What Is Direct Current to Alternating Current Inverter?

A direct current to alternating current inverter is a sophisticated electronic device that transforms the stable, unidirectional flow of direct current (DC) into the oscillating waveform of alternating current (AC). Since most household appliances, industrial equipment, communication devices, and commercial systems are designed to operate on AC power, an inverter becomes essential whenever the primary energy source produces DCâsuch as a battery bank, solar photovoltaic array, fuel cell system, or automotive electrical system.

A direct current to alternating current inverter not only changes the type of current but may also adjust voltage levels, regulate frequency, stabilize output under varying load conditions, and provide protection against overload, short circuits, and reverse polarity. Modern inverters are used in renewable energy systems, emergency backup installations, portable power stations, RVs, boats, telecom sites, medical support equipment, and mobile power environments where AC power is required but unavailable.

Types of DC-AC Inverters

DC-AC inverters differ significantly in waveform purity, output stability, conversion efficiency, and suitability for specific applications. The main categories include:

1. Pure Sine Wave Inverters

These inverters generate an AC waveform that closely replicates grid-quality electricity. The output features smooth, continuous voltage oscillation with minimal harmonic distortion, making it compatible with all AC-powered devices. Sensitive electronicsâsuch as medical monitors, refrigeration compressors, audio devices, laser printers, and precision measurement instrumentsâoperate best on pure sine wave power. These inverters typically offer high efficiency, low noise, and stable operation under both linear and non-linear loads.

2. Modified Sine Wave Inverters

A modified sine wave inverter uses a stepped waveform that approximates AC power. Although not as clean as pure sine wave output, this type performs adequately for many non-sensitive devices, including power tools, lighting equipment, small appliances, and general-purpose electronics. Modified sine wave inverters are more cost-effective but may cause increased heat, lower efficiency in some motors, or buzzing noise in audio equipment.

3. Square Wave Inverters

Once common in small or low-cost electrical systems, square wave inverters produce a simple on/off AC waveform. This waveform is harsh for most modern electronics and is primarily compatible with resistive loads like heaters or incandescent bulbs. Because of poor performance with inductive and capacitive loads, square wave inverters are rarely used in contemporary systems.

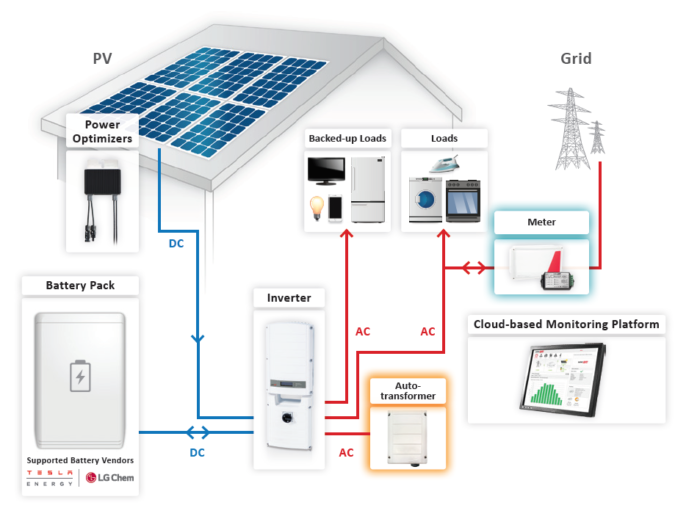

4. Hybrid Inverters

Hybrid inverters integrate battery charging, solar input control, grid synchronization, and energy management in a single platform. These inverters can automatically switch between solar energy, battery storage, and utility grid power, optimizing system efficiency. Hybrid inverters are the backbone of modern off-grid and grid-tied solar systems, providing seamless power transition during outages and offering advanced monitoring functions.

How Does a DC-AC Inverter Work?

A DC-AC inverter performs conversion through multiple coordinated electrical stages, each responsible for shaping and regulating the characteristics of AC output.

1. Input Filtering and Conditioning

The inverter receives DC power from a battery or solar module. Input filters remove noise and voltage spikes that may cause output instability.

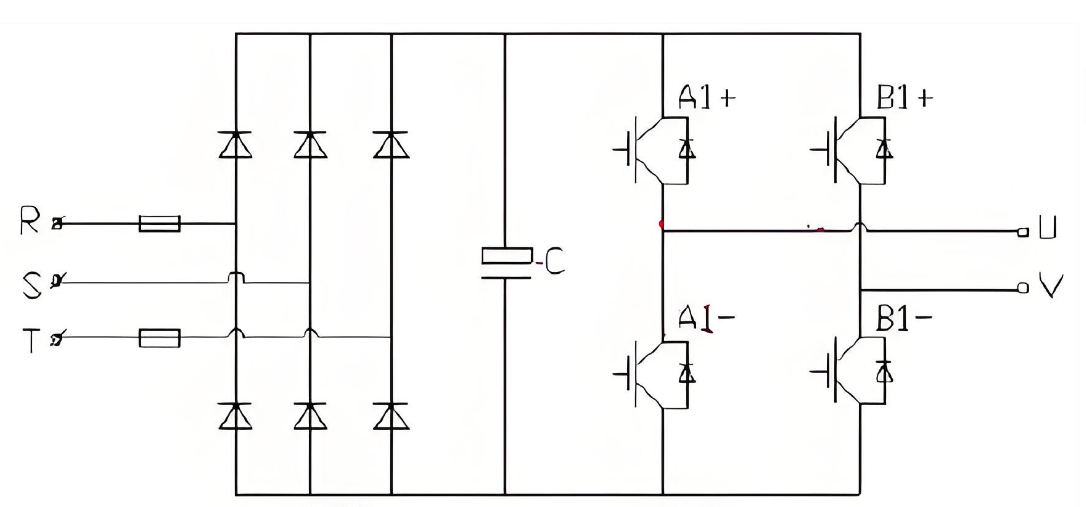

2. High-Frequency Switching Stage

At the core of the conversion process are semiconductor switches (MOSFETs or IGBTs). These switches operate at high frequencyâoften tens of kilohertzâto chop the DC into rapid pulses. The switching frequency and modulation pattern determine the waveform shape and voltage regulation.

3. Pulse-Width Modulation (PWM)

PWM is used to control the effective voltage delivered to the load. By adjusting the width of each pulse in the switching pattern, the inverter can simulate the smooth rise and fall of AC voltage.

4. Step-Up or Step-Down Conversion

Some inverters use transformers or boost converters to raise or lower DC voltage before waveform synthesis. This allows 12V, 24V, or 48V DC inputs to generate 120V or 230V AC output.

5. Waveform Smoothing and Filtering

Inductors and capacitors smooth the PWM output, reducing harmonic content and producing a stable AC sine wave.

6. Output Regulation and Protection

Advanced inverters constantly monitor output voltage, frequency, temperature, load level, and internal current flow. Protection features prevent damage from overload, overheating, short circuits, polarity reversal, or low input voltage.

DC to AC Conversion Formula

The dc to ac conversion formula is essential for determining how much usable AC power an inverter can produce from a DC source:

AC Output Power = DC Input Power Ă Inverter Efficiency

Where:

DC Input Power = DC Voltage Ă DC Current

Inverter efficiency typically ranges from 85% to 96%.

To estimate how much AC load an inverter can safely support, users should consider cable loss, temperature effects, continuous versus surge power, and battery voltage drop under load. For converting DC voltage levels into AC voltage, inverters use a combination of high-frequency switching and transformer-based or transformerless boost stages.

How to Convert DC to AC without Inverter?

Although not recommended for most modern applications, DC can be converted to AC without a conventional inverter through alternative methods.

1. Motor-Generator System

A DC motor mechanically drives an AC generator. As the generator rotates, it produces an alternating voltage waveform. This method is robust but extremely inefficient, noisy, and heavy, making it unsuitable for portable or energy-sensitive environments.

2. Rotary Converters

Rotary converters were historically used in railways and heavy industry to convert DC to AC. They consist of rotating machinery and commutators that mechanically modulate current. Today they are rarely used due to high maintenance requirements and poor energy efficiency.

3. Electronic Oscillator + Transformer Method

A custom-built oscillator circuit can generate AC-like waveforms, which are then amplified and stepped up through a transformer. While feasible in theory, this method requires advanced electronics knowledge and cannot match the stability or safety of a commercial inverter.

All alternative methods produce unstable or noisy AC output, reinforcing that a modern inverter remains the safest and most reliable solution.

DC Current to AC Current Calculator

A dc current to ac current calculator helps users determine the AC current available after conversion losses. The calculation is:

AC Current = (DC Voltage Ă DC Current Ă Efficiency) Ă· AC Voltage

Example:

- DC voltage: 12V

- DC current: 50A

- Efficiency: 90%

- AC output voltage: 120V

AC Current = (12 Ă 50 Ă 0.9) Ă· 120 = 4.5A AC

Key considerations include battery voltage level, load characteristics, wire length, and conductor size. Low battery voltage reduces AC output, and long cable runs may cause voltage drops. This calculation is widely used in solar power engineering, RV system design, and battery-power planning.

Applications of DC-AC Inverters

DC-AC inverters are indispensable across a wide range of industries and environments. By enabling DC sources to run AC loads, they open up deployment possibilities for many types of power systems.

- Solar PV systems converting sunlight into usable home or commercial AC power

- RVs, campers, and vans powering home-style appliances on the road

- Marine systems supporting onboard AC circuits on yachts and boats

- Industrial field tools used in remote or temporary work sites

- Emergency and backup systems providing reliable power during grid failure

- Portable power stations used in camping, travel, or disaster relief

- Telecom towers powering AC-based equipment in remote locations

- Medical support devices requiring stable AC power from mobile batteries

The ability to transform DC energy into AC makes inverters one of the most versatile electrical devices in modern power systems.

Safety Guidelines for Using a DC-AC Inverter

Proper installation ensures reliability, safety, and long operational life. Following good engineering practice reduces risk and prevents avoidable failures.

- Use appropriate cable gauge to prevent overheating and voltage drop.

- Maintain reliable grounding to minimize shock hazards and noise issues.

- Ensure ventilation so that heat can dissipate and components stay within safe temperature.

- Avoid overloading by keeping AC load within rated continuous and surge capacities.

- Install circuit breakers and fuses in both DC input and AC output as required for system protection.

- Keep inverter away from moisture and dust to prevent corrosion and tracking.

- Check connection tightness regularly to avoid arcing and unwanted resistance.

- Monitor battery condition because weak or damaged batteries can cause unstable operation.

How to Test a DC-AC Inverter?

Thorough testing evaluates the health, efficiency, and reliability of the inverter. A structured test process helps identify potential issues before they lead to downtime.

1. DC Input Voltage Check

Verify that the battery or DC source is supplying stable voltage. Under-voltage conditions may trigger protective shutdown, while over-voltage can damage components.

2. AC Output Voltage Measurement

Use a digital multimeter to confirm that the inverter is producing the correct AC voltage according to its rating (such as 110V, 120V, or 230V).

3. Load Test

Connect a resistive load or a group of appliances with known power ratings. Observe whether the inverter maintains consistent voltage and frequency under load without overheating or shutting down.

4. Waveform Quality Inspection

An oscilloscope can reveal waveform type, distortion, spikes, and harmonic content. This is particularly important when powering sensitive electronics or motors.

5. Temperature Monitoring

During extended operation, monitor the inverter casing and internal components for excessive heat. High temperature can indicate insufficient ventilation or overloading.

6. Safety Feature Validation

Test overload protection, low-voltage shutdown, over-temperature shutdown, and short-circuit response. Confirm that the inverter behaves safely during fault conditions.

Why Do DC-AC Inverters Fail? Common Problems

Inverters may fail due to a variety of electrical, mechanical, and environmental factors. Understanding these reasons helps designers and users prevent downtime.

- Overloading that pushes components beyond their power and thermal limits.

- Poor ventilation leading to heat buildup and thermal stress on semiconductors.

- Low-quality components that degrade faster under high-frequency switching.

- Incorrect wiring causing hot spots, arcing, or repeated fuse failures.

- Battery instability with large voltage swings affecting DC input.

- Moisture and dust causing corrosion, short circuits, or insulation breakdown.

- Harmonic distortion and noise stressing internal power stages over long periods.

Routine inspections, correct system sizing, proper cooling, and adherence to installation guidelines significantly reduce the risk of inverter failure and extend service life.

FAQs

1. What size inverter should I choose?

Choose an inverter with a continuous rating 20â30% higher than your total load, and ensure the surge rating can handle motor or compressor startup currents.

2. Are pure sine wave inverters worth the investment?

Yes. They provide grid-quality output, protect sensitive electronics, reduce noise, and improve motor efficiency and lifespan compared with modified or square wave inverters.

3. Can an inverter run from a car or RV battery?

Yes, but verify that the battery has sufficient capacity and that cables are correctly sized. Avoid draining the battery below recommended voltage levels to preserve battery health.

4. Do inverters waste energy?

Inverters lose approximately 5â12% of energy as heat. High-efficiency models reduce this loss and are preferable in solar and off-grid systems where every watt counts.

5. How long can an inverter operate continuously?

A high-quality inverter can run continuously as long as it has proper ventilation, a stable DC supply, and operates within its rated load and temperature limits.

6. Can solar panels connect directly to an inverter?

Most systems require a solar charge controller and battery buffer to manage voltage and protect both panels and inverter. Only specialized inverters are designed to accept direct PV input.

7. How often should an inverter be inspected or tested?

For general use, inspection every few months is recommended. Off-grid, telecom, medical, or mission-critical systems may require more frequent testing and monitoring.