Looking for PCB manufacturer in Oman? This blog covers list and selection guide, evaluation methods of production capacity and lead time for PCB manufacturer in Oman.

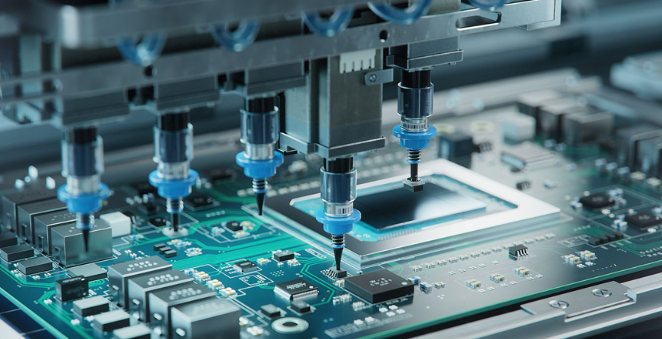

When it comes to sourcing high-quality printed circuit boards (PCBs) for your electronic projects, partnering with a reputable PCB manufacturer in Oman can be the game-changer your business needs. A professional PCB manufacturer in Oman not only ensures compliance with global quality standards but also offers localized support that minimizes supply chain disruptions. This guide delves into the key advantages of working with an Oman-based PCB factory, addresses common industry pain points, and provides all the essential information to help you make an informed decision for your PCB sourcing needs.

Challenge of PCB Manufacturing in Oman

- Is it difficult to find a manufacturer that can deliver high-quality PCB prototypes within a short timeframe in Oman?

- Do you struggle with inconsistent product quality when cooperating with local PCB manufacturers in Oman?

- Are you facing challenges in getting custom PCB solutions that match your specific project requirements in Oman?

- Is the high minimum order quantity (MOQ) of most PCB manufacturers in Oman making it hard to carry out small-batch production?

- Do you worry about delayed deliveries from PCB manufacturers in Oman affecting your project progress?

Our Solutions to These Challenges

- 24-hour rapid prototyping service: We have a dedicated rapid sampling production line that ensures your PCB prototypes are completed and delivered within 24 hours, solving the problem of long waiting times for samples.‚Äč

- Multi-layer quality control system: We implement 8 strict quality inspection procedures from raw material incoming to finished product delivery, with a pass rate of 99.8%, ensuring consistent and reliable product quality.‚Äč

- Customized one-stop solutions: Our professional technical team conducts in-depth communication with you to understand your project needs, providing personalized PCB design, manufacturing and assembly services that fully match your requirements.‚Äč

- Low MOQ support: We offer a minimum order quantity of 1 piece, allowing you to carry out small-batch production without pressure, reducing your initial investment and trial costs.‚Äč

- Efficient supply chain and production management: With 19 years of industry experience, we have established a stable supply chain and optimized production processes, ensuring on-time delivery rate of 99.2% even for large-batch orders.

Why Choose EBest Circuit (Best Technology) for Your PCB Manufacturer?

Reasons Why Choose EBest Circuit (Best Technology) for Your PCB Manufacturer:

- Superior quality assurance: We adopt high-grade raw materials from well-known brands and implement a full-process quality control system, ensuring each PCB meets international quality standards.

- Strict quality control procedures: 8 layers of quality inspection, including AOI automatic optical inspection, X-Ray non-destructive testing, and functional testing, to eliminate defective products to the greatest extent.

- Competitive pricing: Benefiting from mature supply chain integration and large-scale production, we provide cost-effective pricing while ensuring quality, helping you reduce production costs.

- Fast delivery speed: Standard orders are delivered within 3-7 days, and emergency orders support 24-hour rapid prototyping, ensuring your project progresses as scheduled.

- Comprehensive certifications: We hold multiple international certifications including ISO9001:2015, ISO13485:2016, REACH, RoHS, and IATF16949, which are recognized in global markets.

- Low MOQ advantage: 1 piece MOQ, supporting small-batch trial production and personalized customization, suitable for projects in different stages.

- 19 years of industry experience: We have rich experience in manufacturing various types of PCBs, serving thousands of customers and accumulating a wealth of practical solutions for complex projects.

- Diversified product range: We produce rigid PCBs, flexible PCBs, rigid-flex PCBs, metal-based PCBs, ceramic PCBs, RF PCBs, HDI PCBs, thick copper PCBs, etc., meeting diverse application needs.

Top 10 PCB Manufacturers in Oman

| Company Name | Main Business | Core Advantages | Process Capability | Delivery Time |

| Oman Cables Industry SAOG | Instrumentation cables, PCB-related electrical components, medium/low voltage cables | Muscat-based manufacturing base, extensive MENA distribution network | Standard PCB component processing, stable process control | 7-14 days |

| Al Hassan Engineering Co. SAOG | Electronics manufacturing, PCB assembly, power conversion equipment | 300+ technical staff, nationwide channel network | Multi-layer PCB assembly, standard manufacturing processes | 5-10 days |

| National Electrical Industries | PCB manufacturing, electrical component production/assembly | Stable quality, localized after-sales service | Standard line width/spacing 80őľm, max 16-layer boards | 7-15 days |

| Majan Switchgear | Industrial control PCBs, electronic control boards, electrical equipment | Industrial-grade vibration/high-temperature resistance processes | Industrial-grade PCB manufacturing | 8-14 days |

| IEI Oman | Custom PCB design/manufacturing, electronic system integration | Strong design capability, personalized solution customization | Small-batch high-precision PCB manufacturing | Prototyping 5-10 days / Mass production 10-20 days |

| Al Hassan Electricals | PCB production, electrical wiring, small electronics assembly | Rapid response, small-batch order support | Single/double-sided PCB manufacturing | 6-13 days |

| Stars Light | Lighting-related PCBs, electronic driver boards | Energy-efficient PCB design, ISO certification | Low-power PCB manufacturing | 7-15 days |

Quality Certification of PCB Manufacturer in Oman

- ISO9001:2015 Quality Management System Certification: The most basic and widely recognized certification in the PCB manufacturing industry, ensuring that manufacturers have standardized quality management processes.‚Äč

- ISO13485:2016 Medical Device Quality Management System Certification: Required for PCB manufacturers serving the medical device industry, ensuring products meet medical-grade quality and safety requirements.‚Äč

- REACH Certification: Ensures that PCB products do not contain excessive restricted substances, meeting the environmental protection requirements of the European market.‚Äč

- RoHS Certification: Restricts the use of six hazardous substances in electronic and electrical products, a necessary certification for PCB products to enter the global market.‚Äč

- IATF16949 Certification: Special quality management system certification for the automotive industry, required for PCB manufacturers supplying automotive electronic components.‚Äč

- IPC-A-610 Electronic Assembly Acceptability Standard Certification: Ensures that PCB assembly processes and product quality meet international industry standards.

How to Evaluate the Production Capacity of PCB Manufacturer in Oman?

Evaluation Guide to Production Capacity of PCB Manufacturer in Oman:

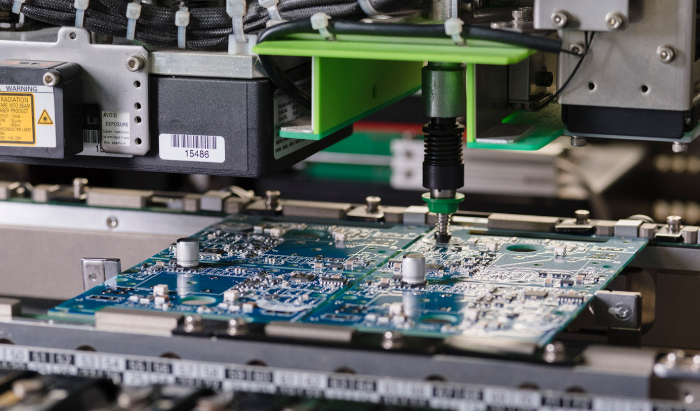

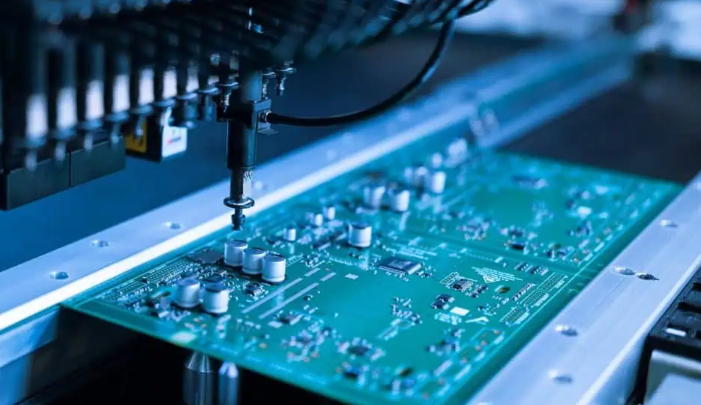

- Check the advanced level of production equipment: Prioritize manufacturers equipped with high-precision CNC drilling machines (with drilling accuracy up to ¬Ī0.01mm), 100% AOI (Automatic Optical Inspection) coverage for PCB layers, and laser drilling machines capable of handling hole diameters as small as 0.1mm‚ÄĒthese parameters directly reflect processing precision.‚Äč

- Understand the maximum production capacity: Inquiry about monthly output (e.g., whether it can reach 50,000+ square meters of PCBs) and the capability to undertake large-batch orders (such as single orders exceeding 10,000 units), which ensures they can meet your long-term production needs.‚Äč

- Evaluate the process capability: Key indicators include minimum line width/line spacing (target manufacturers that can achieve 40őľm/40őľm or better), maximum number of layers for multi-layer PCBs (32 layers or more is ideal for complex projects), and whether they can handle special processes like blind/buried vias (with via diameter ‚ȧ0.2mm) and rigid-flex combination (with flex layer thickness ‚ȧ0.1mm).‚Äč

- Investigate the raw material supply chain stability: Confirm if they have 3+ fixed cooperative suppliers for core raw materials (e.g., copper clad laminates) and a 48-hour response mechanism for raw material shortages‚ÄĒthis avoids production delays caused by material outages.‚Äč

- Check the number of production lines and automation degree: Manufacturers with 5+ production lines and 80%+ automation rate (e.g., automatic soldering and cutting equipment) can ensure stable production efficiency (daily output ‚Č•1,000 PCBs) and consistent product quality (error rate ‚ȧ0.5%).‚Äč

- Understand the experience in undertaking complex projects: Ask for case studies, such as whether they have supplied PCBs for high-end fields like medical (ISO13485 certified), automotive (IATF16949 certified), or aerospace, having served 20+ customers in these fields indicates strong technical capability.‚Äč

- Evaluate the quality control system: Reliable manufacturers have 8+ quality inspection links (from raw material incoming to finished product delivery), a finished product pass rate of 99.5% or higher, and a full-process quality traceability system (tracking each PCB‚Äôs production batch and inspection records for 3 years).‚Äč

- Check the technical team strength: A professional team should have 15+ full-time technical personnel (including PCB designers and process engineers) and provide 24-hour technical consultation and solution support‚ÄĒthis ensures timely resolution of problems during cooperation.

How to Evaluate the Delivery Time of German PCB Manufacturer in Oman?

Evaluation Guide to Delivery of PCB Manufacturer in Oman:

- Confirm the standard delivery cycle for different types of PCB products: For prototypes, the industry benchmark delivery time is 3-5 days; for small-batch orders (100-500 units), it should be within 7-10 days; for large-batch orders (1000+ units), a reasonable cycle is 10-20 days. Compare the manufacturer‚Äôs quoted time with these benchmarks to evaluate its efficiency.‚Äč

- Understand the emergency order processing capability: Inquiry whether they support 24-hour rapid prototyping for single/double-sided PCBs and 48-hour delivery for multi-layer PCBs (the industry‚Äôs fast emergency response standard). Also confirm the maximum order quantity for emergency processing (e.g., up to 50 prototype units) to meet urgent project needs.‚Äč

- Investigate the historical on-time delivery rate: A reliable PCB Manufacturer in Oman should have an on-time delivery rate of 99% or higher. Verify this data through at least 6 months of third-party order records or customer reviews covering over 100 orders to ensure authenticity.‚Äč

- Check the production schedule management system: Ensure the system can realize real-time production progress tracking and has a scheduling error rate of less than 1%. It should also automatically send reminders when the production deviates from the plan by more than 24 hours, avoiding delays caused by schedule confusion.‚Äč

- Understand the supply chain management level: Confirm that core raw materials (such as copper clad laminates) have a safety stock of at least 15 days of production demand. The manufacturer should also have a 24-hour response mechanism for supply chain risks to ensure delivery stability even when raw material supply is tight.‚Äč

- Confirm the logistics cooperation system: Prioritize manufacturers with 3+ fixed cooperative logistics partners in Oman. Their customs clearance efficiency should be within 2-3 working days for local deliveries, and the transportation damage rate should be controlled below 0.1% to ensure timely and intact delivery.‚Äč

- Evaluate the communication efficiency of the order follow-up team: The team should provide daily progress updates via email or SMS. For potential delivery problems, they need to respond within 2 hours and propose a solution within 8 hours to avoid passive delays.‚Äč

- Check the after-sales guarantee for delivery delays: Clear compensation clauses should be available, such as a 5% order value reduction for each day of delay (capped at 30% of the total order value). For delays exceeding 7 days, the manufacturer should offer free expedited re-production and priority delivery.

FAQs of PCB Manufacturing in Oman

Q1: Are PCB prices in Oman higher than overseas suppliers?

A1: Yes. Local PCB prices are usually higher due to smaller production scale and imported laminate costs. Many engineers prototype in Oman for convenience but move volume production to Asia for better pricing.

Q2: Can Oman PCB manufacturers handle HDI, microvias, or controlled impedance?

A2: Basic multilayer and controlled-impedance builds are available, but advanced HDI (stacked vias, laser microvias, 10+ layers) is limited. For RF or high-density boards, buyers often work with established international factories.

Q3: How long does PCB production take in Oman?

A3: Standard lead times range from 7‚Äď14 days. Complex multilayers, HDI, or hybrid RF stack-ups may take 20‚Äď30 days depending on material availability.

Q4: Do PCB factories in Oman support PCBA (SMT/THT) assembly?

A4: Some local suppliers offer SMT assembly, but capacity is modest. Fine-pitch BGA, 01005 components, or volume SMT runs are usually outsourced to larger Asian assembly lines.

Q5: Is it easy to find advanced materials like Rogers or Taconic in Oman?

A5: Not always. High-frequency laminates, flexible PI materials, and specialty copper foils are typically imported. This often extends lead time and increases cost unless production is done in a region with stocked inventory.

Tags: Oman PCB Manufacturer, PCB Manufacturer in Oman, PCB Manufacturing Company Oman, Top 10 PCB Manufacturer in Oman, Top PCB Manufacturer in Oman