If you are developing lighting products, displays, or electronic devices that use LEDs, then LED PCB assembly is a crucial step in turning your idea into a working product. Among many requirements, 94v0 LED PCB assembly is one of the most requested because of its fire-resistant properties. Whether used in indoor lighting, automotive systems, or industrial equipment, the quality of the assembly process plays a key role in how well an LED product performs and how long it lasts.

At EBest Circuit (Best Technology), we provide full turnkey LED PCB assembly services tailored to meet global quality standards. Our facility in China is certified to ISO9001, IATF16949, ISO13485, and AS9100D, so we can serve various industries. We support both prototypes and high-volume production and no minimum quantity requirements.

What is a LED PCB?

A LED PCB is a specialized circuit board designed to support and power LEDs efficiently. Unlike traditional PCBs, LED PCBs often require better thermal management because LEDs generate significant heat during operation. To solve this, metal core PCBs, especially aluminum-based PCBs, are commonly used for LED applications. These boards offer excellent heat dissipation and mechanical stability.

Key Features of LED PCBs:

- Metal Core Base (Often Aluminum and copper): Helps manage heat generated by LEDs.

- Copper Traces: Conduct electricity efficiently.

- Solder Mask and Surface Finish: Protect the board and enhance durability.

- Customized Shapes and Sizes: Designed based on the final product’s form.

LED PCBs are widely used in lighting fixtures, automotive headlights, backlit displays, signage, and industrial illumination systems. Their main advantage is efficient heat dissipation, which prolongs the LEDâs lifespan and ensures consistent brightness.

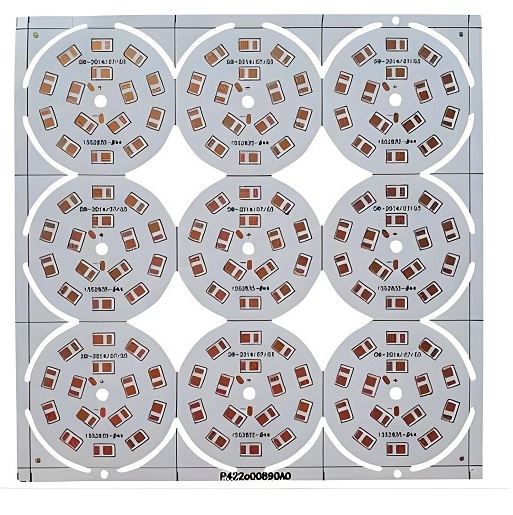

LED PCB Without Components

LED PCB vs LED PCB Assembly

Understanding the difference between a LED PCB and LED PCB assembly helps clarify the scope of your project needs.

- A LED PCB refers to the bare printed circuit board that includes copper tracks and pads but no components mounted on it.

- LED PCB assembly is the full process of mounting LEDs and other electronic parts on the PCB to make it functional.

If you only order the PCB, it wonât work until it goes through the assembly process. At EBest Circuit (Best Technology), we handle both PCB fabrication and LED PCB assembly, saving you time and reducing the risk of issues between design and production.

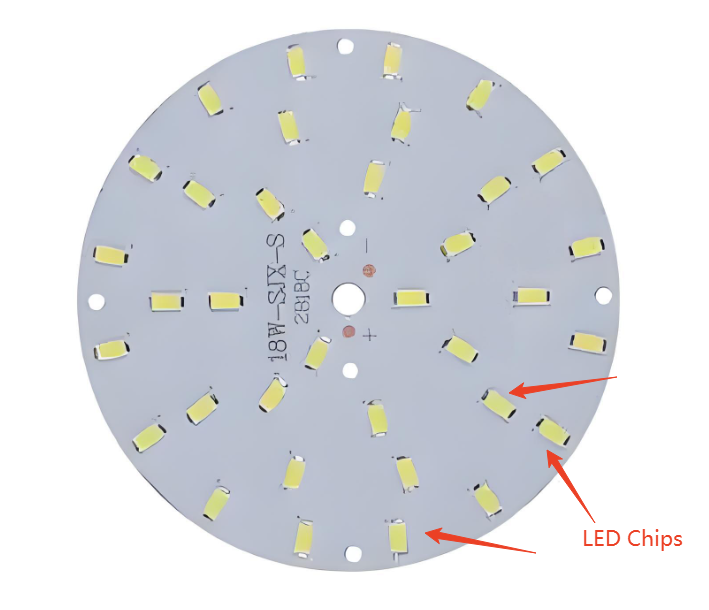

LED PCB Assembly with LED Chips

Detailed LED PCB Assembly Process

The LED PCB assembly process is a multi-stage procedure that demands strict quality control at every phase. Below is a detailed breakdown of how EBest Circuit (Best Technology) handles LED PCB assembly from start to finish. We deeply know the importance of quality, so each step are well-controlled to ensure the final product performs reliably.

1. File Review and BOM Verification

Before anything begins, our engineers carefully review your Gerber files, Bill of Materials (BOM), assembly drawings and perform DFM check to ensure compatibility and avoid errors. If there are any problems, our guys will send approvements to you for approval and continue until get your confirmation!

2. Component Procurement and Inspection

The process begins with sourcing high-quality LEDs and supporting components like resistors, capacitors, and connectors. We work only with trusted suppliers like mouser, digikey, find chips to ensure that all components meet performance and safety standards. Upon arrival, all components undergo incoming quality control (IQC), including visual inspection, functional testing, and packaging verification. In EBest Circuit (Best Technology), we support partial components sourcing, that means you can provide components or provide partial components to us.

3. Solder Paste Printing

Solder paste is applied to the solder pads on the bare PCB using a stencil printer. This step is critical because the quantity and placement of solder paste directly influence the quality of the solder joints. We use automated stencil printing machines to apply the paste consistently across all boards, ensuring optimal solder volume and alignment. After printing solder paste, we will perform SPI inspection to make sure the evenly paste spreading.

4. SMT Pick and Place

Once the solder paste is printed, the board moves to the pick and place stage, where automated SMT machines precisely place each component on the board. LEDs must be correctly oriented and positioned to maintain consistent brightness and color uniformity. Our pick and place machines handle small SMD LEDs (01005 sizes) as well as larger power LEDs with high accuracy.

5. Reflow Soldering

The boards with placed components are passed through a reflow oven. The oven heats the board in a controlled temperature profile that melts the solder paste and solidifies the electrical connections. Each LED PCB requires a customized reflow profile to avoid damaging sensitive LEDs and ensure strong, void-free solder joints.

6. AOI Inspection (Automated Optical Inspection)

After reflow soldering, we perform AOI inspection using high-resolution cameras that scan the entire board for defects such as misaligned components, solder bridges, insufficient solder, or missing parts. AOI helps detect errors early, reducing rework and ensuring product reliability.

7. Functional Testing

Functional testing is essential for LED PCB assembly. We power up each board to verify that all LEDs light up properly, and test for brightness, color temperature, voltage, and current draw. Any boards that fail the test are isolated and analyzed to determine the cause.

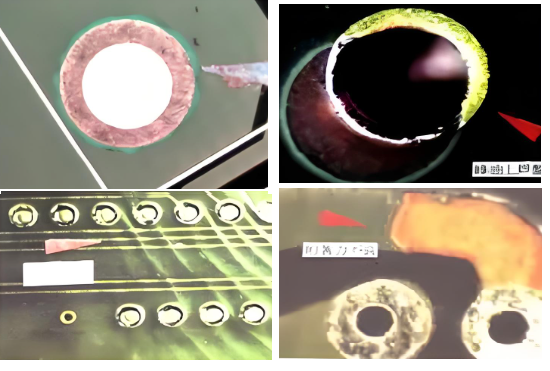

Common LED PCB Assembly Defects and Analysis

Even with advanced machines and experienced engineers, LED PCB assembly can face challenges. Understanding common defects helps prevent quality issues and reduce product failure in the field. Below are typical types of defects, their causes, and how we address them.

- Virtual Soldering (Cold Solder Joint)

This occurs when the solder doesnât properly bond to the component lead or pad. It often happens due to oxidized leads, contaminated surfaces, or incomplete solder melting. These joints can lead to intermittent connections, flickering LEDs, or total circuit failure.

- Pad Lifting

Prolonged heating or excessive temperature during rework may cause the copper pad to detach from the PCB substrate. This defect is common when the PCB lacks proper thermal resistance or heat treatment was not controlled during manufacturing.

- Solder Bridging (Short Circuit)

When too much solder paste is applied or components are placed too closely, it can create a bridge of solder between adjacent pins or pads. This causes unexpected electrical connections, leading to short circuits or component failure.

- PCB Warping or Cracks

Improper material selection, uneven thermal expansion, or poor lamination techniques can cause the board to warp or crack. This leads to misalignment of components and can even cause open circuits due to mechanical stress.

- Moisture Absorption

If the PCB is not properly baked before assembly, it may retain moisture. During reflow soldering, trapped moisture vaporizes, forming bubbles or delamination, which can damage internal layers or cause short circuits.

- Poor Heat Dissipation

LEDs generate heat, and insufficient thermal designâsuch as no heat sink, poor copper thickness, or inadequate via designâcan lead to LED overheating, early lumen degradation, or even component burn-out. This is critical in high-power LED assemblies.

- Inadequate Spacing Between Traces or Pads

If the design leaves insufficient spacing between LED pins or traces, it raises the risk of short circuits during soldering, especially with high current LED applications.

- Misalignment Between PCB Layers

In multi-layer LED PCBs, improper consideration of thermal expansion coefficients or misalignment during layer stacking may cause warping during soldering, affecting overall reliability.

- No Pre-Baking

Flexible LED strips or moisture-sensitive components should be pre-baked before soldering. Skipping this step may result in component cracking, color variation, or reduced LED lifespan.

How We Prevent These Defects?

At EBest Circuit (Best Technology), we take proactive measures to reduce these risks:

- Design Optimization: We assist clients with DFM (Design for Manufacturability) to improve spacing, heat dissipation, and alignment.

- Controlled Processes: We monitor solder paste thickness, reflow oven temperature, and component placement accuracy using real-time SPC systems.

- Material Handling: All PCBs are pre-baked to remove moisture, and we use appropriate solder pastes based on the design and LED type.

- Inspection and Testing: AOI, X-ray, and functional testing help us catch any defect early and ensure that each LED assembly works correctly

How We Ensure the Highest Quality During LED PCB Assembly?

At EBest Circuit (Best Technology), delivering high-quality LED PCB assemblies is our top priority. Hereâs how we maintain consistent quality:

- Advanced Equipment

We invest in automated and high-precision machines for every step of assembly. Our AOI systems, reflow ovens, and pick and place machines are regularly maintained and calibrated to ensure accuracy.

- Skilled Technicians and IPC Standards

All assembly work is carried out by trained personnel who follow IPC-A-610 standards for electronic assemblies. Our teamâs experience helps us tackle complex assemblies with confidence.

- MES System and Traceability

We use a Manufacturing Execution System (MES) to monitor production in real-time. Each board has a unique traceability code, allowing us to track its production history, components used, and test results.

- Quality Audits and Final Inspection

Before shipping, every batch undergoes final quality control (FQC), including random sampling and full functional testing. This ensures that our customers receive only fully functional and reliable LED PCBs.

LED PCB Assembly Machines We Use

Reliable LED PCB assembly depends on the quality of equipment used. At EBest Circuit (Best Technology), we invest in modern assembly machines that allow for fast, accurate, and repeatable results. Our equipment includes but not only:

- Yamaha & Juki Pick-and-Place Machines

- Solder Paste Printers (Fully Automated)

- 3D SPI Inspector

- Nitrogen Reflow Oven

- Dual Online AOI Machine

- X-ray Inspection

- FAI tester

- PT-500M-2ABN loader

- Dry Ice Cleaner

- Selective Wave Soldering

- Multiply Aging Testing

Our 94v0 LED PCB Assembly Daily Capabilities

94v0 LED PCBs are manufactured using flame-retardant materials that meet UL94V-0 standards. This rating indicates that the material self-extinguishes quickly after being exposed to a flame, which is crucial for safety. Hereâs what we offer daily:

- Daily Output: Up to 10,000 LED PCBs depending on complexity.

- Board Types: Rigid, flexible, aluminum-core, and copper-core boards.

- LED Options: Standard SMD LEDs, COB (chip on board), and high-power LEDs.

- Applications: LED lighting fixtures, automotive lights, medical devices, signage, and industrial systems.

- Customization: We support custom shapes, multiple layers, and specialized surface finishes.

- Minimum Order Quantity: No strict MOQ; we accept small-batch and large orders.

- Prototyping Speed: 3â5 working days for prototypes.

China LED PCB Assembly Manufacturer â EBest Circuit (Best Technology)

When it comes to LED PCB assembly in China, having a dependable partner can make a big difference in your productâs quality, lead time, and overall success. At EBest Circuit (Best Technology), we specialize in delivering high-quality LED PCB assembly services tailored to your needsâwhether you’re developing lighting systems, automotive LEDs, or consumer electronics.

Hereâs why companies worldwide choose us:

- One-stop Service: From PCB fabrication to full assembly, testing, and packaging, we handle every step in-house.

- Fast Turnaround: Whether you need prototypes or large-scale production, we offer quick turnaround times, clear communication, and reliable delivery.

- Competitive & Transparent Pricing: Direct factory pricing with no hidden costs.

- Professional Support at Every Stage: Our experienced engineers help with design review, material selection, and process optimization, so your project runs smoothly from start to finish.

- Flexible Order Quantities: We handle both prototyping and mass production with equal attention to detail.

- Smart Manufacturing: With our MES system, we track every board throughout production, giving you full traceability and confidence in product quality.

If youâre looking for a China-based LED PCB assembly manufacturer that delivers quality, speed, and peace of mind, EBest Circuit (Best Technology) is here to support you. Contact us today for a quote or to discuss your next projectâweâre ready to help.

FAQs

1. What does 94v0 mean in LED PCB assembly?

Itâs a UL rating for flame-retardant PCBs, meaning the material self-extinguishes after ignition, ensuring safer products.

2. What is the difference between aluminum and FR4 for LED PCBs?

Aluminum provides better heat dissipation and is ideal for high-power LEDs. FR4 is suitable for low-power or budget-friendly applications.

3. What types of LEDs can you assemble?

We assemble SMD LEDs, COB LEDs, high-power LEDs, and custom LED arrays for various applications.

4. How do you ensure the LEDs wonât overheat?

We use metal core PCBs, apply thermal pads, and follow optimized reflow profiles to manage heat effectively.

5. Do you offer testing for assembled LED PCBs?

Yes, we offer functional testing, burn-in testing, and optional aging tests for long-term reliability.

6. Whatâs the typical lead time for LED PCB assembly?

Prototypes: 3â5 working days; volume orders: 7â15 days depending on complexity.

7. Do you support custom designs?

Yes, we support custom LED PCB designs, including unique shapes, sizes, and special surface finishes.

8. How can I get a quote for LED PCB assembly?

You can send us your Gerber files, BOM, and specifications. Our team will provide a clear, competitive quote within 24 hours.

Tags: china led pcb assemblyâ, led pcb assembly machineâ