Have you ever wondered why some electronic devices fail even when the PCB looks flawless? Or why high-volume production sometimes delivers inconsistent boards? These issues often trace back to undetected component defects, poor soldering, or faulty connections. Without proper testing, even a single defective part can lead to product failure, costly recalls, or customer dissatisfaction.

This is where an ICT tester equipment comes in. By performing in-circuit testing (ICT), manufacturers can quickly detect missing components, shorts, opens, and incorrect placements before the boards leave the production line. With the right ICT test electronics and in-circuit test fixtures, you gain fast, accurate, and reliable validation of each PCB, saving both time and money.

In this article, weâll answer key questions such as:

- What exactly is an ICT tester, and how does it work?

- Why is ICT testing so critical for electronics manufacturing?

- How does ICT differ from functional testing or flying probe testing?

- When should you use ICT versus functional testing for your boards?

By understanding these points, youâll see how ICT testing can prevent defects, improve production efficiency, and ensure reliable end productsâturning potential headaches into controlled, predictable outcomes.

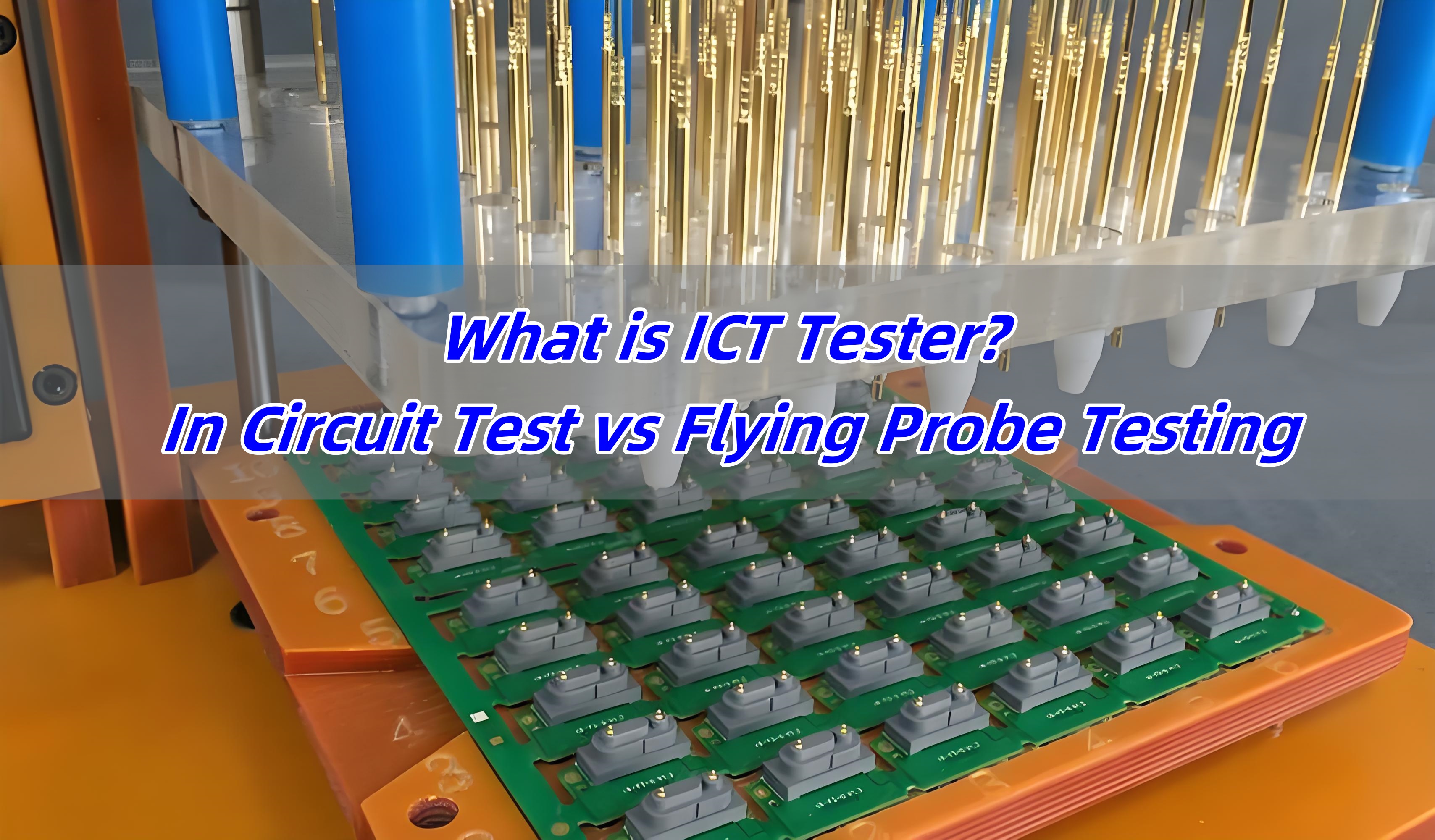

What is an ICT Tester?

An ICT tester is a system designed to perform in-circuit testing (ICT) on printed circuit boards after assembly. It is often recognized by its âbed-of-nailsâ fixture, which has hundreds or even thousands of pins arranged to contact specific points on the PCB. Each pin corresponds to a pad, via, or test point, allowing the tester to measure voltages, resistances, and currents at component level.

ICT testers can:

- Detect missing, incorrect, or faulty components.

- Identify open circuits, short circuits, and soldering defects.

- Measure parameters such as resistance, capacitance, and diode orientation.

- Verify integrated circuit placement and connectivity.

Because ICT is thorough and fast, it has become an industry-standard approach, especially in high-volume production lines.

Why is the ICT Test Important?

The ICT test is important for several reasons. In large-scale manufacturing, even a single defect can ripple into thousands of defective units. Detecting issues early reduces costs, avoids recalls, and protects brand reputation.

For example, in automotive electronics, where safety systems depend on flawless PCBs, ICT is crucial. An undetected fault in an airbag control system could have serious consequences. In consumer electronics, ICT prevents faulty smartphones, laptops, or home appliances from reaching the market.

The ICT test is also important for process improvement. It provides engineers with statistical data that highlights recurring problems, such as solder bridging or component misplacement. Manufacturers can use this data to refine processes, reduce defect rates, and improve yields.

What is the Purpose of the ICT Test?

The main purpose of ICT testing is to validate the quality and functionality of each component on the PCB. Unlike functional testing, which looks at the boardâs overall behavior, ICT digs into details at component level.

ICT ensures that:

- Every resistor has the correct value.

- Capacitors and inductors are present and within tolerance.

- Diodes and transistors are oriented properly.

- Integrated circuits are placed in the right sockets and connected.

By catching defects at the source, ICT reduces the risk of failures at the productâs final stage. This is especially valuable in industries where long-term reliability is critical, such as aerospace, defense, and medical devices.

How Does an ICT Tester Work?

An ICT tester works by pressing the in-circuit test fixture against the PCB, making contact with the test pads or vias. Once contact is established, the system injects signals into the board and records the response.

Hereâs a breakdown of the process:

- Fixture Setup â The board is placed into a bed-of-nails fixture designed for its exact layout.

- Signal Injection â Test probes inject electrical signals into various nodes of the circuit.

- Measurement â The tester measures voltage, current, resistance, and capacitance at each point.

- Analysis â Software compares the measured values with predefined thresholds.

- Reporting â The system highlights any failures or deviations for quick troubleshooting.

ICT is highly automated, with a cycle time ranging from a few seconds to less than a minute. This makes it efficient for high-volume production, where time savings directly translate to lower manufacturing costs.

Advantages of ICT Testing

- High Accuracy â Detects even subtle component defects.

- Fast Cycle Time â Ideal for mass production.

- Detailed Data â Provides insight into manufacturing trends.

- Early Detection â Reduces rework and repair costs.

- Reliability â Improves long-term performance of products.

What is the Difference Between Functional Testing and ICT Testing?

Both functional testing and ICT testing play important roles in quality assurance, but they target different aspects of the PCB.

- ICT Testing â Focuses on component-level verification. It checks each resistor, capacitor, diode, transistor, and IC independently. ICT identifies defects like shorts, opens, wrong components, or poor solder joints.

- Functional Testing â Evaluates the overall system behavior. It simulates real-world operating conditions, ensuring the PCB performs its intended function. Functional testing may involve powering up the device, running software, or checking communication protocols.

To put it simply: ICT looks at how the board is built, while functional testing checks how the board behaves. Both tests are complementary, and many manufacturers use them together.

Functional Testing vs ICT Testing

When to Use ICT and Functional Testing?

Choosing between ICT and functional testing depends on project goals and production stage.

Use ICT testing when:

- Boards are still in the manufacturing phase.

- Component-level accuracy needs to be validated.

- High-volume production demands fast, repeatable results.

Use functional testing when:

- The assembly is nearly complete.

- The productâs performance under real operating conditions needs to be verified.

- System-level testing is required, such as communication between multiple boards.

For best results, many manufacturers use a combination of ICT and functional testing. ICT catches early-stage defects, while functional testing provides final validation before shipment.

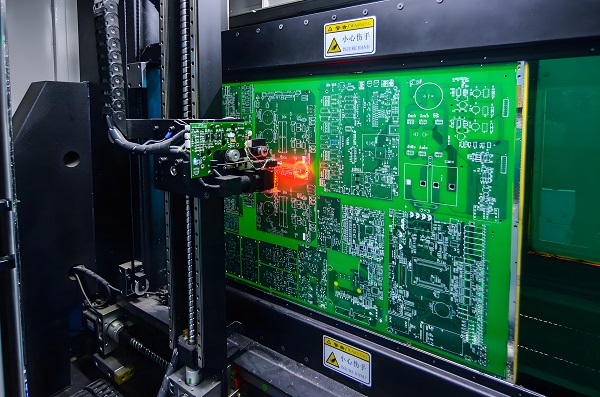

In-Circuit Test vs Flying Probe: What are Differences?

When comparing in-circuit testing (ICT) with flying probe testing, the differences come down to cost, speed, and flexibility.

In-Circuit Test (ICT):

- Uses a custom in-circuit test fixture.

- Offers fast cycle times (seconds).

- Best for high-volume production.

- High upfront cost for the fixture, but lower cost per test afterward.

Flying Probe Test:

- Uses moving probes instead of a fixture.

- Slower than ICT, since probes move sequentially.

- Excellent for prototypes and low-volume runs.

- No fixture cost, making it more flexible and cost-effective for small batches.

In practice, many manufacturers start with flying probe testing during prototyping. Once the design is finalized and volumes increase, they shift to ICT testing for efficiency.

In-Circuit Test vs Flying Probe

Applications of ICT Testing

ICT testing is used in a wide range of industries:

- Automotive â For safety-critical systems like airbags, ABS, and engine control units.

- Medical Devices â For life-support systems, imaging equipment, and diagnostic tools.

- Aerospace and Defense â Where reliability under extreme conditions is non-negotiable.

- Consumer Electronics â From smartphones to laptops, ensuring consistent quality.

- Industrial Equipment â For automation controllers and power management systems.

In each of these cases, ICT contributes to higher reliability, lower failure rates, and better compliance with international standards.

Why Choose EBest Circuit (Best Technology) for ICT and PCB Testing?

EBest Circuit (Best Technology) is a reliable PCB manufacturer in China, trusted by more than 1,000 customers across industries worldwide. We specialize in small to medium-volume PCB manufacturing, PCB assembly, and complete electronic manufacturing services.

As one of the most experienced circuit board suppliers, our capabilities cover a wide range of PCB types, including rigid PCBs, flex PCBs, rigid-flex PCBs, aluminum PCBs, RF/microwave PCBs, high-speed and high-frequency PCBs, and HDI PCBs. Beyond manufacturing, we also provide turnkey assembly, component sourcing, box build assembly, PCBA testing, and full electronic testing services.

With over 19 years of experience, our engineering, production, and quality teams fully understand the unique needs of industries such as medical, automotive, and aerospace. We strictly follow international standards, working under IPC-A-600 for PCB manufacturing and IPC-A-610 for PCB assembly. All of our products meet IPC Class 2 standards, and for projects requiring higher reliability, we also deliver Class 3 or Class 3A compliance. Combined with strong engineering support and competitive pricing, we help customers achieve both reliability and cost-effectiveness.

FAQs

1. What does ICT stand for in electronics testing?

ICT stands for in-circuit testing, which validates the quality of individual PCB components.

2. Can ICT testing replace functional testing?

No. ICT and functional testing serve different purposes. ICT checks construction, while functional testing checks performance.

3. How long does an ICT test take?

Most ICT tests take only a few seconds, depending on the number of test points.

4. Is an in-circuit test fixture reusable?

Yes, but each fixture is custom-designed for a specific PCB layout.

5. Which is better: in-circuit test or flying probe?

ICT is best for high-volume runs due to speed. Flying probe is better for prototypes or small batches.

Tags: Ict test electronics, in circuit testing, In-circuit test fixture, PCB testing