When engineers start a new project or a graduating students want to complete a graduation project, one of the first questions they ask is: How much does a PCB board cost? The answer depends on several factors like size, layers, material, and whether assembly is included. Whether you’re prototyping or mass-producing, understanding PCB board price helps you budget better and avoid hidden costs. In this guide, we’ll break down the basics of pcb board price, answer some of the most common questions, and show how to save money without compromising on quality.

What Is the Difference Between a Circuit Board and a PCB?

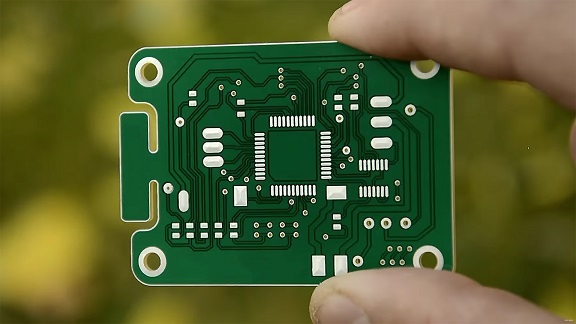

Before break down the cost of PCB, let’s explain the difference between circuit board and a PCB. Although people often use the terms interchangeably, there’s a slight difference. A circuit board is a general term that can refer to any board used in an electronic device.

A PCB (Printed Circuit Board) is a specific type that uses conductive tracks etched onto a substrate, usually FR4 or ceramic. All PCBs are circuit boards, but not all circuit boards are PCBs. When we talk about pcb board price, we usually mean a professionally manufactured, layered board ready for component mounting.

How Much Does PCB Cost Per Square Inch?

On average, the pcb board price per square inch ranges from $0.50 to $5, depending on the complexity and order size. For basic two-layer PCBs made in large volumes, the cost can be on the lower end. But for high-frequency, multi-layer, or specialty material boards, the price goes up.

| PCB Type | Price Per Square Inch |

| Basic 2-layer FR4 PCB | $0.50 – $1.00 |

| 4-layer PCB | $1.50 – $2.50 |

| 6+ layer PCB | $2.50 – $4.50 |

| Ceramic or metal-core | $3.00 – $5.00+ |

These prices vary by manufacturer, lead time, surface finish, and testing requirements.

What Factors Affect PCB Board Price?

Several factors play a critical role in determining the PCB board price, the most influential factors include:

1. Number of Layers

The more layers a PCB has, the higher the cost. A 2-layer board is relatively inexpensive to fabricate, but as you move to 4, 6, or even 10 layers, the complexity increases significantly. Each additional layer means more lamination cycles, drilling, and alignment steps.

2. Board Size and Shape

Larger boards use more material, which drives up the price. Unusual shapes that require non-standard routing also increase the manufacturing complexity, sometimes requiring custom tooling or manual cutting.

3. Material Selection

Standard FR4 is the most cost-effective material. However, specialty substrates such as ceramic, aluminum, polyimide, or Rogers laminates are much more expensive. These are often used for high-frequency or high-heat applications and add to the total cost.

4. Trace Width and Spacing

High-density designs with narrow traces and tight spacing require more precise manufacturing, which involves advanced processes and tighter quality control. That adds cost due to increased difficulty and possible yield loss.

5. Surface Finish

Finishes like HASL (Hot Air Solder Leveling) are economical, while others like ENIG, ENEIG and Immersion Silver add durability but come at a premium. The choice depends on the soldering process and environmental conditions.

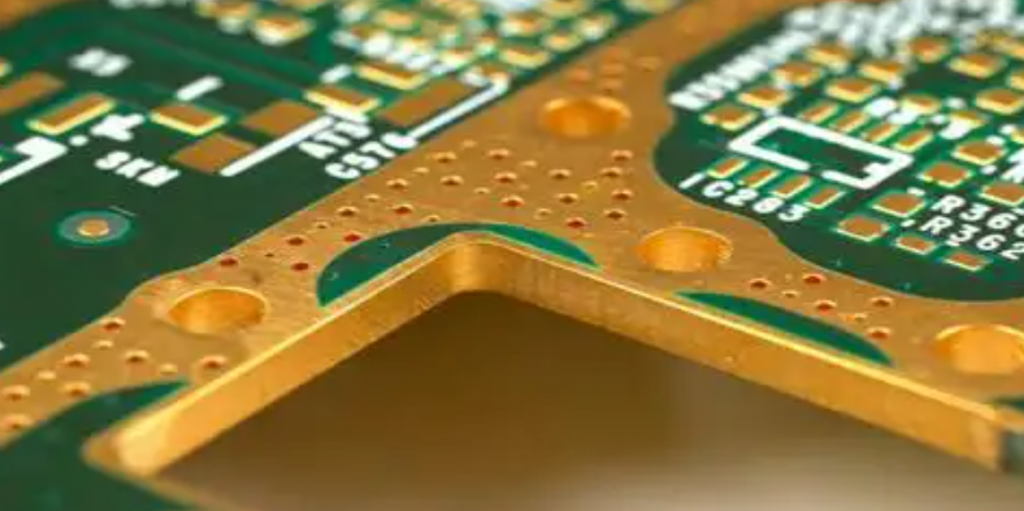

6. Via Type and Count

Through-hole vias are cheaper, but blind and buried vias, microvias, or via-in-pad structures add extra drilling and lamination steps. These specialized vias are common in HDI (High-Density Interconnect) boards and push the cost higher.

7. Solder Mask Color

Green is standard and least expensive. Other colors such as red, black, white, or blue may cost slightly more. Clear or custom colors are rare and usually priced higher.

8. Turnaround Time

Shorter lead times often require priority in the production queue and overtime labor, which increases costs. Standard production schedules offer better pricing if you’re not in a rush.

How Much Does PCB Assembly Cost?

PCB board price doesn’t include assembly unless specified. PCB assembly (PCBA) adds labor, equipment use, and component sourcing into the cost. On average:

- Simple boards (fewer than 50 components): $5 – $20 per board.

- Medium complexity: $20 – $30 per board.

- High complexity or low volume with many components: $30+ per board.

For large runs, the price drops significantly, often down to a few dollars per board for simple designs. Using turnkey assembly (where the manufacturer handles everything) is usually cheaper in bulk.

How to Reduce PCB Cost on Printed Circuit Boards?

Here are some proven ways to bring down your pcb board price without sacrificing quality:

1. Design with standard board sizes, FR4 material, and common thickness (1.6mm) to avoid customization fees.

2. Reduce the number of layers if possible. Reusing reference designs or optimizing layout to avoid unnecessary complexity can significantly lower manufacturing costs.

3. If you’re ordering small PCBs, ask your manufacturer to panelize multiple boards in one larger sheet. This can improve production efficiency and reduces per-unit costs.

4. Unless you need advanced protection or plan multiple soldering cycles, HASL can be a suitable and affordable finish.

5. Reducing the number of different drill sizes simplifies the manufacturing process and lowers setup costs.

6. High-volume production significantly lowers the cost per unit. If you can predict demand, batch your orders for better pricing.

Working with an experienced and flexible PCB manufacturer like EBest Circuit (Best Technology) allows you to get valuable feedback on cost-saving opportunities without compromising functionality. We provide full DFM checks to avoid rework costs.

How to Choose a PCB Board?

Choosing the right PCB for your project helps ensure reliability while controlling the pcb board price. Here’s what to consider:

1. Application Requirements

If you’re working on a consumer product, a standard FR4 board will do. But for high-power LEDs, RF circuits, or automotive electronics, you may need special materials like Rogers, Dupont.

2. Electrical Performance

Check if your circuit demands controlled impedance, high-frequency transmission, or thermal management. The right material and layout will support this without unnecessary expense.

3. Size and Component Density

Tight spaces or miniaturized designs may require multi-layer boards or HDI technology. Choose your layer count based on how compact your design needs to be.

4. Budget and Volume

For low-volume projects, it’s often better to work with manufacturers who support small batch or prototype services. For production runs, choose a vendor that offers scalable pricing.

For most general electronics, a 2-layer FR4 PCB will do the job. But for high-power LEDs, RF applications, or miniaturized devices, materials like aluminum, ceramic, or Rogers laminates may be required. Consult with a professional PCB manufacturer like EBest Circuit (Best Technology) to get a cost-effective and reliable solution tailored to your needs.

What Is the Most Common PCB Thickness?

The industry standard for PCB thickness is 1.6mm (0.063 inch). It offers good balance between mechanical strength and space savings. However, depending on application, PCBs can range from 0.4mm to over 3.2mm.

Can I Make My Own PCB Board?

Yes, you can make a basic PCB at home using copper-clad boards and etching chemicals. But DIY boards are only suitable for low-frequency, non-critical applications. They lack the precision, durability, and reliability of professional boards.

If you need consistent performance, especially in multi-layer or fine-pitch designs, outsourcing to a PCB fabrication specialist is the best route. At EBest Circuit (Best Technology), we offer cost-effective PCB solutions with fast turnaround and tight quality control. Whether you’re prototyping or scaling up, our engineering team is here to help.

FAQs

1. Is it cheaper to order PCBs from China?

Yes. Many Chinese manufacturers like EBest Circuit (Best Technology) offer excellent prices and quality due to economies of scale and efficient production lines.

2. Can I get a single PCB prototype made?

Absolutely. Many companies offer low-volume or single-piece orders for prototyping purposes.

3. Do PCB prices include components?

Not usually. PCB board price refers to the bare board. Assembly and components are charged separately.

4. Is ENIG finish worth the extra cost?

If you need better surface flatness, corrosion resistance, or plan multiple reflows, ENIG is a good investment.

5. What’s the lead time for PCB manufacturing?

Standard is 5–7 days. Express options range from 24 to 72 hours, depending on the manufacturer.

Tags: pcb board cost, pcb board price