Why Are There Yellowing Areas on DBC/DCB Substrate?

1.Background

The phenomenon of yellowing on some areas of DBC substrate (Al2O3) always happen, and the shades of yellow colors are different, customers worried that it will affect the performance and function of DBC substrate and the finished ceramic PCBs. So we did this analysis interiorly and came up with this report. That’ll be helpful for customers to have a thorough understanding of this phenomenon.

2.Investigation & Analysis

1).DBC-DCB substrate sintering principle

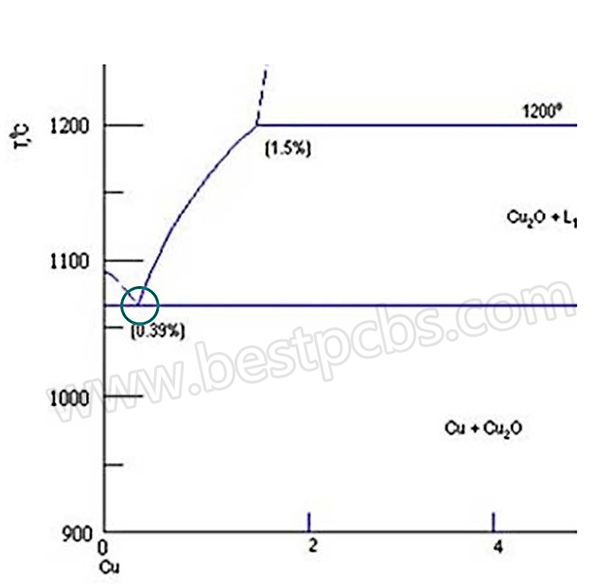

Al2O3-DBC/DCB substrates are substrates directly bonded by Al2O3 ceramic and copper at a high temperature environment and reaction with inert gas, so it also named as ceramic base copper clad. The basic theory is that the copper will be transferred to a thin Cu2O layer (copper oxide) to the copper surface at a high temperature and in a certain oxygen level, and when the temperature is higher than the eutectic point, Cu-Cu2O eutectic liquid phase will be appeared.

The Cu2O phase has good affinity with Al2O3 ceramics, which makes the interface energy decreasing. At the same time, the eutectic liquid phase can make the interconnection between copper and ceramics become more firmly. CuAlO2 and other composite oxides generated by chemical reaction between Cu-O and Al2O3, will be the soldering material for eutectic brazing, and then enhance the cohesive between two parts.

Cu2O + Al2O3 → CuAlO2

2).the Bonding Layer of DBC Substrate

From the above sintering principle of DBC/DCB substrate, we can know that CuAlO2 will be formed after sintering of copper plate and Al2O3 ceramics. CuAlO2 which is a dark red ceramic oxide, has good acid and alkali resistance, so it will be difficult to clean completely that bonding layer after the normal treatment of corrosive copper solution. A picture below is showing the status of ceramic surface after the surface copper is corroded by specialized chemical liquid. From this picture, we can see the area where copper is bonded is more dark and yellow, comparing with area that no copper bonded

3).Elements analysis in the area of yellowing

The following figure shows the EDX analysis results of the untreated ceramic substrate (marked by red line) and the sintered yellowing ceramic substrate.

The contents of Si, Ca, Mg and other elements in the yellowing area are increased.

Si, Ca, Mg and other elements mainly come from Al2O3 ceramics, used as Al2O3 ceramic sintering aid (96% Al2O3 ceramics, in addition to the main ingredient Al2O3, there are also magnesium calcium oxide).

This indicates that during the sintering process of DBC/DCB substrate, sintering aid inside of Al2O3 ceramic will be leaked to the surface of ceramic, at a high temperature environment.

As known from the sintering literature of Al2O3 ceramics, when the content of sintering aid (especially SiO2, etc.) increased, the color of the ceramic will be changed to yellow.

4).Uneven Color in the Yellowing Area

Based on the above analysis, it can be speculated that the yellowing area of the ceramic is caused by the influence by CuAlO2 in the bonding layer or the sintering aid inside of ceramic substrate, and both of them are generated during the sintering reaction of DBC/DCB substrate. Both reactions have some uncertainties, such as the generated CuAlO2 binding layer, because it's an interface reaction, the thickness difference after reaction will be in a nano-scale degree, and the same for the exudation of sintering aid. This uncertainty in the amount of reaction leads to inconsistent colors on the surface of the ceramic substrate.

5).The Impact of Yellowing Ceramic on the Performance of DBC Substrate

In order to determine whether the yellowing ceramic have an impact on the performance of DBC/DCB substrate, a series of tests on ceramic with and without yellowing were done by EBest Circuit (Best Technology). Please refer to the details of test report of ceramic yellowing. The results show that the yellowing of the ceramic substrate does not affect the performance of DBC/DCB substrate.

Conclusion:

The yellowing of the ceramic is caused by the influence of CuAlO2 in the bonding layer or the sintering aid in ceramic substrate during sintering procedure of DBC/DCB. The uneven yellow color was caused by the slight difference in the thickness of CuAlO2, or in the amount of sintering aid exuded from the substrate, But the yellowing ceramic, basically will not affect the performance of DBC/DCB substrate

Click here to download PDF revsion of "Analysis-Report-of-DBC-Substrate-Al2O3-Yellowing-BestTechnology"

Please click here for immediate quotation online

Please contact us today for more information about Ceramic circuit board (Ceramic PCB).

ISimply drop your email or phone number in the contact form, and we'll promptly provide you with a quotation.