What is a rigid-flex aluminum substrate?

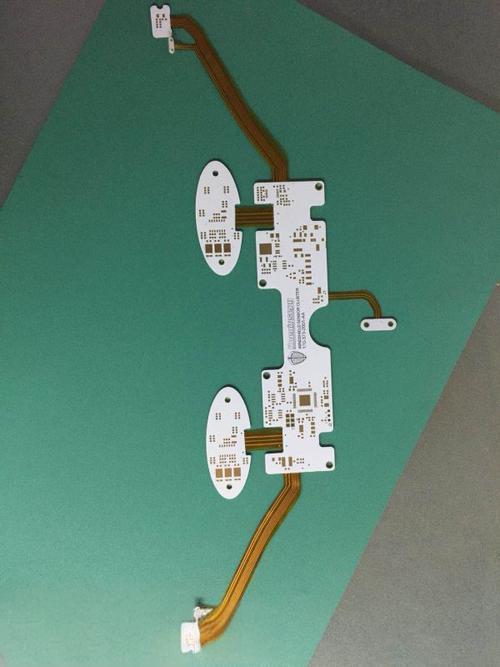

Rigid-flex aluminum substrate is a hybrid PCB structure that combines rigid and flexible sections, with aluminum used as a thermal-conductive base. Think of it as a single circuit board with areas that bend and fold—yet it stays strong and dependable under pressure.

Unlike traditional rigid PCBs, this type doesn’t rely solely on fiberglass or FR4. Instead, it mixes rigid substrates (like aluminum for heat dissipation and strength) with flexible layers (usually made of polyimide). These parts are layered together in a rigid flex stackup to create a solid yet adaptable foundation.

The aluminum core enhances performance, especially in high-power or high-temperature environments. The flexible sections allow the board to fit into tight or curved enclosures—perfect for compact designs.

What is the rigid flex process?

Creating a rigid-flex aluminum substrate involves multiple, tightly controlled steps. This process ensures the reliability and functionality of each part, from the stiff aluminum core to the bendable flex areas.

Here’s how it works:

- Material Preparation: Aluminum is selected as the rigid base layer. Polyimide films are chosen for the flex sections. Copper foil is used for the conductive pathways.

- Layering: These materials are laminated together in a multi-layer PCB stackup, carefully aligning the rigid and flexible parts. Adhesives must tolerate both mechanical stress and high heat.

- Drilling and Plating: Vias are drilled to connect layers. These vias are plated with copper to ensure stable electrical performance between rigid and flexible sections.

- Etching and Imaging: Circuit patterns are etched into the copper layers.

- Coverlay and Protection: The flex parts are protected with a coverlay—a thin film that protects the flexible circuit from damage or oxidation.

- Testing: Each board goes through strict electrical and mechanical testing to ensure it can bend without breaking and still conduct flawlessly.

This precise rigid flex process demands high skill and advanced machinery.

Rigid-flex aluminum substrate Types

Depending on your application, several types of rigid-flex aluminum substrates are available. Each is designed for specific environments and use cases.

- Single-Sided Rigid-Flex: One layer of copper on the flexible section. Simple and cost-effective.

- Double-Sided Rigid-Flex: Copper on both sides of the flex section for increased routing options.

- Multi-Layer Rigid-Flex: Complex designs with 4+ layers, often used in aerospace, medical, and high-end automotive electronics.

- Hybrid Stackups: Combine aluminum with other rigid materials (like FR4 or CEM-3) for specific mechanical or thermal goals.

Each type has trade-offs in cost, thickness, and flexibility. But with aluminum in the core, they all shine in thermal management and durability.

Rigid-flex aluminum substrate Benefits

Rigid-flex aluminum substrate combines the advantages of rigidity and flexibility.

- 1. Thermal Conductivity

Aluminum is an excellent heat conductor. It keeps your circuits cool even when running at full power.

- 2. Space Saving

With a rigid-flex structure, you can fold or twist the board to fit inside small or oddly shaped enclosures.

- 3. Mechanical Strength

The rigid aluminum base offers strong mechanical support. It doesn’t warp or bend easily.

- 4. Improved Reliability

Fewer solder joints and connectors mean fewer points of failure.

- 5. Streamlined Assembly

Fewer separate pieces to assemble = faster manufacturing and lower cost over time.

- 6. Design Freedom

Curves, folds, unusual angles? No problem.

When you combine these strengths, you get a PCB that’s not only dependable but also efficient in heat, space, and power.

Can rigid-flex aluminum substrate handle heat?

Yes. Thanks to the aluminum base layer, a rigid-flex aluminum substrate can dissipate heat much faster than standard FR4 PCBs. That makes it ideal for high-power LEDs, motor drivers, power converters, and even automotive ECUs that run hot under load.

Aluminum pulls heat away from sensitive components and spreads it across the board. This reduces thermal stress and extends the lifespan of the device.

What is a flexible aluminum PCB?

A flexible aluminum PCB might sound like a contradiction—but it exists. These boards use ultra-thin aluminum or aluminum-polymer composites to create circuits that bend slightly without breaking.

They don’t flex as much as pure polyimide-based flex PCBs, but they offer a middle ground. You get better heat handling than plastic-based flex boards and more flexibility than rigid aluminum PCBs.

They are perfect for wearables, automotive lighting strips, and foldable displays—places where space and heat must be controlled.

But when you need more complex bends, a rigid-flex aluminum substrate—with a true polyimide flex section—is still the better option.

What is the difference between rigid flex and flex with stiffener?

A flex PCB with stiffener uses an added material (like FR4 or stainless steel) to reinforce a flexible circuit. It’s a workaround to create rigid zones. But these are added separately and don’t become part of the electrical circuit.

A rigid-flex PCB, on the other hand, is built from the ground up to have both rigid and flex sections. The materials are laminated together and share common copper layers. The transition between flex and rigid is smooth, continuous, and far more robust.

Here’s a simple comparison:

| Feature | Flex with Stiffener | Rigid-Flex PCB |

|---|---|---|

| Electrical Integration | Not shared | Shared between zones |

| Mechanical Strength | Moderate | Very strong |

| Size & Thickness | Bulkier | More compact |

| Cost Over Time | May increase due to failure | Higher upfront, lower long-term |

| Assembly Time | Longer | Faster and more integrated |

So if your application requires reliability, space-saving, and superior performance, rigid-flex is your clear winner.

Where is rigid-flex aluminum substrate used?

Rigid-flex aluminum substrate PCB is widely used. Here’s where they make an impact:

- 1. Automotive Electronics

From advanced driver assistance systems (ADAS) to engine control units (ECUs), cars need compact, heat-resistant boards that perform under pressure.

- 2. LED Lighting Systems

LEDs generate heat—and need compact control circuits.

- 3. Wearable Technology

Smartwatches, fitness bands, and medical patches need bendable electronics that won’t break.

- 4. Industrial Equipment

Sensors, controls, and power systems in factories demand reliable boards that won’t fail under heat or vibration.

- 5. Medical Devices

Surgical tools, monitors, and implants need small, reliable PCBs.

- 6. Consumer Electronics

From foldable phones to compact drones, smart devices keep shrinking.

In short, any product that needs to be compact, tough, and thermally stable is a candidate for rigid-flex aluminum technology.

Conclusion:

Rigid-flex aluminum substrate combines the strength of rigid substrates with the flexibility of a bendable PCB. It offers better heat dissipation, space-saving structure, and high reliability for demanding applications. From automotive to LED lighting and wearable devices, it suits various environments where traditional PCBs fall short. It’s a solid choice for efficient, compact, and heat-resistant circuit solutions.

Want to design and produce rigid-flex aluminum substrates? Contact us now at sales@bestpcbs.com

Tags: Aluminum Flex-Rigid PCB, rigid flex pcb, rigid substrates, Rigid-flex aluminum substrate