What Is PCB Conformal Coating?

Conformal coating is a protective transparent layer applied to the surface of a printed circuit board (PCB). It effectively shields electronic components and traces from moisture, dust, and chemical corrosion. The coating conforms precisely to the PCB’s shape—hence the name—forming a thin, flexible “invisible armor.”

Why Do You Need Conformal Coating?

1. Prevent Moisture-Induced Short Circuits & Leakage

In high-humidity environments, moisture condensation on the PCB can cause leakage current or electrolytic corrosion, leading to system malfunctions or failure.

2. Resist Dust & Contaminants

In industrial, automotive, or kitchen environments, dust, oil, and metal particles can accumulate on the board, creating conductive paths.

3. Enhance Resistance to Salt Spray & Chemicals

Marine and offshore electronics are exposed to salt spray, which can rapidly oxidize solder joints and copper traces

4. Improve Mechanical Stability

Some coatings (e.g., silicone) are elastic, reducing stress on solder joints from vibration.

5. Meet Industry Standards

Sectors like automotive, medical, and military often require compliance with IPC, AEC-Q100, or MIL-STD—conformal coating is a key process.

When Is PCB Conformal Coating Required?

Not every PCB needs a conformal coating, but it becomes crucial when the board faces tough conditions. Think moisture, dust, chemicals, or big temperature swings—these can cause corrosion, short circuits, or signal issues. Electronics in cars, airplanes, industrial machines, or outdoor lighting often need this extra layer of protection.

Miniaturized or high-density PCBs also benefit from conformal coating. Tiny spaces between components increase the chance of shorts or solder joint problems. A thin protective layer helps keep the circuits safe and reliable.

Boards that go through frequent heating, cooling, or vibration also get an advantage. The coating helps absorb stress, reducing cracks and extending the board’s lifespan. In short, if your PCB works in a challenging environment, conformal coating is usually a smart choice. Here is a table of what applications require PCB conformal coating.

| Application | Environment Challenge | Recommended Coating Type |

| Automotive ECUs | Moisture, vibration, temperature changes | Polyurethane (PU) |

| Aerospace electronics | Extreme temperature swings, humidity | Silicone (SR) |

| Industrial machinery | Chemicals, dust, mechanical stress | Acrylic (AR) |

| Outdoor lighting | UV exposure, rain, dust | Parylene or UV-cured coatings |

| High-density PCBs | Miniaturized components, tight spacing | Conformal coating layer (thin PU or acrylic) |

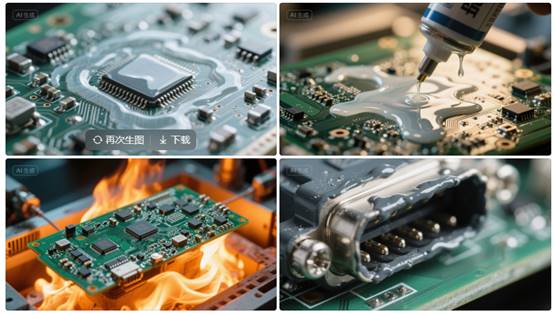

Risks of Skipping Conformal Coating

→ Product early failure: Damaged within warranty, increasing after-sales cost

→ Customer complaints & brand damage: Poor reliability harms reputation

→ Mass recall risk: May require full batch rework

→ Fail certification: May not pass IP, CE, or UL tests

Bottom line: Saving on coating cost could cost ten times more in repairs

Common Misconceptions

Myth 1: Only outdoor devices need coating

→ Humid climates, kitchen grease, and industrial dust are also threats.

Myth 2: Potting can replace conformal coating

→ Potting is for structural protection—higher cost, harder to repair. Coating is lighter and more flexible.

Myth 3: Coating guarantees protection

→ Uneven application, bubbles, or missed areas reduce effectiveness. Process control is critical.

How to Choose the Right Coating?

| Type | Pros | Cons | Applications |

| Acrylic | Easy to apply & repair, low cost | Moderate chemical resistance | General industrial, consumer |

| Polyurethane | Good chemical & moisture resistance | Hard to repair | Automotive, outdoor |

| Silicone | High temp resistance, flexible | Higher cost | High-temp, LED lighting |

| UV-Curable | Fast cure, precise coverage | Requires UV lamp, shadow areas hard to coat | Precision modules, selective coating |

Conclusion

PCB conformal coating is not optional—it’s essential for improving product reliability, lifespan, and market competitiveness.

Recommendation: Evaluate coating needs early in design. Reserve keep-out zones and protect test points to avoid rework.