Looking for PCB Malta manufacturer? This blog covers main pain points of Malta PCB manufacturer and our solutions to these points.

Malta’s electronics industry relies heavily on reliable PCB Malta manufacturer and high-quality PCB manufacturing Malta services. As demand for precision electronics grows locally, sourcing a trustworthy PCB manufacturer in Malta becomes crucial for seamless production workflows. This guide covers the top local players, core industry pain points, and how leading local manufacturers deliver tailored solutions aligned with Malta‚Äôs unique production needs and EU compliance standards.

Top PCB Malta Manufacturer in 2026

| Company Name | Main Business | Core Advantages | Process Capability | Lead Time |

| EBest Circuit Co., Limited | PCB prototyping/mass production/HDI boards | 19-year experience, 24h urgent prototyping | 40-layer HDI, 0.1mm line width | 24hrs-15 days |

| Electronics Malta Group | Consumer electronics PCBs | Cost-effective, RoHS compliance | 16-layer, flexible substrate | 4-18 days |

| Malta Electronics Solutions O√ú | Medical PCB | ISO13485, cleanroom | 24-layer, biocompatible | 12-22 days |

| TechPrint Malta Ltd | Single/double-layer PCBs | Fast small-batch | Standard finishes | 2-10 days |

| HDI Malta Electronics O√ú | HDI/telecom PCBs | REACH compliance | 30-layer HDI, PTFE | 14-25 days |

| GreenCircuit Malta Ltd | Eco-friendly PCBs | Waste recycling | Halogen-free | 9-18 days |

Pain Points of PCB Malta Manufacturer

- Urgent PCB prototyping demands cannot be met, with standard lead times exceeding 7 days, delaying project progress.‚Äč

- Design flaws are detected late in production, leading to rework, increased costs, and extended timelines.‚Äč

- Inconsistent product quality across batches, with issues like board warpage and poor solderability affecting usability.‚Äč

- High material costs for special substrates (e.g., high-frequency, medical-grade) without cost-saving alternatives.‚Äč

- Limited process capability for complex designs, such as HDI boards with blind/buried holes and fine line widths.‚Äč

- Lack of professional support for PCB printing Malta, resulting in unclear silk-screen and poor mark visibility.‚Äč

- Unreliable delivery schedules, with frequent delays due to inefficient production planning.‚Äč

- Insufficient testing processes, leading to hidden electrical faults in finished PCBs.

Our PCB Solutions to These Pain Points

- Pre-Production Design Support: Provide free DFM analysis to identify potential design flaws early, avoiding rework. Our team optimizes designs for manufacturability while maintaining performance, addressing late-stage design issue pain points.‚Äč

- Flexible Prototyping Service: Offer 24-hour urgent PCB prototyping and 3-7 day standard prototyping, fully meeting tight project schedules. Advanced automated lines ensure fast sampling without compromising quality.‚Äč

- Cost-Optimization Solutions: Cooperate with top substrate suppliers to provide cost-effective alternatives for special materials. Customize cost-sensitive plans based on production volume, reducing material cost burdens.‚Äč

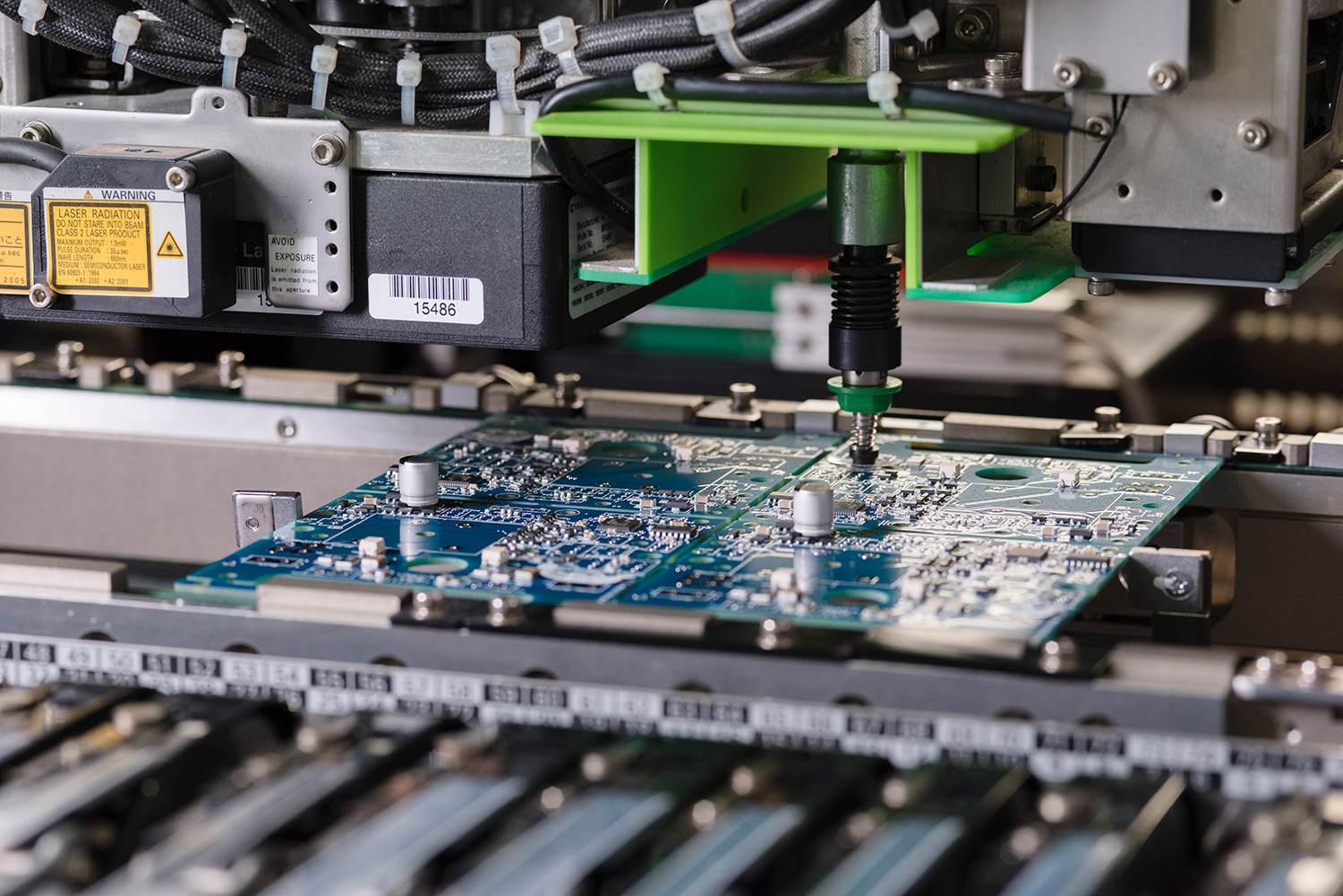

- Advanced Process Capability: Master HDI, blind/buried hole, and fine line processing technologies to handle complex designs. Professional PCB printing Malta equipment ensures clear silk-screen and durable marks.‚Äč

- Strict Quality Control: Implement full inspection for mass production, including automated optical inspection (AOI), electrical testing, and board warpage detection. Achieve consistent quality across batches with a 99.8% pass rate.‚Äč

- MES System Full-Process Traceability: MES enables real-time production monitoring and full-process traceability, covering raw material intake, processing, testing, and delivery. Clients access real-time progress to avoid delivery doubts. MES-driven smart planning ensures 99.2% on-time delivery.‚Äč

- Post-Delivery Support: Offer technical consultation and fault analysis for finished products. Provide rework solutions for any quality issues, ensuring worry-free use of PCB Malta products.

Why Choose EBest(Best Technology) as PCB Malta manufacturer?

Reasons Why Malta Clients Choose EBest(Best Technology) as PCB Malta Manufacturer:

- 24-Hour Urgent Prototyping: Unique rapid production lines complete PCB prototyping within 24 hours, the fastest in the Malta market for urgent orders.‚Äč

- Competitive Pricing: 19 years of industry experience enables optimized supply chains, offering 10-15% lower costs than peers for the same quality PCB manufacturing Malta.‚Äč

- Cost-Sensitive Solutions: Customize material selection and process plans based on project needs, reducing unnecessary expenses without sacrificing performance.‚Äč

- High On-Time Delivery Rate: 99.2% of orders are delivered on schedule, supported by smart production scheduling and sufficient inventory.‚Äč

- Strict Quality Control: Mass production adopts 100% full inspection, with 8-stage quality checks from material incoming to finished product delivery, ensuring stable quality.‚Äč

- Rich Industry Experience: 19 years of serving global clients helps optimize designs and processes, reducing overall project costs by 8-12%.‚Äč

- Free DFM Analysis: Professional team provides detailed design optimization suggestions before production, eliminating rework risks.‚Äč

- Comprehensive Certifications: Hold ISO9001:2015, ISO13485:2016, REACH, RoHS, and IATF16949 certifications, meeting diverse industry requirements.

- One-Stop Service: Integrate PCB printing Malta, prototyping, mass production, and testing, simplifying procurement processes for clients.‚Äč

- Localized Support: Set up a local service team in Malta to provide fast technical consultation and after-sales support, responding within 2 hours.

Our PCB Rapid Prototyping Service

EBest’s PCB rapid prototyping service prioritizes speed to meet our clients’ urgent project needs. With four dedicated express production lines, we achieve a 99.5% on-time delivery rate for 24-hour expedited prototyping, 50% faster than the average in the Maltese market. Even for complex PCB designs, from single-layer boards to 40-layer HDI prototypes, we maintain the same rapid turnaround time, thanks to the strong support of high-precision exposure machines and automated processing equipment. Each prototype undergoes 18 rigorous quality checks (including AOI optical inspection and impedance testing), ensuring a 99.8% yield rate, consistent with mass production standards. Whether you face last-minute design adjustments or urgent project deadlines, our expedited service delivers reliable Maltese PCB prototypes on time, helping you shorten development cycles and gain a competitive edge in the market.

Our Lead Time for PCB Prototyping

| Layers | Normal Service | Fastest Service |

| 1 | 7 Days | 24 H |

| 2 | 8 Days | 24 H |

| 4 | 10 Days | 48 H |

| 6 | 10 Days | 72 H |

| 8 | 12 Days | 72 H |

| ‚Č•10 | TBD | TBD |

Case Studies of PCB Manufacturing Malta

Background: A Malta industrial automation equipment firm required high-reliability PCB Malta for its new control system, targeting harsh industrial environments with strict temperature stability and anti-interference for 2GHz high-frequency signals.‚Äč

Requirements: 16-layer HDI PCB, operating temperature -40‚ĄÉ to 85‚ĄÉ (1,000-hour thermal cycle resistance), impedance control ¬Ī5% for 2GHz signals, prototype lead time ‚ȧ10 days, mass production (5,000 units) ‚ȧ20 days.‚Äč

Difficulties: Impedance stability control for 2GHz high-frequency signals (industry standard Df ‚ȧ0.01), 16-layer lamination risk of board warpage exceeding IPS standard (‚ȧ0.75%), and compressed lead time 30% shorter than market average.‚Äč

Solutions: Adopted high-temperature FR-4 substrate (Tg 180‚ĄÉ) and optimized lamination parameters (180‚ĄÉ/350PSI) to control warpage ‚ȧ0.5%; Used precision etching (¬Ī0.02mm tolerance) with 3 rounds of impedance calibration tests; Allocated dedicated expedited lines via MES scheduling for time guarantee.‚Äč

Results: Prototypes delivered in 7 days, 5,000 mass-produced units in 18 days (10% faster than required). All passed 1,000-hour thermal cycle and 2GHz anti-interference tests, with 100% pass rate and warpage ‚ȧ0.4%. The client launched on schedule, and 60% of their subsequent industrial control projects designate us as the exclusive PCB manufacturer in Malta.

FAQs of PCB Manufacturing Malta

Q1: How to avoid board warpage in multi-layer PCB production?

A1: We optimize lamination parameters (temperature, pressure, holding time) and adopt symmetric layer design to balance stress. Post-production mechanical correction and thermal aging treatment further reduce warpage. Contact us for customized warpage control solutions for your PCB Malta project.

Q2: Can design flaws be detected before PCB prototyping?

A2: Yes. We provide free DFM analysis to check for design issues like unreasonable line width/space, improper hole size, and silk-screen conflicts. This reduces rework rates by over 90%. Reach out for pre-production design validation.

Q3: What surface treatment is best for PCB printing Malta in humid environments?

A3: Immersion gold or OSP surface treatment is recommended for humid conditions, as they offer excellent corrosion resistance. We can tailor surface treatment plans based on your application environment. Inquiry now for personalized suggestions.

Q4: How to reduce costs for small-batch PCB manufacture Malta?

A4: We offer shared mold services and optimize material cutting to reduce waste. Our cost-sensitive solutions can lower small-batch production costs by 10-15%. Contact us to get a cost-saving quote.

Q5: What tests are conducted for medical PCB products?

A5: Medical PCBs undergo electrical testing, insulation resistance testing, biocompatibility testing, and temperature cycle testing, complying with ISO13485 standards. We provide full test reports for each batch. Inquiry for medical-grade PCB prototyping and production services.

Tags: Malta PCB company, Malta PCB factory, PCB Malta, PCB manufacture Malta, PCB manufacturer in Malta, PCB manufacturing Malta, PCB Printing Malta, PCB prototyping