After we have talked about PCB inspection in last article, so today we move to the solder paste printing inspection. If you would like to learn something about PCB inspection, please click The Application of AOI in PCB Inspection.

Solder paste printing, the very beginning of SMT, is the root of most defects on the PCB. The defects occur in printing process is up to 60%-70%. Thus, if the defects can be avoided in this link, then the damage is able to save cost minimized. Therefore, most of printed circuit board manufacturers have already equipped with AOI testing in SMT production lines.

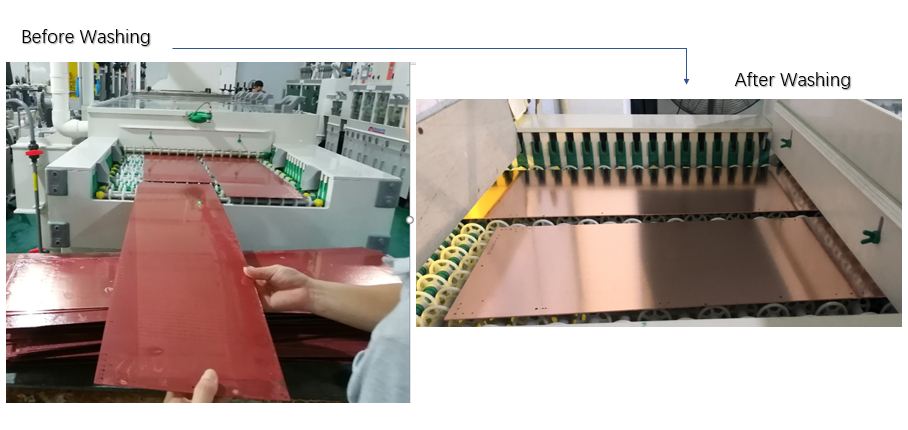

There are various of printing defects, but they can be generally divided into insufficient or excessive solder paste, the solder paste in the middle part of large pads scraped etc.. The reason why these defects are formed including unreasonable setting of printing machine parameter, low accuracy, improper selection for scraper and so on. However, it is effective to monitor the solder paste printing by AOI technology and analyze the number as well as types of defects, so that enhance the capability of printing.

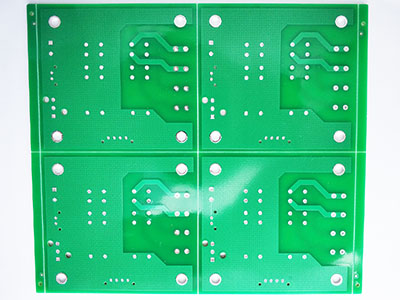

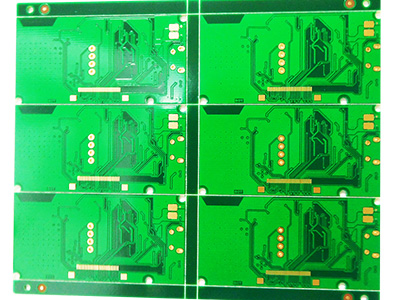

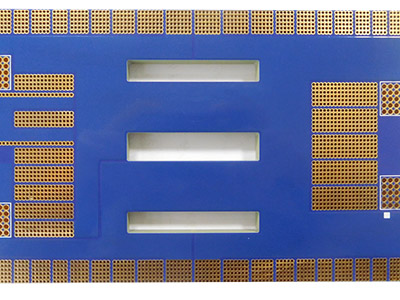

Best Technology is the premier expert in manufacture of PCB and PCBA. Our unique AOI testing technology and high quality products give you a competitive supply of printed circuit board and rigid-flex circuit board. To learn more, contact us at 0755-29091601 or check our website: https://www.bestpcbs.com/

Tags: AOI, AOI testing, solder paste printing, solder paste printing inspection