An โRF PCB manufacturerโ specializes in creating printed circuit boards for high-frequency applications. This is a field where precision is not just a goal; it is an absolute requirement. This article will guide you through the world of RF circuit boards, from fundamental concepts to advanced manufacturing capabilities.

Many engineers face significant hurdles when moving from standard PCBs to RF circuit PCB designs. What are the most common pain points?

- โSignal Loss and Integrity Issues:โโ The circuit looks perfect on screen, but the real-world performance is poor. Signals weaken or distort across the board, ruining data transmission.

- โImpedance Mismatch:โโ Achieving a consistent impedance is incredibly difficult. Even a tiny error in trace width or material thickness can cause signal reflections, degrading performance.

- โHeat Management Problems:โโ High-frequency operation generates heat. Standard PCB materials cannot dissipate this effectively, leading to overheating and potential failure.

- โManufacturing Inconsistency:โโ A great design is useless if it cannot be built reliably. Many fabricators lack the tight process controls needed for RF work, leading to frustrating variations from board to board.

- โMaterial Selection Confusion:โโ The range of specialized RF laminates (like Rogers, Taconic, PTFE) is vast. Choosing the wrong material for your application’s frequency and thermal needs is a common and costly mistake.

Fortunately, these challenges have clear solutions. Partnering with a specialist โRF PCB manufacturerโ transforms these obstacles into opportunities for optimal performance.

- โPrecision Engineering:โโ They use advanced simulation software to model signal behavior before production. This ensures the final board maintains excellent signal integrity from input to output.

- โAdvanced Process Control:โโ They maintain extremely tight tolerances on trace width, spacing, and dielectric thickness. This rigorous control is the only way to guarantee a perfect impedance match.

- โThermal Management Expertise:โโ They understand the thermal properties of specialized materials. They select laminates that effectively dissipate heat and design stack-ups that manage thermal expansion.

- โCertified Consistency:โโ A top-tier manufacturer invests in state-of-the-art equipment and rigorous quality certifications like ISO 9001. Every batch meets the same high standard, every time.

- โMaterial Guidance:โโ They act as a consultant. Their engineers help you select the most cost-effective and performance-appropriate RF laminate for your specific project needs.

At EBest Circuit (Best Technology), we are a specialized โRF PCB manufacturerโ focused on these exact solutions. Our team thrives on complex, high-frequency challenges. We combine deep material knowledge with cutting-edge fabrication processes to deliver boards that perform as promised. Feel free to contact us at โsales@bestpcbs.comโ to discuss your project.

RF PCB Manufacturer – EBest Circuit (Best Technology)โ

EBest Circuit (Best Technology) is a leading โRF PCB manufacturerโ with โ19+ years of experienceโ in high-frequency printed circuit board fabrication. We specialize in โRF/microwave PCBs, โhigh-speed digital PCBs, and โhybrid RF-digital designs, offering โfull turnkey solutionsโ from design to assembly.

Our expertise covers โRogers, Taconic, and other high-frequency laminates, ensuring optimal signal integrity for โ5G base stations, radar, aerospace, and wireless communicationโ applications.

1. โRF PCB Materials & Stackupsโ

We support a wide range of โhigh-frequency materialsโ with โlow dielectric loss (Df) and stable Dk:

- โRogersโ (RO4000ยฎ, RO3000ยฎ, RT/duroidยฎ)

- โTaconicโ (TLX, TLY, RF-35)

- โIsolaโ (IS680, IS410)

- โPTFE-based laminatesโ (for mmWave applications)

- โHybrid constructionsโ (mixing FR4 with RF materials for cost optimization)

โTypical Properties:โโ

- โDk (Dielectric Constant):โโ 2.2 โ 10.2

- โDf (Dissipation Factor):โโ 0.001 โ 0.004 @ 10GHz

- โCopper Foil:โโ Low-profile (โค1ยตm Ra) for reduced insertion loss

2. โRF PCB Fabrication Capabilitiesโ

| Parameter | Standard Capability | Advanced Capability |

|---|---|---|

| โLayersโ | 1-32L | Up to 50L (rigid-flex) |

| โLine/Spaceโ | 4/4 mil | 3/3 mil (HDI) |

| โMin. Hole Sizeโ | 8 mil | 4 mil (laser-drilled) |

| โImpedance Controlโ | ยฑ10% (>50ฮฉ) | ยฑ5ฮฉ (โค50ฮฉ) |

| โSurface Finishesโ | ENIG, OSP, HASL | ENEPIG, Hard Gold, Immersion Silver |

3. โRF-Specific Featuresโ

✔ โControlled Impedance Routingโ (microstrip, stripline, coplanar waveguide)

✔ โLow-Loss Plated Through Holes (PTHs)โโ for RF signal integrity

✔ โVia Shielding & Back-Drillingโ to reduce stub effects

✔ โEmbedded Passivesโ (resistors, capacitors) for compact RF designs

✔ โHigh-Precision Laser Cuttingโ for RF antenna arrays

Why Choose EBest Circuit (Best Technology) for RF PCBs?

โ1. Engineering Expertiseโ

- โSignal Integrity Analysisโ (HyperLynx, ADS)

- โEMI/EMC Optimizationโ for RF circuits

- โThermal Management Solutionsโ (metal-core, thermal vias)

โ2. Fast Prototyping & Mass Productionโ

- โ24-hour rapid prototypingโ for RF designs

- โNo MOQ restrictionsโ (ideal for R&D and low-volume RF projects)

- โFull turnkey assemblyโ (SMT, RF testing, box build)

โ3. Quality & Reliabilityโ

✅ โISO 9001:2015 & IATF 16949 Certifiedโ

✅ โ97% On-Time Deliveryโ with real-time WIP tracking

✅ โ100% Electrical Testingโ (including RF parameter validation)

In a nutshell, EBest Circuit (Best Technology) provides โhigh-performance RF PCBsโ with โlow loss, tight impedance control, and superior signal integrity. Whether for โ5G base stations, satellite communications, or IoT devices, we deliver โreliable, high-frequency PCBsโ with fast turnaround and competitive pricing. Pls feel free to contact us for your RF PCB requirements!โโ

What Is the Difference Between RF Printed Circuit Board and Normal PCB?

First, what does RF stand for? It means Radio Frequency. This refers to electromagnetic waves typically ranging from about 3 MHz up to 300 GHz. An RF PCB is designed to carry these high-frequency signals. So, how is it different from a standard PCB used in, for example, a simple toy or a power supply? The difference is profound.

Think of it like this: a normal PCB is like a local road. It handles traffic moving at slower speeds. An RF PCB is like a Formula 1 racetrack. It is engineered for incredible speed and precision. Even the smallest bump or imperfection can cause a disaster.

Here are the three key distinctions:

- โThe Core Material:โโ Standard PCBs often use FR-4, a glass-reinforced epoxy laminate. It is a great general-purpose material. However, for RF signals, FR-4 has a high “loss tangent.” It absorbs signal energy, turning it into heat. RF PCBs use low-loss laminates like PTFE or ceramic-filled hydrocarbons. These materials allow the signal to pass through with minimal loss.

- โThe Importance of Impedance:โโ In standard digital boards, impedance control is often less critical. In RF work, it is everything. Every trace must be precisely calculated and fabricated to maintain a specific characteristic impedance (usually 50 or 75 ohms). This prevents signal reflections and ensures maximum power transfer.

- โThe Design Philosophy:โโ RF circuit PCB design requires accounting for electromagnetic effects that are negligible at lower frequencies. Aspects like skin effect (where current flows only on the conductor’s surface) and parasitic capacitance/inductance become dominant factors. The layout is not just about connecting points; it is about shaping the electromagnetic field.

In short, while all PCBs provide electrical connections, an RF PCB is a carefully tuned component in itself. Its material, layout, and manufacturing are all optimized for guiding high-frequency energy efficiently.

What Is RF PCB Material?

The foundation of any high-performance RF board is its material. RF PCB material is a specialized laminate designed to excel in high-frequency environments. The right choice directly determines the board’s loss, thermal stability, and reliability.

Key properties define a good RF material:

- โDielectric Constant (Dk):โโ This measures how much the material “slows down” an electrical signal. A stable Dk is crucial. If it varies with frequency or temperature, your impedance will be unpredictable. RF materials have a tight Dk tolerance.

- โDissipation Factor (Df) or Loss Tangent:โโ This is perhaps the most critical property. It indicates how much signal energy is lost as heat. A lower Df value means less signal loss. RF materials have an extremely low loss tangent compared to FR-4.

- โThermal Coefficient of Dk:โโ This tells you how much the Dk changes with temperature. A low value means your circuit’s performance remains stable even as it heats up.

- โCoefficient of Thermal Expansion (CTE):โโ Materials expand when heated. A CTE that closely matches that of copper is vital. A mismatch can cause broken connections or delamination during assembly or operation.

Common materials used by an โRF laminate PCB manufacturerโ include PTFE (Teflonยฎ), ceramics, and specialized hydrocarbon resins. Brands like Rogers, Taconic, and Arlon are industry leaders. Selecting the right one is a balance of performance, cost, and manufacturability. This is where an experienced โRF PCB manufacturer in Chinaโ or elsewhere can provide invaluable guidance.

What Is RF Circuit PCB Design?

RF circuit PCB design refers to the process of designing printed circuit boards that handle signals in the radio frequency range, typically above 30 MHz. These boards serve as the physical platform for amplifiers, antennas, mixers, and oscillators used in wireless systems.

The primary goal is to preserve signal integrity while reducing loss and unwanted coupling. Unlike low-frequency designs, where DC resistance dominates, RF design must account for distributed parametersโinductance (L) and capacitance (C)โthat vary along the trace.

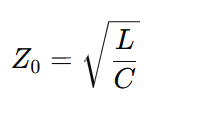

The characteristic impedance Z0 is central to RF PCB design, defined as:

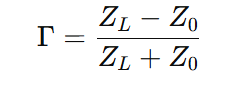

A mismatch between source and load impedances leads to reflections, quantified by the reflection coefficient:

Where ZL is the load impedance. To minimize reflections and achieve efficient power transfer, ZL must closely match Z0, usually 50 ฮฉ for most RF systems.

Key Design Principles of RF PCBs

Controlled Impedance Design

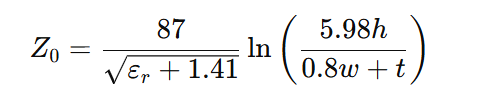

Every RF trace functions as a transmission line, not just a conductor. The impedance depends on geometry and dielectric properties. For microstrip structures, the impedance is approximated by:

where:

- (h): dielectric height,

- (w): trace width,

- (t): copper thickness,

- ฮตr: dielectric constant.

A deviation of even ยฑ10% from the target impedance can distort RF signals, increasing insertion loss and reflection.

Impedance Matching

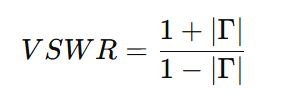

Impedance matching ensures maximum power transfer between circuit stages. When mismatch occurs, reflected energy travels back to the source, forming standing waves. The relationship between reflection coefficient and Voltage Standing Wave Ratio (VSWR) is:

In practice, designers use Smith charts, stub tuners, or LC matching networks to visualize and optimize matching.

Transmission Line Effects

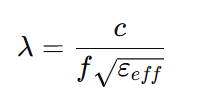

At RF frequencies, traces behave like distributed elements rather than lumped components. Propagation delay, attenuation, and coupling must be analyzed using electromagnetic simulation. The wavelength ฮป is given by:

where (c) is the speed of light, (f) the frequency, and ฮตeffโ the effective dielectric constant.

Material Selection for RF PCB

The choice of substrate determines dielectric stability and signal loss.

| Material | Dielectric Constant (ฮตr) | Loss Tangent (tanฮด) | Frequency Stability | Typical Use |

|---|---|---|---|---|

| FR-4 | 4.2โ4.7 | 0.02 | Poor above 1 GHz | Low-cost applications |

| Rogers RO4350B | 3.48 | 0.0037 | Excellent up to 10 GHz | RF amplifiers, filters |

| PTFE (Teflon) | 2.1 | 0.0009 | Outstanding up to 30 GHz | Aerospace, radar systems |

Key considerations:

- Lower tanฮด means lower dielectric loss.

- Stable ฮตrโ ensures consistent impedance.

- Surface roughness of copper affects conductor loss, especially at GHz frequencies.

PCB Stack-up and Geometry

RF designs usually adopt multilayer stack-ups to separate high-frequency and control layers. A common four-layer configuration might include:

- Top Layer โ RF signal traces

- Inner Layer 1 โ Solid ground plane

- Inner Layer 2 โ Power plane

- Bottom Layer โ Control and bias circuits

Proper ground referencing is vital. The return path should be directly beneath the signal line to maintain uniform impedance. Vias must be minimized or placed symmetrically to prevent inductive discontinuities.

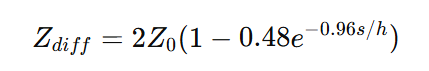

Differential routing is used for balanced RF lines (e.g., antennas or mixers). The differential impedance Zdiff is roughly:

where (s) is the spacing between differential traces.

Layout and Routing Techniques

Minimizing Coupling and Crosstalk

Keep high-power and low-power RF paths separated. Perpendicular routing between layers reduces unwanted coupling.

Shielding Methods

Use guard traces and via fences around sensitive lines. Stitching vias at 1/20th wavelength intervals confine electromagnetic fields effectively.

Return Path Optimization

Ensure ground continuity with via stitching near corners or component pads. Avoid long current loops that may radiate noise.

Simulation and Testing in RF PCB Design

RF verification relies on both simulation and measurement.

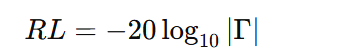

- S-Parameter Analysis:

- S11: Return loss (input reflection).

- S21: Insertion loss (forward transmission).

- Ideal design targets:

- S11< -10 dB)

- S21 > -3 dB)

The Return Loss formula is:

- Time Domain Reflectometry (TDR): Detects impedance discontinuities along traces.

- Network Analyzer Testing: Validates gain, phase shift, and bandwidth performance.

Accurate measurement ensures the PCB meets design specifications before mass production.

Applications of RF Circuit PCB

RF PCBs are embedded in numerous systems:

- Wireless communication modules (Wi-Fi, Bluetooth, LTE)

- IoT sensors and gateways

- Automotive radar and collision avoidance systems

- Satellite and aerospace communication

- Medical telemetry and imaging devices

As the world transitions to 5G and beyond, RF PCB design has become central to achieving higher data rates and stable wireless connections.

Technical Capability for RF PCB Manufacturer

At EBest Circuit (Best Technology), our RF PCB manufacturing capabilities are built on nearly two decades of specialized experience in high-frequency circuit fabrication. We combine state-of-the-art equipment with rigorous quality control processes to deliver PCBs that meet the demanding requirements of modern RF applications, from 5G infrastructure to aerospace systems.

โ1. Precision Manufacturing with Advanced Equipmentโ

- โLaser Direct Imaging (LDI)โโ

- Min. trace/space: โ3/3 mil (standard) โ 1/1 mil (advanced)โโ

- Copper thickness: Inner layers (HOZ-20OZ) | Outer layers (1OZ-20OZ)

- โPlasma Etching Systemsโ

- Critical for RF signal integrity, supports โ10:1 aspect ratio microviasโ and โ0.15mm ultra-fine holesโ

โ2. Rigorous RF Performance Validationโ

- โ40GHz Network Analyzersโ

- Direct measurement of insertion loss/return loss up to โ40GHzโ

- โTime-Domain Reflectometry (TDR)โโ

- Full-path impedance control: โโยฑ5% (standard) | ยฑ3% (advanced)โโ

- โMaterial Characterizationโ

- โDk/Df testingโ for Rogers, Taconic, and other high-frequency laminates

โ3. RF-Optimized Material Portfolioโ

| โMaterial Classโ | โStandard Optionsโ | โHigh-Frequency Solutionsโ |

|---|---|---|

| FR4 | KB6165 (TG150) | Isola 370HR, FR408HR |

| High-Frequency Laminates | โ | Rogers 4350/5880, Taconic TLY-5 |

| Ultra-Low Loss Materials | โ | Nelco N4000-13, PTFE-based substrates |

| โDielectric Layersโ | 1080/2116/7628 PP | Ultra-thin cores (0.1mm, copperless) |

โ4. Key Process Capabilitiesโ

- โImpedance Controlโ

- Inner layers (1OZ): ยฑ5% (4/4mil) โ โโยฑ3% (3/3mil)โโ

- โHigh-Frequency Surface Finishesโ

- ENIG (Ni 3-8ฮผm | Au 0.025-0.125ฮผm) for โmmWave applicationsโ

- Electroless NiPdAu (Pd 0.05-0.125ฮผm) for superior solderability

โ5. Multilayer RF PCB Expertiseโ

- โLayer Stack-Up: 1-32 layers (High-TG mandatory for 8+ layers)

- โThickness Control:

- Ultra-thin: โ0.15mmยฑ0.05mmโ (ENIG only)

- Thick-board: โ8.0mmโ (special back-drilling)

- โHybrid Construction: FR4 + Rogers material combinations

โ6. Scalable Production & Fast Turnkeyโ

- โMax. Panel Size: 1980mm (single/double-sided) | 750mm (multilayer)

- โHigh-Mix Flexibility:

- Supports โ2,000pcs/batchโ for ultra-small boards (<0.0004mยฒ)

7. Design Support Servicesโ

- DFM (Design for Manufacturing) analysis for RF layouts

- Signal integrity and thermal management consulting

- Material selection guidance based on application requirements

- Rapid prototyping with engineering feedback within 24 hours

Through continuous investment in advanced equipment and process optimization, EBest Circuit (Best Technology) maintains its position as a leading RF PCB manufacturer capable of meeting the most demanding high-frequency application requirements.

How Do RF Laminate PCB Manufacturers Ensure Quality?

Quality in RF manufacturing is not an afterthought. It is integrated into every step. For an โRF laminate PCB manufacturer, ensuring quality means controlling every variable that could affect the final electrical performance. The process is meticulous.

- โIncoming Material Inspection:โโ It starts with the raw laminate. We verify the dielectric thickness and copper cladding weight against specifications. Using a material with the wrong Dk will ruin the entire batch.

- โProcess Control During Fabrication:โโ We constantly monitor critical parameters. Etching chemistry, lamination pressure and temperature, and plating thickness are all tightly controlled. This consistency is key to achieving the designed impedance.

- โElectrical Testing:โโ 100% of our RF boards undergo electrical testing. We use fixtures to test for continuity (no shorts or opens). More importantly, we sample-test boards for high-frequency parameters like impedance and loss, ensuring they meet the customer’s data sheet.

- โMicrosection Analysis:โโ We regularly cross-section sample boards. This allows us to physically measure critical features: trace width, dielectric thickness, and plating quality. This data confirms our processes are in control.

This systematic approach separates a true specialist from a general-purpose fabricator. It is how we guarantee that the board you receive will perform exactly like the one you designed.

How to Select RF PCB Manufacturers?

Choosing the right partner is critical. Your โRF PCB designโ’s success depends on their skill. Here is a simple checklist to help you select an โRF PCB manufacturer.

- โProven Experience:โโ Ask for examples of previous work. A good โRF microwave PCB manufacturerโ will have a portfolio of projects similar to yours.

- โTechnical Questions:โโ Gauge their expertise. Ask them how they control impedance or which materials they recommend for your frequency band. Their answers will reveal their depth of knowledge.

- โQuality Certifications:โโ Look for ISO 9001 certification. This shows a commitment to a documented quality management system.

- โTesting Capabilities:โโ Ensure they have the necessary equipment to verify RF performance, not just basic connectivity.

- โCommunication and Support:โโ You need a responsive partner. Choose a manufacturer that assigns a dedicated engineer to your project for clear and technical communication.

Whether you are looking for an โRF PCB manufacturer in the USA, China, or Europe, these core criteria remain the same. The goal is to find a partner, not just a supplier.

Case Study: RF Microwave PCB Board Manufacture by EBest Circuit (Best Technology)โ

โChallenge: High-Frequency Signal Integrityโ

A 5G base station OEM required โ24-layer RF microwave PCBsโ with:

- โStrict impedance controlโ (ยฑ3%) for 28GHz mmWave signals

- โLow-loss laminateโ (Df <0.004) to minimize attenuation

- โPlated through-holes (PTH) with 10:1 aspect ratioโ for dense interconnects

โOur Manufacturing Solutionโ

- โMaterial Expertise:

- Selected โRogers 5880โ (Dk=2.2, Df=0.0009) for critical RF layers

- Hybrid stack-up with โFR408HRโ for cost-sensitive digital layers

- โAdvanced Processes:

- โLaser-drilled microviasโ (0.10mm) + โplasma desmearโ for void-free plating

- โ3/3 mil trace/spaceโ with ยฑ2ฮผm alignment tolerance (LDI technology)

- โQuality Validation:

- โ40GHz network analyzerโ confirmed insertion loss <0.15dB/inch

- โ100% TDR testingโ ensured impedance consistency across panels

โEBest Circuit (Best Technology)โs RF Microwave PCB Capabilitiesโ

◼ โMaterials: Rogers, Taconic, Isola, Nelco, PTFE, and hybrid FR4 options

◼ โCritical Tolerances:

- Line width/spacing: โ1/1 milโ (special process)

- Hole size: โ0.10mm (laser)โโ | โ0.15mm (mechanical)โโ

- Impedance control: โโยฑ3%โโ (standard), โโยฑ2%โโ (advanced)

◼ โTesting: - 40GHz RF performance validation

- TDR, thermal cycling, IST (interconnect stress testing)

◼ โApplications: 5G mmWave, satellite comms, radar, medical RF devices

In conclusion, an โRF PCB manufacturerโ bridges the gap between high-frequency theory and real-world application. This article has explored the critical aspects that define quality in RF circuit board production. From material science to precision manufacturing, each step is vital for success.

At EBest Circuit (Best Technology), we are passionate about tackling complex RF and microwave challenges. Our expertise in โRF circuit PCB designโ and manufacturing ensures your project is built to the highest standards. We are committed to being your reliable partner. Pls contact our team of experts at โsales@bestpcbs.com for RF PCB manufacturing supports.