A motor board is a key part of any system that controls electric motors. Whether you’re building a small robot, a smart curtain, or a DIY RC car, the motor board is the part that connects your brain (the microcontroller) to your muscle (the motor).

You cannot connect a motor directly to an Arduino, Raspberry Pi, or other microcontroller because motors need more power than these boards can handle. Thatâs where a motor driver board comes in. It supplies power and manages direction, speed, and safety.

In this guide, weâll explore what a motor board is, the types available, how it works, and why itâs so important for any project with moving parts.

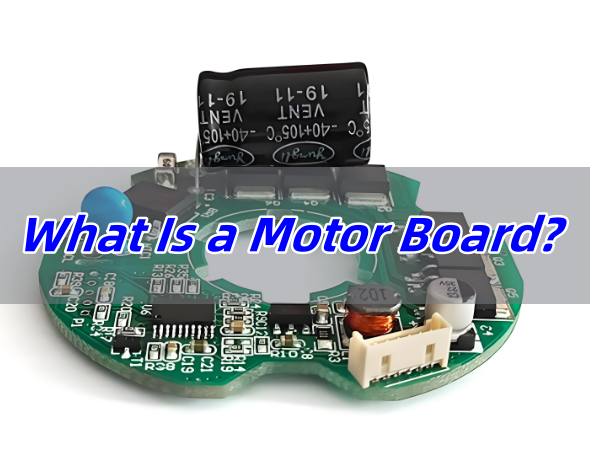

What Is a Motor Board?

A motor board is a small printed circuit board (PCB) designed to control electric motors. It acts like a translator between your low-power controller and your high-power motor. You send simple signals to the board, and the board powers and controls the motor for you.

Motor boards are often used in robotics, automation systems, and electric vehicles. They are essential when you want to move wheels, turn gears, lift arms, or rotate anything using a motor.

They can work with different types of motors, such as:

- DC motors

- Stepper motors

- Servo motors

- Brushless DC motors (BLDC)

Each motor type may require a different kind of motor board.

What Does Motor Board Mean?

The term motor board means a circuit board made specifically for motor control. It includes components like driver chips, power inputs, connectors, and sometimes sensors.

In simple terms, itâs a smart power switch. You tell it what to do (via signals from a microcontroller), and it supplies the right amount of power to the motor.

For example, when building a robot, the main board might handle logic, sensors, and communication. The motor board only deals with moving the wheels. That separation makes the system more reliable and easier to design.

Types of Motor Board

There are many types of motor boards, and each one is built to handle specific motors or motion requirements. Here are the most common:

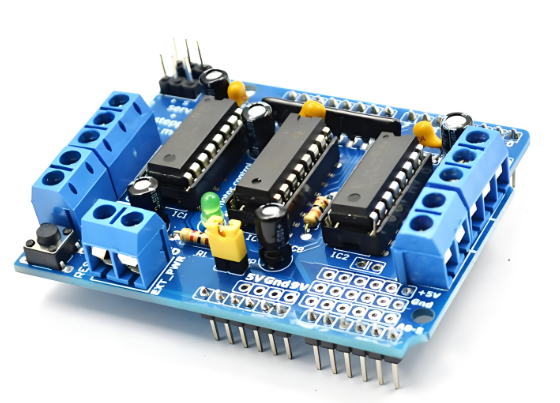

1. DC Motor Driver Boards

These are used for basic motors that rotate in one direction or both. You can control speed and direction using PWM (pulse width modulation) and digital pins. A popular example is the L298N motor driver board, which can run two DC motors at once.

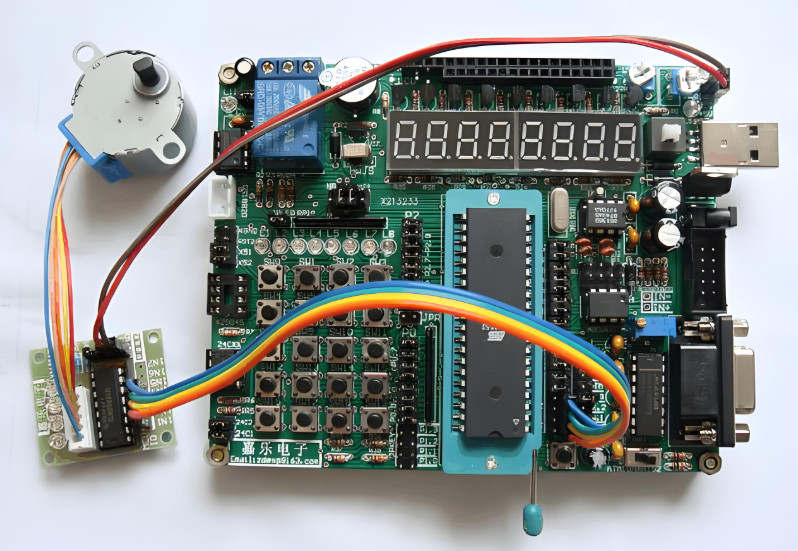

2. Stepper Motor Boards

Stepper motors move in fixed steps, not continuous rotation. These are great for projects that need precise movements, like 3D printers or CNC machines. Boards like the A4988 or DRV8825 are common choices. They control the step rate and direction.

3. Servo Motor Boards

Servos move to specific angles. They are used in robotic arms, RC cars, and camera gimbals. Servo boards control the angle through a PWM signal. Some boards allow you to connect many servos at once for large projects.

4. Dual H-Bridge Motor Boards

An H-Bridge lets current flow in both directions through a motor. This means your motor can spin forward or backward. A dual H-bridge board like the L298N or L293D can control two DC motors independently.

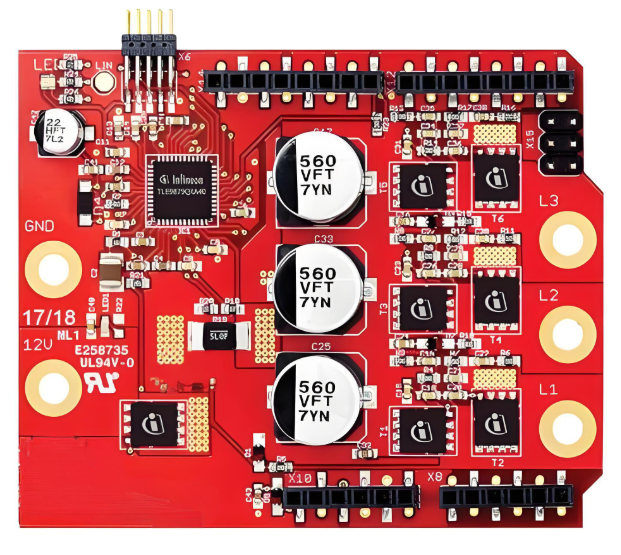

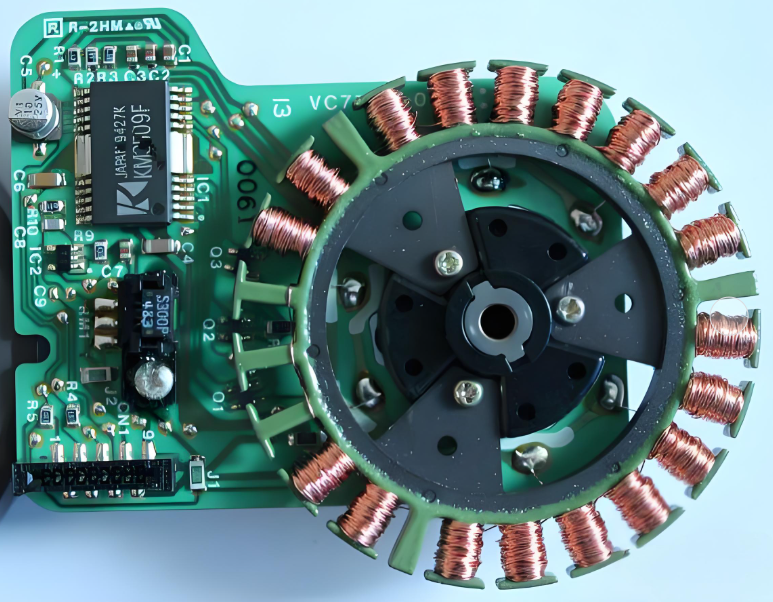

5. Brushless DC Motor (BLDC) Boards

BLDC motors are used in drones, electric skateboards, and industrial tools. They need more complex driver boards that handle three-phase power and feedback from position sensors. These boards often include FETs, controllers, and overcurrent protection.

6. Electric Motor Boards for Vehicles

These high-power boards control large motors in e-bikes or scooters. They usually feature thermal sensors, regenerative braking, current limiters, and fault indicators. They are more robust than typical hobby motor boards.

What Does a Motor Driver Board Do?

A motor driver board takes control signals from a microcontroller and uses them to control the motorâs power. It does several important jobs:

- Amplifies signals: Microcontrollers output low voltage. Motor driver boards boost these to match motor power requirements.

- Controls direction: By switching current direction, the motor can spin forward or backward.

- Adjusts speed: PWM signals let you change motor speed smoothly.

- Protects components: Built-in diodes or protection chips guard against backflow current (back EMF), which can harm your controller.

- Manages current: Some drivers limit current to prevent motor or circuit damage.

So, the motor driver board is the part that makes motors usable with small electronics.

What Color Is a Motor Board Usually?

Most motor boards are green, the standard color for PCBs. This green color comes from the solder mask, which protects the copper traces underneath.

However, boards also come in:

- Red â used by SparkFun and many other hobby suppliers

- Blue â seen in some open-source projects

- Black â popular for higher-end or custom boards

- Yellow or White â rarely used but available

The color doesnât affect performance. Itâs just for looks and branding. Pick based on function, not color.

How to Make a Motor Board?

If you want to build your own motor board, here are the basic steps:

1. Choose Your Motor

Decide if you’re using a DC, stepper, or servo motor. Each needs a different driver.

2. Pick a Driver Chip

Choose a suitable IC:

- L298N for two DC motors

- A4988 for stepper motors

- TB6612FNG for better efficiency

3. Design the Circuit

Use PCB design software like: KiCad, EasyEDA, Eagle. Include connectors, capacitors, and resistors as needed. Add power input terminals and logic pin headers.

4. Create the PCB

You can:

- Order from a PCB maker online like PCBway (lowest price but poor quality) or EBest Circuit (Best Technology) (competitive price with higher quality and 5 years quality guarantee).

- Etch it manually at home (not recommended for beginners)

5. Assemble the Board

Solder all components. Double-check the orientation of ICs, diodes, and power connections.

6. Test It Safely

Start with a small motor. Use a current-limited power supply. Test using an Arduino with simple code.

Building your own board is a great learning project, but for complex systems, buying a tested module is safer and faster.

Why Do You Need a Motor Driver?

Microcontrollers are smart, but theyâre weak when it comes to power. Motors often need 6Vâ24V and 1A or more. An Arduino pin provides only 5V and about 20â40mA.

If you connect a motor directly to the microcontroller, two things might happen:

1. The microcontroller resets or freezes

2. The motor doesnât spinâor worse, the controller burns out

A motor driver board solves this. It protects your control board while giving the motor what it needs.

It also adds:

- Precise control (change speed or reverse easily)

- Electrical isolation in some cases

- Protection features like thermal shutoff or current limiting

So, every project with motorsâbig or smallâshould include a driver.

What Is the Use of a Motor Driver Board?

A motor driver board is used in any system that requires motion. Here are some common uses:

1. Robotics

From mobile robots to robotic arms, motor drivers control wheels, joints, and actuators. You can run multiple motors and coordinate movement smoothly.

2. Automation

In smart homes and factories, motors open doors, close blinds, or move conveyor belts. Motor boards provide the control logic behind these actions.

3. Drones and RC Vehicles

Brushless motor driver boards keep drones stable and responsive. In RC cars, motor boards drive wheels, steering, or servo-based suspension.

4. 3D Printers and CNC Machines

These use stepper motor drivers to move the nozzle or cutter precisely. Each axis has its own board.

5. Electric Bikes and Scooters

High-current boards manage wheel motors, brakes, and regenerative systems.

A motor board is more than just a piece of hardwareâitâs the control center that makes electric motors useful in real projects. Without one, your motor canât respond to speed or direction commands, and your controller may get damaged trying to power it directly.

There are many types of motor boards, from basic DC motor drivers to advanced BLDC boards used in EVs. You can buy them off the shelf or design your own if youâre building a custom system. Whether you’re working on a robot, a drone, or a smart appliance, the motor driver board is a must-have. It turns signals into motion, safely and efficiently.

FAQs

1. Can I run a DC motor without a motor board?

You can, but itâs risky. Motors draw more current than microcontrollers can handle. You could damage your board.

2. What is the best motor driver board for beginners?

The L298N is affordable, easy to use, and works with most Arduino projects.

3. Can a motor board control more than one motor?

Yes. Dual motor boards control two motors. Some advanced boards can control four or more.

4. Are all motor boards compatible with all microcontrollers?

Not always. Check the logic level (3.3V vs. 5V) and connection type. Most hobby boards are designed for Arduino compatibility.

5. Is it safe to build your own motor board?

Yes, with proper design and low-voltage testing. Always double-check your connections and power ratings.