SMT (Surface Mounted Technology) is the most popular Technology and process in electronic assembly industry. SMT refers to a series of process processes based on PCB. Due to the better outcome and higher efficiency, SMT has become the primary approach used in the process of PCB assembly. In some extent, the turn-key service is a way to reduce the cost.

There are the SMT progressing in the following.

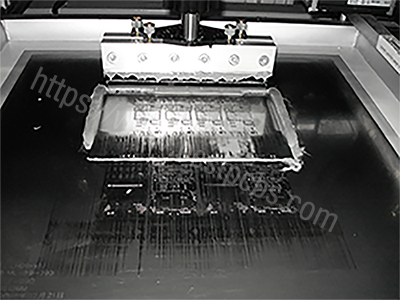

1. Solder paste printing: The function is to print the solder paste to the PCB pad to prepare for the welding of components. The screen-printing machine is located at the front end of SMT production line.

2. Part mounting: The function is to accurately install surface assembly components into fixed positions on the PCB. The equipment is the SMT machine, located behind the screen-printing machine in the SMT production line.

3. Furnace curing: its function is to melt the patch adhesive, so that the surface assembly components and PCB board firmly stick together. The equipment used is the curing furnace, located behind the SMT machine in the SMT line.

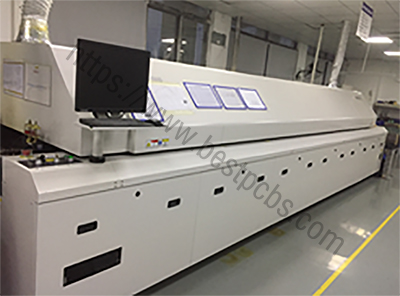

4. Reflow welding: The function is to melt the solder paste, so that the surface assembly components and PCB board firmly stick together. The reflow furnace is located behind the SMT machine in the SMT line.

5. AOI optical detection: its function is to detect the welding quality and assembly quality of assembled PCB board. The equipment used is automatic optical detection (AOI)

6. Maintenance: its function is to detect the failure of the PCB board for repair. The tools used are soldering iron, repair workstation and so on. Configured after AOI optical detection.

7.Dividing board: its function is to cut PCBA of multiple connecting boards, so that they are separated to form a single individual, generally using V-cut and machine cutting.

8. Grinding plate: its role is to scrub the burr parts to make them smooth and flat.

9. Washing plate: its function is to remove welding residues such as flux and other harmful to human body on assembled PCB board and manually clean it.

Turnkey service reduces customers’ time in contacting with multiple suppliers for separate steps in PCB assembly manufacturing. And the scientific order arrangement system allows customers to get PCB assembly products with higher quality and less cost in a shorter time than the traditional way of PCB assembly.