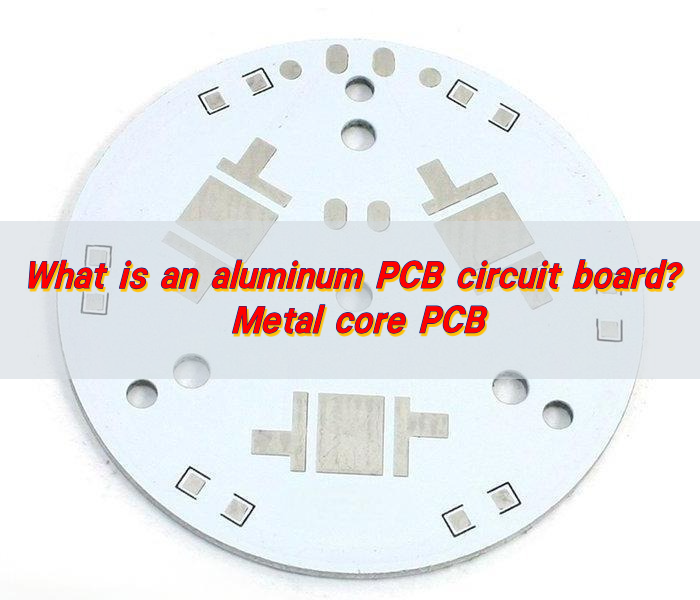

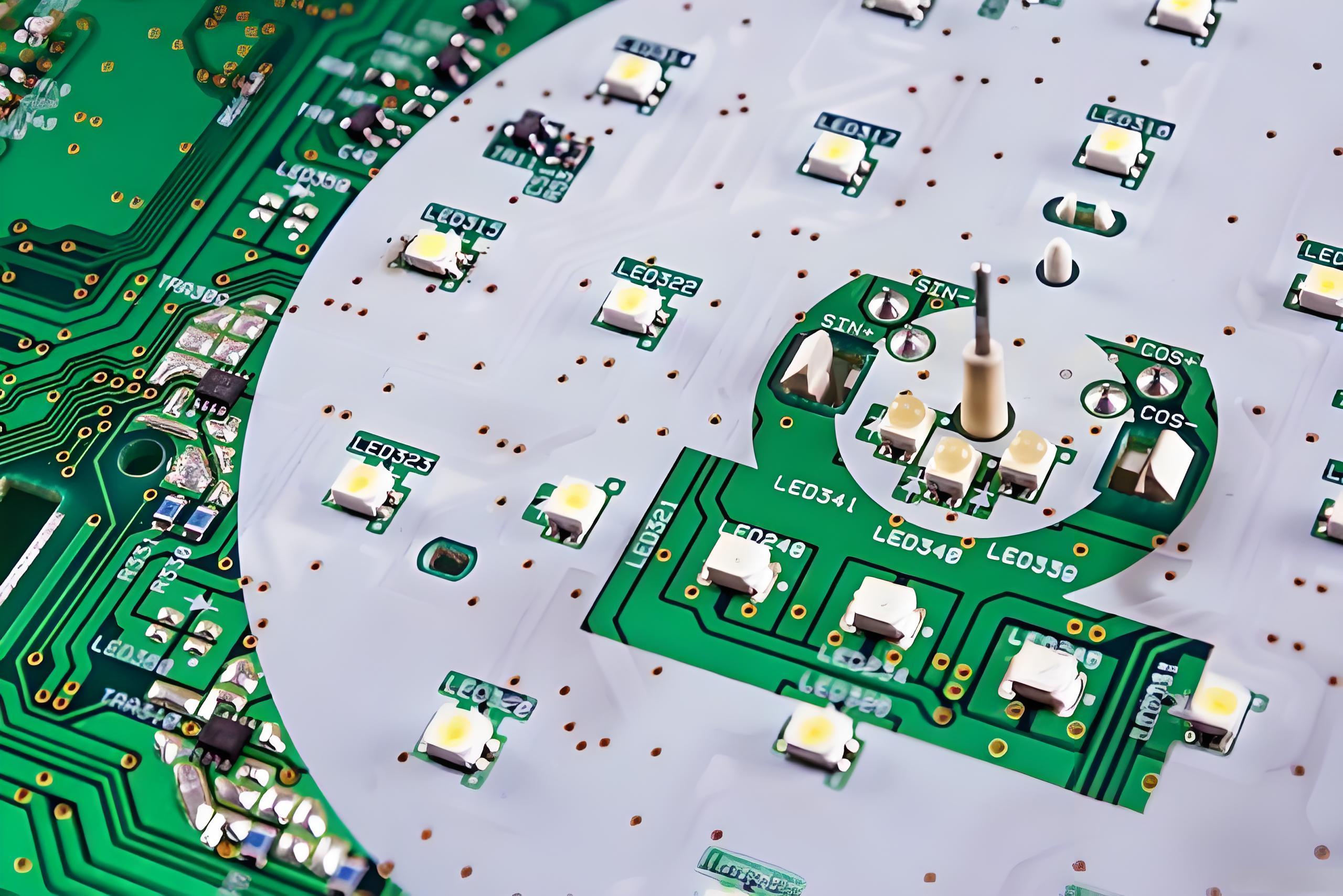

An aluminium PCB circuit board, or metal core PCB, is a type of circuit board built on an aluminum base for better heat dissipation. Unlike standard FR-4 boards, it handles high temperatures and heavy loads with ease.

It’s commonly used in LED lighting, automotive systems, and power electronics where performance and durability matter.

How to make aluminum PCB?

Making an aluminium PCB circuit board involves several precise steps. Each layer plays a role in the board’s thermal, electrical, and structural performance.

- Aluminum Base Layer: This is the bottom layer and acts as the backbone. It’s made from high-quality aluminum alloy that’s strong, lightweight, and thermally conductive.

- Dielectric Layer: This insulating layer sits between the aluminum and copper. It transfers heat efficiently while keeping electrical signals safe.

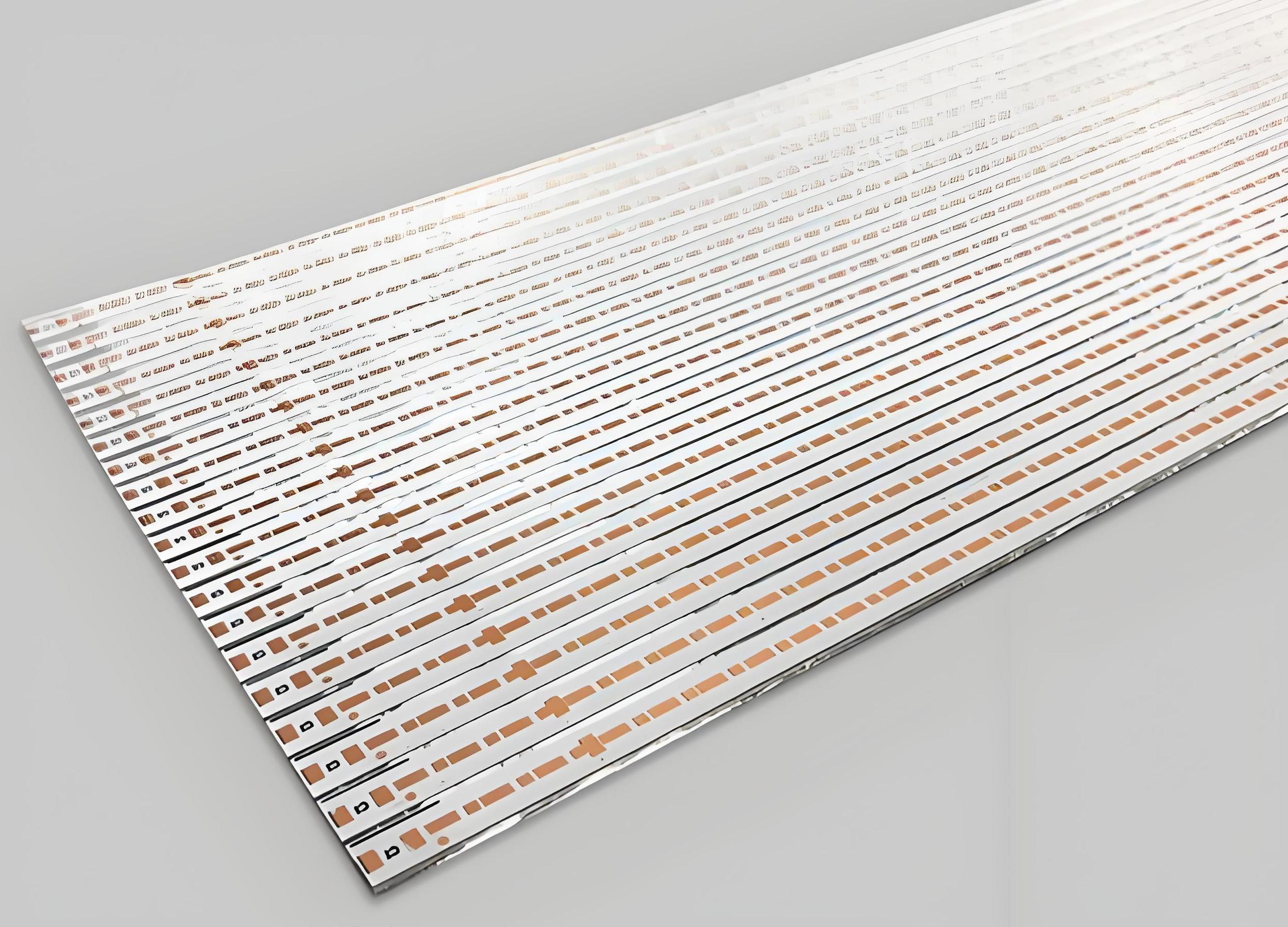

- Copper Layer: This is where the actual circuitry is formed. Copper is etched to create the pathways that electrical signals follow.

- Solder Mask and Silkscreen: The solder mask protects the copper from oxidation and short circuits. The silkscreen marks component placements and part numbers.

- Drilling & Surface Finishing: Holes are drilled for component leads. Surface finishes like ENIG or HASL are applied to improve solderability.

Every step demands precision. At EBest Circuit (Best Technology), we fine-tune this process to create aluminum PCBs that meet strict quality standards.

What is the structure of aluminum PCB?

The structure of an aluminum circuit board is simple but effective:

- Metal Core (Aluminum Layer): Offers mechanical strength and heat sinking.

- Thermal Dielectric Layer: Transfers heat away from the copper layer.

- Copper Circuit Layer: Routes the signals and power across the board.

Depending on the design, it can be:

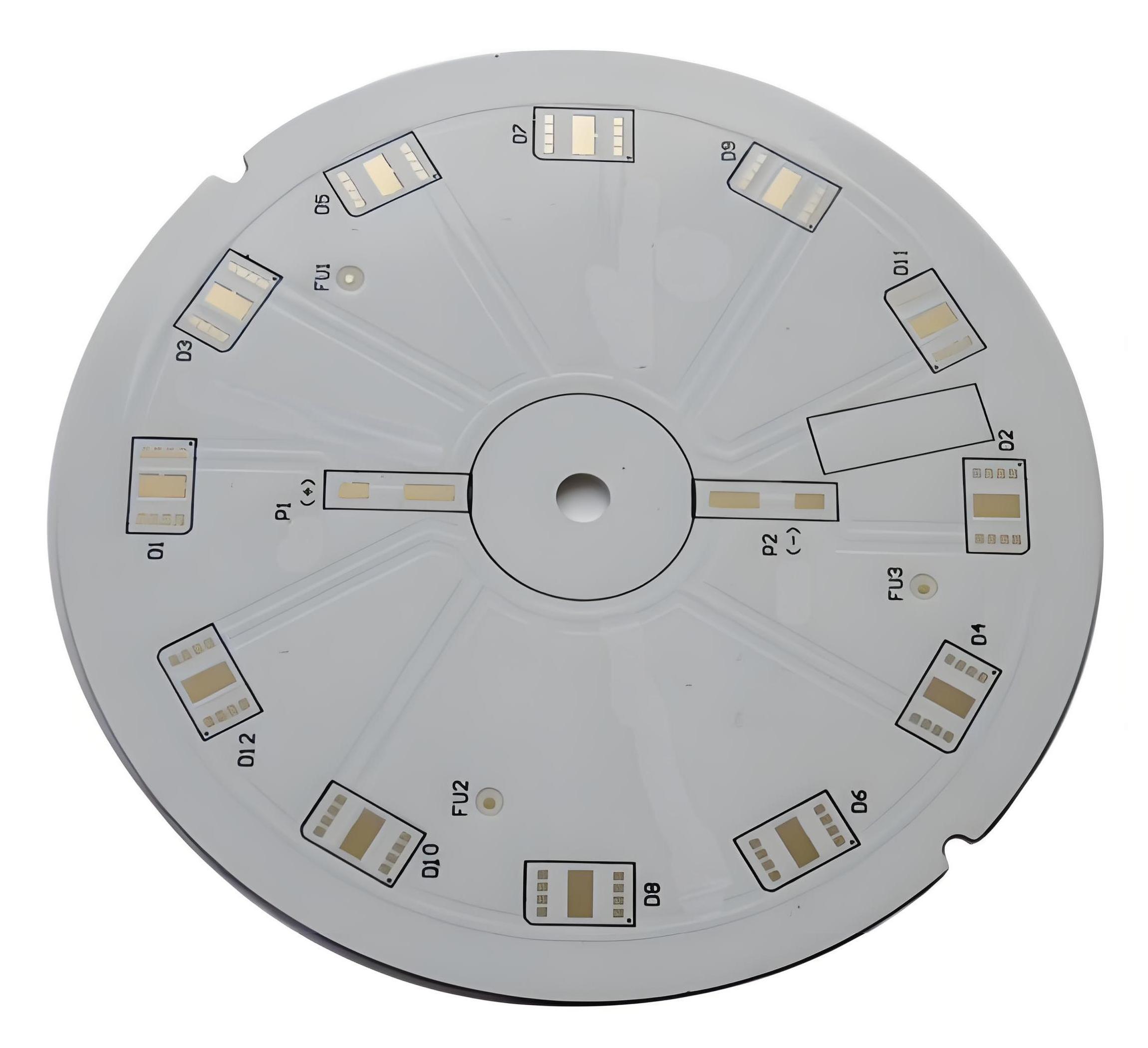

- Single-layer: Common for LED applications.

- Double-layer: For more complex circuits.

- Multilayer: Combines performance and compact size.

- Rigid-flex: For advanced or tight-space applications.

Each type supports different applications but shares the same core benefit—effective thermal management.

How thick is aluminum PCB?

The thickness of an aluminium PCB circuit board varies based on the application:

- Aluminum Base Layer: Typically ranges from 0.8mm to 3.2mm.

- Copper Layer: 1oz to 3oz (35μm to 105μm).

- Dielectric Layer: Between 100μm and 200μm.

Thicker boards offer better heat dissipation and mechanical strength, while thinner boards save space and cost. The right choice depends on power levels, component density, and enclosure design.

What is the maximum temperature for aluminum PCB?

Aluminum PCBs are designed to handle heat with ease. In most cases, they can operate continuously between 130°C and 150°C. During brief soldering processes, they can withstand up to 250°C.

This makes them perfect for high-temperature environments, especially in LED lighting and power electronics. But, performance depends on:

- Copper weight

- Quality of the dielectric layer

- Circuit design and cooling system

At EBest Circuit (Best Technology), we choose high-grade materials to ensure long-lasting temperature stability.

What are the pros and cons of aluminum PCB?

Let’s start with the advantages:

- Superior Heat Dissipation: Heat moves quickly away from sensitive parts. This boosts performance and extends product life.

- Lightweight Yet Durable: Aluminum is stronger than FR-4 and lighter than ceramic boards.

- Longer Lifespan: Better thermal handling reduces component failure rates.

- Eco-Friendly: Aluminum is recyclable, reducing environmental impact.

- Cost-Effective for Power Applications: Reduces need for extra heat sinks and thermal pads.

And now the few limitations:

- Not as flexible as polymer-based PCBs

- Slightly higher initial cost than FR-4 (but lower maintenance and longer lifespan)

In real-world use, the advantages far outweigh the disadvantages, especially since it is designed and manufactured by BEST Technology.

What is the difference between aluminum and FR-4 PCB?

Let’s compare the two:

| Feature | Aluminum PCB | FR-4 PCB |

| Thermal Conductivity | High, handles heat well | Low, needs heat sinks |

| Material | Metal core (Aluminum) | Fiberglass epoxy (FR-4) |

| Durability | Tough, resists shock | Less impact-resistant |

| Cost (initial) | Slightly higher | Lower |

| Cooling Accessories | Often not needed | Frequently needed |

| Weight | Moderate | Lightweight |

If your project involves high power or heat-sensitive components, aluminum wins hands down.

When to use aluminum PCB?

Aluminum PCBs aren’t for everything, but when heat is involved, they’re unbeatable.

Use them in:

- LED lighting (especially high-brightness)

- Power supply modules

- Automotive electronics

- Electric vehicle components

- Communication base stations

- Audio amplifiers

They’re also great when you want to reduce size and weight without sacrificing strength.

What are aluminum PCBs used for?

These boards are everywhere, though often hidden inside devices:

- 1. LED Applications: LEDs produce heat, and aluminum PCBs are ideal for pulling that heat away. This prevents light degradation and extends lifespan.

- 2. Automotive Systems: Cars generate vibration, heat, and require stability. Aluminum PCBs resist shock and stay cool—perfect for control modules and lighting.

- 3. Power Electronics: Used in DC/AC converters, battery management systems, and solar inverters.

- 4. Industrial Controls: Drive controllers, motor regulators, and sensors need tough, reliable PCBs. Aluminum handles the stress and heat like a pro.

- 5. Medical Equipment: From diagnostic machines to surgical lighting, these boards maintain performance and safety in critical conditions.

- 6. Telecommunication Systems: They provide reliability in routers, amplifiers, antennas, and base stations.

Aluminum PCBs support modern devices across industries, from smart homes to renewable energy systems.

Conclusion:

Aluminium PCB circuit boards bring the perfect mix of strength, efficiency, and thermal control. They handle harsh environments and extend the lifespan of electronics. Their use in electronic products is increasing due to their superior thermal management, improved durability and long-term cost-effectiveness.

At EBest Circuit (Best Technology), we specialize in high-performance aluminum PCB design and manufacturing. Our boards are built to meet international standards and customized to your needs.

Want to upgrade your products with dependable aluminum PCBs? Contact us today at: sales@bestpcbs.com

Tags: aluminium pcb board for led, aluminium pcb circuit board, aluminum pcb board, Metal Core PCB