What is cm1400du 24nf? Let’s discover its datasheet, weight, benefits, applications, selection guideline, lifespan and cost and alternative choice via this blog together.

Are you worried about these problems?

- Does your equipment suffer from performance instability or shortened lifespan due to poor thermal management?

- Are you struggling to find efficient, stable power solutions within cost constraints?

- Is your design compromising layout flexibility due to bulky power module footprints?

As a power module supplier, EBest Circuit (Best Technology) can provide you service and solutions:

- Optimized Thermal Design: Custom thermal support ensures CM1400DU-24NF operates stably at high temperatures, extending operational life.

- Cost-Performance Optimization: Competitive pricing through supply chain efficiency, delivering high-performance power modules without compromising quality.

- Compact Integration Solutions: Streamlined compact designs paired with one-stop technical consulting for rapid integration, unlocking spatial efficiency and design agility.

Welcome to contact us if you have any request for power module: sales@bestpcbs.com.

What Is CM1400DU 24NF?

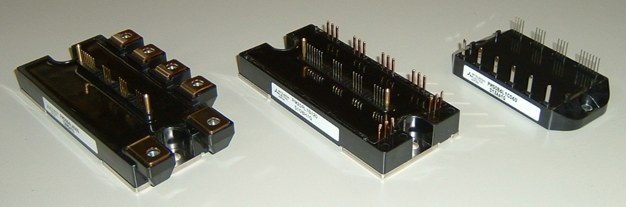

The CM1400DU 24NF is a 1400V/24A dual-unit IGBT power module manufactured by ON Semiconductor. It integrates two insulated-gate bipolar transistors (IGBTs) with anti-parallel diodes and uses an industrial-grade half-bridge package design. It is suitable for low-to-medium power conversion applications such as frequency converters, servo drives, and photovoltaic inverters.

CM1400DU 24NF Datasheet

| Parameter Name | Parameter Value |

| Manufacturer | POWEREX / Mitsubishi Electric |

| Product Series | MegaPower Dual IGBT MOD™ |

| Collector Current (Ic) | 1400A (Max) |

| Collector-Emitter Breakdown Voltage (VCES) | 1200V (Max) |

| Maximum Power (Pmax) | 3900W |

| On-State Voltage (VCE(on)) | 2.5V @15V VGE, 1400A IC (Typical) |

| Configuration Type | Half Bridge |

| Switching Frequency | Hard Switching: 30kHz; Soft Switching: 60-70kHz |

| Input Capacitance (Cies) | Varies with VCE (Refer to Datasheet) |

| Package Type | Insulated Dual Module |

What Is Weight of CM1400DU 24NF?

The measured weight of the CM1400DU-24NF module is approximately 38 grams (including all terminals and the metal substrate). Its compact industrial package design ensures heat dissipation performance while minimizing the load on the mounting structure, making it suitable for weight-sensitive air-cooled/miniaturized power electronic devices.

Why Choose CM1400DU-24NF?

Advantages of CM1400DU-24NF:

- High Power & High Efficiency: 1200V/1400A high-voltage, high-current design, supporting 3900W power output; hard switching at 30kHz and soft switching at 60-70kHz for high-frequency applications, reducing switching losses and improving system efficiency.

- Extreme Environment Adaptability: Insulated dual-module package, wide operating temperature range of -40°C to 150°C, industrial-grade high-voltage certification, stable operation in harsh environments, reducing failure rate.

- Technological Reliability Backing: Jointly developed by Mitsubishi and Powerex, employing advanced silicon wafer technology, optimizing short-circuit robustness, and meeting stringent standards for new energy and rail transportation.

- Convenient Heat Dissipation & Installation: Modular design supports base mounting; multi-hole terminals reduce impedance, improve heat dissipation efficiency, and reduce additional heat dissipation costs.

- Low-Loss Turn-On: Typical 2.5V turn-on voltage drop, reducing turn-on losses by 40% compared to traditional IGBTs; dynamic capacitor optimization design improves energy efficiency ratio.

- Safety, Isolation & Compatibility: Electrical isolation complies with EMC standards; built-in temperature monitoring enhances system safety and adapts to the needs of multiple application fields.

- Long-term cost advantages: High reliability reduces maintenance, stable supply ensures project progress, and improves return on investment.

- Wide range of applications: Adaptable to multiple fields such as new energy, industrial drives, and rail transportation, supporting future technology upgrade paths.

When to Use CM1400DU-24NF?

Applications of CM1400DU-24NF:

- Industrial Variable Frequency Drive: AC motor frequency converters with power ≤15kW (water pumps/fans/compressors)

- Servo drive power modules: robotic arms/CNC machine tools

- Photovoltaic Power Generation Systems: String photovoltaic inverters, DC-AC conversion units (single-phase/three-phase, ≤20kW)

- Uninterruptible Power Supply (UPS): Online UPS inverter bridge (10-15kVA power range)

- Home Appliance Variable Frequency Control: Air conditioner compressor drive modules, high-end refrigerator variable frequency power boards

- Light Electric Transportation: Electric forklift/AGV motor controllers (48V/72V system boost inverter)

How to Select A CM1400DU 24NF?

1. Core Electrical Characteristics Verification

Voltage/Current/Power Boundary Verification

- Static Verification: Use Agilent B1505A Semiconductor Parameter Analyzer to test leakage current under 1200V blocking voltage, ensuring ≤1mA.

- Dynamic Verification: Capture 1400A peak current surge waveform via Tektronix oscilloscope, confirming no avalanche breakdown.

Double Pulse Test for Loss Quantification

- Test Standard: Execute per JEDEC JC-70, measure Eon/Eoff values, and compare against datasheet specifications.

- Drive Matching: Adjust gate resistance (Rg=10Ω~50Ω) to optimize switching speed, balancing switching loss and EMI noise.

On-State Voltage Drop Threshold Check

- Low-Temperature Test: Verify Vce(on) ≤3.0V at -40°C (15V drive/1000A), preventing increased low-temperature conduction resistance.

2. Application Scenario Compatibility Analysis

Industrial Scenario Stability Verification

- High-Frequency Power Supply: Test temperature rise curve at 50kHz switching frequency, ensuring junction temperature ≤150°C.

- Robot Servo: Validate parameter drift ≤5% across -40°C~150°C wide temperature range.

New Energy Wide Voltage Matching

- Photovoltaic Inverter: Support 200-1000VDC input range, pass ASTM B117 salt spray test for outdoor durability.

- Wind Power Converter: Pass IEC 61400-2 vibration resistance test, simulating 20g impact acceleration.

Automotive Grade Compliance Confirmation

- Electric Vehicles: Meet AEC-Q101 automotive certification and ISO 16750-2 electrical load test.

- Charging Stations: Comply with IEC 61851-1, supporting 1000V/350A DC fast charging scenarios.

3. Thermal Management Implementation

Heat Dissipation System Parameter Design

- Heatsink Selection: Use 6063-T5 aluminum alloy heatsink with anodized surface for corrosion resistance.

- Liquid Cooling System: Design parallel flow channels with flow resistance ≤50kPa, integrate flow meter for real-time monitoring.

Thermal Simulation and Measurement Calibration

- Simulation Tool: Utilize ANSYS Icepak for thermal-fluid coupling simulation, predict junction temperature distribution.

- Measurement Calibration: Monitor hotspot temperature via infrared thermal imager under full load, error ≤±3°C.

Temperature Sensor Configuration

- Sensor Type: Integrate NTC thermistor (β=3950) for linearized temperature output.

- Over-Temperature Protection: Set dual thresholds at 130°C/150°C to trigger drive circuit shutdown.

4. PCB Layout and Package Compatibility

Heat Dissipation Pad Design Specifications

- Pad Dimensions: Adopt ≥25mm×25mm copper area, copper thickness ≥2oz (70μm).

- Solder Selection: Use SAC305 lead-free solder (melting point 217°C) for -40°C~125°C solder joint reliability.

Pin Stress Management

- Stress Analysis: Simulate pin stress via ANSYS Mechanical, ensuring stress ≤50% of material yield strength.

- Soldering Process: Employ selective laser reflow to prevent pin bridging or cold soldering.

Module Package Compatibility

- Mechanical Compatibility: Verify module mounting holes align with PCB locating pins within ≤0.1mm tolerance.

- Electrical Compatibility: Test pin-to-PCB trace impedance matching to avoid signal reflection.

5. Supply Chain Compliance and Traceability

Authorized Channel Procurement

- Channel Screening: Validate Mouser/Digi-Key authorization via Mitsubishi official website for genuine supply.

- Batch Traceability: Require batch COO, RoHS test reports, and third-party reliability test reports.

Environmental and Safety Certification

- Environmental Compliance: Pass REACH SVHC screening to ensure no prohibited substances.

- Safety Certification: Module packaging bears UL certification mark and CE declaration of conformity.

Anti-Counterfeiting Traceability Mechanism

- Security Label: Adopt Mitsubishi original laser anti-counterfeiting label with QR code verification.

- Logistics Monitoring: Track logistics temperature/humidity via supply chain system to ensure storage compliance.

6. Multidimensional Design Verification Process

Simulation and Measurement Integration

- Circuit Simulation: Build inverter model via PSIM to validate module dynamic response under load transients.

- Measurement Validation: Conduct power cycling test to verify parameter drift over 1000 full-load transitions.

Reliability Validation via Burn-In Testing

- High-Temperature Aging: Perform 1000-hour aging at 125°C to monitor module parameter degradation.

- Thermal Cycling: Execute -40°C~125°C temperature cycling to validate solder joint and package reliability.

Failure Analysis Support

- Failure Modes: Analyze failure causes via SEM/EDS and provide improvement recommendations.

- Application Notes: Access Mitsubishi original application notes to optimize drive circuit design and layout.

7. Cost Efficiency and Alternative Solution Evaluation

Bulk Procurement Cost Analysis

- Price Gradient: Compare unit price differences between Mitsubishi original and competitors like Powerex/Infineon across 100/500/1000-piece batches.

- TCO Analysis: Calculate total lifecycle cost including procurement, maintenance, and failure losses.

Lifecycle Management

- Supply Assurance: Evaluate Mitsubishi’s 3-year warranty and ≤24-hour after-sales response time.

- Alternative Solutions: Assess compatibility and performance differences with CM200DY-24NF or Infineon FF600R12KE4 modules.

What Is the Lifespan of CM1400DU-24NF?

The CM1400DU-24NF is designed for a lifespan of over 15 years in typical industrial applications, but must meet conditions: a long-term stable operating junction temperature (Tj) ≤125°C, a heat dissipation system ensuring a substrate temperature ≤110°C, and avoidance of transient current surges exceeding 60A. Actual lifespan is affected by thermal design, switching frequency, and grid environmental stress; its durability is verified through IEC 60747 accelerated aging certification.

How Much Does CM1400DU 24NF Cost?

The current spot market reference price for CM1400DU-24NF ranges from $15.50 to $22.80 per unit (as of Q3 2024 data), with exact pricing influenced by order volume, distribution channels, and tariff policies. For small orders under 100 units, mainstream European and American distributors typically quote tax-inclusive prices between $20.80 and $22.80, ideal for agile small-scale projects. For bulk orders exceeding 500 units, negotiated pricing can drop to $15.50–$18.20 per unit.

To ensure competitive pricing and supply chain reliability, buyers are advised to engage authorized ON Semiconductor distributors like Avnet or Arrow Electronics. Always monitor tariff fluctuations and verify distributor credentials to balance cost efficiency with procurement security.

Alternative Choice for CM1400DU 24NF

| Manufacturer | Model | Features | Price Range |

| Infineon | IKW25N120T2 | 1200V/25A, superior switching characteristics | $23.5−$26.9 |

| Mitsubishi | CM75DY-24H | 1400V/75A, stronger current capability | $35.0−$42.0 |

| STMicro | STGWA40H120DF2 | 1200V/40A, integrated temperature sensor | $20.8−$24.5 |

Welcome to contact us if you need any help for CM1400DU 24NF: sales@bestpcbs.com.