‚ÄčAutomotive printed circuit board‚Äč is the foundational nervous system of modern vehicles, enabling everything from engine management to advanced driver-assistance systems (ADAS). This article provides a comprehensive guide to automotive PCB types, applications, certifications, and how to select a reliable partner for your ‚Äčprinted circuit boards for the automotive industry.

Are you struggling to find a supplier who can consistently deliver high-quality, reliable ‚Äčautomotive printed circuit boards‚Äč that meet stringent industry standards?

- ‚ÄčInconsistent Quality and Reliability:‚Äč‚Äč Receiving PCBs that fail under the harsh conditions of an automotive environment, leading to costly recalls.

- ‚ÄčDifficulty Meeting Strict Certifications:‚Äč‚Äč Navigating the complex web of required certifications like IATF 16949 and AEC-Q100 compliance.

- ‚ÄčLimited Design for Manufacturability (DFM) Support:‚Äč‚Äč Working with manufacturers who lack the expertise to optimize designs for robust, high-yield production.

- ‚ÄčUnreliable Supply Chain and Long Lead Times:‚Äč‚Äč Experiencing project delays due to supplier bottlenecks or material shortages.

- ‚ÄčChallenges with Complex Technologies:‚Äč‚Äč Finding a partner capable of handling HDI, heavy copper, and advanced substrates for demanding applications.

The solutions lie in choosing automotive printed circuit board manufacturers with proven expertise and a commitment to excellence.

- ‚ÄčImplementing Rigorous Quality Control:‚Äč‚Äč Employing automated optical inspection (AOI), flying probe testing, and comprehensive functional testing to ensure every ‚Äčautomotive circuit board‚Äč is flawless.

- ‚ÄčHolding Necessary Automotive Certifications:‚Äč‚Äč Possessing IATF 16949 certification and deep experience with AEC-Q100 qualified components as a baseline requirement.

- ‚ÄčProviding Expert DFM Analysis:‚Äč‚Äč Offering early-stage engineering support to optimize designs for reliability, thermal management, and cost-effectiveness.

- ‚ÄčEnsuring a Robust and Transparent Supply Chain:‚Äč‚Äč Maintaining strong relationships with material suppliers to guarantee component availability and on-time delivery.

- ‚ÄčMastering Advanced PCB Technologies:‚Äč‚Äč Demonstrating proven capability in manufacturing complex boards like those used in powertrain, ‚Äčautomotive printed circuit board market‚Äč leaders.

As a leading automotive printed circuit board supplier, EBest Circuit (Best Technology) combines state-of-the-art manufacturing with stringent IATF 16949 quality systems to deliver automotive-grade in the more competitive market. We specialize in high-reliability automotive printed circuit boards solutions for critical applications such as dash cameras, LiDAR sensors, 5G connected cars, and Battery Management Systems (BMS), employing advanced processes like Wire Bondable Gold. Our boards are engineered to withstand rigorous thermal cycling and vibration stress, ensuring unparalleled performance and longevity. Pls feel free to contact us at sales@bestpcbs.com to discuss your printed circuit board automotive project requirements.

What is Automotive Printed Circuit Board?

An ‚Äčautomotive printed circuit board‚Äč is a specialized board used to mechanically support and electrically connect electronic components in a vehicle.

Understanding the ‚ÄčPCB automotive meaning‚Äč is key: these are not standard consumer-grade PCBs; they are engineered to withstand extreme temperatures, constant vibration, and exposure to chemicals while ensuring flawless operation for years. They are the bedrock upon which vehicle electronics are built.

In summary, the automotive PCB is a high-reliability, mission-critical component essential for the functionality, safety, and innovation in today’s automobiles.

What are the Types of Printed Circuit Board Automotive?

Modern vehicles require a wide variety of electronic functions, which in turn demand a diverse range of printed circuit boards. Selecting the right type is crucial for reliability, performance, and cost-efficiency. Automotive PCBs can be classified based on construction & complexity, mechanical properties, and electrical & thermal performance. Here is a streamlined overview:

Classification by Construction & Complexity

- Single-Sided & Double-Sided PCBs: Simple boards for lower circuit density. Single-sided PCBs host components on one side, while double-sided boards allow for more complex routing. Suitable for basic sensor modules and automotive printed circuit board relays.

- Multi-Layer PCBs: Stack multiple layers with insulation for higher component density and complex routing. Ideal for core systems like Engine Control Units (ECUs), infotainment, and ADAS modules.

- HDI (High-Density Interconnect) PCBs: Microvias, fine lines, and higher pad density support space-constrained, high-performance applications such as advanced cameras, LiDAR, and radar modules, crucial for the growing automotive printed circuit board market.

Classification by Mechanical Properties

- Rigid PCBs: Provide structural stability for general automotive electronics.

- Flexible PCBs: Bendable and foldable, perfect for areas with motion or limited space, like dashboards or steering columns.

- Rigid-Flex PCBs: Combine rigid support for components with flexible interconnects for compact, high-performance assemblies.

Classification by Electrical & Thermal Performance

- Heavy Copper PCBs: Copper thickness exceeding 3 oz to handle high current loads. Used in power distribution modules, battery management systems (BMS), and printed circuit board motors.

- Metal-Clad PCBs (MCPCBs): Feature a metal core for superior heat dissipation, essential for LEDs, power converters, and other high-heat applications.

- RF/High-Frequency PCBs: Engineered for high-frequency signal integrity using specialized laminates. Used in automotive radar, GPS/GNSS, and V2X communication systems.

In summary, by classifying PCBs according to construction & complexity, mechanical properties, and electrical & thermal performance, engineers can select the right type‚ÄĒfrom basic single-layer boards to advanced RF or metal-clad boards‚ÄĒto meet the exact requirements of each automotive electronic system.

What are the Specific Applications of Printed Circuit Boards for the Automotive Industry?

Printed circuit boards in the automotive industry power nearly every electronic and control system within a vehicle. From perception to propulsion, they form the backbone of both conventional and intelligent mobility. Below is an overview of key application domains where automotive PCBs play a crucial role.

1. Powertrain and Vehicle Control

PCBs are essential in Engine Control Units (ECUs), transmission modules, and power management systems. In electric vehicles, they manage high-voltage operations in battery management systems (BMS), motor controllers, and onboard chargers, ensuring efficient energy conversion and precise control.

2. Advanced Driver Assistance and Autonomous Driving

Modern driving intelligence relies heavily on PCB-based electronic modules.

- ADAS and Autonomous Systems: Core functions such as adaptive cruise control, lane keeping, and collision avoidance use high-performance multi-layer or HDI PCBs to process massive sensor data in real time.

- Perception and Sensing: PCBs are integral to LiDAR, millimeter-wave radar, ultrasonic sensors, infrared cameras, and vision-based systems, providing stable signal integrity and EMI resistance.

- High-Precision Positioning & Mapping: High-frequency PCBs are used in GNSS and RTK positioning modules, supporting centimeter-level vehicle localization.

- L4 and Specialized Autonomous Vehicles: Applications extend to mining trucks, port logistics vehicles, agricultural machinery, delivery robots, and even flying cars, where durable and thermally efficient PCBs withstand extreme conditions.

3. Safety and Body Electronics

- Reliability is paramount in airbag control, ABS, stability control, and tire pressure monitoring systems (TPMS). Automotive-grade PCBs ensure consistent signal processing and protection from thermal and mechanical stress.

- They are also found in body control modules for lighting, seat adjustment, window lifts, and climate systems, contributing to both safety and comfort.

4. Infotainment and Connectivity

The modern vehicle cabin is a digital ecosystem powered by complex PCB assemblies.

- Infotainment Systems: Multi-layer PCBs drive instrument clusters, center consoles, and digital dashboards.

- Connectivity Modules: Components such as T-Box units, telematics control units (TCUs), and wireless communication modules (Wi-Fi, 4G/5G, V2X) rely on RF and high-frequency PCB technology for stable data transfer.

- Smart Cockpit Electronics: Includes head-up displays (HUDs), smart mirrors, voice control units, driver monitoring systems (DMS), and multi-screen dashboards, all demanding compact, high-reliability PCB layouts.

5. Core Hardware and Electrical Platforms

Automotive PCBs also serve as structural foundations for critical electronic modules such as:

- Domain Controllers integrating ADAS, infotainment, and body control functions.

- Gateways and central computing units managing in-vehicle communication networks.

- IGBT power modules and inverters that handle energy flow in electric propulsion systems.

- AUTOSAR-based ECU architectures, where PCB layout precision ensures timing and signal synchronization.

6. Lighting and Human‚ÄďMachine Interface (HMI) Systems

- Metal-clad PCBs (MCPCBs) dominate automotive lighting, including headlights, interior illumination, and signal lamps, due to their superior heat dissipation. PCBs also support touch panels, button interfaces, and steering-mounted controls in modern HMI systems.

In summary, the role of PCBs in the automotive industry extends far beyond simple circuitry. From powertrain control to autonomous navigation and cockpit intelligence, they serve as the electronic foundation that integrates perception, decision-making, and execution‚ÄĒdefining the intelligence and reliability of the modern automobile.

What Certifications are Required for the Automotive Printed Circuit Board Market?

Entering the automotive printed circuit board market requires strict adherence to a set of industry-recognized quality standards. These certifications are not optional‚ÄĒthey are essential for any supplier aiming to be taken seriously in the automotive sector.

- IATF 16949: This is the cornerstone quality management system for the automotive industry, emphasizing defect prevention, continuous improvement, and consistent product quality.

- PPAP (Production Part Approval Process): A critical framework that ensures components and assemblies meet customer design and quality requirements before full production. Automotive PCB suppliers use PPAP to validate production readiness and guarantee compliance with OEM standards.

- AEC-Q100/Q101: These standards cover stress test qualifications for integrated circuits (Q100) and discrete semiconductors (Q101). While they directly apply to components, a reputable medical, industrial, and automotive controller printed circuit board supplier must design and assemble PCBs with these stress tolerances in mind.

- ISO 9001: The baseline quality management standard forming the foundation for IATF 16949, ensuring a systematic approach to quality across processes.

- ISO 14001: An environmental management standard reflecting a manufacturer’s commitment to sustainability and minimizing ecological impact.

- Customer-Specific Requirements: Leading automakers often impose additional standards that suppliers must meet, reflecting unique production, safety, or performance expectations.

In summary, a manufacturer‚Äôs certifications‚ÄĒIATF 16949, PPAP, AEC-Q100/Q101, ISO 9001, ISO 14001, and customer-specific requirements‚ÄĒserve as the primary indicators of their ability and commitment to delivering reliable, high-quality automotive printed circuit boards.

How to Ensure Quality in Printed Circuit Board Automotive Manufacturing?

Ensuring quality in ‚Äčprinted circuit board automotive‚Äč manufacturing is a multi-stage process. This involves a rigorous system of checks, tests, and process controls throughout production. Quality is engineered in from the start.

- ‚ÄčDesign for Excellence (DFX):‚Äč‚Äč Quality begins with a design optimized for reliability (DFR) and manufacturability (DFM).

- ‚ÄčMaterial Selection:‚Äč‚Äč Using only high-Tg, CAF-resistant laminates and certified materials from reputable sources.

- ‚ÄčProcess Control:‚Äč‚Äč Implementing Statistical Process Control (SPC) at every step‚ÄĒfrom lamination and drilling to plating and solder mask application‚ÄĒto minimize variability.

- ‚ÄčComprehensive Testing:‚Äč‚Äč Employing a battery of tests, including Electrical Testing (Flying Probe, Fixture), AOI, X-Ray inspection, and accelerated life testing (like Thermal Cycle Testing).

- ‚ÄčTraceability:‚Äč‚Äč Maintaining full lot traceability for materials and processes is critical for any potential ‚Äčautomotive printed circuit board repair‚Äč or recall analysis.

In short, quality is not a single step but a culture embedded in the entire manufacturing workflow, ensured through proactive design, controlled processes, and exhaustive verification.

How to Choose the Best Automotive Printed Circuit Board for Your Projects?

Choosing the most suitable automotive printed circuit board for your project begins with a clear understanding of the application requirements and the PCB types discussed above. The right choice directly impacts reliability, performance, and long-term durability. Consider the following factors:

1. Match the PCB Type to Your Application

- Single-Sided or Double-Sided PCBs ‚Äď Ideal for simple control circuits, basic sensor modules, or automotive relays.

- Multi-Layer PCBs ‚Äď Best suited for core electronic systems such as Engine Control Units (ECUs), infotainment modules, and ADAS, providing complex routing and high component density.

- HDI PCBs ‚Äď Designed for space-constrained, high-performance applications like LiDAR, radar, or advanced camera systems, ensuring compact layouts with excellent signal integrity.

- Flexible or Rigid-Flex PCBs ‚Äď Perfect for areas exposed to motion, bending, or tight spaces, such as dashboards, steering columns, and camera linkages.

- Heavy Copper PCBs ‚Äď Essential for high-current applications including battery management systems and power distribution modules.

- Metal-Clad PCBs (MCPCBs) ‚Äď Optimal for high-heat modules, such as LED lighting or power converters, delivering efficient thermal management.

- RF / High-Frequency PCBs ‚Äď Critical for communication systems and radar modules that require stable high-frequency signal performance.

2. Consider Environmental and Mechanical Requirements

- Determine if the board will operate under high temperatures, vibration, or frequent motion, and select mechanical properties accordingly (rigid, flexible, or rigid-flex).

- Evaluate thermal management needs, particularly for modules generating heat, to avoid performance degradation.

3. Assess Electrical and Signal Requirements

- High-speed or high-frequency signals need PCBs designed for minimal signal loss and controlled impedance.

- Heavy current loads demand thicker copper layers, while RF or communication circuits require specialized laminates.

4. Factor in Reliability and Compliance

- Ensure that the PCB type can withstand the lifetime conditions of the vehicle.

- For critical systems like ADAS or powertrain modules, prioritize PCBs with proven long-term stability, high reliability, and thermal endurance.

5. Align Design Complexity with Manufacturing Capabilities

- Confirm that the chosen PCB type can be reliably manufactured to meet layer count, trace width, via density, and material requirements.

- For prototypes, simpler boards may suffice, while high-density, multi-layer, or HDI boards require experienced fabrication processes.

By following these guidelines, engineers and designers can translate project requirements into a well-matched PCB type, ensuring optimal performance, longevity, and cost-efficiency. This approach directly connects the selection process with the types of PCBs previously described, providing a logical, application-driven decision path.

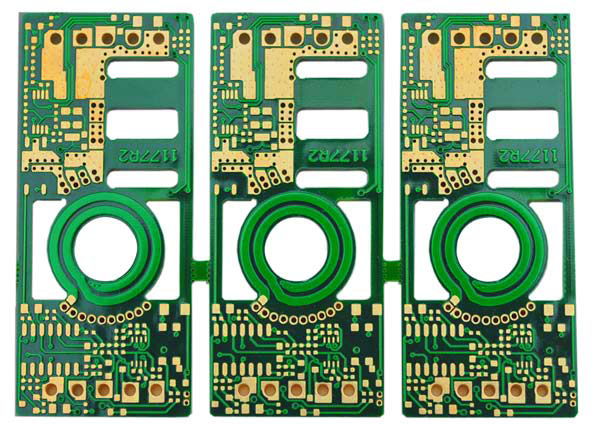

Case of Automotive Circuit Board Fabrication by EBest Circuit (Best Technology)

A recent project at EBest Circuit (Best Technology) involved the fabrication of a sophisticated 8-layer FR4 PCB, showcasing our capability to produce high-reliability boards for the most demanding automotive applications. This specific circuit board is engineered to serve as the core processing unit in advanced automotive systems where miniaturization, signal integrity, and reliability are non-negotiable.

Thanks to its 3-stage HDI design and robust construction, this PCB is ideally suited for several critical roles within the vehicle’s electronic architecture:

- ‚ÄčADAS Domain Controller / Central Compute Module:‚Äč‚Äč This board can act as the nerve center for Level 2+ autonomous driving, processing data from various sensors (cameras, radar) to enable features like adaptive cruise control and lane-keeping assist. Its high-density interconnects are essential for the powerful System-on-Chip (SoC) and memory components required for this complex data fusion.

- ‚ÄčMulti-Functional Gateway:‚Äč‚Äč In modern zonal vehicle architectures, this PCB is perfect for a high-speed gateway that manages communication between different vehicle domains (powertrain, chassis, body, infotainment). Its 8 layers and controlled impedance support high-speed data protocols like CAN FD and Ethernet.

- ‚ÄčHigh-Resolution Front Camera Module for Vision Systems:‚Äč‚Äč The combination of HDI technology and a compact form factor makes this board an excellent choice for the main processor in automotive camera systems. It handles image signal processing for object and lane detection, critical for perception in ADAS.

- ‚ÄčDigital Instrument Cluster / Integrated Cockpit Display Controller:‚Äč‚Äč This PCB can drive high-resolution digital dashboards or central infotainment screens. Its reliability and ability to support high-speed data transfer ensure smooth, real-time graphics rendering for the driver.

- ‚ÄčLiDAR Control Unit:‚Äč‚Äč For autonomous driving systems relying on LiDAR, this board provides the necessary platform for the control and data acquisition electronics, where signal integrity and thermal performance are paramount.

‚ÄčPCB Specifications:‚Äč‚Äč

- ‚ÄčLayers:‚Äč‚Äč 8

- ‚ÄčBase Material:‚Äč‚Äč FR4

- ‚ÄčTg Value:‚Äč‚Äč Tg 180

- ‚ÄčInner/Outer Layer Copper Weight:‚Äč‚Äč 1 oz

- ‚ÄčSolder Mask:‚Äč‚Äč Green

- ‚ÄčSilkscreen:‚Äč‚Äč White

- ‚ÄčBoard Thickness:‚Äč‚Äč 1.6 mm

- ‚ÄčTechnology:‚Äč‚Äč 3 step HDI (High-Density Interconnect)

- ‚ÄčVia Process:‚Äč‚Äč Resin Filled Vias

- ‚ÄčSurface Finish:‚Äč‚Äč ENIG (Electroless Nickel Immersion Gold), 1 ¬Ķ”

- ‚ÄčKey Features:‚Äč‚Äč High-Density Routing, Excellent Thermal Reliability, Superior Signal Integrity

Why Choose EBest Circuit (Best Technology) for Your Trusted Automotive Printed Circuit Board Supplier?

With 19 years of expertise and IATF 16949 certification, EBest Circuit (Best Technology) delivers more than just boards‚ÄĒwe provide engineered printed circuit board automotive solutions. We specialize in manufacturing complex PCBs for critical applications, from 20oz heavy copper for power management to advanced designs for LiDAR and 5G connectivity, backed by rigorous testing and full traceability.

1. IATF 16949 Certified with Full PPAP Support‚Äč

- Our IATF 16949:2016 certification and PPAP expertise are just the foundation. We implement ‚Äčfull lot traceability‚Äč across our production process. This enables precise root cause analysis for any field issue, turning potential setbacks into opportunities for continuous improvement and guaranteed supply chain integrity.

‚Äč2. Advanced Manufacturing Tailored for Automotive Challenges‚Äč

Our factory is equipped to handle the most demanding automotive specs:

- ‚ÄčPower Electronics:‚Äč‚Äč We specialize in ‚ÄčHeavy Copper PCBs up to 20 oz‚Äč for robust battery management systems (BMS) and power controllers.

- ‚ÄčHigh-Density Interconnects (HDI):‚Äč‚Äč We produce complex, multi-layer boards with ‚Äčlaser drill capabilities down to 0.10mm‚Äč and ‚Äč3/3mil line/space, essential for compact ADAS modules and high-speed infotainment systems.

- ‚ÄčThermal Management:‚Äč‚Äč We are experts in ‚ÄčMetal Core PCBs (MCPCBs) up to 10 layers‚Äč and ‚ÄčCeramic PCBs, providing critical thermal management for LED lighting, LiDAR sensors, and powertrain systems.

- ‚ÄčProven Scale & Speed:‚Äč‚Äč With a ‚Äčmonthly capacity of 260,000 sq. ft.‚Äč‚Äč and the ability to ship urgent prototypes in ‚Äčas fast as 24 hours, we keep your development cycles agile and production on schedule.

‚Äč3. Rigorous Quality ‚Äč

Quality is engineered into every step. Our commitment is validated by:

- ‚ÄčState-of-the-Art Inspection:‚Äč‚Äč We utilize advanced equipment like ‚ÄčAutomatic Optical Inspection (AOI), X-Ray copper thickness testers, and Flying Probe Testers‚Äč to ensure zero defects.

- ‚ÄčAdherence to Strict Standards:‚Äč‚Äč Our processes strictly follow IPC standards, and we hold certifications including ‚ÄčISO 9001, ISO 13485, AS9100D, and UL, REACH, RoHS compliance.

- ‚ÄčReliability Testing:‚Äč‚Äč We perform ‚Äčthermal cycling, vibration, and shock testing‚Äč to simulate the harsh automotive environment, ensuring long-term durability.

‚Äč4. A True Turnkey Partner for End-to-End Simplification‚Äč

We simplify your supply chain with a comprehensive one-stop solution:

- ‚ÄčFrom Design (DFM) to Box Build:‚Äč‚Äč Our engineering team provides expert ‚ÄčDesign for Manufacturability (DFM)‚Äč‚Äč feedback and supports you through ‚ÄčPCB fabrication, component sourcing (avoiding counterfeit parts), PCB assembly (SMT & THT), and full system integration.

- ‚ÄčTechnical Collaboration:‚Äč‚Äč We pride ourselves on solving complex challenges others can’t, such as achieving reliable ‚ÄčWire Bondable Gold surfaces‚Äč for critical sensor applications.

‚Äč5. A Proven Track Record of Trust‚Äč

- With over ‚Äč1,700 satisfied clients across 40 countries‚Äč and a ‚Äč97% on-time delivery rate, EBest Circuit (Best Technology) is a trusted partner for applications ranging from engine control units and airbag sensors to advanced 5G telematics platforms.

‚ÄčTo conclude, automotive printed circuit boards‚Äč are complex, high-reliability components that are vital to the safety, performance, and innovation of modern vehicles. This guide has explored their types, applications, and the critical factors in selecting a automotive printed circuit board supplier. Succeeding in the demanding automotive sector requires a printed circuit board supplier with proven expertise, stringent quality controls, and a partnership approach. EBest Circuit (Best Technology) embodies these principles, making us the ideal choice for your ‚Äčautomotive printed circuit board and PCBA solutions. For a consultation on your next project, please contact our team at sales@bestpcbs.com.

Tags: automotive circuit board, Automotive Printed Circuit Board, printed circuit board automotive