EMS PCB assembly refers to Electronics Manufacturing Services that cover more than just assembling a printed circuit board. In a true EMS model, the provider manages the full scope of manufacturing activities required to turn a design into a production-ready product.

Typical EMS PCB assembly services include:

- Coordination of PCB fabrication

- Component sourcing and lifecycle management

- SMT and through-hole assembly

- Inspection, testing, and quality documentation

- Ongoing production and engineering support

For companies moving beyond simple prototypes, EMS PCB assembly offers a structured approach to manufacturing that reduces internal workload and improves consistency.

EMS PCB Assembly vs Standard PCB Assembly Service

The difference between EMS PCB assembly and standard PCB assembly becomes apparent as project complexity increases.

A standard PCB assembly service usually focuses on:

- Build-to-print assembly

- Limited responsibility beyond soldering and inspection

- Customer-managed materials and logistics

An EMS PCB assembly service, by contrast, takes responsibility for:

- Design-for-manufacturing feedback

- Component sourcing and approved substitutions

- Coordinated planning across fabrication, assembly, and testing

- Quality control and traceability

In practical terms, standard PCB assembly executes instructions, while EMS PCB assembly manages the manufacturing outcome.

Why Choose EMS PCB Assembly Service?

Companies choose EMS PCB assembly when they need more control and fewer surprises during production.

Common reasons include:

- Smoother transition from prototype to production

- Reduced supply-chain risk through managed sourcing

- More predictable quality and yield

- Lower total cost over time, even if unit prices are higher

For products with long lifecycles, compliance requirements, or complex BOMs, EMS PCB assembly provides a level of stability that transactional assembly services cannot.

What Are the Most Common Risks in EMS PCB Assembly?

EMS PCB assembly is not risk-free. When poorly managed, it can introduce new challenges instead of solving existing ones.

The most common risks include:

- Prototype success that does not translate into production yield

- Unapproved component substitutions due to shortages

- Insufficient testing coverage for real-world use

- Communication gaps between engineering, sourcing, and production

Our approach prevents these issues through:

- Early DFM / DFT engineering review

- BOM-level lifecycle and sourcing analysis

- Defined process controls across all build stages

- Formal change management and traceability

Risk is not eliminatedÔÇöbut it is controlled before it affects delivery or reliability.

Factors That Affect EMS PCB Assembly Cost

EMS PCB assembly cost is influenced by far more than assembly labor.

Key cost factors include:

- PCB material selection and layer count

- Component availability and sourcing channels

- Assembly complexity and package density

- Inspection, testing, and documentation requirements

We focus on total cost of ownership, helping customers avoid hidden expenses caused by rework, delays, or redesigns later in production.

Top 7 EMS PCB Assembly Service Providers

The EMS market includes providers with very different strengths and target customers. Below are seven well-known EMS PCB assembly service providers, each serving distinct needs:

| EMS Provider | Primary Market Focus | Core EMS PCB Assembly Strengths | Best Fit For |

| Best Technology | Prototype to low / mid-volume, high-mix projects | Engineering-driven EMS PCB assembly, strong DFM/DFT support, transparent component sourcing, flexible volumes | Startups, SMEs, industrial & medical projects needing flexibility and close engineering support |

| Jabil | Global, high-volume manufacturing | Massive global footprint, advanced supply-chain management, automation at scale | Large OEMs with stable, high-volume, multinational programs |

| Flex | High-volume, complex supply chains | End-to-end EMS, strong logistics and digital manufacturing capabilities | Enterprises requiring global production and supply-chain resilience |

| Sanmina | High-reliability & regulated industries | Complex PCB assembly, strong compliance systems, aerospace & industrial focus | Aerospace, defense, medical, and mission-critical electronics |

| Celestica | Advanced manufacturing & cloud infrastructure | Automation-heavy EMS, digital manufacturing processes | Data-center, networking, and advanced industrial electronics |

| Plexus | Engineering-intensive EMS projects | Strong NPI support, lifecycle management, regulated-market expertise | Products with long lifecycles and frequent engineering changes |

| Benchmark Electronics | Industrial, medical, aerospace | Balanced EMS offering with emphasis on quality and compliance | Medium-to-high complexity products in regulated sectors |

Why Companies Choose Best Technology?

Not every project needs a global EMS giant. Many require engineering depth, flexibility, and accountability.

Best Technology is selected by customers who need:

- Early engineering involvement, not post-design execution

- Transparent, traceable component sourcing

- Support for prototype, low-volume, and ongoing production

- Stable quality systems suitable for demanding applications

We approach EMS PCB assembly as a long-term manufacturing partnership, not a transactional service.

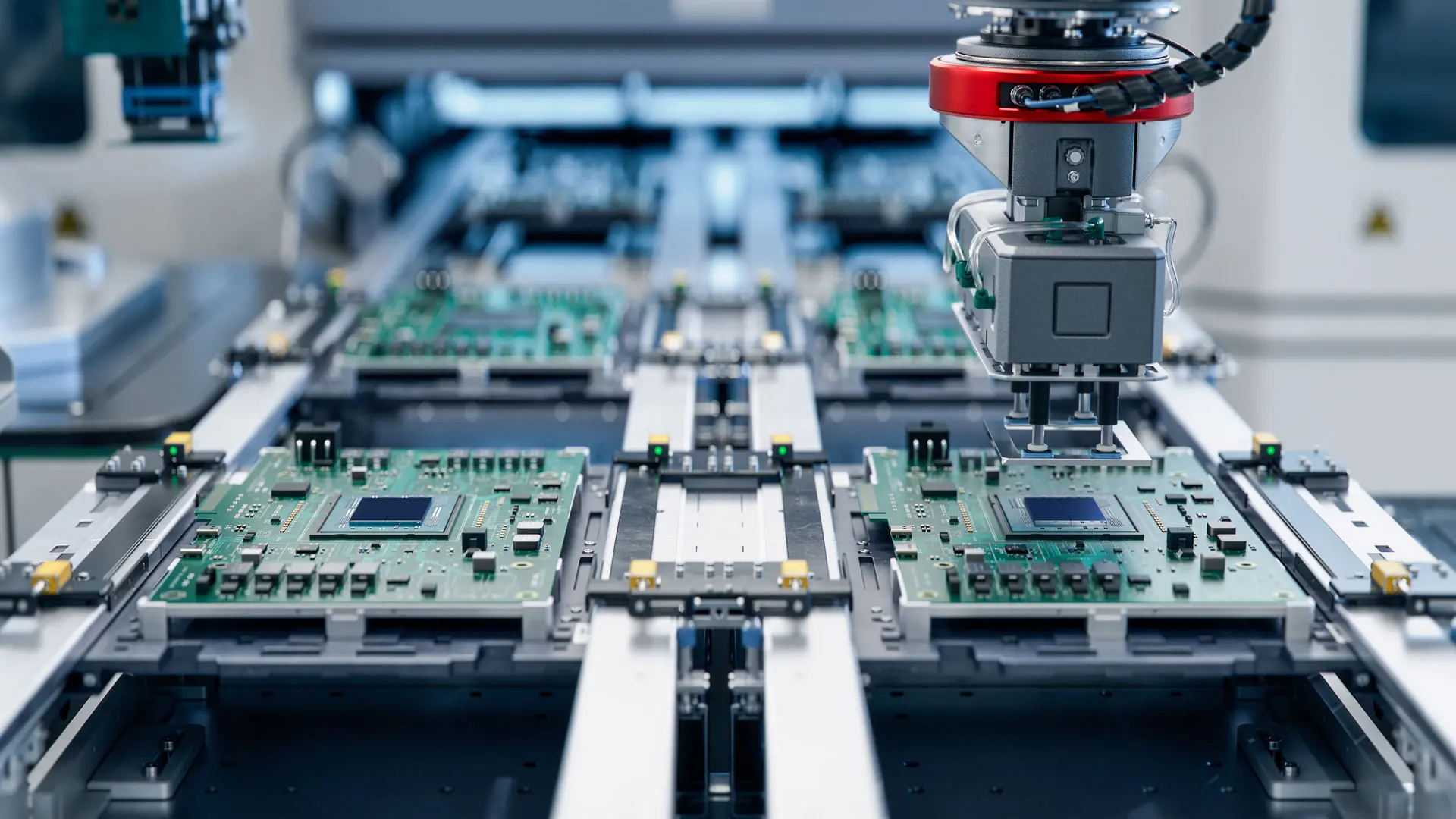

Our EMS PCB Assembly Capabilities

Our facilities and processes support EMS PCB assembly projects across a wide range of complexity levels:

- SMT, through-hole, DIP PCB & box building assembly

- Various PCB types including HDI, RF, MCPCB, ceramic PCB, rigid flex PCB and so on

- Mixed-technology and fine-pitch designs

- BGA, QFN, QFP small chips

- Prototype, low-volume, and medium-volume production

- AOI, X-ray, and functional testing

- Full documentation and traceability

All capabilities operate within a unified EMS framework to ensure consistency as production scales.

Is Our EMS PCB Assembly Right for Your Project?

Our EMS PCB assembly services are a strong fit if you:

- Plan to scale beyond prototypes

- Need sourcing stability and lifecycle management

- Require predictable quality and delivery

- Want engineering support, not just assembly capacity

If your priority is lowest unit price alone, a basic assembly vendor may be a better match.

If your priority is manufacturing confidence, EMS is the right model.

Common FAQs

1. What does EMS mean in PCB assembly?

EMS stands for Electronics Manufacturing Services, covering sourcing, assembly, testing, and production coordination.

2. Is EMS PCB assembly suitable for startups?

Yes. Many startups use EMS partners to avoid redesigns and supply-chain issues as they scale.

3. What is the typical MOQ for EMS PCB assembly?

MOQ depends on project complexity. We support prototype and low-volume builds as well as ongoing production.

4. How long does EMS PCB assembly usually take?

Lead time varies by materials and complexity, typically ranging from several weeks to a few months.

5. Can you manage component shortages?

Yes. Component risk is addressed through sourcing strategy, approved alternates, and lifecycle analysis.

6. What files are required to start?

Gerbers, BOM, pick-and-place data, assembly drawings, and test requirements.

Start Your EMS PCB Assembly Project

If you are evaluating EMS PCB assembly and want to understand whether our approach fits your product, the next step is a technical discussionÔÇönot a sales pitch.

Share your design files or project requirements, and our engineering team will review manufacturability, sourcing risk, and production readiness.