In RF and microwave PCB materials, DK means Dielectric Constant, also known as relative permittivity (εr).

Designing an RF or microwave PCB involves far more than routing traces—you must understand how materials behave at high frequencies. One of the most critical parameters is DK. Whether you are building a 1 GHz RF amplifier, a 10 GHz radar board, or a 77 GHz millimeter-wave automotive sensor, DK directly affects signal integrity, impedance, and loss.

This guide covers what DK means, why it matters, how it affects impedance, common RF PCB materials and their DK values, and how to choose the right laminate for RF, microwave, and mmWave designs.

What Does DK Mean in RF PCB Material?

DK = Dielectric Constant = Relative Permittivity (εr)

It describes how much an RF signal slows down as it passes through the PCB substrate.

- Air has DK ≈ 1

- FR-4 has DK ≈ 4.2–4.8

- RF materials like Rogers typically have DK ≈ 2.2–3.5

In RF engineering, DK affects:

- signal speed

- impedance

- wavelength

- phase stability

- overall RF performance

Lower DK materials allow signals to travel faster and lose less energy, which is why they are widely used in RF, microwave, 5G, and mmWave designs.

Importance of DK in Impedance Control

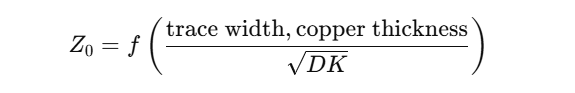

Controlled impedance is required for RF transmission lines such as microstrip, stripline, and CPW structures.

DK directly affects characteristic impedance (Z₀), because:

If the DK varies, impedance varies—and this creates reflection, mismatch, and signal loss.

This means:

- If DK increases → impedance decreases

- If DK decreases → impedance increases

Consistency is everything. Even a 1–2% DK variation can shift the impedance by noticeable amounts, leading to:

- signal reflections

- poor return loss

- increased insertion loss

- degraded power transfer

Therefore, RF PCB materials must have tight DK tolerance, usually around ±0.04 or better.

How Does DK Affect Impedance Control in RF PCBs?

Understanding DK helps engineers design stable, predictable transmission lines.

1. Impedance Matching

Lower DK requires wider traces to maintain 50Ω impedance. Higher DK requires narrower traces, which increases fabrication difficulty.

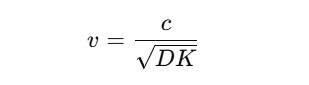

2. Phase Velocity & Delay

Signal speed is inversely related to DK:

Lower DK → faster signal → better phase performance.

This matters in:

- phased-array antennas

- differential pair timing

- radar systems

- power dividers & couplers

3. Dielectric Loss

While DF (dissipation factor) is the main loss-related parameter, DK influences how the electromagnetic field interacts with the substrate.

Higher DK = more energy trapped in substrate = higher loss at microwave frequencies.

4. Manufacturing Tolerances

Low DK materials allow wider traces, which reduces:

- etching variation

- copper width tolerance

- impedance deviation between batches

This makes low-DK materials more manufacturable for high-volume RF boards.

Common Types of RF PCB Materials

Below are the most widely used material categories for RF, microwave, and mmWave PCBs.

1. FR-4 (Limited RF Use)

- DK = 4.2–4.8

- Usable for ≤ 1 GHz

- High loss, unstable DK, poor high-frequency performance

Not suitable for microwave or 5G boards.

2. Hydrocarbon Ceramic Laminates (Rogers RO4000 Series)

Examples: RO4003C, RO4350B, RO4835

- DK ≈ 3.27–3.48

- Low loss

- Stable DK across frequency

- Compatible with FR-4 manufacturing

Ideal for: WiFi antennas, RF amplifiers, 10–20 GHz radar, high-power RF designs.

3. PTFE-Based RF Materials

Examples: RT/duroid 5880, RT/duroid 6002, RO3000 series

- DK = 2.17–3.0

- Very low loss

- Best for 24–80 GHz mmWave

- Requires specialized processing

Used in: ADAS 77 GHz radar, satellite RF modules, high-end filters, mmWave front-end designs.

4. Ceramic-Filled PTFE & Hybrid Laminates

Used in ultra-high-frequency and high-reliability applications:

- stable DK

- low CTE

- excellent thermal stability

Applications: Space, military RF systems, phased-array radar.

Here is a summarized RF material parameter:

| Material Category | Typical DK | Frequency Use | Notes |

| FR-4 | 4.2–4.8 | <1 GHz | High loss, unsuitable for RF/microwave |

| Rogers RO4000 Series | 3.27–3.55 | 1–20 GHz | Cost-effective, stable DK |

| Rogers RO3000 Series | 3.0, 3.38 | 10–40 GHz | Low loss, mmWave-ready |

| PTFE (Teflon) laminates | 2.17–2.6 | up to 60 GHz+ | Very low loss, used for 5G & radar |

| Ceramic-filled laminates | 2.2–6.0 | up to 77 GHz | Good CTE, stable DK |

Typical DK Values of Popular RF PCB Materials

Rogers RO3000 Series

| Material | DK @ 10 GHz | Notes |

| RO3003 | 3.00 ± 0.04 | Excellent for mmWave, 5G, radar |

| RO3006 | 6.15 | Compact RF components |

| RO3010 | 10.2 | Miniaturized RF circuits |

Rogers RO4000 Series

| Material | DK | Notes |

| RO4003C | 3.38 | Low-loss, cost-effective |

| RO4350B | 3.48 | High-power RF, stable performance |

| RO4835 | 3.48 | High reliability, PIM stability |

PTFE (Duroid) Materials

| Material | DK | Notes |

| RT/duroid 5880 | 2.20 | Super low DK, radar & aerospace |

| RT/duroid 5870 | 2.33 | Low loss for satellite comms |

Why RT5880 is Important for High-Frequency Designs?

RT5880 is especially favored for:

- 77 GHz automotive radar

- Ka-band satellite communications

- High-end phased-array antennas

- Microwave lenses & radomes

- Low-loss RF feed networks

Its ultra-low DK and extremely low loss tangent make it one of the best choices for millimeter-wave and low-loss RF applications.

RF PCB Design

PCB Material Selection for RF, Microwave & Millimeter-Wave Designs

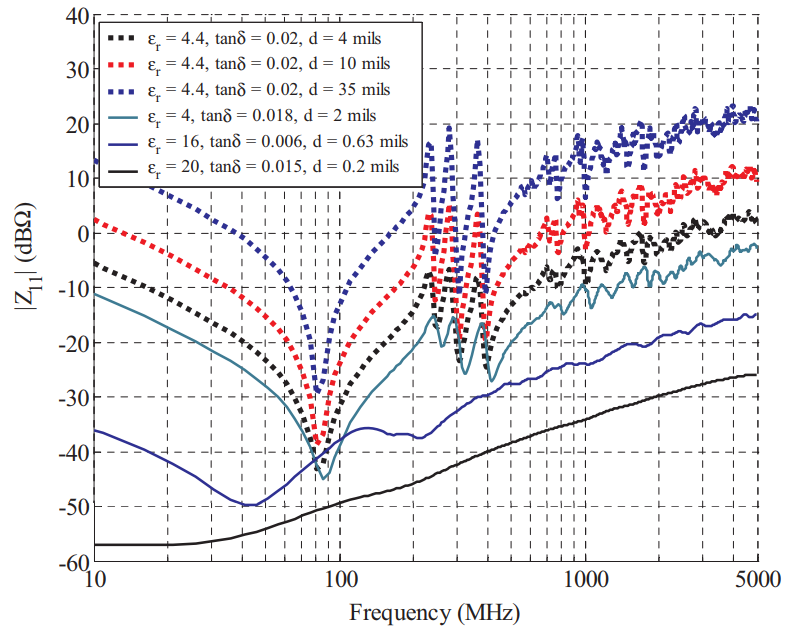

Choosing the right PCB material is one of the most important steps in designing an RF, microwave, or millimeter-wave circuit. At high frequencies, the dielectric constant (DK), dissipation factor (DF), copper type, and thermal stability directly affect signal loss, impedance, and long-term reliability. Below is a practical guide to help you choose the most suitable RF PCB laminate for your frequency and performance requirements.

1. DK Stability Over Frequency and Temperature

In RF systems, DK accuracy and stability are more important than the DK number itself. Materials with unstable DK can cause:

- impedance drift

- phase delay variation

- poor antenna radiation efficiency

- frequency shifting in filters and resonators

Choose materials with:

- tight DK tolerance (±0.02–±0.04)

- low TCDk (temperature coefficient of dielectric constant)

- stable DK from 1 GHz up to 40+ GHz

Best choices: Rogers RO3003, RO4350B, RT/Duroid 5880.

2. Loss Performance (Dissipation Factor / DF)

Loss increases rapidly as frequency goes higher. A low DF is essential for maintaining signal integrity at:

- microwave bands (6–30 GHz)

- millimeter-wave bands (24–80 GHz)

General guidance:

- DF ≤ 0.0010 → Required for 24–80 GHz mmWave

- DF 0.002–0.004 → Suitable for 1–20 GHz microwave

- DF > 0.010 → Not suitable for RF (typical FR-4)

Low-loss materials: RT/duroid 5880, RO3003, RO4835.

3. Copper Roughness (Conductor Loss)

At high frequencies, current flows mostly on the copper surface (skin effect). Rough copper dramatically increases loss.

Prefer:

- rolled annealed (RA) copper for mmWave

- reverse-treated copper for reduced roughness

- low-profile copper foils for minimized loss

Materials like RT/duroid 5880 and RO3003 can be purchased with ultra-smooth copper.

4. Thermal Stability (CTE & Tg)

RF circuits that handle high power—such as power amplifiers and automotive radar—need laminates with:

- low Z-axis CTE

- high glass-transition temperature (Tg)

- stable thermal conductivity

Why this matters:

- prevents via cracking

- improves solder joint reliability

- minimizes dimensional changes during reflow

- reduces drift in circuit performance over temperature

Strong performers: RO4350B, RO4835, RO4003C.

5. Frequency Range Compatibility

The best material changes depending on the target operating frequency.

| Frequency Range | Recommended RF PCB Materials |

| 1–6 GHz (RF) | RO4003C, RO4350B, Taconic RF-35 |

| 6–24 GHz (Microwave) | RO4835, RO3003, RO3006 |

| 24–80 GHz (Millimeter-Wave) | RT/duroid 5880, RO3003, ultra-smooth copper laminates |

Using the right material ensures correct impedance, low loss, and predictable electrical behavior.

So in summary:

To choose the ideal RF PCB substrate, evaluate:

- DK accuracy & stability

- DF (loss)

- copper roughness

- CTE & thermal performance

- fabrication difficulty

- operating frequency

- your budget vs performance

For most RF applications (1–20 GHz), RO4003C / RO4350B provide the best balance. For millimeter-wave (24–80 GHz), RT/duroid 5880 or RO3003 deliver superior performance with extremely low loss.

Why EBest Circuit (Best Technology) Supports RF PCB Projects Well?

EBest Circuit (Best Technology) provides strong support for RF, microwave, and millimeter-wave PCB production. Our team works with Rogers, Taconic, PTFE, ceramic-filled PTFE, hydrocarbon laminates, and hybrid stack-ups.

Customers value our service because:

- We hold ISO9001, ISO13485 for medical, IATF16949 for automotive, and AS9100D for aerospace

- We manage full production through MES systems to keep real-time traceability

- We support impedance control with stable processes

- We produce many RF board types, including RO3003, RO4003C, RO4350B, and RT5880

- Our engineers review stack-ups and provide DFM to reduce risk

- We offer competitive pricing with consistent quality

EBest Circuit (Best Technology) works closely with RF designers worldwide. We help convert a concept into a stable, manufacturable board. For teams that need stable performance, reliable impedance control, and smooth communication, EBest Circuit (Best Technology) provides a trusted path for RF PCB manufacturing.

FAQs

1. What DK value works well for millimeter-wave PCB design?

Materials like RO3003 or RT/duroid 5880 work well because they keep a steady DK and low loss at high frequencies, which helps the circuit stay stable.

2. Does DK affect RF and microwave filter design?

Yes, DK affects impedance and phase along the line, so a small DK shift can change a filter’s response. A stable DK keeps the filter closer to its intended shape.

3. Why do many antennas use low-DK materials?

Low-DK materials spread the field more evenly and support wider bandwidth, which helps antennas keep stable resonance and steady radiation patterns.

4. Can FR4 work for RF designs?

FR4 can support low-frequency RF work, but its DK drifts with temperature and humidity. Higher-frequency circuits need RF laminates with better DK stability.

5. How does DK influence microstrip impedance?

DK shapes how fast signals move and how fields sit in the dielectric, so higher DK lowers impedance and lower DK raises it. Designers adjust trace width based on this behavior.

Related Post:

1. Rogers RO4350B Datasheet & Material Guide for RF PCB

2. High Frequency Rogers RO5880 PCB Manufacturer

3. Why Choose RO4350B Material for High Frequency PCB?

4. What is Radio Frequency PCB? RF PCB Design Guidelines

Tags: DK dielectric constant, microwave pcb material, pcb material selection for rf microwave millimeter wave design, rf pcb material, what does dk mean