SMT PCB assembly manufacturer solutions are becoming increasingly important as Indiaâs electronics manufacturing ecosystem expands rapidly across automotive, telecom, industrial control, and consumer electronics sectors. This article explains how to evaluate a custom partner, what production capabilities matter most, and how global supply chains â including EBest Circuit (Best Technology) â support India-focused PCBA projects with stable quality and engineering precision.

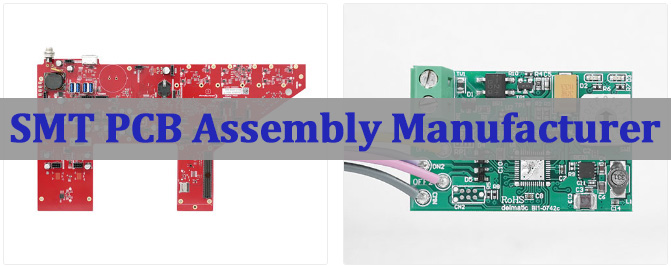

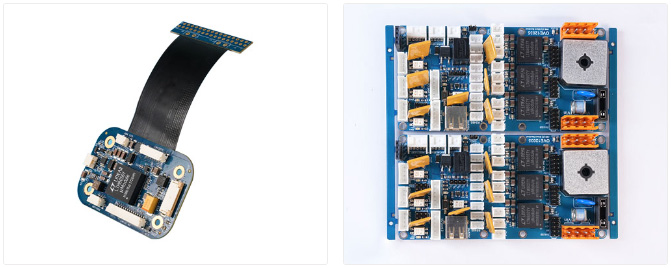

EBest Circuit (Best Technology) is a global SMT and PCBA manufacturing partner that cares for people and environment while delivering reliable circuit board SMT assembly solutions across multiple product category requirements, from medical electronics to industrial and IOT applications. The company offers comprehensive capabilities covering rigid PCBA, flex PCBA, rigid-flex PCBA, ceramic PCBA, and IMS PCBA, allowing engineers to choose the most suitable structure for thermal, mechanical, or high-density design needs.

With engineering-driven solutions and quality systems aligned with ISO 9001, ISO 13485, IATF 16949, AS9100D, UL, REACH, and RoHS, EBest Circuit (Best Technology) delivers stable production, sustainable processes, and efficient scaling from prototype to mass production. A warm welcome to contact us anytime via sales@bestpcbs.com for SMT design, prototyping, or assembly support.

What Services Should You Expect From A Custom SMT PCB Assembly Manufacturer in India?

A professional partner does far more than basic component placement. Engineers usually expect a complete manufacturing workflow that covers DFM analysis, SMT programming, testing integration, and traceability management.

Typical services include:

- PCB fabrication and SMT assembly integration

- Component sourcing and lifecycle management

- Double-sided SMT assembly with nitrogen reflow capability

- AOI, SPI, X-ray inspection and functional testing

- Prototype, NPI, and medium-volume production support

For India-focused projects, flexibility is particularly important. Many OEMs require rapid engineering feedback to adapt designs to local supply chains or export regulations. Therefore, a capable SMT PCB assembly manufacturer must provide strong communication between design engineers and production teams.

Another key expectation is engineering consultancy. Experienced manufacturers help optimize pad design, stencil thickness, and thermal profile settings before production begins. This approach reduces early defects and shortens project ramp-up cycles.

Why Choose SMT PCB Assembly Manufacturers in India for Your Projects?

Indiaâs PCBA ecosystem is growing due to favorable policies, strong domestic demand, and increasing investments in electronics infrastructure. Many companies choose India-based assembly partners to reduce logistics risk and improve regional responsiveness.

Advantages often include:

- Shorter delivery time for local markets

- Government incentives supporting electronics manufacturing

- Expanding skilled labor pool in SMT operation

- Competitive assembly costs for medium-volume production

However, not every project is suitable for a purely local solution. High-density designs, fine-pitch components, or advanced testing requirements sometimes require collaboration with experienced global manufacturers. As a result, many OEMs adopt a hybrid strategy that combines India assembly with international engineering support.

Top 5 PCB SMT Assembly Double Sided Manufacturer in India

Double-sided SMT assembly plays a vital role in modern PCB design, especially for compact electronics. Manufacturers that specialize in double-sided placement typically offer:

- Dual-side reflow with precise thermal profiling

- Adhesive or pallet solutions for bottom-side components

- Optimized component sequencing to avoid tombstoning

- Automated inspection systems to verify alignment accuracy

| Company Name | Double-Sided SMT Focus | Engineering Capability |

|---|---|---|

| Sahasra Electronics | Multilayer PCB Dual-Side Assembly | AOI, X-ray Inspection |

| SFO Technologies | Fine-Pitch & Compact PCB Design | Automated Optical Inspection |

| Kaynes Technology | High-Mix Low-Volume SMT | MES Traceability System |

| Avalon Technologies | Medium-to-High Volume Production | Thermal Profiling Control |

| VVDN Technologies | High-Density SMT Assembly | Inline SPI, Functional Testing |

While India-based manufacturers provide regional manufacturing strength, many OEMs still collaborate with global SMT PCB assembly manufacturer partners to enhance engineering support and supply chain flexibility.

When evaluating top manufacturers, engineers often compare production line configuration rather than brand reputation alone. Important metrics include placement speed, component range capability, and inspection coverage.

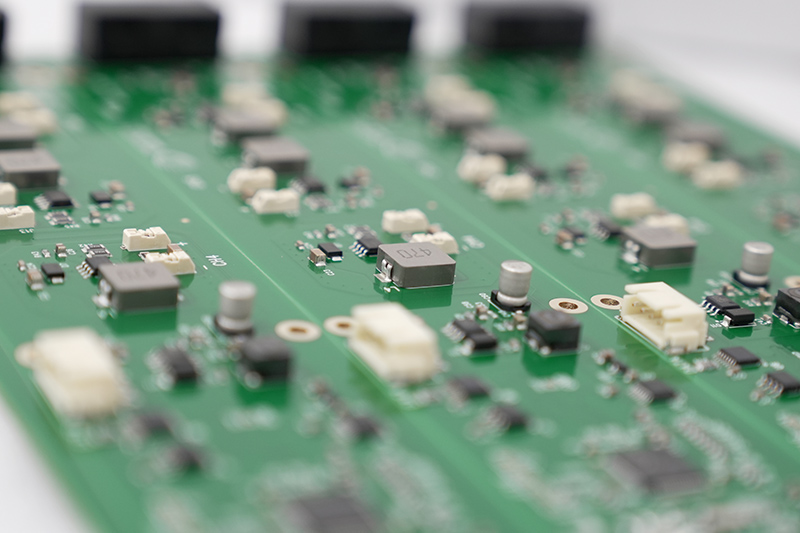

A reliable pcb smt assembly double sided manufacturer should demonstrate strong experience with multilayer boards, QFN or BGA packages, and fine-pitch ICs. These capabilities ensure stable yields even under high component density conditions.

What SMT Machines Do Leading SMT PCB Assembly Manufacturers in India Use?

Production equipment strongly influences placement accuracy and throughput. A modern SMT machine for PCB assembly manufacturer environment typically includes a combination of high-speed chip shooters and precision placement systems.

Common equipment categories include:

- High-speed pick-and-place machines for passive components

- Multi-function placement platforms for ICs and connectors

- Automatic solder paste printers with SPI inspection

- Nitrogen reflow ovens with multi-zone thermal control

- Inline AOI and X-ray inspection stations

Indian PCBA companies increasingly adopt globally recognized equipment brands to support export-grade manufacturing. Advanced machines improve consistency in solder paste deposition and placement accuracy, which directly reduces defects during reflow.

Beyond hardware, process programming is equally important. Optimized feeder arrangement, accurate component libraries, and precise stencil design contribute significantly to production efficiency.

What Capabilities Should You Compare Among PCB SMT Assembly Manufacturers Serving India?

Choosing the right partner requires more than comparing prices. Engineers typically evaluate manufacturing capability through measurable parameters:

- Maximum PCB size and layer count support

- Minimum component pitch and package compatibility

- Double-sided assembly capability

- Production throughput and line configuration

- Quality management certifications

A capable pcb smt assembly manufacturers network should also provide flexible volume scaling. Many India-based OEM projects start with small prototype runs before expanding to larger batches. Manufacturers that support both stages reduce the need for supplier switching.

Another comparison factor is supply chain management. Reliable component sourcing ensures stable production scheduling, especially when dealing with global shortages or alternative part substitutions.

How Do SMT PCB Assembly Manufacturers in India Control SMT Process Stability And Yield?

Process stability is achieved through strict monitoring across every production step. Leading manufacturers apply data-driven methods to maintain consistent quality.

Key control strategies include:

- Real-time SPI inspection to verify solder paste volume

- Automated optical inspection after reflow

- Temperature profiling based on board thermal mass

- Statistical process control (SPC) monitoring

By analyzing defect patterns, engineers can adjust placement force, stencil aperture design, or reflow parameters. This systematic approach allows smt pcb assembly manufacturers in india to maintain high yield even when handling complex PCB designs.

Traceability systems also contribute to stability. Barcode tracking and MES integration help identify process deviations quickly, minimizing production downtime.

Can China SMT PCB Assembly Manufacturers Complement India Supply Chains For Global Production?

Many global OEMs combine India assembly with experienced China SMT PCB assembly manufacturers to achieve balanced cost and capability.

This hybrid strategy offers several advantages:

- Access to advanced engineering resources

- Mature supply chain networks for electronic components

- Faster prototype turnaround

- Flexible production scaling between regions

EBest Circuit (Best Technology) often supports customers with engineering validation, quick-turn prototypes, and specialized PCB fabrication while India-based partners handle regional assembly or logistics. This collaborative model enhances resilience against supply chain disruptions.

What Certifications Should A SMT PCB Assembly Manufacturer Provide For India Export Compliance?

Export-focused electronics require compliance with multiple international standards. A reliable SMT PCB assembly manufacturer typically maintains certifications such as:

- ISO 9001 for quality management

- ISO 13485 for medical electronics

- IATF 16949 for automotive applications

- AS9100D for aerospace manufacturing

- UL and RoHS compliance

These certifications indicate that the manufacturer follows structured production procedures and rigorous inspection protocols. For OEMs exporting from India, certification alignment ensures smoother customs clearance and regulatory acceptance.

Why Are Global OEMs Partnering With EBest Circuit Best Technology For Custom India PCBA Projects?

Global companies often look beyond local assembly to find partners with strong engineering depth and international manufacturing experience. EBest Circuit (Best Technology) combines advanced SMT production capability with flexible customization services tailored to India-focused projects.

Key strengths include:

- One-stop PCB fabrication and SMT assembly integration

- Experienced engineering team supporting complex designs

- MES-based traceability for regulated industries

- Multi-region production strategy supporting India supply chains

- Responsive technical support via sales@bestpcbs.com

Instead of focusing only on placement speed, EBest emphasizes process optimization. From DFM review to final testing, every step aims to improve long-term product reliability.

In summary, SMT PCB assembly manufacturer selection plays a decisive role in the success of India-focused electronics projects, especially when balancing cost efficiency with global-level engineering quality. As India continues to expand its electronics manufacturing capabilities, OEMs increasingly rely on experienced partners who can deliver stable SMT processes, advanced inspection, and scalable production support.

Working with a trusted partner such as EBest Circuit (Best Technology) allows companies to combine international manufacturing expertise with flexible India-market strategies. For more information or inquiries, please reach out using the contact form on our Contact page.

Tags: China SMT PCB Assembly Manufacturers, PCB SMT Assembly Double Sided Manufacturer, PCB SMT Assembly Manufacturers, smt pcb assembly manufacturer, SMT PCB Assembly Manufacturers in India