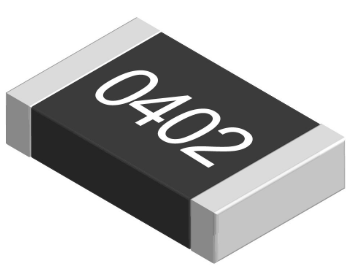

As electronic devices continue to shrink while performance expectations rise, component miniaturization has become a critical factor in modern PCB design. Among the most commonly used ultra-small passive components, the 0402 surface-mount resistor plays a key role in enabling high-density layouts, low parasitic effects, and cost-effective mass production.

Despite its tiny footprint, the 0402 resistor supports a wide range of resistance values and electrical characteristics, making it suitable for everything from consumer electronics and IoT devices to automotive and medical applications. However, its small size also introduces design, assembly, and reliability challenges that engineers must understand to avoid failures such as tombstoning, cracking, or power derating issues.

What Is a 0402 Resistor?

A 0402 resistor is a surface-mount chip resistor defined by its imperial package size of 0.04 × 0.02 inches, corresponding to 1.0 × 0.5 mm in metric dimensions. It belongs to the small-outline SMD resistor family and is optimized for automated SMT assembly.

Compared with larger packages such as 0603 or 0805, the 0402 resistor enables:

- Higher routing density

- Shorter signal paths

- Reduced parasitic inductance and capacitance

Typical circuit roles include pull-up and pull-down resistors, current limiting, signal termination, and voltage division in low-power electronics.

Standard Electrical Specifications of 0402 Resistors

Although exact ratings vary by manufacturer, most commercial 0402 resistors follow similar electrical limits.

| Parameter | Typical Specification |

| Resistance range | 0 Ω to 10 MΩ |

| Tolerance | ±1%, ±5% (±0.1% optional) |

| Rated power | 1/16 W (0.0625 W) |

| Max working voltage | 25–50 V |

| TCR | ±100 to ±200 ppm/°C |

| Operating temperature | −55 °C to +155 °C |

Power Derating Considerations

Power ratings are specified at 70 °C ambient temperature. Above this point, power must be linearly derated to zero at the maximum rated temperature. Exceeding power limits may result in resistance drift or catastrophic failure.

Materials and Construction of 0402 Resistors

Thick-Film Construction (Most Common)

Thick-film 0402 resistors are manufactured by screen-printing a resistive paste onto an alumina ceramic substrate. They offer:

- Low cost

- Broad resistance range

- Good long-term stability for general applications

Thin-Film Construction (Precision Applications)

Thin-film resistors use vacuum-deposited metal films and laser trimming, providing:

- Tighter tolerance

- Lower noise

- Improved temperature stability

Internal Layer Structure

- High-purity ceramic substrate

- Resistive layer

- Glass passivation coating

- Multilayer terminations (Ag / Ni barrier / Sn)

Nickel barrier terminations improve solderability and prevent silver migration.

0402 Resistor Footprint and Land Pattern Design

Package Dimensions

| Parameter | Typical Value |

| Length | 1.0 mm |

| Width | 0.5 mm |

| Height | 0.35–0.45 mm |

Recommended Land Pattern (IPC-7351)

| Feature | Dimension |

| Pad length | 0.6–0.7 mm |

| Pad width | 0.4–0.5 mm |

| Pad gap | ~0.3 mm |

PCB Design Best Practices

- Use non-solder mask defined (NSMD) pads

- Maintain symmetrical copper areas on both pads

- Avoid via-in-pad designs unless filled and capped

- Keep trace widths consistent to reduce thermal imbalance

Advantages of Using 0402 Resistors

- Enables compact, high-density PCB layouts

- Lower parasitic effects than larger packages

- Widely available from multiple suppliers

- Compatible with high-speed pick-and-place machines

- Cost-efficient in large-volume manufacturing

Limitations and Challenges of 0402 Resistors

- Limited power dissipation capability

- Higher risk of assembly defects

- Difficult manual rework

- Sensitive to mechanical stress and PCB flexing

For designs requiring higher power margins or easier assembly, 0603 or 0805 packages may be more suitable.

0402 Resistor Soldering & Assembly Guidelines

SMT Assembly Recommendations

- Reflow soldering with controlled thermal profiles

- Type 4 or Type 5 solder paste

- Stencil thickness of 80–100 µm

- Avoid excessive solder paste volume

Tombstoning Prevention

- Equalize pad copper area

- Optimize paste aperture design

- Use slow, uniform preheat ramps

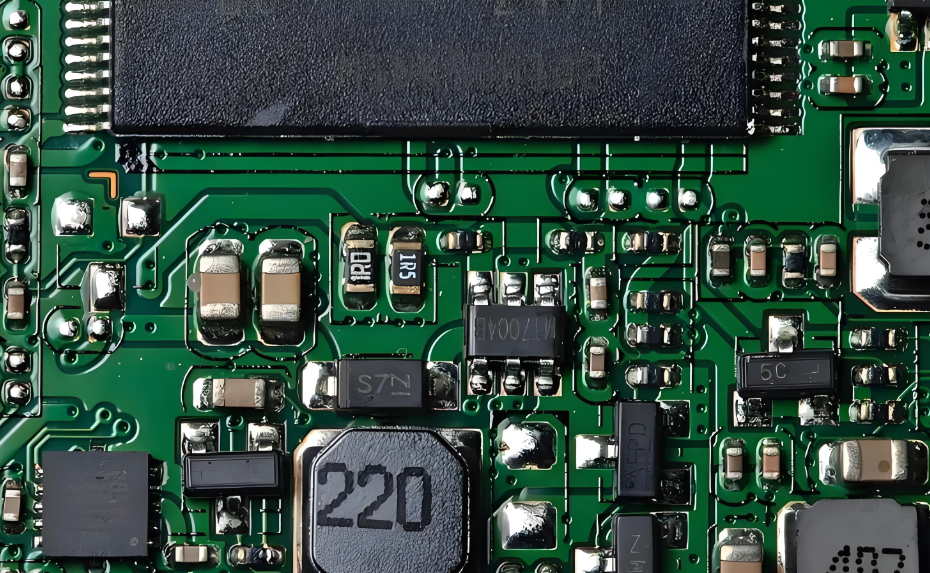

Applications of 0402 Resistors

0402 resistors are widely used in:

- Mobile phones and tablets

- Wearables and smart sensors

- IoT and wireless modules

- Laptop and ultrabook PCBs

- Medical diagnostic equipment

- Automotive infotainment and ADAS systems

How 0402 Resistors Compare with Other Sizes (0201, 0603, 0805)?

| Package | Size (mm) | Power Rating | Assembly Difficulty |

| 0201 | 0.6 × 0.3 | 1/20 W | Very high |

| 0402 | 1.0 × 0.5 | 1/16 W | High |

| 0603 | 1.6 × 0.8 | 1/10 W | Medium |

| 0805 | 2.0 × 1.25 | 1/8 W | Low |

Testing Methods for 0402 Resistors

- In-circuit testing (ICT)

- Four-wire resistance measurement

- Thermal cycling tests

- Automated optical inspection (AOI)

Common Failures in 0402 Resistors and How to Avoid Them

| Failure | Root Cause | Mitigation |

| Tombstoning | Uneven solder wetting | Balanced pad design |

| Cracks | PCB bending | Panel support |

| Resistance drift | Overpower | Apply derating |

| Cold joints | Insufficient paste | Stencil optimization |

How to Choose the Right 0402 Resistor for Your Project?

When selecting a 0402 resistor, evaluate:

- Required resistance and tolerance

- Power dissipation with margin

- Voltage rating

- Temperature coefficient

- Thick-film vs thin-film technology

- Environmental and reliability certifications

- Long-term supply availability

FAQs About 0402 Resistors

1. What does “0402” mean in a resistor?

The “0402” designation refers to the package size of the surface-mount resistor: 0.04 × 0.02 inches, or 1.0 × 0.5 mm in metric units. It indicates the physical dimensions, not electrical characteristics like resistance or power.

2. What is the power rating of a 0402 resistor?

A standard 0402 resistor has a power rating of 1/16 W (0.0625 W) at 70 °C ambient. This rating must be derated at higher temperatures. Using it above the rated power can lead to resistance drift or failure.

3. What resistance values are available for 0402 resistors?

0402 resistors are available in a wide resistance range from 0 Ω (jumper) to 10 MΩ, with common tolerances of ±1% or ±5%. Precision thin-film types may offer ±0.1% tolerance.

4. Can I hand-solder a 0402 resistor?

Hand-soldering 0402 resistors is very challenging due to their tiny size. It requires a fine-tip soldering iron, magnification, and precise control. Automated reflow assembly is strongly recommended for production or high-volume use.

5. Are 0402 resistors suitable for high-frequency circuits?

Yes. Due to their small size and low parasitic inductance/capacitance, 0402 resistors are suitable for RF, high-speed digital, and precision analog circuits. However, ensure the power rating meets the application requirements.

6. Can 0402 resistors handle automotive or harsh environments?

Standard 0402 resistors are typically rated −55 °C to +155 °C. For automotive applications, use AEC-Q200 qualified 0402 resistors, which are designed for vibration, thermal cycling, and humidity resistance.

7. What is the difference between 0402 and 0201 resistors?

- 0402: 1.0 × 0.5 mm, 1/16 W, easier to handle, suitable for most compact circuits

- 0201: 0.6 × 0.3 mm, 1/20 W, very challenging to assemble, typically for ultra-high-density applications.

Tags: 0402 resistor, 0402 resistor assembly, 0402 resistor size, 0402 resistor specification