A PCB manufacturer in Thailand‚Äč is a specialized industrial partner capable of transforming electronic designs into the physical boards that power modern devices, serving as a critical node in the global electronics supply chain. This article explores why Thailand has become a premier destination for PCB fabrication and assembly, providing a list of top vendors, a capability comparison, and strategic insights on selecting the best partner for projects requiring reliability and speed.

Finding a reliable PCB partner in a new market can be daunting. Are you struggling with long lead times, inconsistent quality, or complex logistics that delay your product launch? Many global buyers face significant hurdles when sourcing PCBs.

Common Pain Points:

- Time-Consuming Vetting:‚Äč Identifying and qualifying trustworthy manufacturers from afar is a slow, resource-intensive process.

- Hidden Cost Pressures:‚Äč Unexpected expenses from tariffs, shipping, or communication errors can erode project budgets.

- Inconsistent Quality:‚Äč Working with unvetted suppliers often leads to reliability issues, failed tests, and costly rework.

- Supply Chain Fragility:‚Äč Over-reliance on a single geographic region creates vulnerability to disruptions, affecting delivery certainty.

- Technical Support Gaps:‚Äč A lack of responsive, expert support for Design for Manufacturability (DFM) and engineering queries leads to delays.

Our Proposed Solutions:

- Curated Supplier List:‚Äč We provide a verified list of top PCB manufacturers in Thailand, streamlining your initial search.

- Total Cost Clarity:‚Äč Partnering with a Thai manufacturer offers stable, competitive pricing and can mitigate geopolitical tariff impacts.

- Certified Quality Systems:‚Äč Leading factories adhere to international standards (e.g., ISO, IATF 16949), ensuring consistent, high-yield production.

- Diversified Supply Base:‚Äč Thailand offers a resilient alternative, contributing to a robust multi-regional supply chain strategy.

- Dedicated Engineering Support:‚Äč Full-service providers offer proactive DFM analysis and direct engineer-to-engineer communication to prevent issues.

At BEST Technology, we are a specialized PCB and assembly provider with nearly 2 decades of deep expertise serving global clients. We combine advanced manufacturing capabilities in Asia with a client-centric approach, emphasizing clear communication, fast delivery, and stringent quality control to ensure your project’s success from prototype to mass production. Contact our team today at sales@bestpcbs.com‚Äč to discuss your requirements.

Why Choose a PCB Manufacturer in Thailand?

Selecting a PCB manufacturer in Thailand‚Äč is a strategic decision driven by the country’s robust industrial ecosystem. Thailand has evolved from a regional player to a globally competitive manufacturing hub, offering a compelling blend of economic and operational advantages that appeal to electronics brands worldwide.

- Competitive Operational Costs:‚Äč Thailand provides a favorable cost structure compared to many traditional manufacturing bases. Competitive labor rates, reasonable utility costs, and various government incentives for promoted industries contribute to an attractive total cost of ownership, making it a viable destination for both high-volume and specialized PCB fabrication Thailand‚Äč projects.

- Strong Infrastructure & Logistics:‚Äč The country boasts well-developed industrial estates, reliable power and water supplies, and key deep-sea ports like Laem Chabang. This infrastructure ensures smooth material inflow and finished goods outflow, which is fundamental for a PCB manufacturer in Thailand‚Äč to guarantee consistent fast delivery‚Äč to international markets.

- Skilled Workforce & Industrial Clustering:‚Äč Decades of investment in automotive, HDD, and consumer electronics have cultivated a deep talent pool of engineers and technicians familiar with high-precision manufacturing. The clustering of supporting industries‚ÄĒfrom chemicals to metalwork‚ÄĒcreates a synergistic environment for PCB manufacturing companies in Thailand.

- Pro-Business Government Policies:‚Äč The Thai government actively supports foreign investment through the Board of Investment (BOI), which offers tax incentives, import duty exemptions, and permission for full foreign ownership in targeted sectors, including electronics and component manufacturing.

- Strategic ASEAN Supply Chain Position:‚Äč As a central member of ASEAN, Thailand benefits from regional trade agreements (like ASEAN Free Trade Area and RCEP), offering PCB suppliers in Thailand‚Äč and their customers preferential access to a market of over 650 million people, with reduced tariff barriers.

In summary, Thailand’s appeal lies in its balanced offering of cost efficiency, established infrastructure, skilled labor, supportive policies, and strategic location, making it a reliable and attractive base for sustainable electronics manufacturing.

List of PCB Manufacturer in Thailand

The landscape of PCB manufacturers in Thailand‚Äč includes both large-scale multinational operations and capable specialized domestic firms. Here is a concise list of notable PCB manufacturing companies in Thailand, highlighting their focus and credentials.

| Company Name‚Äč | Board Type Specialization‚Äč | Key Certifications |

|---|---|---|

| Apex Circuit Co., Ltd.‚Äč | Multi-layer, HDI, Heavy Copper | ISO 9001, IATF 16949, UL |

| KCE Electronics Public Co., Ltd.‚Äč | High-layer count, HDI, RF/Microwave | ISO 9001, IATF 16949, ISO 14001 |

| Dynamic Electronics Thailand‚Äč | Double-sided, Multi-layer, Aluminum PCB | ISO 9001 |

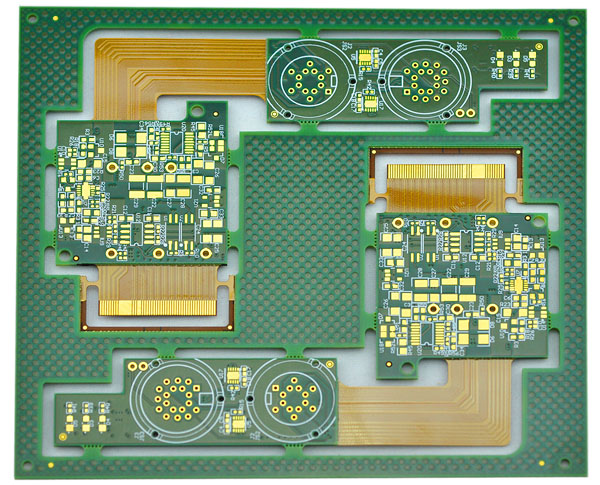

| Printed Circuits (Thailand) Ltd.‚Äč | Flexible PCBs, Rigid-Flex, Multi-layer | ISO 9001, IATF 16949 |

| PCBCraft Co., Ltd.‚Äč | Prototype to mid-volume, Multi-layer | ISO 9001 |

Capability Comparison Among Leading PCB Manufacturers in Thailand

For companies sourcing PCBs, Thailand provides a strong alternative within the global supply chain, especially when balancing production scale, complexity, and delivery requirements. Below is an overview of three well-recognized PCB manufacturers in Thailand, each known for distinct strengths and production focuses.

Sumec Rifa

A global Tier-1 PCB supplier with strong technological investment.

- Profile: Major enterprise with advanced PCB production lines.

- Focus: HDI, rigid-flex PCBs, and automotive-grade electronics.

- Strength: Robust R&D resources and strict adherence to IPC standards.

SPC Group

A versatile electronics manufacturer supporting a broad range of applications.

- Profile: Offers an integrated workflow from design through assembly.

- Focus: Standard rigid boards, multilayer structures, and fast prototyping.

- Strength: Excellent customer support and rapid prototype lead times.

Siam PCB

A long-established Thai manufacturer with deep local experience.

- Profile: Known for reliability and competitive pricing in traditional PCB production.

- Focus: Standard rigid PCBs and conventional multilayer boards.

- Strength: Cost-effective solutions for industrial and commercial applications.

Capability Comparison Table

| Capability Area | Sumec Rifa | SPC Group | Siam PCB |

|---|---|---|---|

| Technology Level | Advanced (HDI, RF) | Standard to Advanced | Standard (Rigid) |

| Minimum Lot Size | Large (Volume Focus) | Flexible (Proto to Mass) | Standard (Economies of Scale) |

| Specialization | Automotive, Aerospace | Consumer Electronics, Protos | General Industrial |

| Lead Time | Standard | Fastest for Protos | Standard |

Different projects require different manufacturing strengths. The choice depends on your technical complexity, expected volume, and budget.

Budget Considerations

Best Fit: Siam PCB or other Tier-2 local manufacturers

- Pros: Lower pricing for standard PCB runs; stable for general industrial use.

- Cons: Not ideal for advanced HDI or specialized PCB technologies.

Quality & Performance Requirements

Best Fit: Sumec Rifa or SPC Group

- Pros: High precision manufacturing, tighter tolerances, advanced testing capabilities.

- Cons: Potentially higher costs and longer initial tooling cycles.

There is no universal ‚Äúbest‚ÄĚ PCB manufacturer in Thailand ‚ÄĒ only the best match for your application.

- For cutting-edge automotive or aerospace projects: Sumec Rifa offers advanced process capabilities.

- For startups or products requiring rapid prototyping and engineering flexibility: SPC Group provides strong support and quick lead times.

- For cost-sensitive industrial applications: Siam PCB delivers reliable production at competitive pricing.

Whether your priority is speed, cost, or advanced functionality, Thailand’s PCB ecosystem offers a diverse range of qualified partners.

Major Industry Challenges Faced by the PCB Fabrication Thailand Market

Despite its strengths, the PCB fabrication Thailand‚Äč market contends with global and local challenges.

- Intense regional competition from Vietnam and Malaysia pressures margins and demands continuous efficiency improvements.

- A skilled labor shortage for highly advanced processes requires ongoing training and investment. Fluctuations in global demand for electronics can lead to capacity volatility.

- Furthermore, rising environmental regulations necessitate investment in greener technologies and waste management.

- Finally, PCB manufacturers in Thailand‚Äč must navigate complex international logistics and currency exchange risks to maintain their fast delivery‚Äč promises to global clients.

Successful manufacturers are those proactively investing in automation, workforce development, and sustainable practices to navigate these hurdles.

How to Pick the Best PCB Manufacturer in Thailand for Your Project?

Selecting the best PCB manufacturer in Thailand‚Äč requires a methodical approach tailored to your project’s unique demands. Don’t just choose a name; choose a capability match.

- Define Your Technical Requirements:‚Äč

Start with board specifics: layer count, material (FR-4, Rogers, Ceramic, Aluminum), special needs like HDI, impedance control, or high-frequency performance.

This will instantly narrow the field of PCB manufacturers in Thailand.

- Evaluate Core Capabilities & Certifications:‚Äč

Scrutinize their technical portfolio.

Do they have proven experience with your board type?

Required certifications (e.g., IATF 16949 for automotive, ISO 13485 for medical) are non-negotiable for quality assurance.

- Assess Scale and Flexibility:‚Äč

Can they handle your volume, from prototype to mass production?

A good PCB maker in Thailand‚Äč should offer flexible scaling without compromising on the support or quality offered during the prototyping phase.

- Analyze Communication and Support:‚Äč

Gauge their responsiveness and engineering support.

A partner that provides proactive DFM feedback is invaluable.

This is critical for avoiding delays and ensuring a smooth transition to production.

- Clarify Logistics and Total Cost:‚Äč

Understand their supply chain stability, lead times, and fast delivery‚Äč options.

Obtain detailed quotations that include all costs (tooling, testing, shipping) to accurately compare PCB suppliers in Thailand.

By systematically following these steps, you move beyond a simple vendor selection to forming a strategic partnership that ensures quality, reliability, and timely market entry.

Why More Overseas Buyers Shift Production to a PCB Factory in Thailand?

The trend of overseas buyers shifting orders to a PCB factory in Thailand‚Äč is a direct strategic response to evolving global trade dynamics. This shift is less about discovering Thailand and more about actively de-risking and optimizing supply chains.

- Mitigating Single-Source Risk:‚Äč

The vulnerabilities exposed by over-concentration in one manufacturing region have led companies to adopt a “China Plus One” strategy.

Thailand is a preferred “Plus One” due to its maturity, offering a proven alternative for PCB fabrication Thailand‚Äč needs.

- Navigating Tariff and Trade Pressures:‚Äč

For companies selling into markets affected by tariffs on Chinese goods, shifting a portion of PCB assembly Thailand‚Äč to Thailand can provide significant tariff advantages, improving overall product competitiveness.

- Complementing or Alternative Sourcing:‚Äč

Buyers are not always looking for a full replacement.

Many use Thai PCB manufacturers‚Äč to complement existing supply lines, add specialized capacity (e.g., for certain high-mix products), or serve as a certified secondary source for critical components.

- Pursuing Greater Schedule Stability:‚Äč

Proximity to other Southeast Asian component suppliers and less congested logistics corridors can contribute to more predictable and stable lead times.

A PCB company in Thailand‚Äč focused on fast delivery‚Äč can offer greater schedule certainty.

- Building Strategic Regional Footprints:‚Äč

Establishing a manufacturing relationship in Thailand is part of building a broader ASEAN footprint. It allows companies to be closer to growing regional demand and create a more resilient, multi-location supply network.

In essence, working with a PCB factory in Thailand‚Äč is a strategic move for supply chain diversification, cost management, and building long-term resilience in an unpredictable global trade environment.

What to Expect From a Full-Service PCB Assembly Thailand Provider?

Partnering with a true full-service PCB assembly Thailand‚Äč provider means gaining a seamless extension of your own production floor. They manage the entire process, offering a true turnkey solution. Here‚Äôs what you should expect:

- End-to-End Project Management:‚Äč

A single point of contact who manages everything from the initial quote to final delivery, providing complete supply chain visibility and accountability. - Comprehensive Component Services:‚Äč

This includes full BOM procurement, sourcing optimization, long-lead item planning, and inventory management to mitigate supply chain risks. - Advanced Assembly Capabilities:‚Äč

Look for modern SMT lines for fine-pitch components, through-hole technology, and mixed-technology assembly to handle complex board designs. - Rigorous Quality & Testing:‚Äč

Mandatory in-line and end-of-line testing, typically including Automated Optical Inspection (AOI), X-Ray inspection, In-Circuit Test (ICT), and functional testing to ensure reliability. - Final Integration (Box-Build):‚Äč

For complete products, the provider should offer final electro-mechanical assembly, enclosure integration, software loading, and final packaging.

By offering these integrated services, a top-tier PCB assembly manufacturer in Thailand‚Äč delivers the convenience, reliability, and speed of a true one-stop shop.

When to Work With a PCB Assembly Manufacturer in Thailand for High-Mix Needs?

Partnering with a specialized PCB assembly manufacturer in Thailand‚Äč is a strategic move for managing High-Mix, Low-to-Medium Volume (HMLV) production effectively. Consider this partnership when the following conditions apply to your project:

- Your product portfolio has many SKUs‚Äč with frequent design changes and production line changeovers, demanding high manufacturing agility and flexibility.

- You require rapid, expert technical support‚Äč for diverse board designs, including quick DFM feedback and specialized programming, which local technical teams excel at providing.

- Your production volumes do not justify dedicated mass-production lines; instead, you benefit from smaller, more adaptable assembly lines optimized for quick setups and focused attention on smaller batches.

- Your product mix involves a blend of technologies‚Äč (e.g., both advanced and conventional assemblies), and you need a partner with broad expertise to handle varied requirements under one roof.

- Total cost efficiency and responsiveness are priorities‚Äč over the absolute lowest per-unit cost at ultra-high volumes. A specialized HMLV manufacturer can reduce downtime, minimize setup waste, and offer more attentive project management.

In essence, a Thai PCB assembly manufacturer‚Äč with an HMLV focus offers the optimal balance of technical expertise, operational flexibility, and cost-effective responsiveness for complex, evolving product portfolios.

Case of Supporting PCB Assembly Thailand Projects at EBest Circuit (Best Technology)

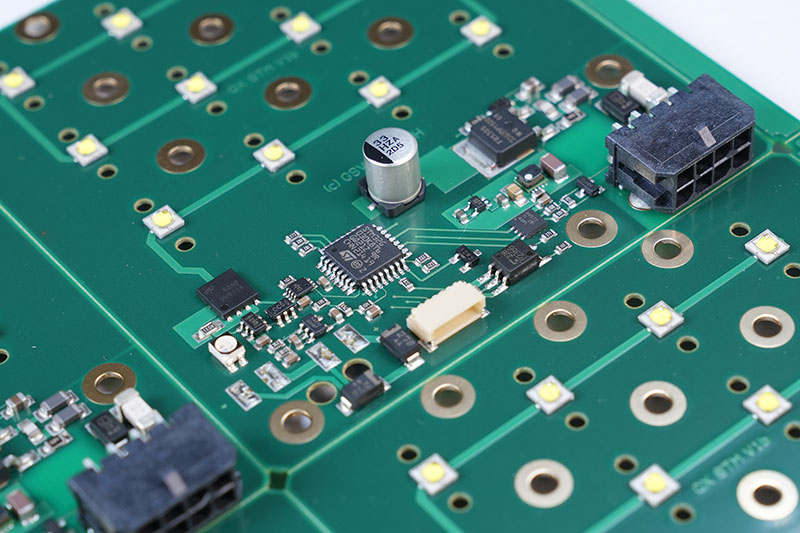

At BEST Technology, we recently partnered with a Thailand-based product development company to manufacture and assemble a complex 6L HDI PCB. This project exemplified our ability to support demanding PCB assembly Thailand‚Äč initiatives requiring advanced fabrication and precise assembly for diverse, high-reliability end-uses.

Diverse Application Scenarios for the Assembled Board:

- Portable Medical Diagnostic Equipment:‚Äč

The board’s high-density interconnect (HDI) design and compact form factor make it ideal for handheld ultrasound probes or portable patient monitors, where miniaturization and signal integrity for sensitive data acquisition are critical.

- High-Performance Industrial Computing Module:‚Äč

Used as a core processing or communication module within factory automation controllers or machine vision systems, where reliability, thermal performance (Tg180), and controlled impedance for high-speed data buses are essential.

- Advanced Professional Wearable Device:‚Äč

Serving as the mainboard in a ruggedized sports watch or a body-worn sensor for athletes, where the thin profile, robust construction, and reliable blind/buried via structure ensure performance in demanding environments.

PCB Technical Specifications for the Project:

| Item | Specification |

|---|---|

| Layers | 6L (6 Layers) |

| Process Type | HDI, 2-step blind & buried vias |

| Lamination Cycles | 2 lamination presses |

| Blind Via Structure | 1‚Äď2, 2‚Äď3, 4‚Äď5, 5‚Äď6 (laser drilled) |

| Buried Via Structure | 3‚Äď4 (mechanical drilled) |

| Base Material | FR4, Tg180, IT180A |

| Finished Board Thickness | 1.0 mm |

| Copper Weight | 1 oz finished copper for inner & outer layers |

| Surface Finish | ENIG 2 őľ” |

| Outline Size | 114.86 √ó 156.81 mm |

| Panelization | 4 pcs per panel |

| Silkscreen Color | Green solder mask / white legend |

| Special Process | Resin via plugging + surface planarization |

| Delivery Standard | Impedance test coupons + test report |

Leveraging our expertise in advanced PCB fabrication‚Äč and assembly, we ensured rapid prototyping, stringent quality control, and fast delivery, enabling our client to accelerate their product’s time-to-market for these sophisticated applications.

Why do Customers Work with EBest Circuit (Best Technology) for PCB Fabrication Thailand Projects?

Customers partner with BEST Technology for their PCB fabrication Thailand‚Äč initiatives because we provide specialized solutions for demanding applications. Here are the key reasons we are the chosen partner:

- Specialization in Advanced Materials:‚Äč

We solve critical problems that standard FR-4 manufacturers cannot, specializing in high-performance RF PCB, HDI PCB, heavy copper PCB, high frequency high speed PCB, ceramic PCBs‚Äč (Al‚āāO‚āÉ, AlN) and metal-core PCBs‚Äč essential for superior thermal and electrical management. - Expert Application Engineering:‚Äč

Our deep materials science expertise allows us to advise clients on optimal substrate selection for their specific needs in high-power, high-frequency, and high-reliability applications, such as RF amplifiers, power converters, and advanced LED systems. - Commitment to Quality and Reliability:‚Äč

We are IATF 16949 certified, implementing stringent quality control processes that ensure the reliability and consistency required for mission-critical electronics, providing peace of mind for our customers. - Fast and Predictable Delivery:‚Äč

We combine our technical specialization with a strong operational commitment to fast delivery, overcoming the long lead times typically associated with niche, advanced PCB technologies and accelerating our clients’ time-to-market. - Single-Source Solution for Complex Needs:‚Äč

We act as a reliable, end-to-end partner for clients who cannot afford performance compromises, offering a single point of accountability for fabricating complex, high-value boards that are vital to product success.

As a specialized provider, BEST Technology‚Äč stands out by addressing the most demanding needs in the market. Our core strengths in advanced materials like ceramic and metal-core PCBs, combined with rigorous IATF 16949-certified quality control and a steadfast commitment to reliable timelines, make us the ideal partner for projects where performance cannot be compromised.

A PCB manufacturer in Thailand‚Äč is more than a production facility; it’s a strategic partner enabling resilient, cost-effective, and high-quality electronics manufacturing. This guide has outlined the rationale for choosing Thailand, how to select a partner, and the evolving trends shaping this vital industry. Pls feel free to contact us anytime to start your PCB fabrication and PCB assembly Thailand project via sales@bestpcbs.com.

FAQs

Q: What is the 3W rule in PCB?

- A:‚Äč The 3W rule is a guideline for reducing crosstalk between parallel PCB traces. It states that to minimize inductive coupling, the separation (center-to-center) between two traces should be at least three times the width (W) of a single trace. For example, if a trace is 6 mils wide, keep other traces at least 18 mils away.

Q: What is the 20h rule in PCB?

- A:‚Äč The 20h rule is a technique used in PCB stack-up design to reduce electromagnetic interference (EMI) from the edge of a power plane. It recommends that the power plane should be recessed from the edge of the ground plane by a distance equal to 20 times the dielectric separation (h) between them. This helps contain fringe fields and reduces radiation.

Tags: best pcb manufacturer in thailand, list of pcb manufacturer in thailand, pcb assembly thailand, PCB Factory in Thailand, PCB Manufacturer in Thailand, pcb manufacturers in thailand