For high-power products, the concept of “heat” is often mentioned, which is especially important in high-power products. It not only determines the service life of the product, but also relates to whether the product can work properly.

We will explain the “heat” problem in circuit board design from three aspects: the generation of heat, the impact of heat on the product and the “heat” in the system layout.

1. Heat generation:

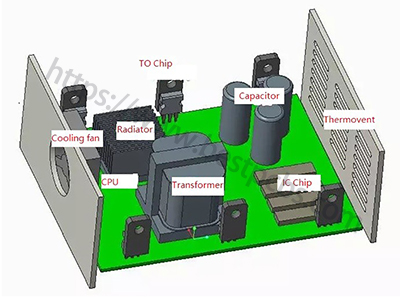

Heat generation in a system takes several paths:

1) Power consumption of the component itself

2) Efficiency of power conversion devices

3) High frequency signal conversion heating

4) Power consumption of contact resistance and wire resistance during signal transmission

2. Impact of fever on products

The operating temperature of components is generally below 80 degree, and the operating temperature of commonly used capacitors and resistors is generally controlled below 50 degree. If the temperature of the system is not controlled, the following conditions may occur:

1) The temperature rise will cause the working parameters of components to change, resulting in the unstable working performance of the whole system.

2) Temperature rise will accelerate the aging of components, affecting the accuracy and life of components.

3) Temperature rise will cause circuit board deformation and poor connection of components.

3. “Hot” considerations in system layout

1) Selection and layout of the chassis: choose materials with good thermal conductivity, such as aluminum alloy

2) Black heat absorbing material is coated inside the shell to enhance the function of radiation heat absorption

3) The shell is closely combined with the components with high calorific value to conduct heat dissipation

4) A large number of heating components should be placed at the edge of the plate to shorten the heat transfer path. Heat-resistant components should be kept away from light sources.

5) In the design process, the appropriate wire width and copper thickness should be selected, and the influence of wiring density on the current-carrying capacity should also be considered. Copper foil should be filled in the gap of the board surface as far as possible for heat conduction. The heat conduction hole can help effectively heat dissipation and reduce local temperature.

In the design of circuit board, how to effectively control the temperature of the system is a problem that must be considered.