Demand for high-quality Cyprus PCB manufacturer services is surging amid the expansion of local electronic projects, driven by AI and high-end device upgrades. Securing a reliable Cyprus PCB manufacturer that balances quality, speed and cost remains a top challenge. This article tackles core pain points in Cyprus PCB manufacturing, offers actionable solutions, and guides you in selecting the optimal PCB factory in Cyprus or global partner.

Are You Facing These Problems of Cyprus PCB Manufacturing?

- Is the PCB Cyprus prototyping service too slow to meet urgent project schedules?

- Does the Cyprus PCB factory fail to provide accurate DFM suggestions leading to repeated revisions?

- Are the quality standards of Cyprus PCB Manufacturing inconsistent with your product requirements?

- Does the PCB manufacturer in Cyprus lack flexibility in handling small-batch and customized orders?

- Is the pricing of Cyprus PCB company uncompetitive with hidden costs?

- Does the Cyprus PCB plant have limited process capabilities for high-layer or special-material PCBs?

- Is the after-sales support of Cyprus PCB manufacturer inadequate when quality issues occur?

Full-Process Guarantee from Requirement to Delivery

- Pre-order Consultation: Offer free technical communication to clarify requirements and avoid misunderstandings, solving the problem of inadequate DFM support from local Cyprus PCB factory.â

- Rapid Prototyping: 24-hour urgent prototyping service to meet tight schedules that local PCB Cyprus services can hardly satisfy.â

- Flexible Production: Accept small-batch and customized orders with no minimum quantity limit, making up for the inflexibility of Cyprus PCB manufacturing.â

- Strict Quality Control: Implement full inspection for mass production to ensure consistent quality, exceeding the standards of ordinary Cyprus PCB company.â

- Transparent Pricing: Quote with detailed breakdowns, no hidden costs, providing more competitive prices than local Cyprus PCB plant.â

- Efficient Logistics: Cooperate with reliable carriers to ensure on-time delivery, matching the 99.2% on-time rate commitment.â

- After-sales Support: 7Ã24-hour technical team response to solve quality issues promptly, surpassing the after-sales level of Cyprus PCB manufacturer.

Why Cyprus Clients Choose EBest Circuit( Best Technology) for PCB Manufacturer?

Reasons Why Cyprus Clients Choose EBest Circuit(Best Technology) for PCB Manufacturer:

- 19 Years of Experience: Rich industry experience optimizes processes and materials to further reduce costs for clients.

- Free DFM Analysis: Professional team provides pre-production design optimization to avoid rework, a service rarely offered by ordinary Cyprus PCB company.

- Comprehensive Certifications: Hold ISO9001:2015, ISO13485:2016, IATF16949, REACH and RoHS certifications, meeting various industry requirements in Cyprus.

- Competitive Pricing: Provide cost-sensitive solutions, helping clients reduce 15%-20% of procurement costs compared to PCB manufacturer in Cyprus.

- 24-Hour Rush Prototyping: Emergency orders can be completed within 24 hours, far faster than the average lead time of Cyprus PCB factory.

- High On-time Rate: 99.2% of orders are delivered on schedule, ensuring project progress is not delayed.

- Strict Quality Control: Mass production adopts AOI and X-Ray full inspection, with defective rate controlled below 0.03%, higher than Cyprus PCB manufacturing standards.

- Diversified Process Capabilities: Support 1-64 layers of PCBs, HDI, blind/buried holes and special materials, making up for the process limitations of Cyprus PCB plant.

Top 10 PCB Factory in Cyprus

| Company Name | Main Business | Core Advantages | Process Capabilities | Lead Time |

| EBest Circuit Co., Limited | PCB manufacturing, prototyping, assembly, DFM analysis | 24-hour urgent service, full certifications, 99.2% on-time rate | 1-64 layers, HDI, blind/buried holes, impedance control | 24h prototyping, 3-7 days small batch, 10-15 days mass production |

| Elmatic AB | PCB manufacturing, custom circuit boards | Swedish local service, high-precision production | 1-16 layers, FR-4 material, surface mount technology | 5-7 days prototyping, 15-20 days mass production |

| Printed Circuits Sweden AB | PCB production, assembly, testing | Strict quality control, industrial-grade products | 1-24 layers, thick copper, high-frequency PCBs | 7-10 days prototyping, 20-25 days mass production |

| Eurocircuits Sweden | PCB prototyping, small-batch manufacturing | Fast response, online quoting system | 1-12 layers, standard and flexible PCBs | 3-5 days prototyping, 12-18 days mass production |

| Electroprint AB | Custom PCB manufacturing, technical support | Specialized in complex designs, local after-sales | 1-20 layers, blind holes, impedance control | 6-8 days prototyping, 18-22 days mass production |

| PCB Tech Sweden AB | PCB production, assembly, logistics support | Integrated service, stable supply chain | 1-18 layers, FR-4, aluminum substrate | 4-6 days prototyping, 16-20 days mass production |

| Nordic Circuits AB | High-precision PCB manufacturing, prototyping | Advanced equipment, medical industry certification | 1-32 layers, HDI, medical-grade PCBs | 8-10 days prototyping, 22-28 days mass production |

| Scanboard AB | PCB manufacturing, small-batch customization | Flexible production, competitive pricing | 1-14 layers, standard PCBs, surface treatment | 5-7 days prototyping, 14-18 days mass production |

| Tech Print Sweden AB | PCB production, testing, assembly | Fast delivery, reliable quality | 1-16 layers, FR-4, high-temperature materials | 4-6 days prototyping, 15-19 days mass production |

| SwedCircuit AB | Custom PCB manufacturing, technical consulting | Industry experience, personalized service | 1-20 layers, blind/buried holes, thick copper | 7-9 days prototyping, 19-23 days mass production |

How to Choose A Reliable Cyprus PCB Manufacturer?

- Verify Core Certifications: Prioritize a Cyprus PCB manufacturer with ISO9001:2015, ISO13485:2016 and IATF16949 certifications, ensuring compliance with EU REACH and RoHS standards for risk-free application.â

- Assess Quality Control System: Confirm the PCB factory in Cyprus adopts AOI+X-Ray full inspection, with mass production defect rate â¤0.03% and traceable quality records for each batch.â

- Check Delivery Capabilities: Inquire about on-time rate (â¥95% as baseline, top providers reach 99.2%), 24-hour urgent prototyping support and EU-targeted logistics solutions.â

- Evaluate Process Flexibility: Ensure the Cyprus PCB plant covers required processes (1-64 layers, HDI, high-frequency materials like Rogers) and accepts small-batch orders with no MOQ preference.â

- Confirm Transparent Pricing: Choose a Cyprus PCB company offering detailed cost breakdowns, no hidden fees, and cost-sensitive solutions to cut procurement costs by 15%-20%.â

- Review Technical Support: Optimize for Cyprus PCB manufacturing with 24-hour free DFM analysis and 7Ã24 after-sales service, resolving issues within 2 hours to avoid project delays.â

- Check Industry Experience: Prioritize partners with 10+ years of experience, â¥85% client repurchase rate and verified cases in your field.â

- Validate Supply Chain Stability: Ensure the PCB manufacturer in Cyprus sources from EU-compliant suppliers, with â¥99.8% batch qualification rate, 24-hour stock replenishment and reduced import delay/tariff risks.â

- Leverage EU Compliance Proximity: A professional Cyprus PCB manufacturer grasps EU regulatory requirements, ensuring REACH/RoHS compliance without extra certification costs.â

- Prioritize Logistics Efficiency: Local PCB factory in Cyprus shortens EU project delivery cycles, reducing transit time by 30% compared to non-EU manufacturers.â

- Value Time Zone Alignment: Cyprus PCB company operates in the same time zone as most European clients, enabling timely communication and issue resolution.â

- Seek Local Service Support: Reliable Cyprus PCB plant provides on-demand technical support and on-site inspections, eliminating cross-border communication barrier

How to Evaluate the Production Capacity of Cyprus PCB Manufacturer?

Evaluation Guide to Production Capacity of Cyprus PCB Manufacturer:

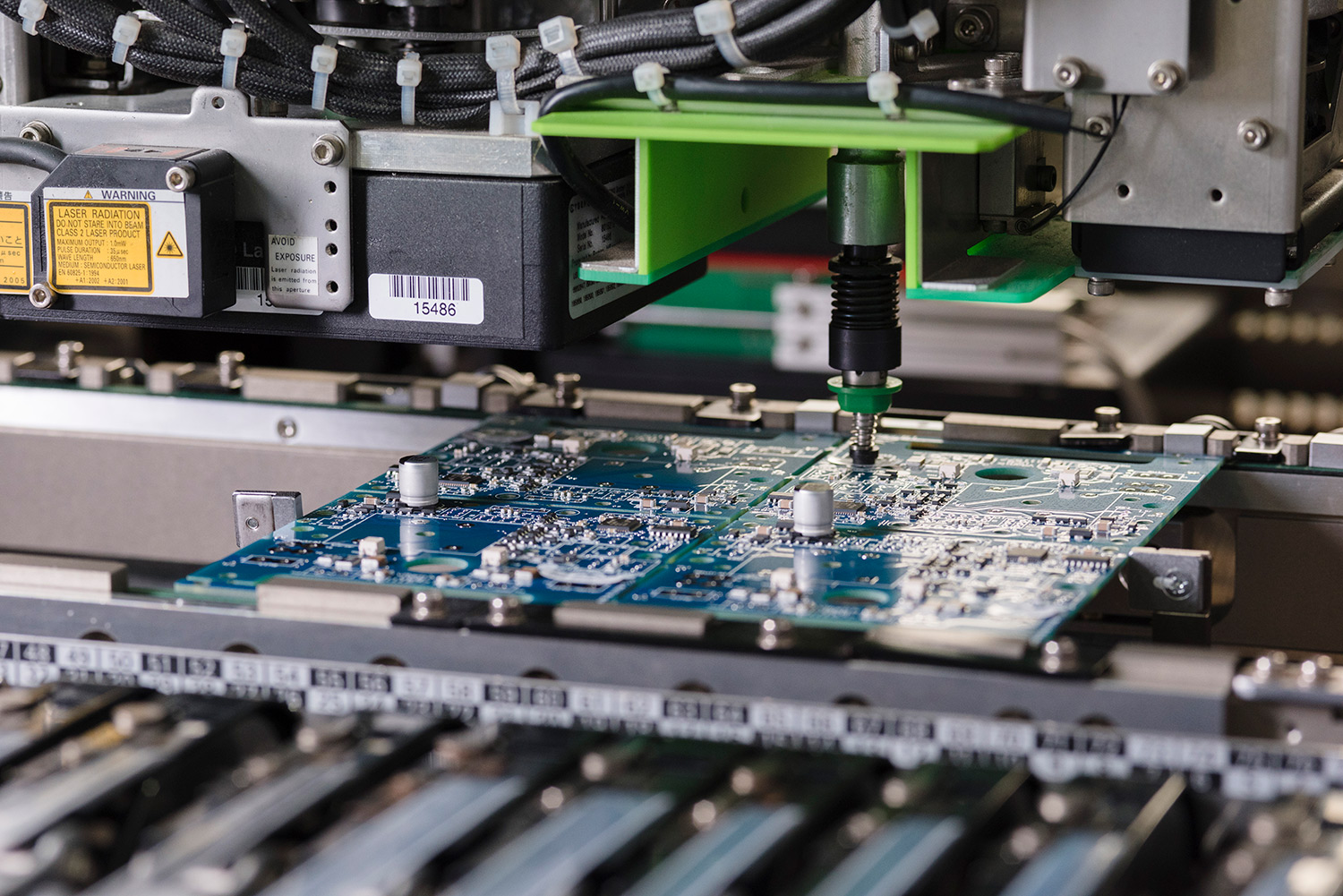

- Check production equipment: Confirm drilling machines with minimum aperture â¤0.1mm, plating thickness tolerance ±5%, and AI testing equipment with defect leakage rate near 0 for stability and advanced performance.â

- Verify process capabilities: Ensure support for 1-64 layers, minimum line width/space â¥3mil/3mil, and high-frequency processes with material loss factor (Df) â¤0.002 and copper foil roughness (Rz) ï¼1.5μm.â

- Assess quality control system: Require AOI+X-Ray full inspection (coverage 100%), mass production defective rate <0.03%, and complete certifications like ISO9001:2015 and IATF16949.â

- Examine raw material supply: Ensure core substrate batch qualification rate â¥99.8%, support for M9-grade materials (BCB resin, quartz cloth), and compliance with RoHS/REACH standards.â

- Evaluate production scale: Confirm daily capacity â¥5000ã¡, with small-batch order response time â¤4 hours to match your volume demands.â

- Check technical team strength: Assess DFM analysis response â¤24 hours and complex process problem-solving rate â¥95% for professional support.â

- Review past cases: Prioritize partners with â¥70% cooperation in similar industries and client repurchase rate â¥85% for reliable experience.â

- Verify digital management level: Confirm MES system adoption, with scan code recipe loading efficiency improved by 1200% and production data traceability coverage 100%.

How to Evaluate the Delivery Time of Cyprus PCB Manufacturer?

Evaluation Guide to Delivery Time of Cyprus PCB Manufacturer:

- Confirm standard lead time: Clarify cycles by order type, prototyping (12h-7days), small batch (3-10days), mass production (10-25days) and align with industry benchmarks for Cyprus PCB Manufacturing.â

- Check urgent service capacity: Evaluate support for 12-24h rush orders, with urgent order completion rate â¥98%, a standard higher than average Cyprus PCB Factory.â

- Assess scheduling flexibility: Confirm emergency order insertion response â¤4h, with monthly flexible scheduling capacity â¥50 orders, adapting to project progress changes.â

- Review on-time rate data: Request past 6-month statistics (on-time rate â¥95% as industry baseline), excluding force majeure, to verify if it matches the 99.2% standard of top Cyprus PCB Manufacturer.â

- Examine logistics cooperation: Ensure logistics partners control long-distance delay rate â¤2% (vs industry average 18%), with customized solutions like pre-warehousing for PCB Cyprus orders.â

- Clarify delay compensation: Confirm terms such as 3%-5% of order value as compensation for delays caused by the manufacturer, with clear definition of delay (exceeding agreed time by â¥24h).â

- Evaluate order tracking system: Verify real-time production sync via digital platform, with progress updates every 2h and automatic alerts for abnormalities, a must-have for reliable Cyprus PCB Company.â

- Confirm inventory capacity: Check common material (FR-4, aluminum substrate) stock coverage â¥90%, with stock replenishment cycle â¤24h to shorten production preparation time for Cyprus PCB Plant orders.

FAQs of Cyprus PCB Manufacturing

Q1: How to avoid design issues leading to PCB rework? â

A1: We provide free DFM analysis before production to detect line width, spacing and aperture problems in advance. Unlike many Cyprus PCB manufacturer, our professional team optimizes designs to reduce rework rate by over 80%. Contact us for a free analysis.â

Q2: Why do prototyping samples differ from mass production products? â

A2: We adopt unified process standards for prototyping and mass production, with full inspection to ensure consistency. Our sample-mass production consistency rate reaches 99.5%. Inquiry now for stable quality.â

Q3: How to solve signal integrity issues in high-frequency PCBs? â

A3: Many Cyprus PCB Manufacturing lack high-frequency process capabilities. We use high-quality high-frequency materials and precise impedance control technology, with impedance deviation within ±10%. Our 19-year experience ensures signal stability. Get a customized quote today.â

Q4: What to do if the PCB has soldering defects like cold joints or bridges? â

A4: This is caused by inadequate quality control of Cyprus PCB plant. We implement X-Ray and AOI full inspection for soldering, with defective rate controlled below 0.03%. We provide free rework for quality issues. Contact us for reliable products.â

Q5: How to get competitive pricing for small-batch orders? â

A5: Most Cyprus PCB company have high minimum order quantities. We offer no MOQ requirement and transparent pricing for small batches, with cost-saving solutions based on your needs. Inquiry now for favorable quotes.