Quick Turn PCB Boards are the cornerstone of modern electronics development, enabling the rapid physical realization of circuit designs for prototyping and testing. This article explores how these services, particularly those offering strong flexibility, accelerate innovation, reduce risks, and support projects from simple prototypes to complex multilayer assemblies.

In the race to market, engineers and startups often face a critical bottleneck: transitioning a design from a digital file to a functional, testable prototype PCB board. What are the most common pain points that can derail a project timeline when you need a board fast?

- Prototyping cycles are painfully slow, stalling R&D and time-to-market.

- Fear of design errors leading to costly, time-consuming board re-spins.

- Managing separate vendors for PCB print/fabrication and prototype PCB assembly‚Äč complicates logistics and quality control.

- Finding a reliable partner for specialized needs like quick turn PCB service RF boards‚Äč or quick turn multilayer circuit board‚Äč assembly.

- Balancing the need for speed with concerns over quick turn PCB boards cost‚Äč and overall quality.

Addressing these challenges requires a manufacturer built for speed and adaptability. The solution lies in partnering with a quick turn PCB manufacturer‚Äč that combines rapid production with robust engineering support.

- Operating 24/7 manufacturing lines to deliver true quick-turn capabilities, even in 24 hours.

- Offering comprehensive quick turn PCB assembly‚Äč services under one roof, from fabrication to component sourcing and testing.

- Providing expert DFM checks to catch errors before production, saving time and cost.

- Maintaining the strong flexibility‚Äč to handle diverse technologies, from standard boards to advanced RF boards‚Äč and multilayer assemblies.

- Utilizing transparent pricing models and online platforms for instant quotes and order tracking, ensuring clarity on PCB boards cost.

As a leading China leading quick turn 24 hours PCB circuit board assembly manufacturer, BEST Technology empowers innovators with an unparalleled blend of speed, flexibility, and reliability. We relialise that being caught up in a rat race of price is meaningless, and we need to find the most competitive edge to survive in this crowded market. Rapid PCB prototyping and quick-turn PCB assembly provide us with a competitive edge in the market. Our dedicated engineering team and state-of-the-art facilities ensure your PCB board quick turn fabrication‚Äč and assembly needs are met with the highest standards. We have PCB and SMT factories in China. And we have SMT factories in Vietnam to handle orders from different countries. Please rest assured that all our production processes are fully compatible with ISO 13485, IATF 16949, and AS9100D. For your next project, pls feel free to contact us at sales@bestpcbs.com.

What Are Quick Turn PCB Boards?

Quick Turn PCB Boards refer to the expedited manufacturing of printed circuit boards, drastically compressing the standard production timeline from weeks to a matter of days or even hours. This section outlines their core characteristics and process.

- Speed-Centric Process:‚Äč Streamlined workflows, from automated order processing and engineering review (DFM) to panelization and direct machine scheduling, eliminate typical queue delays.

- Core Service Tiers:‚Äč Services are often categorized by turnaround time (e.g., 24-hour, 48-hour, 72-hour) and board complexity, impacting the final quick turn PCB boards cost.

- Technological Enablers:‚Äč Advanced manufacturing equipment like laser direct imaging (LDI) and automated optical inspection (AOI) ensure speed does not compromise precision.

- The Role of “Strong Flexibility”:‚Äč This refers to the manufacturer’s ability to accommodate various specifications (layer count, material, finish) and last-minute changes without derailing the promised timeline, a key differentiator for complex projects.

In essence, quick-turn PCBs are not just about faster machines, but a holistic, agile manufacturing philosophy designed for the iterative nature of modern product development.

How Rapid PCB Prototyping Reduces Development Time for Startups and Engineers?

Rapid PCB prototyping‚Äč is the practical application of quick-turn services, acting as a critical time-compression tool. It allows for immediate validation and iteration.

- Parallel Development:‚Äč Hardware can be developed in parallel with software and mechanical design, as physical boards for testing are available much sooner.

- Fast Failure & Learning:‚Äč Design flaws are identified quickly with a tangible board, allowing for rapid correction and re-spin, turning potential major setbacks into minor, manageable iterations.

- Investor & Stakeholder Engagement:‚Äč A functional prototype is far more compelling for demonstrations, funding pitches, and internal reviews than schematics or 3D models.

- Supply Chain Validation:‚Äč Prototypes allow for early testing of real components and assembly processes, identifying sourcing or manufacturability issues before full-scale production.

By providing immediate feedback, rapid prototype PCB‚Äč services transform the development cycle from a linear, slow march into an agile, iterative sprint, conserving the most valuable resource: time.

From Concept to Test: How a Prototype PCB Board Supports Functional Validation?

A prototype PCB board‚Äč is the crucial bridge between theoretical design and a market-ready product. It serves as the primary platform for functional validation, where the circuit is proven to work as intended in the real world.

| Validation Aspect | Role of the Prototype PCB Board |

|---|---|

| Electrical Performance | Checks signal integrity, power flow, and basic circuit behavior. |

| Thermal Management | Evaluates heat spread and component temperature stability. |

| Mechanical Fit | Verifies board size, hole positions, and connector alignment. |

| Software Integration | Serves as the hardware base for firmware testing and tuning. |

| Environmental & Stress Testing | Supports early tests for temperature, humidity, and vibration. |

This hands-on testing phase is indispensable. It de-risks the entire project, ensuring that when you move to mass production, you are confident in the design’s viability.

What Impacts Quick Turn PCB Boards Cost During Fast Fabrication Runs?

While speed is paramount, understanding the quick turn PCB boards cost‚Äč drivers is essential for budget planning. The final price is a function of several key variables beyond just the turnaround time.

- Board Complexity:‚Äč Layer count (multilayer vs. double-sided), board size, and material (standard FR-4 vs. high-frequency) are primary cost factors.

- Order Quantity:‚Äč Even in quick-turn, unit cost typically decreases with volume due to amortized setup and panelization costs.

- Specialized Requirements:‚Äč Features like controlled impedance for RF boards, blind/buried vias, or specific surface finishes (ENIG, Immersion Silver) add cost.

- Turnaround Time Premium:‚Äč The “rush fee” for 24-hour service is higher than for a 5-day turn, reflecting prioritized scheduling and overtime labor.

- Additional Services:‚Äč Integrated costs for quick turn PCB assembly, electrical testing (flying probe), or comprehensive quality inspections are added to the bare board fabrication cost.

A reputable quick turn PCB manufacturer‚Äč will provide a transparent, itemized quote, helping you make informed trade-offs between speed, features, and cost.

How Quick Turn PCB USA Services Compare to Overseas Fast-Build Options?

The choice between Quick Turn PCB USA‚Äč services and overseas options involves a classic trade-off analysis between cost, communication, and logistical control.

| Factor | Quick Turn PCB USA | Overseas Fast-Build |

|---|---|---|

| Speed | 1‚Äď3 days. | 3‚Äď7+ days. |

| Communication | Easy. | Slower. |

| Unit Cost | Higher. | Lower. |

| Total Cost | Often competitive. | Can rise. |

| IP Security | Stronger. | Variable. |

For projects where time, ease of collaboration, and total project risk are critical, domestic quick turn PCB USA‚Äč services offer compelling value despite a higher initial unit price.

What Tests Are Necessary for a Quick Turn PCB Board Before Assembly?

To ensure a successful quick turn PCB assembly‚Äč phase, the bare boards must be rigorously validated. Skipping testing to save time is a high-risk gamble.

- Automated Optical Inspection (AOI):‚Äč Scans the board for manufacturing defects like shorts, opens, nicks, or insufficient solder mask.

- Electrical Test (Flying Probe or Fixture):‚Äč Verifies net connectivity (no opens) and isolation (no shorts) against the original design files, the most critical test for functionality.

- Impedance Test (for RF/High-Speed):‚Äč For quick turn PCB service RF boards, this ensures controlled impedance traces meet the specified tolerance (e.g., 50ő© ¬Ī10%).

- Solderability Test:‚Äč Checks the quality of the surface finish (e.g., HASL, ENIG) to ensure components will solder properly during assembly.

- Basic Dimensional Check:‚Äč Confirms board outline, hole sizes, and layer alignment are within specification.

These pre-assembly tests are a non-negotiable step in a reliable quick turn PCB‚Äč process, preventing good components from being placed on a faulty board, which is far more costly and time-consuming to rework.

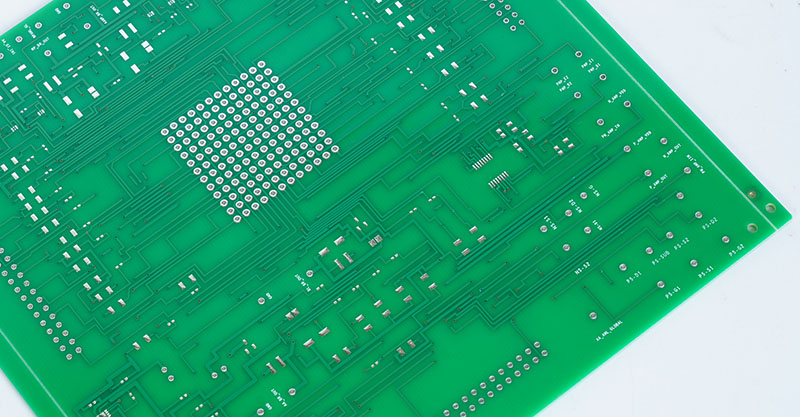

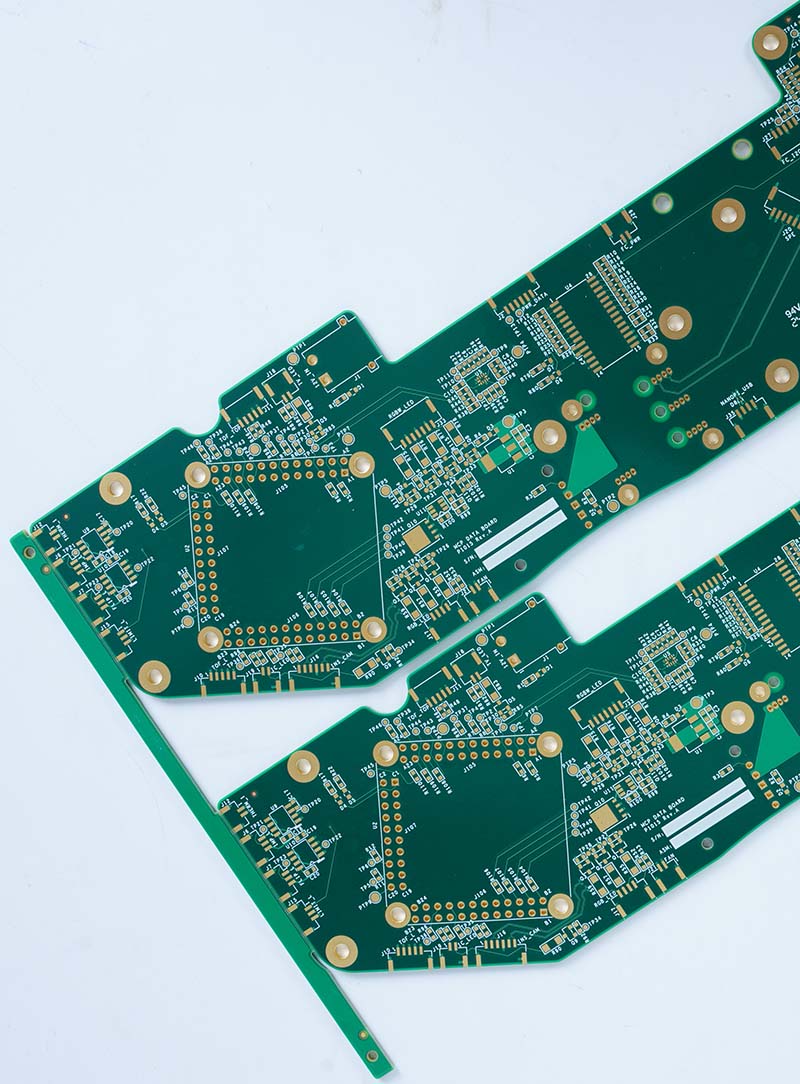

Quick Turn Printed Circuit Boards for RF, Multilayer, and Home Appliance Applications

The strong flexibility‚Äč of a top-tier manufacturer is demonstrated in its ability to handle diverse application-specific demands.

- RF and Microwave Boards:‚Äč Require specialized low-loss materials (Rogers, Taconic), precise quick turn PCB fabrication‚Äč for controlled impedance, and often cavity structures or shielding. A reliable partner for quick turn PCB service RF boards‚Äč is essential for wireless products.

- Multilayer Boards (4+ Layers):‚Äč Used for complex devices, requiring precise layer alignment, advanced via structures (blind/buried), and often mixed materials. A quick turn multilayer circuit board PCB assembly supplier‚Äč must have expertise in lamination and interconnect reliability.

- Home Appliance Controls:‚Äč Demand high reliability, often requiring thicker copper for power sections, specific UL-recognized materials, and robustness for long-term operation. Quick turn PCB board for home appliances‚Äč must balance cost-effectiveness with unwavering durability and safety standards.

A manufacturer’s capability across this spectrum shows true adaptability, providing a one-stop solution for innovators in disparate fields.

Why Is BEST Technology a Reliable Quick Turn 24-Hours PCB Circuit Board Assembly Manufacturer?

Choosing the right partner is critical. BEST Technology‚Äč stands out as a reliable quick turn 24-hours PCB circuit board assembly manufacturer‚Äč for several definitive reasons.

- Integrated One-Stop Service:‚Äč We manage the entire flow from PCB board quick turn fabrication‚Äč to full prototype PCB assembly, including component sourcing, reducing coordination overhead and risk.

- True 24/7 Operational Capability:‚Äč Our dedicated quick turn‚Äč lines and skilled staff work around the clock, making “24-hour” a standard, reliable service, not just a promotional claim.

- Engineering-Led Support:‚Äč Our engineers provide proactive Design for Manufacturability (DFM) analysis, helping optimize your design for both performance and manufacturability before production begins.

- Commitment to Quality at Speed:‚Äč We integrate mandatory AOI, electrical testing, and other QC checks into our accelerated timeline, ensuring the boards you get fast are also boards you can trust.

- Adaptability and Transparency:‚Äč We embrace the strong flexibility‚Äč needed for complex projects and maintain clear communication with instant online quoting and project tracking, so you are never in the dark.

Our mission is to be the enabler of innovation, providing the speed, reliability, and expert partnership that allows your ideas to become reality without delay.

In summary‚ÄĆ, quick turn PCB boards‚Äč are the essential engine for modern hardware innovation, providing the physical platform to test, iterate, and refine ideas with unparalleled speed. This article has detailed how they accelerate development, from functional validation and cost management to serving specialized applications.

For engineers and companies seeking a partner that delivers not just speed, but also reliability, quality, and deep technical expertise across the entire process, BEST Technology‚Äč is the proven choice. We combine the agility of a specialist with the capabilities of a full-service quick turn PCB manufacturer‚Äč to support your most ambitious projects. And we have extensive experience in fabricating medical PCBs and medical PCB assemblies. We have been in the PCB and SMT industry for over 19 years. Pls feel free to contact our team at sales@bestpcbs.com.

Tags: prototype pcb board, Quick Turn PCB Boards, Quick Turn PCB Boards Cost, Quick Turn PCB USA, Quick Turn Printed Circuit Boards, Rapid PCB Prototyping