Through hole PCB assembly service (THT) is a foundational manufacturing process where electronic components with long leads are inserted into pre-drilled holes on a PCB and soldered onto pads on the opposite side. This blog will guide you from understanding the fundamentals of THT to selecting the right partner for your prototyping and production needs.

Choosing a professional through hole PCB assembly service is crucial, yet many buyers face common hurdles. What are the typical pain points when sourcing these services?

- Difficulty finding vendors willing to handle low-volume or complex manual THT work alongside high-mix projects.

- Inconsistent quality and reliability, with issues like cold solder joints or damaged through-holes.

- Unclear or unpredictable through hole PCB assembly service cost, with frequent hidden fees for setup, tooling, or component sourcing.

- Long lead times, especially for prototype PCB assembly, slowing down the product development cycle.

- Lack of technical support and communication from the PCB assembly house, leading to misunderstandings and rework.

Addressing these challenges requires a partner with the right expertise and processes. The corresponding solutions lie in partnering with a specialized assembly provider.

- Offer flexible, scalable services that seamlessly blend manual expertise for prototypes with automated options for volume production.

- Implement rigorous, multi-stage quality control (QC) procedures specifically designed for verifying THT solder integrity and mechanical strength.

- Provide transparent, upfront quoting with a detailed breakdown of all costs, including turnkey PCB assembly options for simplified budgeting.

- Dedicate specialized production lines and skilled technicians to ensure quick turnaround for both prototyping and urgent orders.

- Assign a dedicated engineering support team to collaborate on design for manufacturability (DFM) and provide clear, proactive communication throughout the project.

At BEST Technology, we are a specialist PCB and assembly manufacturer with deep expertise in through-hole technology. We bridge the gap between complex prototype builds and efficient volume fabrication, offering transparent pricing, stringent quality control, and a collaborative approach. It is worth mentioning that our factory is ISO 13485 and AS9100D certified. And importantly, we have implemented a full MES system for traceability.

We mainly provide comprehensive PCBA services for the medical, industrial controls and aerospace industries, supporting all board types including FR4, ceramic PCBs, flex circuits, and rigid-flex boards. Based on last year’s sales data, our top three export markets were Germany, Israel, and the United States. For a reliable partnership, pls feel free to contact us at sales@bestpcbs.com.

What Is Through Hole PCB Assembly Service?

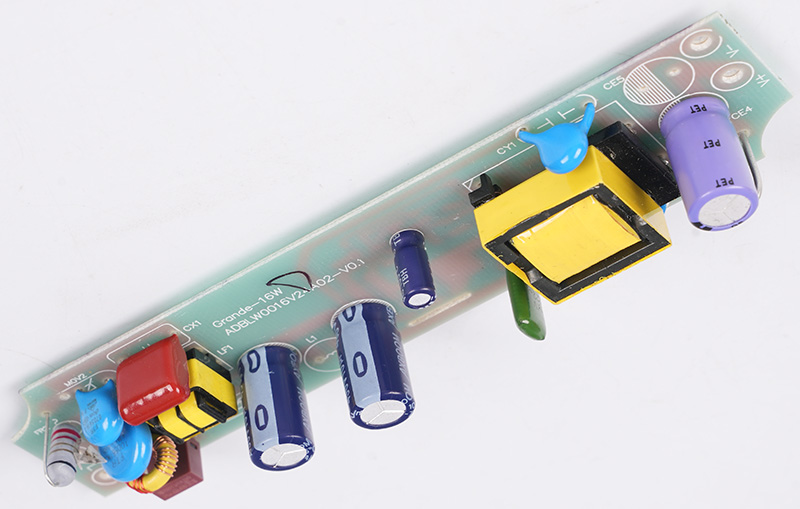

Through-Hole Technology (THT) assembly involves mounting components by inserting their leads into designated holes on a bare PCB and soldering them to pads on the opposite side. This section outlines its core characteristics and modern applications.

‚ÄĘ Process Flow: The typical sequence includes:

- Component insertion (manual or automated),

- Board fluxing,

- Wave or hand soldering,

- Cleaning, and

- Inspection and testing.

‚ÄĘ Key Advantages: Strong mechanical bonding, ideal for components facing high mechanical stress, heat, or harsh environments.

‚ÄĘ Component Types: Common for connectors, power devices, large capacitors/inductors, and reliability-critical components.

‚ÄĘ Modern Role: Essential in aerospace, automotive, industrial equipment, power tools, and prototyping. PCB through hole repair is also simpler than SMT rework.

Table: Comparison of Through-Hole and Surface Mount Technologies

| Characteristic | Through-Hole Assembly | Surface-Mount Assembly |

|---|---|---|

| Mechanical Strength | Very strong, leads pass through PCB | Moderate, sits on surface |

| Power Handling | Better heat dissipation | Lower thermal capacity |

| Board Space | Lower density, needs holes | Higher density, no holes required |

| Rework | Easier, accessible both sides | Harder, precise heating needed |

| Harsh Environment Reliability | Excellent stability | Good, application-dependent |

THT remains indispensable for applications requiring durability and mechanical integrity.

Why Choose Professional Through Hole PCB Assembly Services?

Professional through hole PCB assembly services provide consistency, reliability, and efficiency that DIY or unstructured processes cannot match.

‚ÄĘ Quality Control: Controlled soldering processes (selective/wave) plus advanced inspection (AOI, X-ray, functional testing).

‚ÄĘ Equipment Access: Automated insertion, precision solder systems, and advanced through hole assembly machine options.

‚ÄĘ Scalability: Smooth transition from prototype PCB assembly to mass production.

‚ÄĘ Cost Reduction: Less rework, optimized materials, improved yields.

‚ÄĘ Faster Market Entry: Established processes that shorten lead times.

A specialized provider ensures reliability, lowers risks, and improves product performance.

Why Do Buyers Look for Through-Hole PCB Assembly Services Illinois and Chicago?

Many companies prefer through-hole PCB assembly services illinois and through-hole PCB assembly services chicago for several strategic reasons:

‚ÄĘ Shorter supply chains

‚ÄĘ Reduced logistics cost

‚ÄĘ Fast communication

‚ÄĘ Local support and collaboration

‚ÄĘ Faster response for urgent prototypes or revisions

Table: Specialized Through-Hole Services in Illinois and Chicago

| Service Feature | Capability (Illinois & Chicago) |

|---|---|

| Board Types | Single/double-sided, multilayer, rigid-flex |

| Lead-Free Assembly | RoHS-compliant processes with controlled thermal profiles |

| Automated Insertion | Axial and radial component insertion for high-volume THT |

| Soldering Methods | Wave soldering, selective soldering, precision hand soldering |

| Testing Protocols | ICT, AOI, X-ray inspection, full functional testing |

| Certifications | ISO 9001, AS9100D, IPC-WHMA-A-610 compliant production |

Localizing assembly adds agility, reduces delays, and strengthens regional manufacturing ecosystems.

What Shapes the Through Hole PCB Assembly Service Price?

The through hole PCB assembly service price varies based on multiple project parameters:

‚ÄĘ Board complexity: More holes, layers, or larger size increases labor and time.

‚ÄĘ Component sourcing and characteristics: Part cost, sourcing difficulty, lead time; turnkey PCB assembly may add fees.

‚ÄĘ Order quantity: Higher volume lowers unit cost; prototypes have higher setup costs.

‚ÄĘ Manual vs. automated THT processes: Manual vs. automated insertion; mixed SMT+THT and extra testing increase cost.

‚ÄĘ Additional services such as PCB Assembly Express, DFM, coating, packaging

Table: Cost Drivers in Through-Hole PCB Assembly

| Cost Factor‚Äč | Low Cost Impact‚Äč | High Cost Impact‚Äč | Typical Cost Variation‚Äč |

|---|---|---|---|

| Volume | High volume (>10,000 units) | Low volume (<50 units) | 300-500% difference |

| Board Layers | 1-2 layers | 8+ layers | 150-400% difference |

| Component Count | <50 components | >200 components | 200-300% difference |

| Lead Time | Standard (4-6 weeks) | Expedited (24-72 hours) | 50-200% premium |

| Quality Class | Commercial/Consumer | Military/Medical | 100-300% premium |

| Testing | Basic visual inspection | Full ICT+AOI+Functional | 50-150% additional |

Price directly reflects scope, complexity, and quality requirements. A detailed design package ensures accurate quoting. When requesting a quotation, we would sincerely appreciate it if you could share key project details‚ÄĒsuch as the application industry, usage stage, whether it is a new project, estimated annual volume, and your target mass-production schedule‚ÄĒas this information helps us provide a more accurate and well-tailored price estimate.

How to Evaluate Through Hole PCB Assembly Service Cost?

Evaluating through hole PCB assembly service cost requires more than comparing unit prices.

‚ÄĘ Review quote structure (unit price, NRE, tooling, parts)

‚ÄĘ Assess quality and IPC compliance

‚ÄĘ Evaluate lead time impact and quick-turn options

‚ÄĘ Check communication quality

‚ÄĘ Compare prototype-to-volume scalability

The goal is to balance cost with quality, speed, engineering capability, and long-term risk reduction.

When to Use PCB Assembly Express, Turnkey PCB Assembly, or Prototype PCB Assembly?

Each service model supports different development phases:

‚ÄĘ PCB Assembly Express ‚Äď urgent builds, validated designs, quick iterations

‚ÄĘ Turnkey PCB Assembly ‚Äď one-stop service including sourcing, PCB printing USA, assembly, testing

‚ÄĘ Prototype PCB Assembly ‚Äď supports engineering changes, partial builds, flexible testing, often offered by specialized printed circuit board assembly companies

Table: Service Model Selection Guide

| Criteria‚Äč | PCB Assembly Express‚Äč | Turnkey Assembly‚Äč | Prototype Assembly‚Äč |

|---|---|---|---|

| Volume‚Äč | Any volume (time-constrained) | Medium to high volume | Low volume (1-100 units) |

| Lead Time‚Äč | 24 hours – 1 week | 2-6 weeks (standard) | 1-3 weeks |

| Cost Structure‚Äč | Premium pricing | Volume-based with economies of scale | Higher per-unit, lower total |

| Ideal Project Phase‚Äč | Production/Urgent need | Production | Design/Development |

| Internal Resources Needed‚Äč | Minimal (focused on urgency) | Minimal | Significant engineering |

| Supplier Relationship‚Äč | Transactional | Strategic partnership | Collaborative/Technical |

Choosing correctly aligns cost, speed, and development flexibility.

How Do Printed Circuit Board Assembly Companies and Colorado PCB Assembly Handle THT Work?

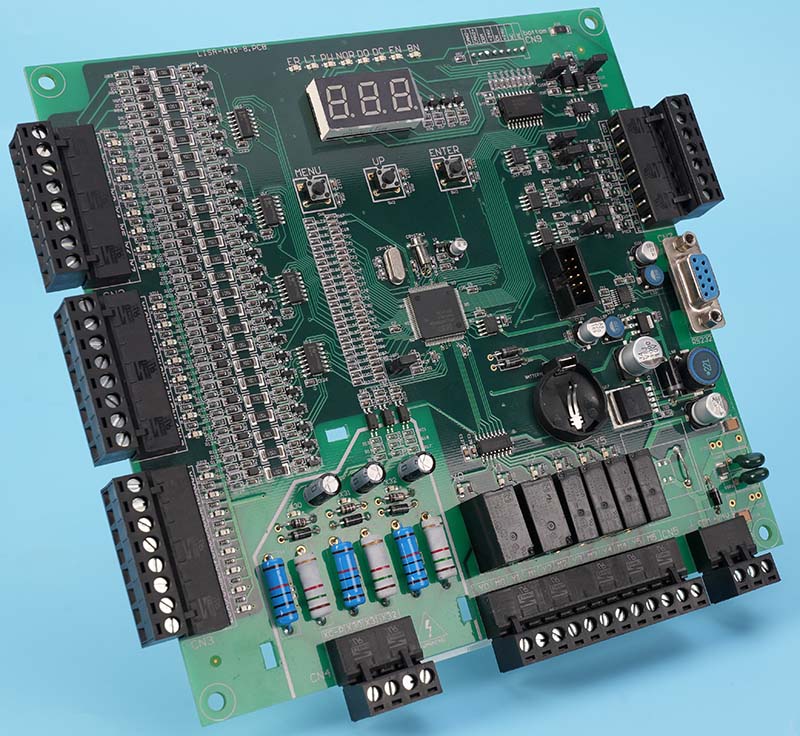

Professional PCB providers, including colorado PCB assembly specialists, follow a disciplined workflow:

‚ÄĘ DFM analysis

‚ÄĘ Component prep and lead forming

‚ÄĘ Manual or automated insertion

‚ÄĘ Selective, wave, or hand soldering

‚ÄĘ Post-cleaning and finishing

‚ÄĘ Inspection and functional testing

This ensures mechanical strength and electrical reliability for every THT joint.

Table: Through-Hole Technology Applications by Industry

| Industry | Typical THT Applications | Key Requirements | Colorado Relevance |

|---|---|---|---|

| Aerospace & Defense | Avionics, communication modules, control systems | High reliability, vibration resistance, wide temp range | Major Colorado aerospace hub |

| Automotive | ECUs, sensors, power modules | Vibration durability, temp cycling, stable performance | Expanding automotive sector |

| Industrial Electronics | Power supplies, motor drives, automation systems | High current handling, thermal stability, long-term reliability | Strong industrial manufacturing base |

| Outdoor Recreation | GPS units, communication gear, monitoring devices | Environmental durability, power efficiency | Direct fit with Colorado outdoor tech market |

| Medical Devices | Monitoring systems, diagnostic devices, life-support electronics | High reliability, regulatory compliance | Growing medical device ecosystem |

Why Choose EBest Circuit (Best Technology) for Reliable Through Hole PCB Assembly Service?

BEST Technology delivers end-to-end through hole PCB assembly service with:

‚ÄĘ Full-process management: We manage your entire project, from pcb printing usa‚Äč and turnkey pcb assembly‚Äč sourcing to final box-build, ensuring seamless integration and accountability.

‚ÄĘ Scalable capability: We expertly handle both low-volume, complex prototype pcb assembly‚Äč and efficient, high-volume production runs, adapting our processes to your scale.

‚ÄĘ High-level quality control and PCB through hole repair kit availability: Our stringent QC protocols, including specialized inspection for THT joints, ensure the mechanical and electrical reliability your products require. We also supply pcb through hole repair kit‚Äč for maintenance needs.

‚ÄĘ Transparent quoting and DFM collaboration: We believe in clear communication and upfront costing. Our engineers work collaboratively with you on DFM to optimize your design for manufacturability and cost.

‚ÄĘ Proven project performance across industries: Our experience across diverse industries, from medical, aerospace to industrial controls, demonstrates our capability to deliver reliable through hole assembly‚Äč for the most demanding applications.

In summary, through hole PCB assembly service plays a crucial role in building reliable, repairable, and high-strength electronics. This blog reviewed pricing factors, workflow, service models, and why professional assembly matters. For expert through hole PCB assembly service, transparent communication, and high manufacturing quality, choose BEST Technology. Pls feel free to contact us at sales@bestpcbs.com to discuss your project.

Tags: Through Hole PCB Assembly Service, Through Hole PCB Assembly Service Cost, Through Hole PCB Assembly Service Price, Through Hole PCB Assembly Services, through-hole pcb assembly services chicago, Through-Hole PCB Assembly Services Illinois