≥ 1.0 N/mm

- UL 94 V-0 flame rating, RoHS 2.0 compliant

How to Select the Right FR 4 Copper Clad Laminate?

Selection depends on application environment, electrical needs, and cost. Follow these 4 steps to avoid over-specification or performance gaps:

Step 1: Match Tg to Thermal Conditions

Choose high Tg (≥150℃) for lead-free soldering or high-temperature environments; regular Tg suffices for low-heat devices to cut costs.

Step 2: Prioritize Flame Retardant Type by Compliance

Opt for halogen-free FR 4 for EU/Japan exports; brominated FR 4 is suitable for non-environmentally restricted markets.

Step 3: Align Dielectric Performance with Frequency

Use regular Dk for <1GHz circuits; low Dk FR 4 for 1-5GHz devices. For >5GHz, switch to PTFE or Rogers materials.

Step 4: Select Thickness & Copper Foil Weight

Thicker substrates (≥1.6mm) for mechanical stress; 2-3oz copper foil for high-current applications (e.g., power supplies).

FAQ: Common Issues & Solutions for FR 4 Copper Clad Laminate

Below are 7 frequent challenges engineers face with FR 4 Copper Clad Laminate and actionable fixes:

Q1: Why Does FR 4 Copper Clad Laminate Delaminate During Soldering?

Root cause: Low Tg or insufficient drying. Solution: Use high Tg (≥150℃) material and pre-bake at 120℃ for 2-4 hours to remove moisture.

Q2: How to Reduce Signal Loss in FR 4 CCL for High-Frequency Use?

Solution: Select low Dk (3.5-4.0) FR 4, minimize copper foil roughness, and control PCB trace width/spacing.

Q3: What Causes Warpage in FR 4 Copper Clad Laminate?

Root cause: Uneven resin distribution or improper cooling. Solution: Choose high-quality prepreg and optimize hot-press cooling curves.

Q4: Is Halogen-Free FR 4 Less Durable Than Brominated FR 4?

No. Modern halogen-free FR 4 meets the same mechanical/electrical standards as brominated versions, with equivalent durability when compliant with IEC 61249-2-7.

Q5: How to Verify FR 4 CCL Compliance with IPC-4101 A1 Grade?

Request supplier test reports for Tg, Td, Dk/Df, and flame rating. Ensure the report references IPC-4101 Sheet 12/13.

Q6: Can FR 4 Copper Clad Laminate Be Used in Automotive Electronics?

Yes. Use high Tg (≥160℃) halogen-free FR 4 with T288 delamination time ≥ 60 mins to withstand automotive temperature cycles (-40℃ to 125℃).

Q7: How to Improve Copper Foil Adhesion on FR 4 Substrate?

Solution: Select copper foil with rough surface, ensure full resin penetration during impregnation, and control hot-press pressure (1.5-2.0 MPa).

Top Applications of FR 4 Copper Clad Laminate in 2026

The versatility of FR 4 Copper Clad Laminate makes it indispensable across electronics sectors. Key applications include:

- Consumer Electronics: Smartphones, laptops, and TVs (regular Tg, halogen-free variants).

- Automotive Electronics: Engine controllers, infotainment systems (high Tg, flame-retardant FR 4).

- Industrial Controls: Servo drives, PLCs (thick substrate, 2oz copper foil).

- Communications: 5G base stations, routers (low Dk FR 4 for mid-frequency signals).

- Medical Devices: Diagnostic tools (halogen-free, high-reliability A1 grade).

Quality Inspection Tips for FR 4 Copper Clad Laminate

Inspect incoming materials to avoid production delays. Focus on 4 critical checkpoints:

- Visual Inspection: No bubbles, scratches, or delamination on the surface; edges are smooth without resin overflow.

- Thickness & Tolerance: Use a micrometer to verify substrate (±0.15mm for 1.6mm) and copper foil (±10% of nominal weight).

- Electrical Testing: Measure Dk/Df at target frequency and insulation resistance (≥10¹²Ω·cm).

- Thermal Testing: Spot-check Tg and T288 delamination time against supplier specifications.

Cost-Saving Strategies for FR 4 Copper Clad Laminate Procurement

Optimize costs without compromising performance using these 3 methods:

1. Avoid Over-Specification

Use regular Tg instead of high Tg for low-heat applications; brominated FR 4 for non-export products.

2. Standardize Thickness & Copper Foil Weight

Consolidate to common specs (1.6mm substrate, 1oz copper) to leverage bulk purchasing discounts.

3. Partner with Reliable Suppliers

Choose suppliers with consistent quality to reduce scrap rates from defective FR 4 Copper Clad Laminate.

Future Trends of FR 4 Copper Clad Laminate

The market is shifting toward higher performance and sustainability. Key trends include low Dk high-Tg variants for 5G/6G, halogen-free formulations as global environmental regulations tighten, and thinner substrates for wearable devices.

Choose Our FR 4 Copper Clad Laminate for Your Projects

We supply high-quality FR 4 Copper Clad Laminate in all grades (regular/high Tg, brominated/halogen-free) that meet IPC-4101 A1 standards. Our products are optimized for reliability and cost-effectiveness across consumer, automotive, and industrial applications. For orders or technical consultations, contact us at sales@bestpcbs.com.