China PCB SMT manufacturer is the first thing global buyers search for when they want dependable quality and timely delivery. But the real question is: how do you choose the right one when there are so many?

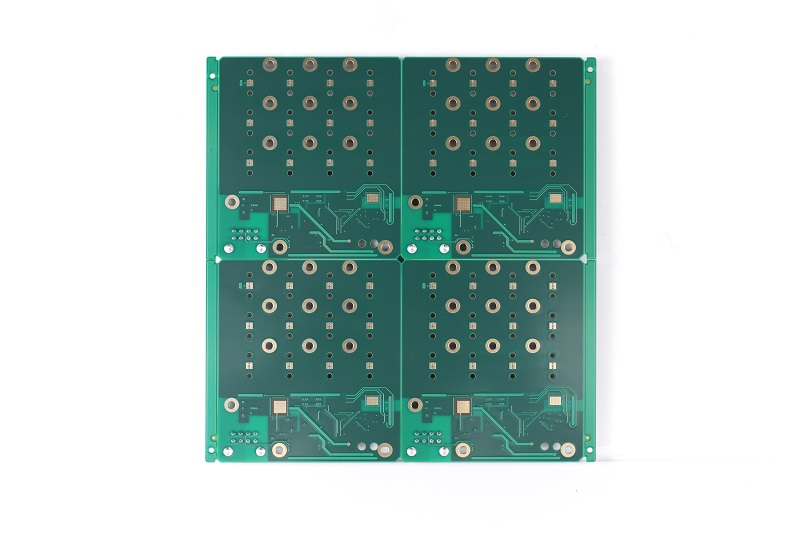

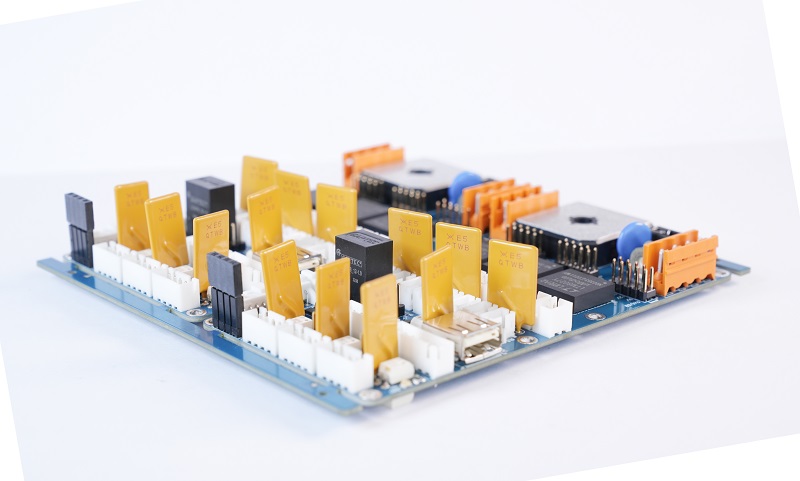

EBest Circuit (Best Technology) is a leading China PCB SMT Manufacturer, offering PCB fabrication and PCBA services in the marketplace. We hold most of the aces in rapid prototype PCB, consistent quality PCBA, advanced SMT technology, and sophisticated equipment. We place a priority on optimizing the SMT process, conducting detailed DFM checks, controlling precision component tolerances, and implementing stringent inspection procedures, since all these go hand in hand with quality. If you’re looking for a China PCB SMT manufacturer offering reliable quality PCBA and fast shipping, EBest Circuit (Best Technology) is a preferred choice. Feel free to email us at sales@bestpcbs.com, and we would love to offer our full engagement.

Who is the best China PCB SMT manufacturer?

The best choice always comes down to consistency, lead time, and real technical support. EBest Circuit (Best Technology) stands out for its ability to offer stable quality through a three-tier inspection system. Using AI visual testing, strict solder paste control, and real-time DFM validation, it drastically reduces common defects like tombstones, solder balls, or misalignment. That means less risk for your production line and fewer headaches for your engineers.

Who is the biggest China PCB SMT manufacturer?

When it comes to large-scale production and full-service capabilities, a few China PCB SMT manufacturers stand out for their capacity, automation level, and global influence. Size isnât only about factory area â itâs about consistent volume delivery, advanced systems, and their ability to support large clients across industries like automotive, telecom, and industrial control. Below are three of the largest players in the China PCB SMT manufacturing landscape:

1. Shenzhen Fastprint Circuit Tech Co., Ltd.

Fastprint is one of Chinaâs publicly listed PCB companies with strong SMT capabilities. Founded in 1999, it operates large-scale production facilities in Guangzhou, Yixing, and the UK. It focuses on high-mix, low-volume and high-tech PCBs, offering HDI, flex, rigid-flex, and IC substrate solutions. Their smart manufacturing setup and overseas branches help them serve top-tier global clients.

2. Zhen Ding Technology (ZDT)

Although its headquarters is in Taiwan, Zhen Ding has major SMT and PCB production bases in China. It is one of the largest PCB manufacturers in Asia, supplying leading brands in consumer electronics, especially smartphones and wearables. ZDT excels at mass production with extensive SMT lines and deep integration into the supply chain of top tech companies.

3. Shennan Circuits Co., Ltd. (SCC)

Shennan Circuits, also a publicly listed company, is known for its high-end PCB and PCBA services. The company supplies aerospace, automotive, and medical customers with multilayer boards and highly reliable SMT assembly. Its plants in Shenzhen, Wuxi, and Jiangsu are equipped with smart MES systems, and it invests heavily in R&D and process control.

To sum up, these large-scale China PCB SMT manufacturers serve some of the worldâs biggest tech brands. However, size alone doesnât guarantee the best fit for every project. For high-mix orders, flexible engineering support, and fast delivery â smaller, agile manufacturers like EBest Circuit (Best Technology) offer a more responsive and cost-effective alternative. They may not be the biggest, but theyâre often the most attentive to detail and customer success.

What is the difference between HDI PCB and traditional PCB?

HDI PCBs are high-density boards with microvias and fine lines, used in smartphones or medical gear. Traditional PCBs donât offer this level of compactness or signal performance. HDI boards need tighter manufacturing controls. EBest Circuit (Best Technology) has mature HDI processes â from laser drilling to stacked via filling â so your high-speed designs perform as expected.

What is the PCBA manufacturing process in China?

Good PCBA starts with a solid plan. First, DFM checks catch early design flaws. Then, component sourcing is arranged from vetted suppliers. SMT follows, using automatic placement, reflow, and AOI inspections. EBest Circuit (Best Technology) optimizes this with a U-line layout, cutting idle time by 40%. Finally, testing and packaging ensure delivery-ready boards. Thanks to smart scheduling and localized warehouses, Best achieves 98% on-time delivery.

Where is EBest Circuit (Best Technology) manufactured?

EBest Circuit (Best Technology)âs main production center is located in Shenzhen, China â a major electronics manufacturing hub. This location provides quick access to parts, skilled labor, and shipping lanes. For global clients, this means not only faster fulfillment but also better cost control. Urgent orders can be processed within 72 hours, thanks to buffer stock and dynamic scheduling.

Is EBest Circuit (Best Technology) trustworthy?

Trust isn’t claimed â it’s built. EBest Circuit (Best Technology) earns it by solving the four biggest pain points in PCB SMT: quality, delivery, cost, and technical support. It uses AI inspection for >99.9% defect capture. Its MES system supports traceability. Dedicated engineers respond within 2 hours. And BOM issues? Automatically flagged before they go to production. This transparency helps global clients sleep better at night.

How to choose a reliable PCBA manufacturer in China?

There are a few signs of a trustworthy partner. First, look for certifications like ISO 9001, IATF 16949, and AS9100D. Next, ask how they handle small mistakes. At Best, every order includes DFM simulation and real-time status tracking. That way, your team sees progress clearly. The best PCBA suppliers arenât the cheapest â theyâre the ones who help you avoid expensive rework later.

Why choose EBest Circuit (Best Technology) for your China PCB SMT manufacturer?

EBest Circuit (Best Technology) focuses on what matters most to global buyers:

- Quality:Â Advanced AOI and X-ray inspections, plus a strict soldering curve system, reduce defects by 85%.

- Delivery:Â With smart scheduling and local warehouses, urgent orders can be shipped within 3 days.

- Cost:Â Transparent quotes, BOM cost simulation, and bulk component deals save clients 15% yearly.

- Support:Â 24/7 online support and dedicated tech managers and engineers â all standard.

Most importantly, Best doesnât cut corners to win orders. It builds systems to avoid defects and delays. Thatâs the real value.

All in all, choosing the right China PCB SMT manufacturer isnât just about cost. You need a partner that truly understands your demands. EBest Circuit (Best Technology) responds to todayâs challenges with strict inspection, fast lead times, and real engineering support. When you’re tired of late shipments, poor soldering, and slow replies â itâs time to switch. Pls send us an email at sales@bestpcbs.com for any questions or requests for a factory visit.