The price of aluminum substrate for drones depends on the specifications of the aluminum material, the thermal insulation layer process, the thickness of the copper foil and the order size. The thicker the material, the more complicated the process and the smaller the quantity, the higher the unit price.

Do you need a custom aluminum PCB for a drone? Perhaps you’re wondering:

- What key factors influence the pricing of drone aluminum PCBs?

- How does the price of drone aluminum PCBs compare to regular PCBs?

- How does customization affect the price of drone aluminum PCBs?

- How does order volume affect the price of drone aluminum PCBs?

BEST Technology, a professional aluminum PCB manufacturer with over 19 years of experience, can answer your questions:

- Prices primarily depend on material quality (aluminum purity, insulation performance), dimensions (standard/custom, large/small), circuit design complexity (number of layers, circuit density), process requirements (surface treatment, special processes), and order size (batch size).

- Prices are higher than those of standard FR-4 fiberglass PCBs due to the higher cost of aluminum and heat dissipation processes; however, they are lower than copper PCBs, offering a more cost-effective balance between thermal conductivity requirements and cost.

- Special dimensions, complex circuit designs (such as multiple layers, high-precision vias), or specialized processes (immersion gold, thick copper) increase production difficulty and cost, leading to higher prices.

- The larger the batch size, the more fully the fixed costs are distributed, and the more advantageous the price is; small batches or sample orders are more expensive because the costs are difficult to spread.

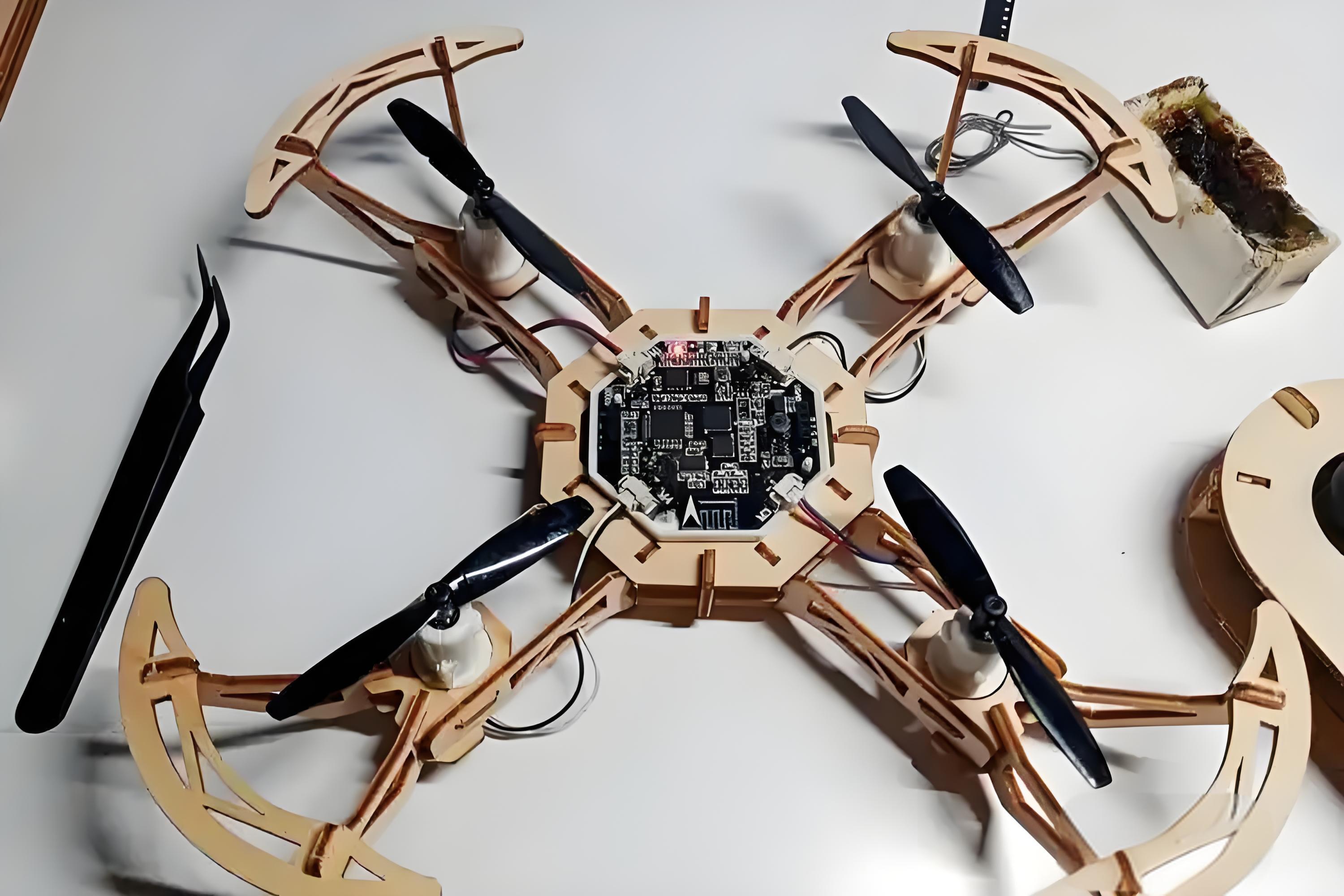

Why are aluminum substrates used in UAVs?

Aluminum substrates are used in drones primarily for their lightweight, heat dissipation, and mechanical strength advantages, while also offering cost-effectiveness.

- Lightweight Design

Aluminum substrates have a density of only one-third that of traditional PCBs (0.6g/cm³). The weight of the same area (10cm×10cm) is reduced from 28.8g to 9.6g, a 66% weight reduction. In drone design, every kilogram of weight reduction can reduce launch costs by tens of thousands of dollars and improve fuel efficiency.

- Heat Dissipation Performance

The thermal conductivity of aluminum substrates reaches 20-50W/m·K, over 10 times that of FR-4 (0.2-0.3W/m·K). When the drone’s motor driver board is operating at full load, the aluminum substrate can keep the surface temperature difference within 5°C, preventing performance degradation caused by local overheating and extending component life.

- Mechanical Strength

Aluminum substrates utilize 6061 aluminum alloy (tensile strength 310 MPa), which is 80% lighter than steel substrates but strong enough to withstand the 30G overload experienced during spacecraft launches.

- Cost and Environmental Protection

Aluminum substrate processing costs are lower than steel substrates and are RoHS compliant. Their recyclability (recycling consumes only 5% of the energy consumed in primary aluminum production) supports sustainable development.

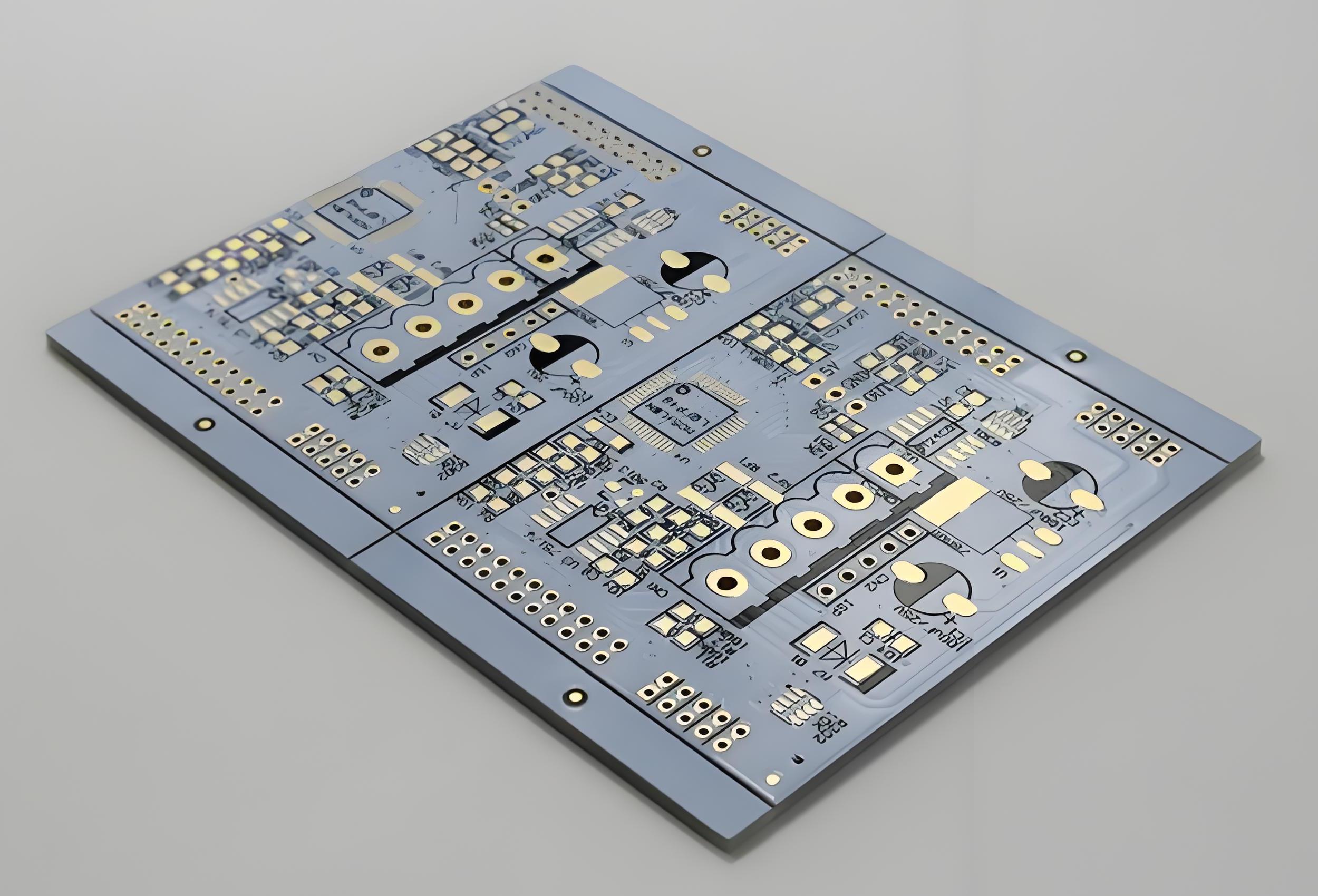

What factors affect aluminum substrate cost?

The cost of aluminum substrates is primarily influenced by the following factors:

Raw Material Cost

- Aluminum Ingot Price: This constitutes the majority of the aluminum substrate cost and is subject to fluctuations in international market prices.

- Other Auxiliary Materials: These include alumina, carbon anodes, and fluoride salts, whose price fluctuations directly impact production costs.

Processing and Labor Costs

- Production Process: Complex processes (such as multi-layer design and precision machining) increase costs.

- Labor and Depreciation: Labor costs per ton of aluminum are approximately 500-800 yuan, with equipment depreciation accounting for 8%-12%.

Market and Economic Factors

- Demand Fluctuations: Changes in demand in industries like construction and electronics directly impact prices.

- International Trade: Tariff adjustments and exchange rate fluctuations may affect the cost of imported raw materials.

How are aluminum substrates chosen for drones?

When selecting an aluminum PCB for drones, factors such as heat dissipation, structural strength, weight, and process costs must be comprehensively considered.

Heat Dissipation Performance

The thermal conductivity of aluminum PCBs can be over 10 times that of FR-4, enabling rapid heat transfer from high-power components like motor driver boards, reducing surface temperature differences to within 5°C and preventing localized overheating.

Structural Strength and Weight

- Thickness: Drones typically use 1.2-1.6mm thick PCBs, balancing structural strength and weight.

- Density: Aluminum PCBs have a density only one-third that of traditional FR-4 (0.6g/cm³ vs. 1.8g/cm³), resulting in a 66% weight reduction for the same surface area.

- Vibration Resistance: 100 hours of continuous vibration at 10-2000Hz and 20G acceleration without deformation of the aluminum core, and a solder joint loss rate of <0.1%.

Process and Cost

- Exposure Process: Suitable for high-precision requirements of line width/line spacing ≤ 0.1/0.1mm, with neat and smooth pad edges, suitable for high-end drone circuits.

- Mixed Dielectric Solution: Optimizing the stackup design can reduce costs by 10%-20%, for example, by using high-TG FR4 material to reduce weight while maintaining mechanical strength.

Electromagnetic Shielding and Reliability

- Aluminum substrates can replace ceramic substrates, reducing the number of components such as heat sinks, and improving product heat resistance and physical properties.

- Oxidation Resistance Test: No discoloration after 10-15 minutes of sweat dripping, indicating good oxidation resistance.

Why are aluminum drones better than other UAV materials?

Aluminum drones are superior to other materials due to their combination of lightweight, high strength, and cost-effectiveness:

- Lightweight Advantages

Aluminum’s density is only one-third that of steel, making it lighter for the same volume, significantly reducing the overall weight of a drone. Using aluminum alloy for a drone’s fuselage frame increases its flight range by approximately 30%.

- Strength and Stiffness

Aluminum alloys (such as 6061 alloy) have a tensile strength of 310 MPa and can withstand 30G overload shocks, meeting the structural requirements of drones operating at high speeds and in complex environments. Carbon fiber composites have a specific strength five times that of aluminum alloys, but are more expensive and are primarily used in high-end drones.

- Processing and Maintenance

Aluminum alloy processing techniques are mature (extrusion, forging, etc.), making them suitable for mass production and recyclable, aligning with environmental trends. In contrast, carbon fiber composites have higher maintenance costs and require specialized equipment.

- Heat Dissipation and Electrical Conductivity

Aluminum substrates have a thermal conductivity of 20-50 W/m·K. In drone motor driver boards, this can reduce chip temperature by 15°C and extend life by three times. Aluminum also has excellent electrical conductivity, making it suitable for components such as motor stators.

- Cost and Applicability

Aluminum alloys cost only one-third to one-half of carbon fiber, making them suitable for large-scale civilian drone production. Carbon fiber composites, while offering superior performance, are expensive and are primarily used in military or high-end consumer products.

How are aluminum substrate costs reduced?

- Optimize material selection: While meeting performance requirements, rationally select aluminum purity and insulation layer materials. For example, for non-critical heat dissipation scenarios, choose aluminum with an appropriate purity to avoid the cost increase of excessively high purity. Prioritize mature, mass-produced insulation materials to reduce the premium of custom materials.

- Simplify design and standardize dimensions: Reduce circuit design complexity, such as optimizing circuit density and eliminating unnecessary layers or high-precision vias, to ease production difficulties. Use standard dimensions to reduce losses and customization costs associated with special cutting, thereby improving production efficiency.

- Scaled procurement and production: Increase order batches and reduce per-ton procurement costs through large-scale raw material procurement. Mass production can spread fixed costs such as equipment commissioning and mold development.

- Optimize process solutions: While performance requirements are met, select the most cost-effective process. For example, in common scenarios, use tin spraying instead of immersion gold.

What are the benefits of aluminum drones?

The benefits go beyond cost savings or raw performance numbers. Aluminum drones feel more responsive in flight and hold up better in demanding environments.

- Better flight stability: Stronger structures reduce vibration and keep sensors accurate.

- Higher payload capacity: Strong yet light materials allow carrying more equipment.

- Improved safety: Less chance of component failure due to overheating.

- Consistent quality: Aluminum substrates maintain performance over repeated flights.

Aluminum drones, with their core advantages of strength, heat dissipation, load-bearing capacity, and environmental resistance, demonstrate reliable practicality in scenarios such as industrial operations, outdoor adventures, and long-duration missions.

How does aluminum thickness impact UAVs?

Thickness plays a critical role in both performance and cost. Too thin, and the board may flex or overheat. Too thick, and you add unnecessary weight, reducing flight time.

Thin substrates are ideal for racing drones or small UAVs that need every gram saved. They still offer adequate heat dissipation for lighter electronics.

Thicker substrates excel in industrial drones, agricultural UAVs, or long-endurance drones. They handle higher currents, stronger vibration, and heavier payloads without losing shape.

What are the best deals on drone aluminum substrates?

Price alone doesn’t guarantee value. The ideal supplier offers bulk discounts, free samples, fast lead times, and clear technical documentation.

Look for suppliers who:

- Offer bulk discounts for larger orders.

- Provide free samples so you can test before committing.

- Have short lead times to avoid production delays.

- Share technical data sheets for full transparency.

This is exactly where EBest Circuit (Best Technology) stands out. With over 19 years in PCB and substrate manufacturing, we provide high-grade aluminum substrates tailored for UAVs, competitive bulk pricing, and a commitment to 7-day delivery for most orders. Every order comes with full technical data sheets and ROHS/REACH compliance, plus expert guidance to help you choose the perfect thickness, material grade, and finish.

If you have any needs for Drone aluminum substrate, please contact us: sales@bestpcbs.com