What is a PCB? PCB meaning circuit board, a basic structure that uses copper foil traces instead of wires to connect and support electronic components. It enables various components to communicate with each other and work together, making modern electronic products reliable, efficient and easy to manufacture.

What is a PCB board?

PCB board is the backbone of almost every device you use each day. It holds circuit board components in fixed positions. It directs signals through copper traces. It creates dependable communication between every part of the device.

When you look at a phone, a watch, a smart home tool, a medical meter, or an automotive controller, there is always a PCB board inside doing the heavy work. It delivers smooth performance. It keeps the device compact. It protects circuits from breaking under pressure. It ensures the final product feels solid and reliable.

PCB boards were chosen because they have a simple structure and stable function. Without them, electronics would be messy, bulky, and fragile. Devices would shake apart. Signals would not follow the right direction. And even simple gadgets would become complicated to build.

As a professional manufacturer, EBest Circuit (Best Technology) Co., Ltd. understands the impact of high-quality PCB boards on product success. And that is why a PCB board matters. It is simple, powerful, and essential.

What is a PCB simple definition?

A PCB simplest definition is this: PCB is a board that connects electronic components through printed copper paths.

A PCB supports components and lets electricity travel across the board in a controlled way. That is the core. That is the purpose.

What does PCB stand for?

PCB stands for Printed Circuit Board. The word āprintedā reflects the way copper pathways are created on the board. These pathways are not drawn by hand. They are produced through precise manufacturing steps that form thin lines of copper on the surface.

The term ācircuitā represents the flow of electricity. It includes every trace, via, component pad, and copper area. The board becomes a complete road map for electric energy.

The word āboardā describes the physical shape. It is flat. It is strong. It is usually made from reinforced fiberglass material like FR-4. It supports all circuit board components in one place.

Together, the three words create the term Printed Circuit Board. A PCB is a board that carries circuits created through printed patterns. The meaning of PCB has become universal in the electronics world.

EBest Circuit (Best Technology) produces PCBs for global customers. No matter the product, a PCB provides the structure for electronics to work.

What is the difference between a circuit board and a PCB?

Circuit board is a broader category. It includes any type of board used to connect circuits. That means prototype boards, breadboards, wired boards, and printed boards all belong to this category.

PCB is a specific type of circuit board. It uses printed copper traces instead of wires. Its structure follows professional manufacturing steps. It is cleaner. It is stronger. It is designed for mass production.

So every PCB is a circuit board. But not every circuit board is a PCB.

The industry usually uses āPCBā when speaking about real products because PCB ensures consistency. It allows automated assembly. It supports mass manufacturing. It keeps signal quality high. Other types of circuit boards work for learning or testing, but they are not built for final production.

How does PCB board work?

PCB board works by transferring electrical signals through copper pathways. These pathways connect each component in a precise pattern. When power enters the system, the path guides electricity to every part that needs it.

When the mapping is clean, the signal stays stable. When the copper lines follow the right width and spacing, the system becomes smooth and safe. And when the entire board is designed well, heat stays under control. Performance becomes more reliable.

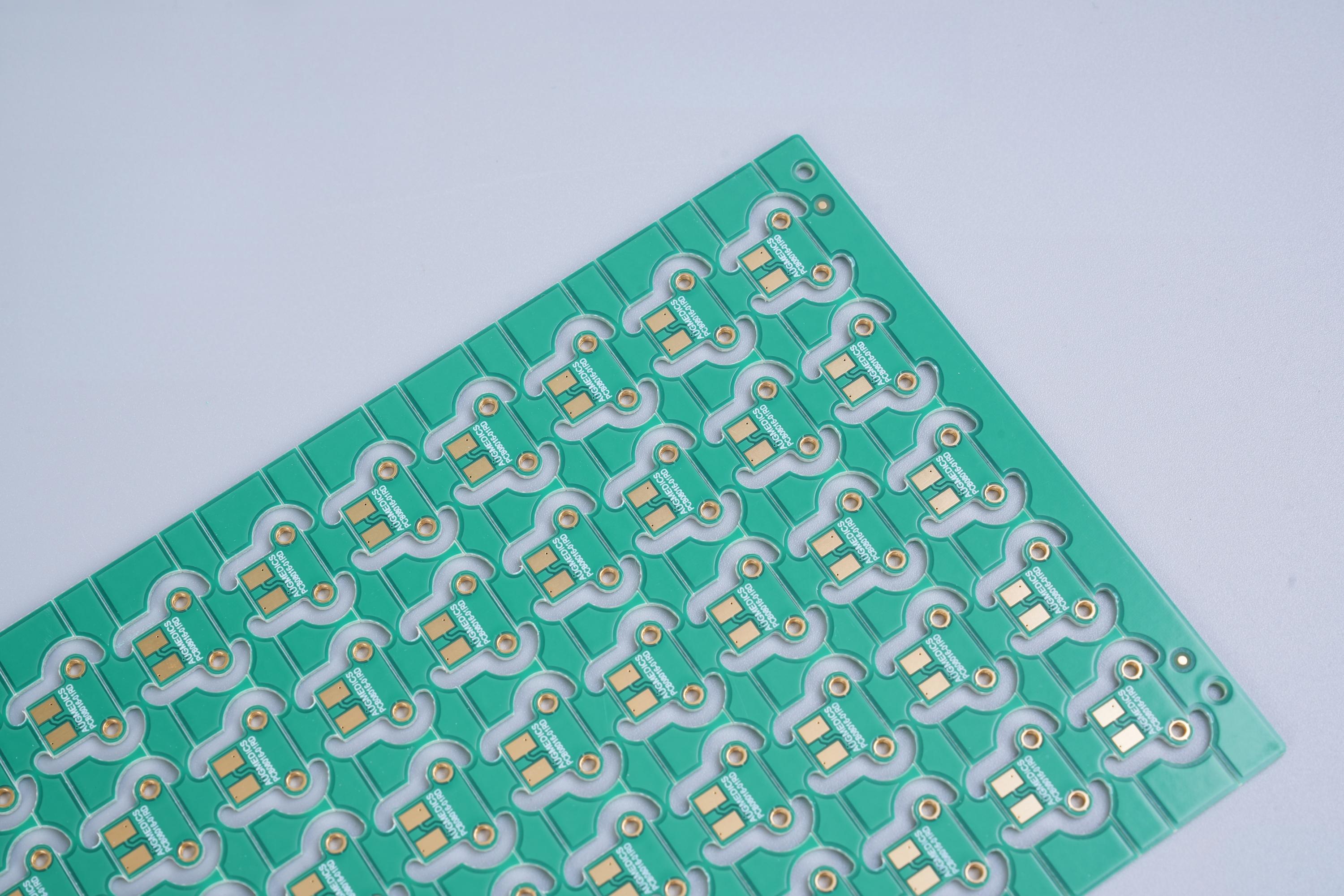

PCB board can have one layer, two layers, or multiple layers stacked together. More layers mean more complex functions. Modern devices often use multi-layer designs because they allow compact size and high performance at the same time.

EBest Circuit (Best Technology) builds boards with 2, 4, 6, 8, and even over 20 layers. Each one works by guiding signals with precision. The success of the final device always depends on how well the PCB board works inside it.

What is a PCB layout?

PCB layout is the visual and functional design of a PCB. It shows where each trace goes. It shows where each component stays. It displays the direction of every signal. And it lays out the full structure of the board so manufacturing can begin. Engineers create this layout using professional software.

A layout includes:

- Component placement

- Copper routing

- Power and ground planes

- Mounting holes

- Vias

- Silkscreen text

- Board outlines

The layout is one of the most important steps in PCB design. A clear layout improves performance. A poor layout can cause noise, interference, or heat issues.

EBest Circuit (Best Technology) Co., Ltd. works closely with clients during layout evaluation to ensure that each PCB can move smoothly into manufacturing without delays.

What is a PCB board made of?

PCB board is made of layered materials that work together to create strength, insulation, and electrical conduction. The structure looks simple on the surface, but the layers have important roles.

- 1. Base Material (Substrate)

The base is usually FR-4, a fiberglass epoxy that provides strength and insulation. Other materials include Rogers high-frequency laminates, polyimide for flexible boards, and aluminum for heat-intensive devices.

- 2. Copper Layer

This layer carries the signals. It can be 1-oz, 2-oz, or thicker, depending on current needs.

- 3. Solder Mask

This is the green, blue, red, yellow, or black coating seen on PCBs. It protects copper traces from oxidation and prevents solder bridging.

- 4. Silkscreen

This is the white print on top. It marks labels, numbers, and component guides.

- 5. Surface Finish

To ensure solder quality, manufacturers apply finishes like ENIG, HASL, OSP, immersion tin, or immersion silver.

Together, these layers form a strong, reliable platform. EBest Circuit (Best Technology) selects materials based on customer needs. High-frequency devices need special laminates. Automotive boards need heat-resistant substrates. LED boards need aluminum-backed structures for better cooling.

What is a PCB board used for?

A PCB board is used in nearly every electronic product on the market. It supports devices that shape daily life, business, entertainment, health, communication, and transportation.

- Phones use PCBs to process signals, display screens, and control sensors.

- Medical tools use PCBs to read data and deliver accurate measurements.

- Automobiles use PCBs to manage engine control, safety features, lighting, navigation, and audio.

- Smart home devices use PCBs to connect to the internet and deliver smart functions.

- Industrial machines rely on PCBs to automate processes and secure stable operation.

PCBs are located inside the product, connecting all components together to ensure the system functions properly. EBest Circuit (Best Technology) supplies PCB boards to companies that build consumer electronics, communication systems, industrial tools, automotive modules, and medical devices.

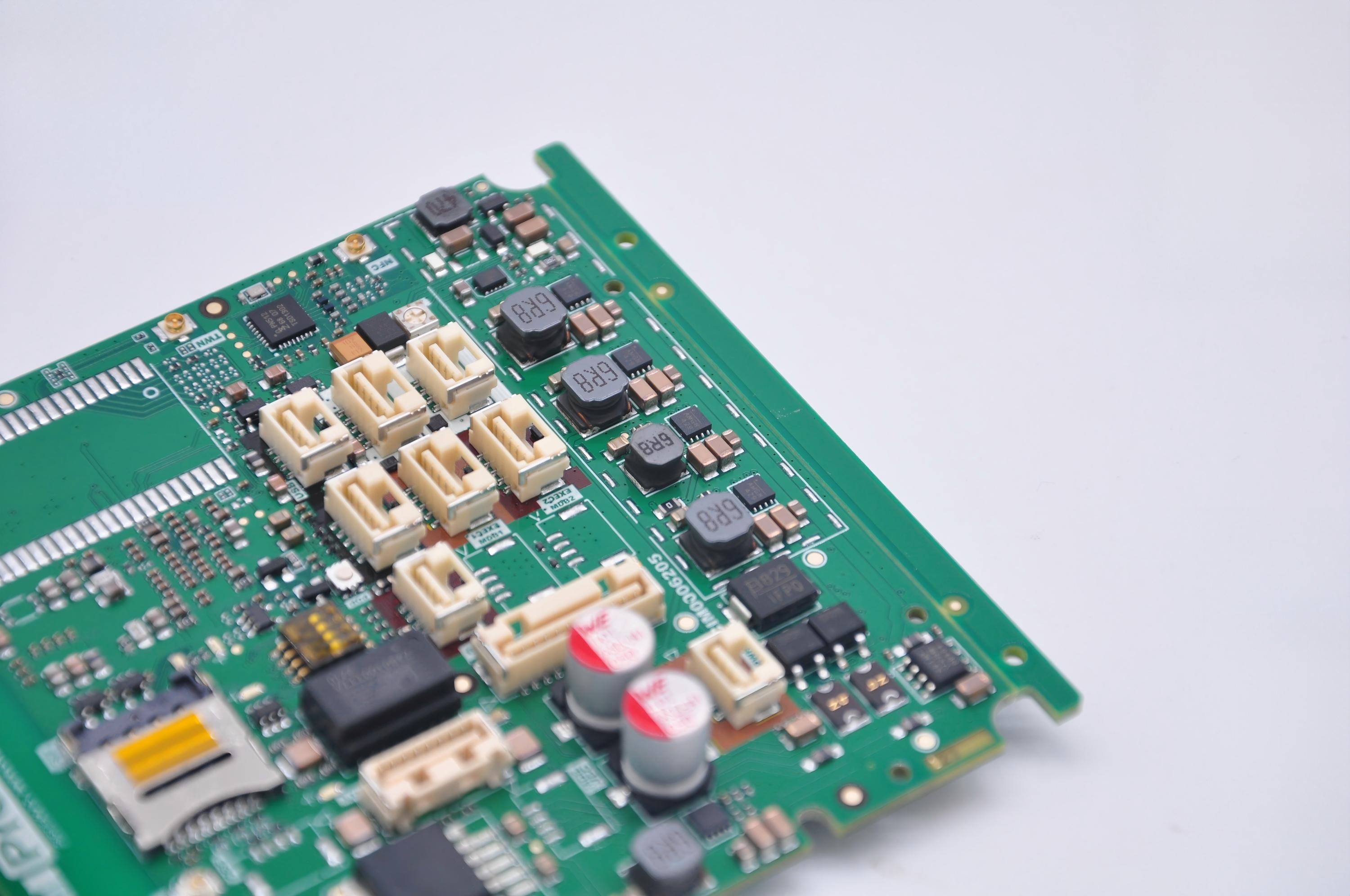

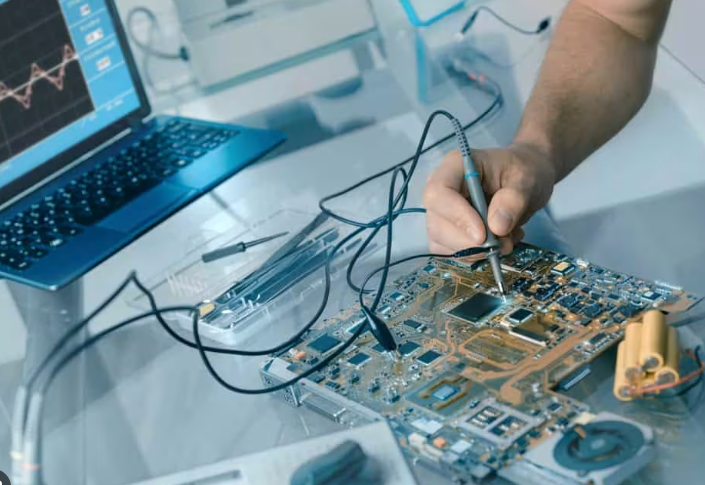

What is a PCB assembly?

PCB assembly, also known as printed circuit board assembly, is the process that mounts components onto the PCB. The PCB only becomes a functional electronic device after assembly.

PCB assembly includes:

- Solder paste printing

- Pick-and-place

- Reflow soldering

- Wave soldering (for through-hole)

- AOI inspection

- X-ray inspection

- Manual touch-up

- Final testing

This process turns the board from a simple platform into a working circuit system.

EBest Circuit (Best Technology) Co., Ltd. offers both PCB fabrication and PCB assembly services, making it a one-stop solution for clients who want faster production and better coordination.

EBest Circuit (Best Technology) offers turnkey PCB assembly with fast delivery, stable quality, and strong engineering support. Our experience makes PCBA smoother and more dependable for customers worldwide.

What Is the Difference Between PCBA and PCB?

PCBA and PCB may look similar, but they represent different stages of production.

- PCB is the bare board. It has copper traces but no components.

- PCBA is the assembled board. It includes resistors, chips, connectors, sensors, and all other parts required to make the circuit operate.

Both are important. Both support the final product. Both must meet quality standards. But only the PCBA performs the actual function of the device.

EBest Circuit (Best Technology) offers both PCB fabrication and full PCBA services. Customers trust the company because one-stop service avoids communication gaps. It creates faster production. It reduces delays. And it keeps the final product consistent.

Conclusion:

PCB is more than a simple board. It is the strength behind modern electronics. From layout to materials, from components to assembly, every step shapes performance. EBest Circuit (Best Technology) Co., Ltd. supports projects with reliable PCB boards and professional printed circuit board assembly.

If you need PCBs, PCBA, or support for your next electronic project, feel free to contact: sales@bestpcbs.com