Seeking for PCB fabrication specifications? This guide covers all critical aspects from material selection to final panel dimensions for reliable PCB manufacturing.

With 18+ years of PCB manufacturing expertise, Best Technology delivers reliable solutions through standardized production processes, every operation follow PCB fabrication specifications to ensure consistency. Our advanced manufacturing capabilities support all surface finishes (ENIG, OSP, immersion silver/tin) and specialty boards including HDI (up to 20 layers), RF (controlling Īµr Ā±0.2), and heavy copper board (6oz+). Competitive pricing with transparent cost structures eliminates hidden fees, while 100% batch inspection guarantees defect rates below 500ppm. We can achieve 24-hour prototype turnaround (from Gerber to shipment) and volume production lead times 30% shorter than industry averages, enabling clients to accelerate time-to-market. For high-mix applications from 5G antennas to industrial controllers, our engineering team resolves fabrication challenges through adaptive process optimization. Welcome to contact us for a quote now: sales@bestpcbs.com.

Definition of PCB Fabrication Specifications

PCB fabrication specifications define the precise technical requirements for manufacturing printed circuit boards, encompassing material properties, dimensional tolerances, processing methods, and quality validation criteria. These specifications document essential parameters such as laminate material grades, copper weight tolerances (typically Ā±10%), drilling positional accuracy (Ā±0.05mm standard), plating thicknesses (25Ī¼m minimum for through-holes), solder mask application standards (15-25Ī¼m LPI thickness), and surface finish requirements (e.g., ENIG with 3-5Ī¼m nickel layer). They establish testing protocols including impedance control verification (Ā±10% tolerance), microsection analysis for plating quality, and IPC Class 2/3 acceptance criteria for visual defects. The specifications also address panelization rules (V-cut depth tolerances), environmental conditioning procedures (thermal stress testing), and final packaging standards (moisture barrier bags with desiccant). By systematically defining these manufacturing parameters, PCB fabrication specifications ensure consistent production quality while maintaining compatibility with assembly processes and end-use operating conditions.

Substrate for PCB Fabrication Specifications

Below are substrate for PCB fabrication specifications :

- Dielectric Constant (Dk) Stability: Choose materials with consistent Dk values across frequencies to minimize signal distortion. For high-speed designs, low-Dk laminates (e.g., 3.2ā3.8) reduce propagation delays, ensuring timing accuracy in applications like 5G or servers.

- Thermal Management Capabilities: Prioritize high thermal conductivity (e.g., 0.8ā2.0 W/mĀ·K) for power electronics or LED boards to prevent overheating. Materials with decomposition temperatures (Td) above 300Ā°C withstand lead-free soldering without delamination or warping.

- Moisture and Chemical Resistance: For automotive or outdoor devices, select substrates with low moisture absorption (<0.1% per IPC-TM-650) to avoid swelling, delamination, or electrical leakage. Chemical-resistant finishes further enhance durability in harsh environments. Mechanical Strength and Flexibility: Rigid-flex designs require polyimide or similar flexible substrates with high tensile strength (e.g., >200 MPa) to endure bending cycles without cracking. Rigid boards may use FR-4 or high-Tg epoxy for structural stability.

- Impedance Control Requirements: Materials with tight dielectric thickness tolerances (e.g., Ā±5%) ensure consistent impedance for differential pairs or RF traces. This precision prevents reflections and signal integrity issues in high-frequency circuits.

- āCost vs Performance Balance: Thicker foils increase material costs by ~15ā30% per step but reduce resistive losses in power electronics.

Copper Foil Thickness & Tolerance For PCB Fabrication Specifications

Copper foil thickness and tolerance of PCB fabrication specification:

- Standard Thickness Optionsā: Covers common weight classes: Ā½ oz (17.5 Āµm), 1 oz (35 Āµm), 2 oz (70 Āµm), and 3 oz (105 Āµm) per square foot. Thinner foils (ā¤Ā½ oz) suit high-density designs, while thicker foils (ā„2 oz) handle high-current traces.

- Manufacturing Tolerancesā: Specifies Ā±10% thickness tolerance for rolled/electrodeposited foils post-etching. Tighter tolerances (Ā±5%) are achievable for impedance-controlled layers through process controls.

- Surface Roughness Parametersā: Defines peak-to-valley roughness (Rz ā¤5 Āµm for standard foils, ā¤1.2 Āµm for low-profile RF applications) to balance adhesion and high-frequency signal integrity.

- Ductility and Elongationā: Requires elongation rates >8% for flexible circuits to withstand bending, while rigid PCBs typically tolerate 3ā5% elongation.

- Current-Carrying Capacityā: Correlates thickness with ampacity: 1 oz foil supports ~1A per 10 mil trace width at 10Ā°C temperature rise, scalable for thicker foils.

- Impedance Control Implicationsā: Thickness variations directly affect trace impedance. A Ā±7% thickness shift may cause Ā±2Ī© deviation in 50Ī© designs, necessitating tighter controls for high-speed layouts.

- Plating Compatibilityā: Ensures foil surfaces accommodate subsequent copper plating (e.g., 25 Āµm hole wall plating) without delamination risks through adhesion testing.

Drilling & Routing Tolerances Specification For PCB Manufacturing

Drilling and routing tolerances of PCB fabrication specification:

- Drilling & Routing Tolerances Specifications: Hereās a structured breakdown of Drilling & Routing Tolerances Specifications for PCB fabrication, designed for clarity and practical application:

- Hole Diameter Tolerance: Standard drilled holes maintain Ā±0.05 mm (Ā±2 mil) tolerance for diameters ā„0.3 mm, while microvias (<0.15 mm) require tighter controls (Ā±0.025 mm). Laser-drilled holes achieve Ā±0.01 mm precision for HDI designs.

- Hole Position Accuracy: Specifies Ā±0.075 mm (Ā±3 mil) positional tolerance relative to datum, critical for multilayer registration. Optical alignment systems reduce this to Ā±0.05 mm for high-density interconnects.

- Routing Edge Tolerance: Outlines Ā±0.1 mm (Ā±4 mil) tolerance for board outlines and cutouts, with Ā±0.05 mm achievable for RF shields or press-fit components.

- Aspect Ratio Limits: Defines maximum 10:1 aspect ratio for mechanical drilling (e.g., 0.3 mm hole depth for 0.03 mm diameter), extending to 15:1 with laser drilling.

- Burr and Roughness Standards: Requires hole wall roughness <25 Āµm Ra to ensure uniform plating adhesion, with burr height <50 Āµm to prevent solder masking issues.

- Slot Width and Spacing: Controls slot widths (Ā±0.1 mm tolerance) and minimum 0.2 mm spacing between adjacent routed features to avoid mechanical stress fractures.

- Tool Wear Compensation: Accounts for drill bit wear (Ā±0.02 mm diameter increase per 1,000 hits) through automated diameter correction systems.

- Material-Specific Considerations: Adjusts feed rates for FR-4 (0.8ā1.2 m/min) versus ceramic substrates (0.3ā0.5 m/min) to minimize smearing or cracking.

Plating Thickness Standardsā

Hereās a practical breakdown of āplating thickness standardsā:

- Copper Plating for Through-Holes & Viasā: Specifies 25 Āµm (1 mil) minimum thickness for hole walls to guarantee electrical connectivity and mechanical durability. Thinner deposits (<20 Āµm) risk cracking during thermal cycling, while excessive plating (>35 Āµm) may cause uneven current distribution.

- Surface Finish Thickness (ENIG, HASL, etc.)ā: Gold over nickel (ENIG): 0.05ā0.10 Āµm gold atop 3ā5 Āµm nickel to prevent oxidation without compromising solderability. HASL (tin-lead/lead-free): 1ā25 Āµm coating to ensure even solder wetting while avoiding bridging.

- Edge Connector Platingā: Demands 50ā75 Āµm hard gold over 2ā3 Āµm nickel for high-wear areas, ensuring 10,000+ mating cycles without degradation.

- Flexible Circuit Requirementsā: Limits copper plating to 12ā18 Āµm for dynamic flex regions to prevent fatigue fractures, paired with 2ā3 Āµm nickel underplate for stress relief.

- High-Current Traces & Planesā: Recommends 35ā70 Āµm copper for power layers to minimize resistive losses, verified by cross-sectional microscopy.

- Plating Uniformity Toleranceā: Enforces Ā±10% thickness variation across panels, measured via X-ray fluorescence (XRF) to avoid impedance mismatches in high-speed designs.

- Plating Adhesion Testingā: Requires >1.5 N/mm peel strength per IPC-6012 to withstand assembly processes like reflow soldering.

- Cost vs Performance Balanceā: Thicker platings increase material costs by ~20% per 10 Āµm but reduce field failures in harsh environments (e.g., automotive underhood).

Solder Mask Specifications

Here are the solder mask for PCB fabrication specifications presented in clear:

Material Propertiesā

- Standard liquid photoimageable (LPI) epoxy-based solder mask

- UL 94V-0 flammability rating for safety compliance

- Dielectric strength >1000V/mil for electrical insulation

- Thermal resistance up to 150Ā°C for lead-free soldering processes

Thickness Specificationsā

- 0.5-1.0 mil (12.5-25Ī¼m) over conductors

- 0.8-1.5 mil (20-38Ī¼m) over laminate surfaces

- Minimum 0.3 mil (8Ī¼m) in any area

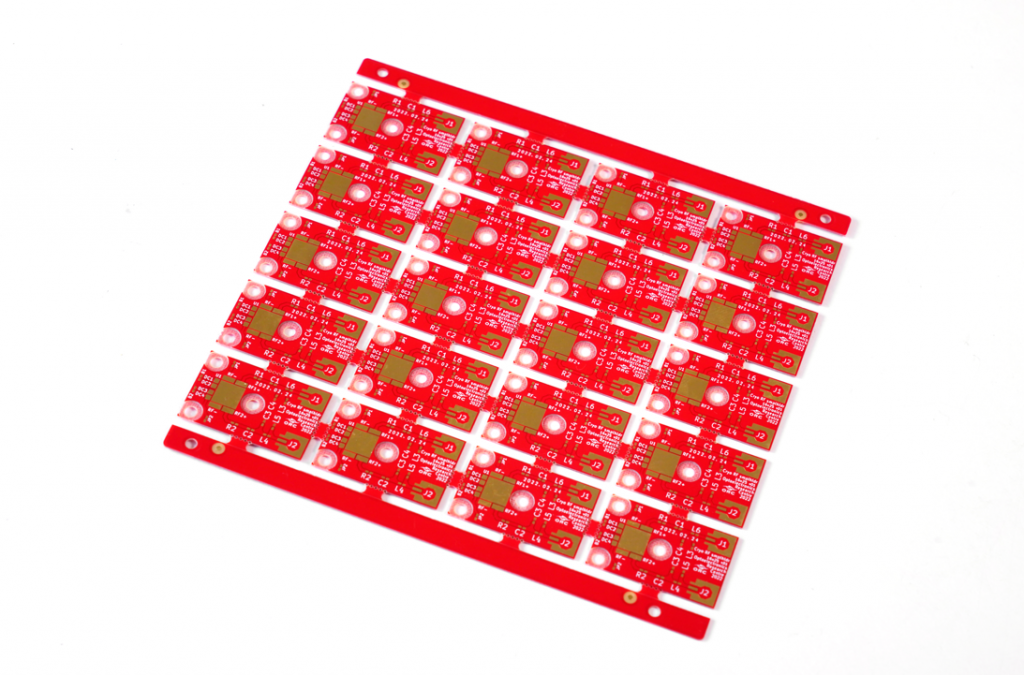

Color Optionsā

- Standard colors: green, red, blue, black, white

- Custom colors available with 10% additional cost

- Matte and glossy finishes selectable

Registration Toleranceā

- Ā±3 mil (76Ī¼m) for standard designs

- Ā±2 mil (51Ī¼m) for high-precision boards

- Alignment marks required for tight-tolerance designs

Opening Requirementsā

- Minimum solder mask opening: 4 mil (100Ī¼m)

- Web width between openings: 3 mil (75Ī¼m) minimum

- Tented vias permitted with 5 mil (125Ī¼m) annular ring

Surface Finish Compatibilityā

- Compatible with HASL, ENIG, OSP, Immersion Silver

- Special formulations available for flexible PCBs

- No interaction with final surface finishes

Curing Processā

- UV exposure followed by thermal cure

- Full cure at 150Ā°C for 60 minutes

- Post-cure hardness: >6H pencil hardness

Quality Standardsā

- IPC-SM-840 Class 3 compliant

- No pinholes, bubbles, or uncured areas

- Adhesion passes tape test per IPC-TM-650

Special Featuresā

- Peelable mask option available

- Selective thickness variation possible

- Edge clearance: 10 mil (250Ī¼m) from board outline

Surface Finishes Requirements

Surface Finish Requirements for PCB Fabrication:

HASL (Hot Air Solder Leveling, Lead-Free)ā

- Thicknessā: 1ā40 Āµm (minimum 1 Āµm over copper).

- Profile Controlā: Dome height ā¤15 Āµm for components with pitch ā¤0.65 mm.

- Cleanlinessā: Zero visible flux residue post-processing.

ENIG (Electroless Nickel Immersion Gold)ā

- Nickel Thicknessā: 3ā5 Āµm with phosphorus content 8ā12%.

- Gold Thicknessā: 0.05ā0.10 Āµm (99.9% purity minimum).

- Reliabilityā: Pass IPC-J-STD-003 solderability testing after 155Ā°C thermal aging.

Immersion Tin (ImmSn)ā

- Thicknessā: 0.8ā1.2 Āµm uniformly coated.

- Shelf Lifeā: 6 months in nitrogen-sealed packaging.

- Handling Protocolsā: Glove-only contact to prevent oxidation.

Immersion Silver (ImmAg)ā

- Thicknessā: 0.2ā0.5 Āµm with ā¤0.1 Āµm variation.

- Tarnish Preventionā: Sulfur-free vacuum packaging required.

- Microvoid Controlā: ā¤5% voiding in post-reflow cross-sections.

Electrolytic Hard Goldā

- Nickel Underlayerā: 1.5ā2.5 Āµm minimum.

- Gold Thicknessā: 0.5ā1.27 Āµm (cobalt-hardened).

- Durabilityā: Withstand 200+ insertion cycles without wear.

OSP (Organic Solderability Preservative)ā

- Coating Thicknessā: 0.2ā0.5 Āµm verified by colorimetry.

- Assembly Windowā: Single reflow cycle recommended.

- Storageā: Dry cabinet (<30% RH) with 6-month expiration.

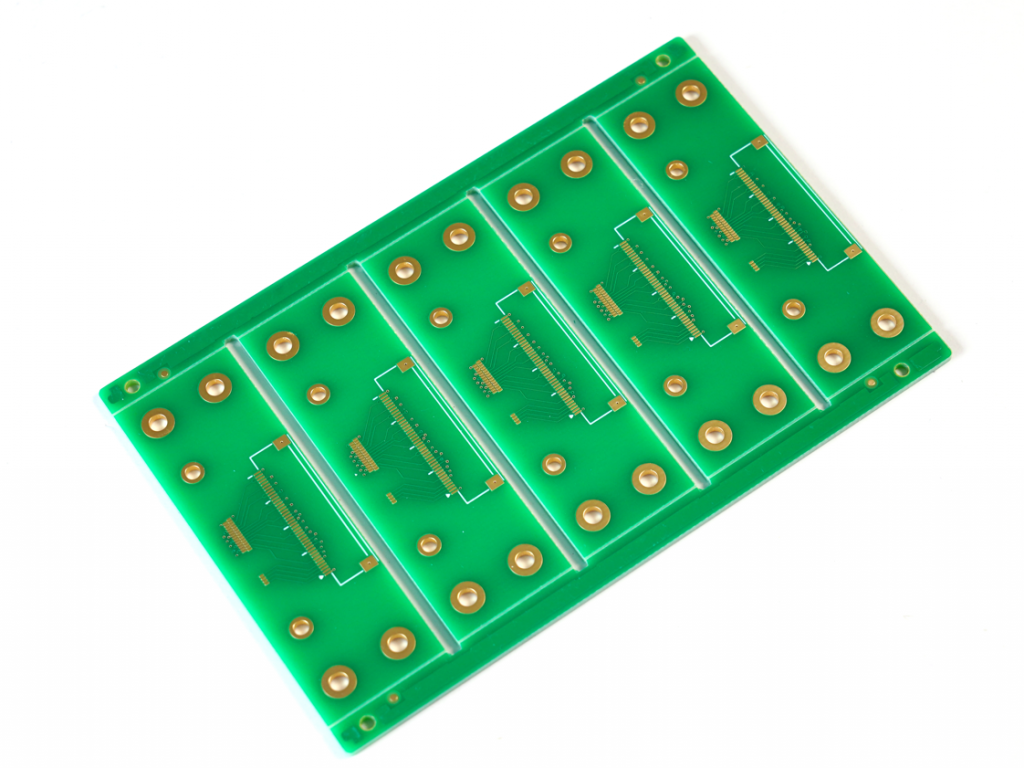

PCB Fabrication Panelization Size Specifications

PCB Fabrication Panel Size Specifications

Standard Panel Dimensions

- Common sizes: 18″x24″, 21″x24″, 18″x21″

- Thickness range: 0.2mm to 3.2mm

- Implementation: Larger panels (24″x30″) available for high-volume production

Design Considerations

- Minimum clearance: 0.5mm between board edges and panel borders

- Tooling holes: Three 3.0mm holes minimum, placed asymmetrically

- Fiducial markers: Two global and two local markers per board

Panelization Methods

- V-cut: 0.4mm depth minimum, 30Ā° or 45Ā° angle standard

- Tab routing: 0.8mm minimum tab width, 2-3 bridges per side

- Perforations: 0.3mm drill holes spaced 1.0mm apart

Breakaway Tab Specifications

- Tab width: 2.0-3.0mm

- Tab spacing: 50-100mm intervals

- Tab location: Avoid placing near fine-pitch components

Material Utilization Guidelines

- Optimal board spacing: 3-5mm between individual PCBs

- Panel utilization target: 75-85% of total area

- Nesting strategy: Consider rotation (90Ā°/180Ā°) for better efficiency

Specialty Panel Requirements

- Flexible circuits: 12″x18″ maximum for consistent handling

- Heavy copper boards: Reduce panel size by 20% for weight management

- RF materials: Limit panel size to minimize material waste

Shipping Considerations

- Maximum shipped panel size: 24″x30″x2″

- Weight limit: 15kg per panel for safe handling

- Packaging: Edge protectors required for panels >18″ in length

Implementation Strategy

- For prototype runs: Use 18″x24″ panels with 5mm spacing

- For mass production: Optimize panel size based on monthly volume

- For mixed-technology boards: Separate rigid and flex sections into different panels

Conclusion

In conclusion, this guide has systematically covered all critical PCB fabrication specifications including material properties, copper thickness tolerances (Ā±10% standard), drilling accuracy (Ā±0.05mm), plating standards (minimum 25Ī¼m), and panel size optimization (18″Ć24″ typical). Proper implementation of these specifications ensures reliable circuit performance, manufacturing yield, and cost efficiency. For projects requiring precision execution of these technical parameters, from high-frequency boards needing tight impedance control to multilayer designs demanding exacting layer alignment. Consult Best Technology’s engineering team for competitive quotations and manufacturing solutions. Their expertise in IPC-class fabrication guarantees your designs meet both performance requirements and industry compliance standards while optimizing production costs. Request a customized quote today: sales@bestpcbs.com.