Test Report of Yellowing Ceramic

The impact of yellowing ceramic

Further to previous “Why Are There Yellowing Areas on DBC/DCB Substrate?”, we’d like to do more testing to see what the different between yellowing substrate and normal without yellowing. In addition to appearance, the biggest impact of performance is the product pressure resistance.

Pressure Resistance Test Results |

|||||||

Type |

Q’ty |

Press 60 sec |

Max pressure value(KV) |

||||

Yellowing |

10 |

OK |

2.5 |

2.51 |

2.52 |

2.48 |

2.51 |

2.49 |

2.50 |

2.49 |

2.48 |

2.52 |

|||

| Normal |

10 |

OK |

2.51 |

2.48 |

2.52 |

2.48 |

2.52 |

2.50 |

2.51 |

2.48 |

2.52 |

2.51 |

|||

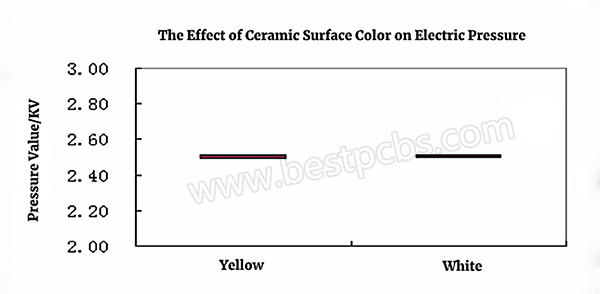

The effect of ceramic surface color on Electric pressure.

Conclusion: There is no difference between them.

Peel Force Comparison

Sample |

Max Peel Force (N) |

Min peel force (N) |

Average Peel Force (N) |

Average Peel of Strength (N/mm) |

1 |

59.4000 |

51.4400 |

54.7600 |

10.9500 |

2 |

58.5900 |

49.3400 |

53.3300 |

10.6700 |

Average Value |

59.0000 |

50.3900 |

54.0400 |

10.8100 |

Yellowing Ceramic

Peel force curve

Ceramic without yellowing (normal)

Sample |

Max Peel Force (N)

| Min peel force (N) |

Average Peel Force (N) |

Average Peel of Strength (N/mm) |

1 |

56.1000 |

44.2400 |

50.5000 |

10.1000 |

2 |

51.7000 |

41.1800 |

45.9700 |

9.1900 |

Average Value |

53.9000 |

42.7100 |

48.2300 |

9.6500 |

Peel force curve

Click here to download PDF revsion of "Test-report-of-ceramic-yellowing"

As a professional DCB/DBC ceramic PCB manufacturer, EBest Circuit (Best Technology) always provides customers ceramic boards with excellent quality. Contact us if you have any questions, or comments for that DCB/DBC ceramic board.

ISimply drop your email or phone number in the contact form, and we'll promptly provide you with a quotation.