What is MCPCB design?

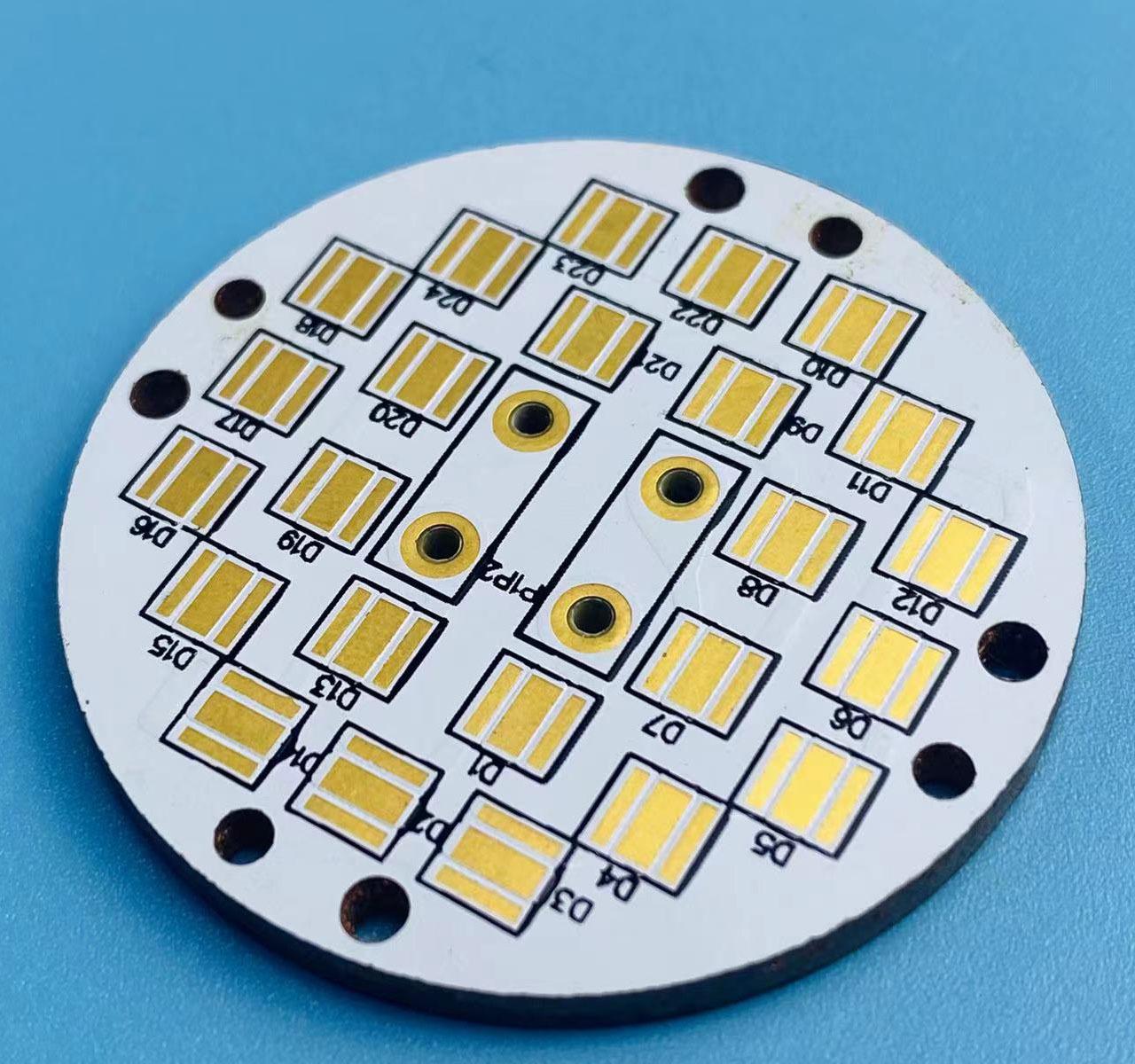

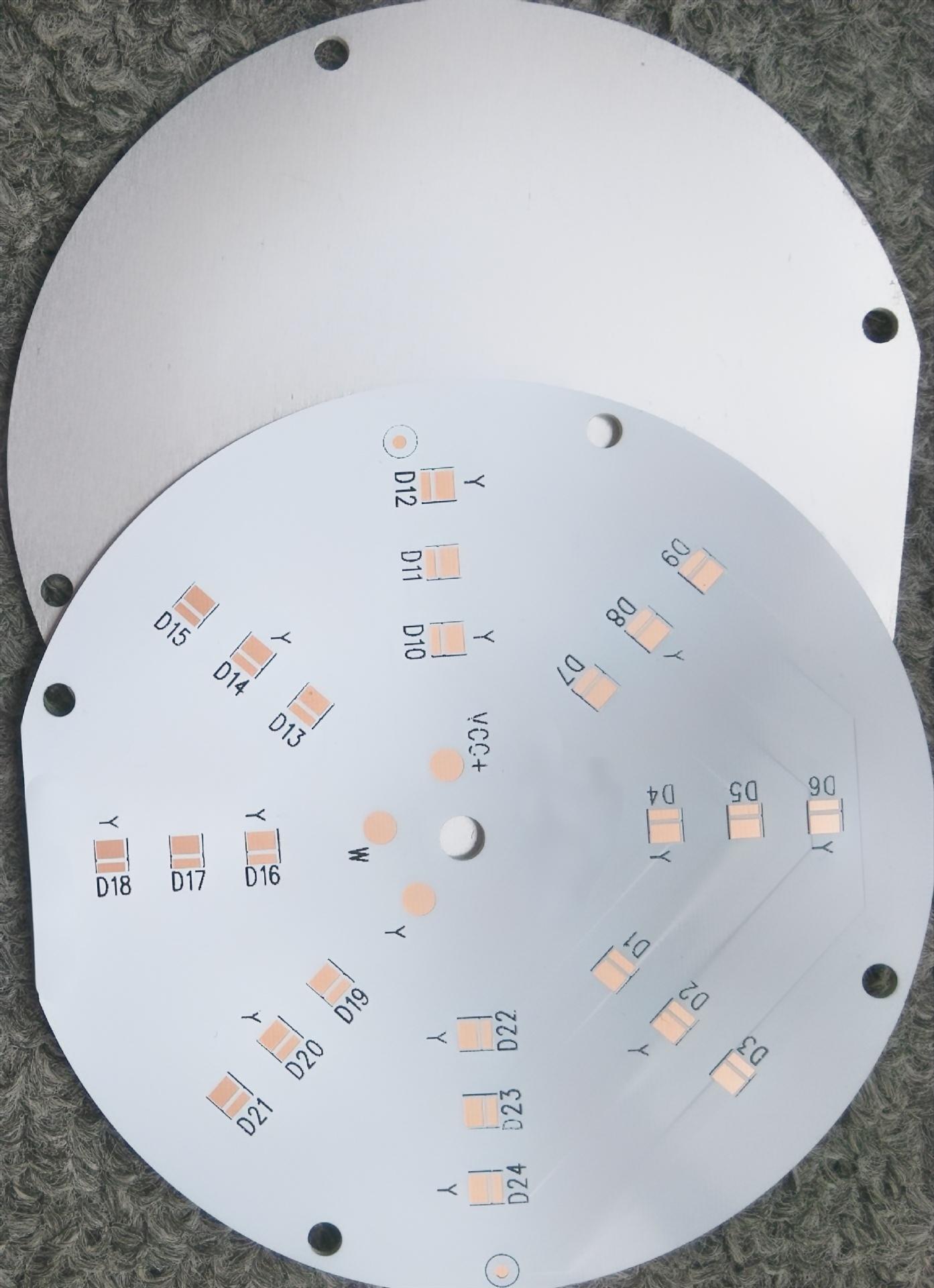

MCPCB stands for Metal Core Printed Circuit Board. Unlike regular PCBs made with fiberglass, MCPCBs use a metal base—usually aluminum or copper—as their core layer. This helps carry heat away from components. In MCPCB design, attention should be paid not only to the electrical layout but also to the thermal flow and mechanical strength.

MCPCBs are ideal for LED lights, power supplies, automotive electronics, and high-temperature environments. Their main job is to conduct heat away from sensitive components while maintaining solid electrical performance.

So, what is MCPCB design? It’s the process of creating a printed circuit board with a metal core that balances power, heat, and cost—all in one compact board.

What is the MCPCB definition?

By definition, an MCPCB is a circuit board that contains:

- A copper circuit layer for electrical conductivity.

- A dielectric layer for insulation.

- A metal base for heat dissipation (aluminum or copper).

The “MC” in MCPCB represents the metal core, which is what sets it apart from standard PCBs. This unique core allows the board to perform better in thermal management, giving it a clear edge in high-power applications.

In simpler terms, MCPCB = Metal + Circuit + Insulation, all working together.

How does MCPCB design affect cost and performance?

When done right, MCPCB design helps reduce overheating, extends component life, and cuts maintenance costs. But if the thermal path isn’t optimized or trace routing isn’t clean, you might face issues like:

- Poor heat dissipation

- Solder joint failure

- Component damage

- Lower LED brightness

All of this can push your costs up. A smart design, on the other hand, balances performance and cost from the beginning. For example:

- Using aluminum instead of copper reduces cost without hurting performance for most LED boards.

- Selecting the right dielectric material keeps the board thin while ensuring heat is controlled.

- Clear trace paths help maintain signal integrity and reduce EMI.

What’s the difference between MCPCB and standard PCBs?

Standard PCBs use FR4 (a fiberglass-reinforced epoxy) as the core. They work well in normal-temperature environments. But as power or current increases, they heat up quickly. And they don’t cool down fast.

MCPCBs, on the other hand, are built for heat. They use a metal core (usually aluminum) instead of FR4. This change gives them superior thermal conductivity, making them ideal for high-power devices.

Let’s put it in simple terms:

- Standard PCB = Best for low-heat, general electronics.

- MCPCB = Best for high-heat, high-performance applications.

This key difference changes how you approach layout, stack-up, and assembly. That’s why MCPCB design must be treated differently from standard boards.

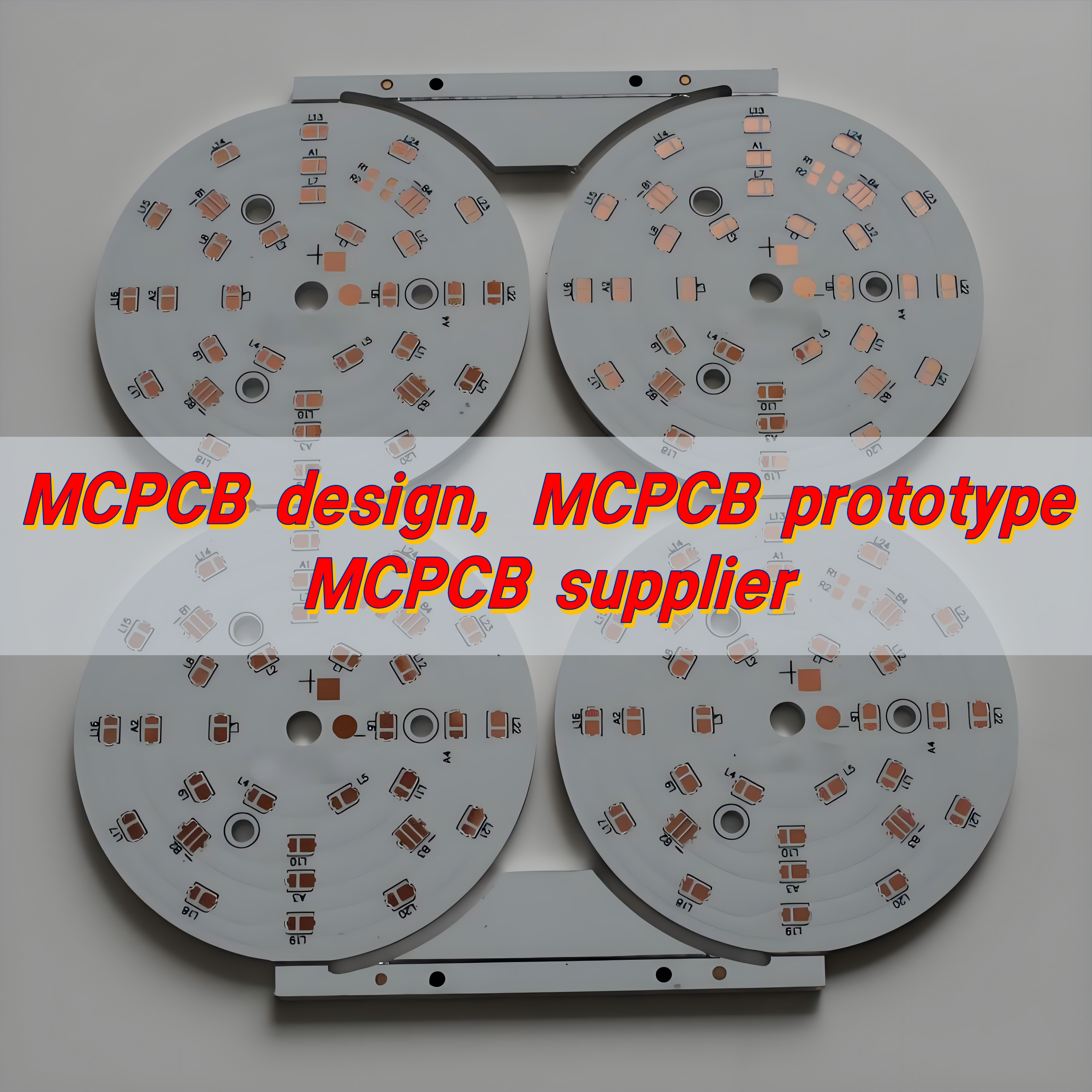

Why use MCPCB prototype for testing?

Testing MCPCB prototypes before committing to mass production can save you a ton of money and weeks of lost time.

A prototype helps you:

- Test thermal behavior in real conditions

- Check for design flaws or unexpected hot spots

- Ensure your LED PCB maintains brightness under load

- Evaluate material quality from your chosen MCPCB supplier

Also, prototyping speeds up development. You get real data fast. This keeps your timeline tight and your product launch on track.

What are key MCPCB design guidelines?

Designing a metal core PCB takes a different mindset. Follow these essential MCPCB design guidelines:

- Know your heat source: Place hot components close to vias or thermal pads.

- Use wide copper traces: Helps current flow without resistance.

- Choose the right metal base: Aluminum for cost-efficiency; copper for higher thermal performance.

- Mind your dielectric layer: Thin layers cool better, but must still insulate properly.

- Leave room for expansion: Heat causes expansion. Mechanical stress can break solder joints.

The more you follow these core rules, the better your board will perform and the longer its actual service life will be.

Why is MCPCB design critical for LED PCB?

LEDs are sensitive. As their temperature increases, their brightness drops. At high temps, their lifespan can also shrink dramatically. That’s why LED lighting depends on MCPCBs to manage heat efficiently.

With a properly designed LED PCB, you get:

- Brighter output with less energy

- Longer LED life

- Stable color over time

- No flicker or degradation

Poor thermal design can degrade LED performance, even if the rest of the circuit is very robust. MCPCB design can protect LED performance.

If you’re in automotive, medical, or commercial lighting, this can make or break product quality.

How is aluminum PCB better for LEDs?

When comparing aluminum PCBs to standard fiberglass ones for LEDs, aluminum wins by a landslide. Here’s why:

- Aluminum conducts heat better: It draws heat away from the LED’s base.

- It’s lightweight and strong: Perfect for compact fixtures.

- It reduces component failure: Lower heat = longer life.

- It’s cost-effective: Compared to copper, aluminum gives great performance without high cost.

Aluminum MCPCBs have become the gold standard for LED applications. They offer the right balance of thermal conductivity, cost, and mechanical strength.

How to choose the right MCPCB supplier?

With nearly two decades of experience, EBest Circuit (Best Technology) offers consistent quality, fast delivery, and responsive support.

When choosing a supplier, look for these essentials:

- In-house MCPCB design services: At EBest Circuit (Best Technology), our expert engineering team collaborates closely with you to streamline development and eliminate communication delays.

- Prototyping capabilities: We offer rapid MCPCB prototype production.

- Material transparency: We use only verified raw materials, including high-purity aluminum and top-tier dielectric insulation, ensuring long-lasting performance.

- Certifications and experience: EBest Circuit (Best Technology) is ISO9001:2015 certified, RoHS/REACH compliant, and trusted by global customers across automotive, medical, industrial, and lighting sectors.

- Quick technical support: Our 48-hour technical response commitment ensures that your questions are answered when you need them most.

- Providing customized solutions: from unique thermal stack-ups to integrated LED designs

Conclusion:

MCPCB design plays a vital role in ensuring performance, reliability, and thermal control in modern electronics—especially in LED PCBs and high-power applications.

And selecting a trusted MCPCB supplier—like EBest Circuit (Best Technology)—ensures expert support, fast prototyping, and consistent quality from concept to production.

Need help with MCPCB design, prototyping, or sourcing? Contact us at sales@bestpcbs.com to get started.

Tags: aluminum pcb, mcpcb definition, mcpcb design, MCPCB prototype, MCPCB supplier