FFC vs FPC connector is a critical component in modern electronics, enabling reliable connections for flexible circuits. This article will compare their differences, address common application challenges, and guide you in selecting the right solution for your flexible flat cable‚Äč needs.

Are you struggling with signal integrity, mechanical failures, or assembly headaches in your flexible circuit designs? Many engineers face significant hurdles when integrating FFC and FPC connectors‚Äč into their products.

- Intermittent connections or signal loss due to poorly mating connectors and cables.

- Difficulty in manual assembly, leading to damaged cable ends or connector latches.

- Confusion between FFC vs FPC cable‚Äč specifications, resulting in mismatched components.

- Signal interference in high-speed applications using standard FFC ribbon cables.

- Mechanical stress causing failure at the connector junction in dynamic flexing applications.

The solution lies in a clear understanding of the FFC FPC difference‚Äč and partnering with a manufacturer that masters their application. As an experienced FPC and PCBA manufacturer, EBest Circuit (Best Technology) provides not just components but complete integration support.

- Supplying precision-engineered FFC/FPC connectors‚Äč and cables with guaranteed mating specifications.

- Offering connectors with Zero Insertion Force (ZIF) or Low Insertion Force (LIF) mechanisms for error-proof assembly.

- Providing expert guidance to clarify FFC vs FPC connector‚Äč selection based on your specific current rating, spacing, and flexibility needs.

- Recommending and sourcing shielded FPC ribbon cables‚Äč or specific FPC connector types‚Äč for EMI-sensitive designs.

- Implementing robust strain relief and optimal board layout in our PCBA manufacturing to enhance flex endurance.

At EBest Circuit (Best Technology), we specialize in the manufacturing and assembly of high-quality Flexible Printed Circuits (FPC) and PCBAs. Our deep expertise in FFC/FPC connectors‚Äč application ensures that your flexible interconnects are reliable, durable, and perfectly suited to your design’s mechanical and electrical demands. For your next project, pls feel free to contact our team at sales@bestpcbs.com.

What Is the Difference Between FFC vs FPC Connector?

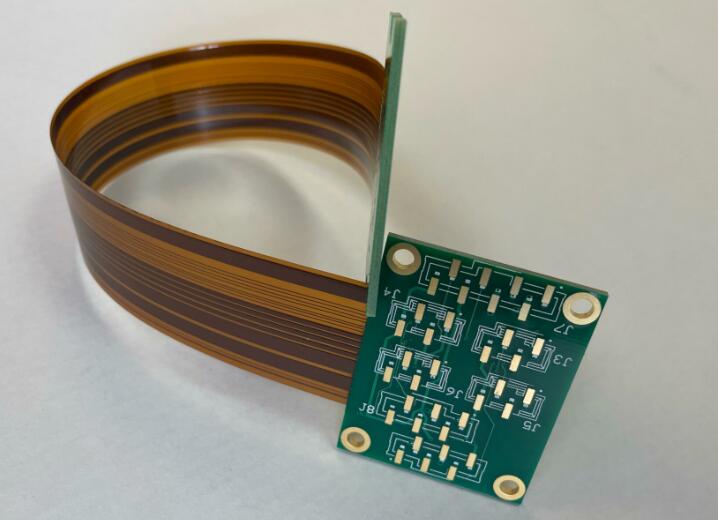

The core difference lies in what they connect. An FPC connector‚Äč is the receptacle soldered onto a PCB, designed to accept a flexible conductor. FFC, meaning Flexible Flat Cable, is the removable cable that plugs into that connector. Think of FPC vs FFC connector‚Äč as a socket versus a plug. The connector’s design must match the cable’s specifications.

| Feature | FPC Connector | FFC Cable |

|---|---|---|

| Nature‚Äč | Component (Receptacle) | Cable Assembly (Plug) |

| Construction‚Äč | Housing, contacts, latch | Flat parallel conductors laminated in plastic |

| Permanence‚Äč | Soldered to PCB | Removable interconnect |

| Customization‚Äč | Type (ZIF, LIF, Top/Bottom contact), pin count | Length, pin count (e.g., FFC cable 40 pin), pitch, thickness |

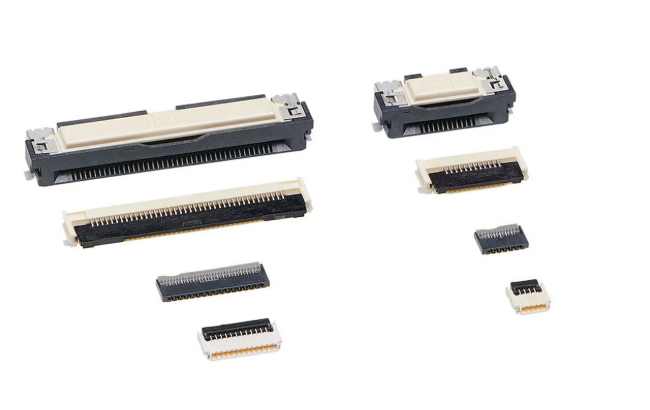

- FPC Connector Types:‚Äč These are defined by their actuation method (ZIF, LIF, Non-ZIF) and contact orientation (top, bottom, double-sided).

- FFC Cable Specs:‚Äč Defined by pitch (e.g., 0.5mm, 1.0mm), pin count (FFC cable 6 pin, 8 pin, 30 pin, etc.), length, and thickness.

In summary, the FFC vs FPC‚Äč comparison is symbiotic: the connector is the interface, and the cable is the conductor. Selecting the correct pair is foundational to system reliability.

What Is the Relationship Between FFC and FPC Connectors?

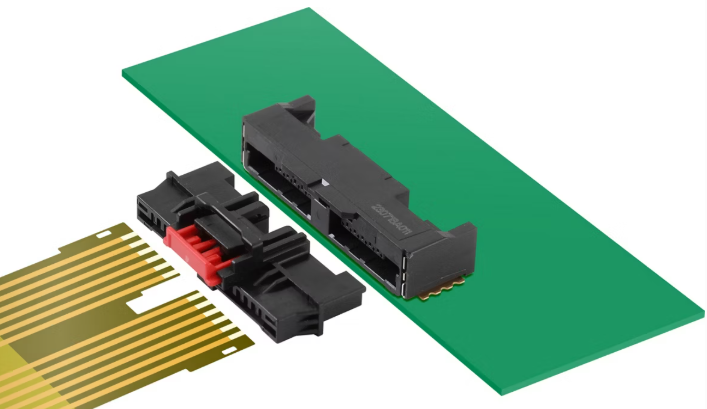

Their relationship is defined by mechanical and electrical compatibility. They form a complete interconnect system. The FPC connector‚Äč is engineered to precisely match the physical dimensions and electrical parameters of the FFC cable.

- Pitch Compatibility:‚Äč The connector’s contact spacing must exactly match the cable’s conductor pitch (e.g., a 1.0mm pitch connector for a 1.0mm pitch FFC cable 4 pin).

- Thickness Compatibility:‚Äč The connector’s clamp must accommodate the total thickness of the flexible flat cable FFC.

- Circuit Alignment:‚Äč The connector’s contacts must align with the cable’s conductors. Some connectors are for “straight” access, others for “right-angle” mating.

- Actuation Mechanism:‚Äč The cable is inserted and locked using the connector’s latch (ZIF) or a simple friction fit.

The key takeaway is that they are not interchangeable without verifying specs. A mismatch, even by a few microns, can cause poor contact or mechanical failure.

What Is the Purpose of FFC Cable in Flexible Flat Cable Connector Design?

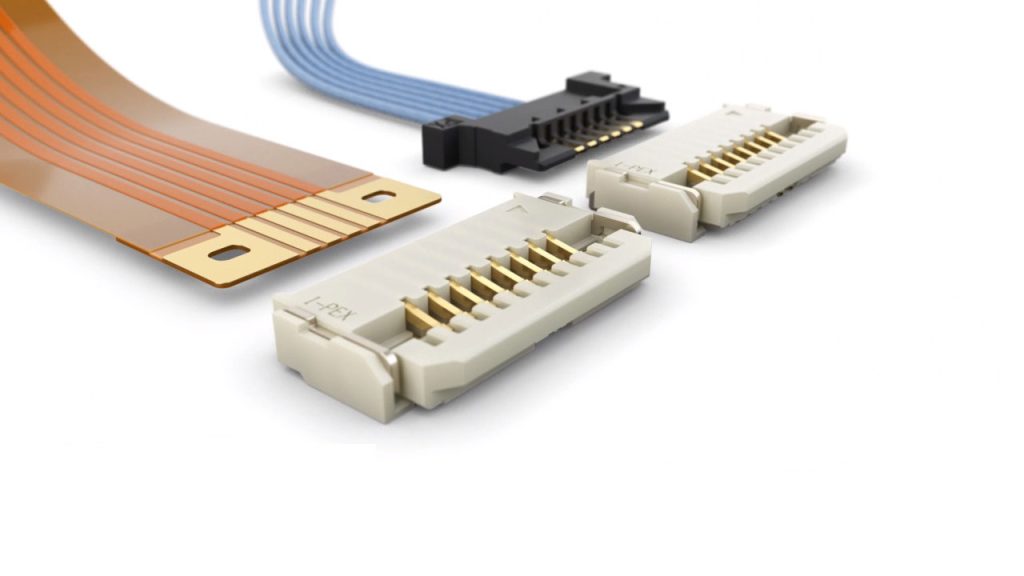

The purpose of the FFC cable‚Äč is to provide a reliable, flexible, and cost-effective conductive link between two PCBs or components within an assembly. Its design directly influences the flexible flat cable connector‚Äč choice.

- Space Savings:‚Äč Enables dense, three-dimensional packaging impossible with round wires.

- Reliability:‚Äč Eliminates the risk of individual wire misplacement during assembly vs discrete wiring.

- Mass Termination:‚Äč All conductors are connected simultaneously upon insertion, drastically reducing assembly time and cost.

- Controlled Impedance:‚Äč In high-speed designs, FPC ribbon cables‚Äč can be engineered for specific impedance.

- Repeatable Flexing:‚Äč Designed to withstand repeated bending in applications like hinge connections.

Therefore, the FFC cable‚Äč is the enabling element for modular design and servicing, while the connector ensures its secure and stable interface.

What Are the Common FPC Connector Problems?

Several issues can plague FPC connector‚Äč applications, often stemming from selection, handling, or manufacturing flaws.

- Poor Contact/Intermittency:‚Äč Caused by contaminated contacts, mismatched cable thickness, or a worn/loose locking mechanism.

- Cable Misalignment:‚Äč The FFC cable‚Äč is not fully inserted or is offset, leading to shorted or open circuits.

- Damaged Latches:‚Äč The ZIF/LIF latch is brittle and can break during assembly or disconnection if not handled properly.

- Mechanical Stress:‚Äč Bending or pulling stress concentrated at the connector-cable junction can tear the cable or break solder joints.

- Soldering Issues:‚Äč Poor solder joints on the connector’s PCB footprint (e.g., tombstoning, insufficient solder) can cause open circuits.

Understanding these failure modes is the first step in prevention through robust design and assembly practices.

How to Select the Right FFC/FPC Connectors for Your Application?

Selecting the right pair requires a systematic approach based on your design’s electrical, mechanical, and environmental needs.

- Pin Count & Pitch:‚Äč Determine the number of signals (FFC cable 30 pin) and the available space (pitch: 0.3mm, 0.5mm, 1.0mm).

- Current Rating:‚Äč Check the current per circuit. Standard FFC cables‚Äč have lower current capacity than thicker custom FPC cables.

- Stack Height:‚Äč Measure the required space between boards to choose a connector with the correct mating height.

- Flex Life & Direction:‚Äč Define how often and in what direction the cable will bend. This affects cable construction.

- Actuation Type:‚Äč ZIF for frequent service, LIF/Non-ZIF for cost-sensitive, permanent applications.

- Shielding Needs:‚Äč For noisy environments, specify cables with shielding layers and corresponding shielded FPC connector types.

A careful evaluation against this checklist ensures a reliable FFC vs FPC cable‚Äč interconnect system.

How Does the Choice Between FFC vs FPC Connector Impact FPC and PCBA Manufacturing?

The choice directly impacts DFM (Design for Manufacturability), assembly yield, and long-term reliability.

- Assembly Automation:‚Äč Standardized FFC/FPC connectors‚Äč with pick-and-place friendly packaging enable faster, automated assembly.

- Soldering Profile:‚Äč The connector’s plastic housing may have a lower maximum temperature than the PCB, requiring a controlled reflow profile.

- Strain Relief Features:‚Äč The design must include features like adhesive stickers, stiffeners, or board keep-outs to protect the connection point.

- Test Accessibility:‚Äč The connector’s location must allow for test probe access if needed.

- Rework Difficulty:‚Äč ZIF connectors are easier to rework than soldered cable ends, affecting serviceability and repair costs.

Integrating connector selection early in the design phase is crucial for manufacturability.

Why an Experienced FPC and PCBA Manufacturer Matters for FFC/FPC Connector Projects?

An experienced partner like EBest Circuit (Best Technology) bridges the gap between component selection and a flawless final product. We understand that FFC vs FPC connector‚Äč success is about the entire ecosystem.

- Holistic Design Review:‚Äč We assess your schematic and layout for connector placement, strain relief, and potential signal integrity issues.

- Component Sourcing & Verification:‚Äč We procure genuine, compatible connectors and cables, verifying specs like pitch and thickness before assembly.

- Process Optimization:‚Äč Our assembly lines are calibrated for sensitive FPC connector‚Äč placement and soldering.

- Testing & Validation:‚Äč We perform continuity, hipot, and functional tests to ensure every flexible flat cable connector‚Äč interface is flawless.

- Failure Analysis & Support:‚Äč If issues arise, our expertise allows us to quickly diagnose whether it’s a connector, cable, or assembly problem.

This end-to-end control minimizes risk and ensures your product’s reliability from the first prototype to mass production.

All in all, FFC vs FPC connectors‚Äč form the essential link between portability and functionality in modern electronics. This comparison has highlighted their distinct roles, common pitfalls, and selection criteria to ensure robust flexible applications.

Partnering with a manufacturer that possesses deep expertise in both FPC and PCBA manufacturing‚Äč is crucial. EBest Circuit (Best Technology) provides the integrated design support, precision manufacturing, and quality assurance needed to navigate the complexities of FFC/FPC connectors‚Äč successfully. Let us help you perfect your flexible interconnect design. Pls feel free to contact us anytime at sales@bestpcbs.com for a consultation on your next flexible PCB or SMT assembly project.

FAQs

Are FPC Connectors Waterproof?

Standard FPC connectors‚Äč are not waterproof. They are designed for indoor, controlled environments. For moisture or dust exposure, you need specifically rated IP connectors or must use conformal coating and gasketing as a secondary sealing method.

Can FFC Cables Be Soldered?

Directly soldering an FFC cable‚Äč is generally not recommended and defeats its purpose as a removable interconnect. The laminate insulation can melt, and the fine conductors are easily damaged. Always use a compatible FPC connector‚Äč for a reliable, solderless connection.

What Are FPC Connectors Used For?

FPC connectors‚Äč are used anywhere a compact, reliable, and flexible electrical connection is needed. Common applications include laptop displays (FFC cable 40 pin‚Äč for LCDs), printers, scanners, cameras, medical devices, consumer electronics, and automotive dashboards where connecting PCBs across hinges or moving parts is required.