Indoor gardening has seen a boom in recent years, especially with the rise of efficient grow light systems. Among these, the chip on board LED grow light—often known as COB LED grow light—has gained popularity for its superior performance. But behind every powerful COB grow light lies a well-designed circuit board that manages everything from heat to power distribution.

In this article, we’ll explore how COB LEDs work and how to design a COB LED PCB to reach better performance. Let’s keep reading.

What Is a Chip on Board LED Grow Light?

A chip on board LED grow light is a type of lighting system where multiple LED chips are mounted directly onto a single substrate or circuit board. Instead of using dozens or even hundreds of individual LED diodes (like in traditional SMD LED grow lights), a COB LED light packs high-intensity chips closely together.

The COB LED PCB (Printed Circuit Board) not only holds these chips but also plays a crucial role in:

- Conducting electrical signals efficiently

- Managing heat buildup

- Supporting the light’s physical structure

So while most people focus on the “light,” professionals know that a high-quality COB LED grow light starts with a reliable, well-designed circuit board.

Chip on Board LED Grow Light, COB LED PCB Manufacturer

Advantages of COB LED in Grow Lights

Why are so many manufacturers and indoor growers switching to COB technology? Here are some reasons.

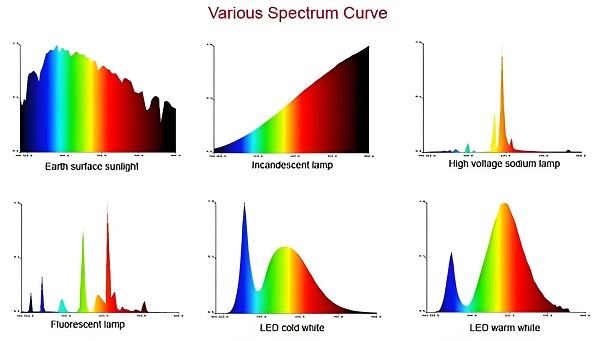

- Full Spectrum Light

A COB LED grow light full spectrum covers all wavelengths needed for healthy plant growth, including red, blue, and white light. So that plants enable to thrive in every stage—from seedling to flowering—without changing the light source.

- High Light Intensity

Because multiple chips are placed together, COB LEDs deliver stronger, more focused light. This can improve canopy penetration and boosts PPFD (Photosynthetic Photon Flux Density), meaning more usable light reaches your plants.

- Energy Efficiency

Compared to older HID or fluorescent lighting, COB LEDs use less electricity and produce less heat for the same or better results.

- Longer Lifespan

Fewer components, better thermal design, and robust build quality allow COB LEDs to last for 50,000 hours or more—if the PCB is properly designed.

- Compact Design

With fewer components, COB grow lights are thinner, lighter, and easier to install—perfect for small grow tents or professional setups.

Factors That Affect COB LED Grow Light Price

The COB LED PCB cost higher than normal LED PCB, do you know why? Here are some factors we summarized for your information:

1. Wattage & Size: More powerful lights require larger boards, thicker copper layers, and more robust cooling solutions.

2. Spectrum Design: Adding UV or IR wavelengths, or fine-tuning the spectrum to specific plant types, often requires specialized LED chips and tailored PCBs.

3. Heat Management: Better thermal control means more expensive materials—like aluminum, copper, or even ceramic substrates—to handle higher heat loads.

4. PCB Material & Build Quality: Cheap PCBs may use thin copper or poor insulation, which can lead to early failures. Investing in a high-performance COB LED PCB ensures long-term reliability.

Why Customizing COB LED PCB Matters?

For most lighting brands, buying standard COB LED modules can feel like a quick solution. But this approach comes with limitations:

- You can’t control LED layout or spectrum design.

- You may struggle with heat management in compact fixtures.

- You depend on another supplier’s quality control, which risks inconsistencies.

- Your products may look and perform like every other generic grow light.

By choosing to customize your COB LED circuit board, you gain:

- Full control over chip placement and power design

- Optimized thermal performance with proper materials and layouts

- Enhanced durability for longer-lasting lights

- A chance to differentiate your product in the market with unique features

In short, the circuit board is where you gain your competitive edge.

COB LED PCB for Grow Lights

Common Challenges in COB LED PCB for Grow Lights

Designing COB LED PCBs for grow lights isn’t just about putting LEDs on a board. There are critical challenges that require engineering expertise:

1. Overheating

High-power LEDs generate significant heat. Without proper thermal vias, heat sinks, and substrate materials, the board can overheat, shortening LED life.

2. Uneven Light Distribution

Poor chip placement can cause hot spots or dark areas in your grow tent, affecting plant growth.

3. Electrical Failures

Low-quality boards might use thin copper layers, poor soldering, or weak insulation—leading to power issues or early burnout.

4. Moisture Damage

Grow rooms are humid environments. Without protective coatings or water-resistant designs, PCBs can corrode or short circuit.

5. Compatibility Issues

Boards not designed for specific drivers or enclosures can cause assembly headaches or require costly redesigns.

How to Design COB LED Circuit Boards for Grow Lights?

When designing COB LED circuit boards for plant grow lights, three critical elements must be optimized: spectrum control, light intensity adjustment, and thermal management. Here are some tips that help you to design a COB LED circuit board:

1. Spectrum Matching

Select high-efficiency LED chips in red (660nm), blue (460nm), and far-red (730nm) wavelengths. Use high-density COB arrays to ensure full coverage of the effective photosynthetically active spectrum (400–780nm).

2. Light Intensity Control

Integrate dimmable circuits with adjustable output from 0–1000 μmol/m²/s. Enable smooth dimming to meet plant needs at all growth stages—from seedling to flowering.

3. Thermal Management

Use ENIG (Electroless Nickel Immersion Gold) surface finish and optimized heat paths. Pair the PCB with a die-cast aluminum housing for efficient heat dissipation. Ensure LED operating temperature stays below 50°C to prevent leaf burn.

4. Pad Design

Apply ENIG or gold plating for all bonding pads. Pad size should exceed chip size by 0.25–0.3mm to prevent misalignment or chip rotation.

EBest Circuit (Best Technology) – Your Partner for COB LED PCB Customization

At EBest Circuit (Best Technology), we specialize in manufacturing high-performance COB LED circuit boards tailored for plant grow light applications. Whether you’re prototyping a new grow light or scaling up production, EBest Circuit (Best Technology) provides reliable, cost-effective, and tailored PCB solutions that help your products thrive in a competitive market.

- Expert assistance before, during, and after your order.

- We welcome prototypes and small-volume runs.

- Reliable quick production and on-time delivery.

- High-quality PCBs with support for special requirements.

- Skilled engineers with deep know-how in COB LED PCB design.

- Over 19 years of expertise in PCB manufacturing.

- Guaranteed reply to inquiries within 12 hours.

- From bare PCB to PCBA and full assembly services.

Our Services for Grow Light Manufacturing

- Prototype Development

- Fast turnaround for small-batch testing

- Custom circuit design tailored layouts for your power, size, and spectrum needs

- Thermal Simulation & Optimization

- Predict and resolve heat issues before production.

- Full Testing including AOI, flying probe, thermal shock, and aging tests

- From small batch to mass production, we scale with your needs

How to Start Your COB LED PCB Project?

To begin your COB LED PCB prototype, please prepare the following:

- Application details (e.g., plant type, grow light usage)

- Power specs (wattage, voltage, current)

- LED chip info (model, quantity, layout) – if available

- Board size and shape (dimensions, drawing or sketch)

- Material preference (aluminum, copper, or ceramic) – optional

- Thermal/environmental needs (max temperature, moisture protection)

- Order quantity (prototype & production volume)

- Target timeline (delivery date for samples)

Once we receive this, we’ll provide design suggestions, quotation, and lead time. Let’s build your custom COB LED PCB—contact us today.

If you’re ready to stand out in the competitive grow light market, start with the right foundation. A custom COB LED circuit board from EBest Circuit (Best Technology) ensures your product is efficient, reliable, and built for success. Contact EBest Circuit (Best Technology) today to customize your COB LED PCB.

FAQs

1. Can you support small batch COB LED PCB orders?

Yes, we welcome both small and large batch orders, perfect for prototyping and niche projects.

2. What materials are best for COB LED Grow Light circuit boards?

We recommend aluminum MCPCB for standard applications and ceramic (AlN) for high-performance needs.

3. How long does PCB prototyping take?

Prototyping typically takes 5–7 working days, depending on complexity.

4. Do you help with thermal design for COB PCBs?

Absolutely. We provide thermal simulation and layout support to ensure your board stays cool.

5. Can I get samples before mass production?

Yes, we offer samples so you can test quality and performance before scaling up.