Struggling to find a reliable PCB Manufacturer Ireland? This comprehensive guide lists the top 10 vendors and provides actionable steps to evaluate their capability, quality control, lead time, and future-readiness, empowering your sourcing decision.

PCB Manufacturer Ireland is pivotal for sourcing reliable printed circuit board solutions in Ireland, as partnering with a trustworthy provider directly impacts product quality and project success. The local PCB manufacturing industry here combines global expertise with homegrown specialization, offering diverse capabilities to meet varying project demands from prototype development to high-volume production. Choosing the right PCB manufacturer Ireland not only streamlines workflow and mitigates risks but also enhances the overall performance of electronic products, making the selection of a capable partner a core priority for any project.

Top 10 PCB Manufacturer Ireland List

| Company Name | Main Business Advantages | Core Advantages | Production Capability | Lead Time |

| EBest Circuit (Best Technology) | One-stop PCB manufacturing & assembly | 99.8% on-time delivery rate | 1-48 layer PCBs | Prototype: 24-48 hours |

| ECS Circuits | Multi-industry PCB manufacturing | 30+ years of experience | 1-24 layer PCBs | Prototype: 5-7 working days |

| Beta Layout | Europe’s largest PCB prototyper | Online instant pricing | 1-6 layer PCBs | Prototype: 1-6 working days |

| Litho Circuits | Semiconductor-focused design | 80% development time reduction | 1-36 layer complex PCBs | Prototype: 4-6 working days |

| Realtime Technologies | Aerospace/medical PCBs | 35,000 sq ft advanced facility | 1-20 layer rigid PCBs | Prototype: 3-5 working days |

| Shipco Circuits | High-performance material specialist | ROHS certified | 1-40 layer HDI boards | Prototype: 6-8 working days |

| PCB Runner | Local Irish manufacturing | DFM optimization | 1-24 layer mixed boards | Prototype: 4-7 working days |

| Micro Electronics | Industrial control specialist | Lean production system | 1-16 layer rigid PCBs | Prototype: 5-7 working days |

| Irish Circuits | Startup-friendly services | Flexible service models | 1-12 layer basic PCBs | Prototype: 3-4 working days |

| Advanced Circuits | Medical/aerospace grade | AS9100 certified | 1-28 layer high-reliability PCBs | Prototype: 7-10 working days |

How to Choose A PCB Manufacturer Ireland?

Selection Guide to PCB Manufacturer Ireland:

- Certification Alignment: Verify Ireland PCB Manufacturer holds ISO 9001, AS9100 (aerospace), IATF 16949 (automotive), and IPC standards compliance. Certified facilities ensure process control, traceability, and product reliability for Irish designers and engineers.

- Technical Capability Depth: Prioritize Ireland PCB Manufacturer with multilevel HDI, rigid-flex, RF, and high-speed digital circuit expertise. Confirm capabilities in microvia formation, impedance control, thermal management, and advanced substrate handling (e.g., Rogers RO4350, polyimide).

- Lead Time Transparency: Evaluate Ireland PCB Manufacturerâs prototype turnaround (7-14 days for quick-turn) and mass production timelines. Review on-time delivery history and supply chain resilience to avoid project delays for Irish engineering teams.

- Material Sourcing Flexibility: Select Ireland PCB Manufacturer offering diverse laminate options (FR-4, high-Tg FR-4, ceramic, metal-core) with consistent copper weight/thickness availability. This ensures design optimization and cost-effective material matching for local projects.

- Engineering Support Quality: Partner with Ireland PCB Manufacturer providing free DFM (Design for Manufacturing) reviews, stackup guidance, and technical consultation. Responsive CAM engineers help resolve manufacturability issues early in the design phase.

- Environmental Compliance: Choose Ireland PCB Manufacturer adhering to RoHS, REACH, and ISO 14001 standards. Sustainable practices reduce ecological impact and align with Irish regulatory frameworks for electronics production.

- Volume Scalability: Assess Ireland PCB Manufacturerâs capacity for small-batch prototyping through high-volume production. Scalable operations support startup R&D and enterprise production needs without switching suppliers.

How to Evaluate the Production Capability of PCB Manufacturer Ireland?

Evaluation Guide to Production Capability of PCB Manufacturer in Ireland:

- Assess layer manufacturing range: Check if the PCB manufacturer Ireland can handle the required number of layers for your project, from single-layer to high-layer count (40+ layers) for complex applications. Verify their experience with rigid, flexible, and rigid-flex PCBs as per your product needs.

- Examine precision processing capabilities: Evaluate the manufacturerâs ability to produce fine line widths and spacing, with a focus on tolerance control. For HDI boards, confirm their expertise in blind/buried vias and laser drilling technologies, which are critical for high-density designs.

- Review material compatibility: Ensure the PCB manufacturer Ireland supports the specific substrate materials your project requires, such as FR-4 for standard applications, or exotic materials like PTFE, ceramic, or polyimide for high-frequency, high-temperature, or harsh environment use.

- Check production volume flexibility: Determine if the manufacturer can accommodate your production scale, from small-batch prototypes to large-volume mass production. A reliable PCB manufacturer Ireland should maintain consistent quality across all volume ranges.

- Evaluate special process capabilities: For specialized requirements, such as impedance control, controlled depth milling, or surface treatments (OSP), verify the manufacturerâs technical proficiency and relevant certification.

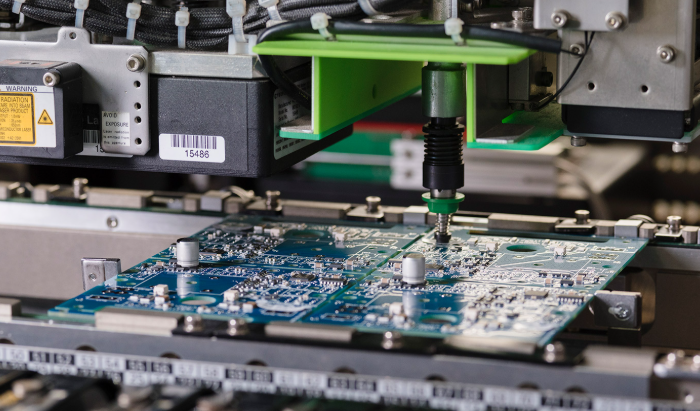

- Inspect equipment sophistication: Inquire about the manufacturerâs production equipment, including LDI exposure machines, precision drilling machines, and automated assembly lines. Advanced, well-maintained equipment is a key indicator of consistent production capability.

How to Check the Quality Control of PCB Manufacturing Company Ireland?

Guide to Check the Quality Control of PCB Manufacturing Company Ireland:

- Verify Quality Certifications: First, check if the Irish PCB manufacturing company holds international quality certifications, such as ISO 9001:2015 for general quality management, ISO 14001 for environmental management, and industry-specific certifications like IATF 16949 for the automotive industry or AS9100 for the aerospace industry.

- Review Incoming Quality Control (IQC) Processes: A robust quality control system begins with rigorous IQC. Confirm that the manufacturer tests raw materials (substrates, copper foil, chemicals) to ensure they meet specifications, including thickness, Tg value, and surface quality.

- Assess In-Process Quality Monitoring: Check if the Irish PCB manufacturing company implements real-time process control at critical stages such as etching, lamination, and plating. This includes monitoring etching parameters to avoid over-etching or under-etching, and controlling lamination temperature/pressure to prevent delamination.

- Evaluate Testing Capabilities: Verify the manufacturer’s testing equipment and procedures, including electrical testing for open/short circuit faults (flying probe testing or bed-of-nails testing), impedance testing using TDR instruments, and automated optical inspection (AOI) for surface defects. For high-reliability applications, check if they offer reliability testing (thermal stress, humidity cycling).

- Check Traceability Systems: A reliable Irish PCB manufacturing company should have a comprehensive traceability system (e.g., MES) that tracks every batch from raw materials to final delivery. This helps in quickly identifying and resolving any quality issues.

- Check Final Quality Inspection (FQC) Standards: Inquire about the final inspection standards, including compliance with IPC-A-600 standards (Level 2 or Level 3) for visual acceptance criteria. Confirm whether they use AQL sampling or 100% inspection for critical applications.

How to Evaluate the Lead Time of PCB Manufacturing Company Ireland?

Evaluation Guide to Lead Time of PCB Manufacturing Company Ireland:

- Clarify standard lead timeframes: Request a detailed breakdown of standard lead times from the PCB manufacturing company Ireland for different order typesâprototypes, small batches, and mass production. Compare these with your project timeline requirements to ensure alignment.

- Assess emergency response capabilities: Inquire about the manufacturerâs ability to handle expedited orders. A flexible PCB manufacturer Ireland should offer emergency turnaround options for critical projects, such as 24-48 hour prototype delivery.

- Review production scheduling transparency: Ask if the manufacturer provides real-time order tracking. Transparent scheduling and regular progress updates can help you anticipate potential delays and adjust your project timeline accordingly.

- Evaluate supply chain stability: A reliable PCB manufacturing company Ireland should have stable relationships with raw material suppliers to avoid material shortages that can cause lead time delays. Inquire about their inventory management practices for key materials.

- Check historical on-time delivery rate: Request data on the manufacturerâs on-time delivery performance. A high on-time rate (99%+) indicates efficient production planning and execution, reducing the risk of project delays.

- Clarify communication protocols for delays: Understand how the PCB manufacturing company Ireland communicates and addresses potential delays. A proactive approach, including early warning and proposed solutions, is essential for effective project management.

Future Trends of PCB Manufacturing Ireland

Future trends of PCB manufacturing in Ireland point to steady but focused growth, driven less by sheer volume and more by higher-value, high-reliability applications. Irelandâs broader electronic component and board manufacturing sector has grown at roughly 2â3% annually in recent years, while the European PCB market is forecast to expand by about 3â5% per year toward 2030, implying that Ireland-linked PCB output is likely to see cumulative value growth in the range of roughly 16â28% over the next five years if it tracks these regional trends.

Within that, segments tied to Irelandâs strong medtech and semiconductor base are expected to outperform: Ireland is one of Europeâs top medtech exporters (over â¬16 billion in annual medtech exports, around 14% of national exports), and hosts operations of many leading semiconductor companies, which together are investing around â¬1 billion in new manufacturing and R&D capacityâboth sectors that consume complex, high-reliability and often HDI or flex/rigid-flex PCBs.

At the European level, flexible PCBs and automotive PCBs are projected to grow faster than standard FR-4 (around 8â10% CAGR in some studies), so Irish PCB work connected to automotive electronics, medical devices, RF, and high-speed digital designs will likely shift toward more advanced stack-ups, controlled-impedance routing, and stricter quality systems (ISO 13485, IATF 16949, IPC Class 3). Overall, Ireland is unlikely to become a low-cost, high-volume PCB hub, but it is well positioned to move further âup the value chainâ into specialized, engineering-intensive PCB manufacturing and PCBA for regulated and high-performance markets.

Frequently Asked Questions About PCB Manufacturing Ireland

Q1: Why do small PCB prototype orders in Ireland cost more than overseas quick-turn services?

A1: Local fabrication shops operate smaller production lines, source many laminates through import channels, and face higher labor costs. These factors push prototype pricing upward, especially for 1â10 piece runs. Engineers often use Ireland-based manufacturers for communication convenience and support but expect higher unit costs.

Q2: Can PCB manufacturers in Ireland reliably produce controlled-impedance traces for high-speed designs?

A2: Yes, most established Irish PCB factories support controlled impedance, but designers need to provide full stack-up details, target values, and trace geometries. Some advanced high-speed materials may require longer lead times due to limited local stock.

Q3: Is it difficult to order multilayer boards with blind or buried vias in Ireland?

A3: Multilayer production is available, but blind or buried vias, stacked microvias, and complex HDI structures are less common. Engineers working on dense or high-speed layouts often choose fabrication partners with deeper HDI capability outside Ireland.

Q4: Are Irish PCB suppliers able to handle fine-pitch BGA footprints during assembly?

A4: Some assembly houses can manage 0.5 mm and occasionally 0.4 mm pitch BGAs, but results vary by facility. Designers typically confirm stencil design, reflow profile, and inspection capability before sending boards with dense BGA layouts.

Q5: How accessible are specialty materials like Rogers, Taconic, and PTFE laminates for RF boards in Ireland?

A5: Specialty RF laminates are available but not widely stocked. Manufacturers often order these materials per project, which increases both cost and lead time. Engineers working on RF modules or antennas frequently choose suppliers with large RF material inventories to avoid delays.

Tags: PCB Manufacturer Ireland