PCB board vs breadboard: which is better? This blog mainly covers cost and application difference, selection guide for PCB board and breadboard.

Are you troubled with these issues?

- Breadboard contacts are prone to cold solder joints, resulting in poor signal stability. How can reliable circuit performance be ensured?

- High-frequency signals are easily interfered with on breadboards, leading to long debugging cycles. How can verification time be shortened?

- Loose breadboard layouts are difficult to adapt to compact product spaces. How can a seamless transition from prototype to mass production be achieved?

As a professional PCB board manufacturer, EBest Circuit (Best Technology) can provide you service and solutions:

- Precision PCB Prototyping Service: Eliminating the risk of cold solder joints and ensuring stable signal transmission through micron-level circuit etching and pad optimization.

- Electrical Characteristic Verification Support: Providing multilayer board impedance control and ground plane copper pour design to reduce high-frequency signal crosstalk and improve debugging efficiency.

- Mass Production Design Guidance: Intervening from the prototype design stage to optimize layout, routing, and manufacturability (DFM) to ensure a smooth transition from small-batch production to mass production.

Welcome to contact us if you have any inquiry for PCB board: sales@bestpcbs.com.

What Is A Breadboard?

A breadboard is a solderless experimental board used for quickly building and testing circuit prototypes. It typically consists of a plastic board with many small holes, connected internally by metal strips. This allows the pins of electronic components to be inserted into the holes and connected via wires to build the circuit. Its main advantages are that it requires no soldering, is reusable, and makes circuit building and modification very convenient, making it ideal for functional verification and debugging in the early stages of circuit design. However, its contact connections have relatively poor stability, making it unsuitable for high-frequency circuits or long-term use.

What Is A PCB Board?

A PCB, or Printed Circuit Board, is the final circuit carrier of electronic products. It is created by printing wires, lines, and holes onto a substrate using electronic processes. Electronic components are then soldered onto the board to achieve complex and stable circuit functions, used in the mass production of various electronic devices. The advantages of PCBs include high connection reliability, strong anti-interference capabilities, and suitability for large-scale production and long-term stable use. However, their design and manufacturing cycles are relatively long, prototyping costs are high when not in mass production, and modifications are very difficult once completed.

PCB Board vs Breadboard: Which Is Better?

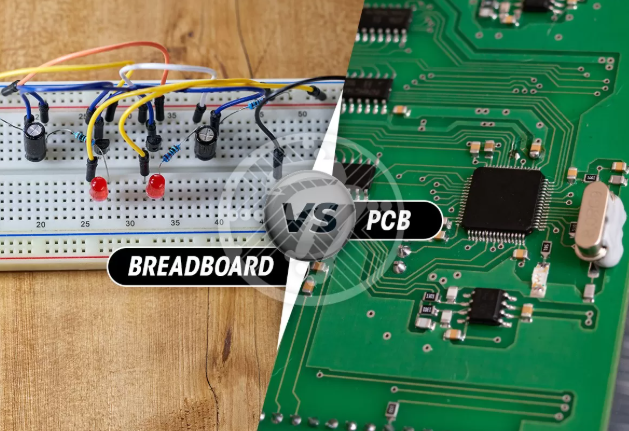

Difference Between PCB Board and Breadboard:

Application Scenario Differences

- Breadboard: ideal for rapid prototyping, educational experiments, early-stage research, and creative electronics projects (e.g., Arduino/STM32 development, sensor testing, basic circuit experiments). Its plug-and-play nature eliminates soldering, supports component reuse, and suits temporary or small-scale projects, especially for beginners and educational settings.

- PCB board: excels in mass production, complex circuits, high-frequency circuits, and high-reliability scenarios (e.g., medical devices, industrial control, automotive electronics, aerospace, IoT devices). Soldering provides stable electrical connections, enables high-density integration, and meets long-term stability demands.

Cost and Benefit Analysis

- Breadboard: has a low initial cost (single board costs tens of dollars), suitable for low-budget or short-term projects. However, frequent plugging/unplugging may cause poor contact, increasing long-term maintenance costs, and is unsuitable for high-frequency/complex circuits.

- PCB board: has a higher initial cost (design, fabrication, and processing fees) but unit costs drop significantly with mass production. Its high reliability and low failure rate reduce overall costs in the long run, especially for mass production and precision equipment.

Design and Flexibility Comparison

- Breadboard: offers design flexibility, allowing instant component replacement and supporting rapid iteration. However, messy wiring, low integration density, and difficulty in high-density/high-frequency circuit design are drawbacks.

- PCB board: requires professional software (e.g., Altium, Eagle) for design, supports precise layout and high-density integration, and suits complex circuits and customization. Once fabricated, circuits are fixed, requiring re-fabrication for modifications, but enables anti-interference and high-precision designs.

Reliability and Stability

- Breadboard: Physical contact connections are susceptible to mechanical stress, leading to poor contact or signal interference, especially in high-frequency or precision circuits.

- PCB Board: Solder joints provide stable electrical connections, strong anti-interference capabilities, and meet industrial-grade reliability standards (such as ISO certification), making it suitable for high-precision, high-reliability applications (such as medical equipment and aerospace).

Maintenance and Scalability

- Breadboard: allows easy maintenance with replaceable components but frequent plugging may accelerate aging. Scalability is limited; large-scale circuits require multiple boards connected with wires, leading to messy wiring.

- PCB board: requires professional tools for maintenance but has low failure rates. It supports modular design and batch soldering, offers strong scalability, and enables functional upgrades via layer addition or layout optimization, suitable for long-term use and mass production

Environmental Protection and Compliance

- Breadboard: materials are recyclable, but frequent replacements may generate waste.

- PCB board: uses lead-free soldering and eco-friendly materials (e.g., FR-4), complying with international environmental standards (e.g., RoHS), suitable for exports to regions with strict environmental requirements (e.g., Europe, US).

Breadboard vs PCB Board: How to Choose?

Selection Guide for Breadboard and PCB Board:

1. Clarify Core Project Goals & Development Stage

- Rapid concept validation/prototype design: For scenarios requiring quick circuit assembly, logic testing, or parameter adjustment (e.g., educational experiments, maker projects, early prototype validation), opt for Breadboard. Its solderless, reusable plug-in design supports “trial-error-iteration” workflows, ideal for short-term, low-cost exploration.

- Productization/mass production: For projects entering stable phases requiring bulk manufacturing or strict reliability (e.g., consumer electronics, industrial equipment, medical hardware), PCB is mandatory. Its fixed layout, robust soldering, and protective coatings (e.g., solder mask, gold plating) ensure long-term stability and manufacturability.

2. Evaluate Circuit Complexity & Performance Requirements

- Low-complexity/low-frequency circuitsĀ (e.g., LED arrays, simple sensors, basic logic circuits): Breadboard suffices due to fewer contact points, lower costs, and minimal parasitic parameter impact on low-frequency signals.

- High-complexity/high-frequency/precision circuitsĀ (e.g., RF modules, high-speed digital circuits, precision analog circuits): PCB is essential. High-frequency signals are sensitive to parasitic capacitance/inductance; PCB enables signal integrity optimization via multi-layer routing, ground plane design, differential pairing, and noise/crosstalk/attenuation mitigation.

3. Balance Cost & Time Efficiency

- Short-term cost sensitivity: Breadboard has low initial investment (5ā50), suitable for budget-constrained or short-cycle projects (e.g., temporary demos, student projects). However, long-term use may incur hidden maintenance costs due to contact oxidation/loosening.

- Long-term cost optimization: PCB design/fabrication fees are higher upfront, but per-unit costs drop significantly in bulk (e.g., <$5/unit at 1,000+ pieces). Supports SMT automation, ideal for stable long-term demand or scaled production.

4. Consider Mechanical Environment & Reliability Needs

- Vibration/harsh environmentsĀ (e.g., automotive electronics, outdoor devices, aerospace): PCBās robust soldering, vibration resistance, and thermal stability make it suitable; breadboard contacts risk intermittent faults from vibration-induced loosening.

- Static/lab environments: Breadboard performs well in stable settings for desktop testing, short-term experiments, or low-reliability use cases.

5. Assess Extensibility & Maintainability Requirements

- Frequent modifications/modular design: Breadboard supports plug-in component adjustments, ideal for algorithm validation or multi-version testing. However, prolonged use may cause contact wear and faults.

- Fixed design/mass production: PCB designs are static; modifications require costly re-fabrication. However, integrated test points and identifiers streamline batch production quality control and troubleshooting, suitable for standardized product development.

6. Align with Technical Maturity & Team Expertise

- Beginners/non-professional teams: Breadboard lowers entry barriers, requiring no soldering skills, ideal for hobbyists, students, or small teams.

- Professional engineers/enterprise R&D: PCB design demands professional tools (e.g., Eagle, Altium Designer) and fabrication processes, suitable for experienced teams or projects requiring high precision/reliability.

7. Assess Extensibility & Maintainability Requirements

- Prioritize Breadboard: When projects are in early exploration, require rapid concept validation, have limited budgets, or low reliability demands.

- Prioritize PCB: When projects demand productization, mass production, strict signal quality/anti-interference requirements, or involve high-frequency/precision circuits.

- Transition Strategy: Validate logic/functionality on Breadboard first, then transition to PCB once design stabilizesāthis balances development efficiency with product quality, a common practice among global engineers, makers, and R&D teams.

When to Use Breadboard Instead of PCB Board?

- Rapid Prototyping and Proof-of-Concept: Breadboards are the preferred choice when you need to quickly build electronic circuit prototypes to validate your design ideas. They require no soldering, support rapid plug-and-play and circuit modifications, making them suitable for rapid design iteration in the early stages of development. For example, makers and startups abroad often use breadboards to quickly test the compatibility of components such as sensors and microcontrollers, saving time and costs associated with PCB design and production (which typically takes days to weeks).

- Education and Learning Scenarios: For students, educational institutions, and DIY enthusiasts, breadboards are used as teaching tools due to their intuitive and easy-to-use features. For example, in electronics courses in primary and secondary schools abroad, students can intuitively understand circuit connection principles (such as series/parallel connections) using breadboards without needing to learn complex PCB design software or soldering processes, lowering the learning threshold.

- Temporary Testing and Troubleshooting: In the later stages of product development or in repair scenarios, breadboards can quickly build test circuits to locate problems. For example, when engineers need to verify the functionality of a module, they can temporarily build test circuits using breadboards, avoiding the high costs of repeatedly modifying PCB designs (the cost of a single PCB fabrication can reach hundreds of dollars).

- Low-complexity, short-term use projects: For one-off, short-term projects (such as exhibition demonstrations and temporary exhibits), breadboards are more advantageous due to their low cost and reusability. International clients often choose breadboards to build simple demonstration circuits, avoiding the high costs of PCB fabrication for short-term needs.

- Design flexibility requirements: When designs require frequent adjustments or exploration of multiple solutions, the modular nature of breadboards allows users to disassemble and reassemble circuits at any time. For example, international R&D teams may use breadboards in the early stages of development to quickly try different combinations of resistors and capacitors to optimize circuit performance without having to create multiple PCB prototypes.

How Does Cost Difference between PCB Board and Breadboard?

- Breadboard: $0.50ā$8.00+. Basic models (400-830 holes) typically range from $2.00 to $5.00. Larger quality models or those with accessories (power rails, bases) can reach $8.00+.

- PCB (Single/Small Batch Prototype): $2.00ā$50.00+. Costs are greatly affected by size, number of layers, complexity, materials, processes, and lead time. The sample price (e.g., 5 pieces) of the most basic double-layer board (~10cm x 10cm, FR-4, standard parameters) spreads to approximately $5.00ā$15.00 per piece. More complex boards (multi-layer, high-density, special materials/processes) or rush orders easily exceed $20.00ā$50.00+ per piece.

How to Choose A Reliable Breadboard Manufacturer?

1. Hard Qualification Verification

- International Certifications & Standards: Prioritize manufacturers with ISO 9001:2015 (Quality Management), ISO 14001 (Environmental Management), UL/CE (Safety Certifications) to comply with target markets like EU/US regulations. Verify certificate authenticity and validity via official certification agency websites.

- Raw Material Traceability & Quality Control: Request supplier lists for raw materials (e.g., ABS plastic, copper foil) and confirm compliance with RoHS/REACH. Inspect quality control points (e.g., soldering temperature, board flatness) through on-site audits or third-party testing.

2. Production Capacity Assessment

- Capacity & Customization: Evaluate monthly output (e.g., 10,000+ pieces/month) and confirm support for small-batch trials (e.g., <500 pieces) and rapid prototyping (3-5 days). Check customization options (dimensions, colors, logo printing) and mold development capabilities.

- Technology & R&D: Review R&D investment ratios and patent portfolios (e.g., conductive materials, anti-oxidation coatings). Prefer collaborations with universities/research institutions for technical leadership.

3. Client Case & Reputation Verification

- Industry Case Studies: Request overseas client cases from the past 3 years (e.g., EU electronics firms, educational institutions), focusing on product/order scale alignment and regional market match.

- Third-Party Reviews: Source feedback from trade fairs, B2B platforms (Alibaba), or review sites (Trustpilot) for metrics like on-time delivery and after-sales response. Avoid relying solely on curated testimonials.

4. Communication & Service Quality

- Cross-Cultural Communication: Confirm multilingual (English/Spanish) sales teams and 24/7 support. Test response times (<12 hours) and issue resolution (e.g., sample defect handling).

- After-Sales System: Clarify warranty periods (1-3 years), return policies, and tech support methods (video tutorials, remote assistance). Overseas clients prioritize local services (e.g., EU warehouses, regional repair centers).

5. Logistics & Supply Chain Transparency

- Export Experience & Logistics Network: Select manufacturers with 5+ years of export experience and familiarity with trade terms (FOB/CIF). Evaluate logistics partners (DHL/FedEx) and storage networks (EU overseas warehouses) for controlled lead times (3-7 days air, 30-45 days sea).

- Supply Chain Visibility: Demand traceability data (material batches, production dates) and third-party logistics tracking (bill of lading numbers, shipment tracking).

Welcome to contact us if you have any request for breadboard or PCB board: sales@bestpcbs.com.