RF PCB manufacturer in China is the first thing engineers search when planning to bring a high-frequency device to market. For RF projects, even the smallest mistake in material or impedance can break the signal integrity. Thatâs why selecting the right builder matters more than ever.

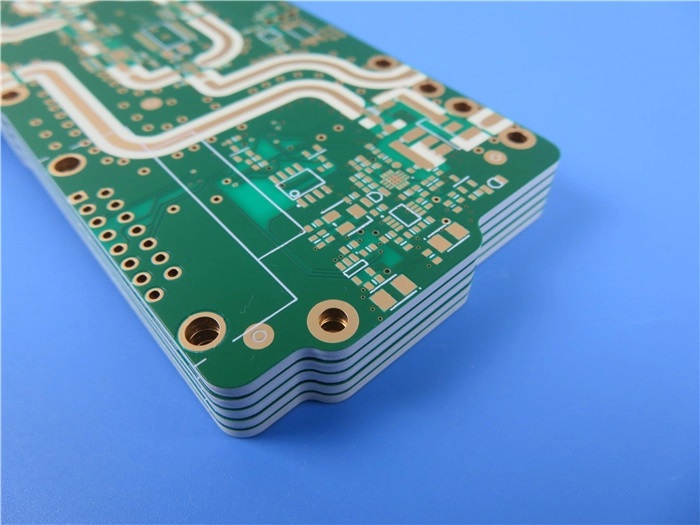

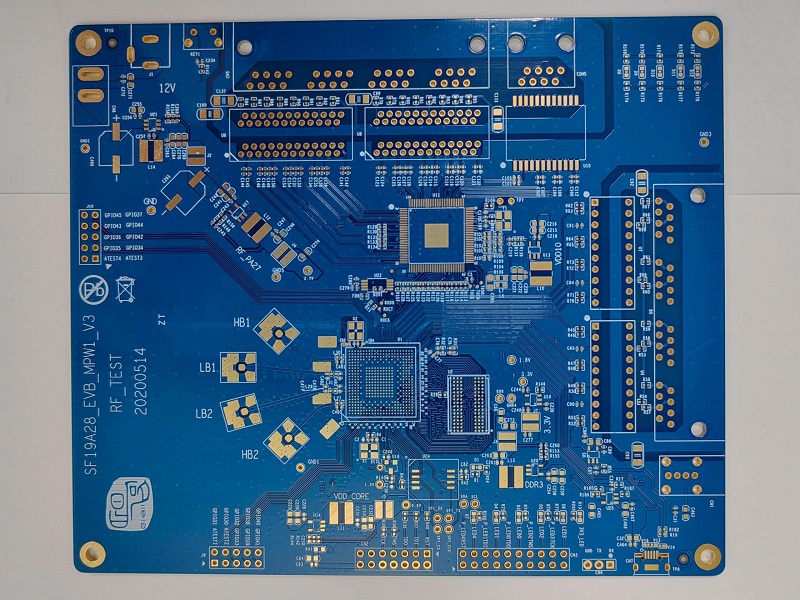

EBest Circuit (Best Technology) is an RF PCB manufacturer in China for rapid prototyping. We have the PCB factory features the latest CNC machining and rapid prototyping equipment. EBest Circuit (Best Technology) delivers high-frequency PCBs tailored to your needs with max panel size capabilities of up to 600Ă500mm. Our RF boards are applicable in 5G antenna boards, medical radar boards, and automotive sensor boards. To sum up, low volume, high mix, superior quality, and flexible prototype service have increased our competitive edge in the marketplace. If you have comments you’d like to share with us, please feel free to contact us via our Contact Page from our corporate website, our Facebook page, our YouTube page, or our Twitter account.

What is the Best RF PCB Builder?

The best RF PCB builder is the one who balances signal performance, turnaround time, and design support. They must control impedance, minimize dielectric loss, and handle advanced materials like Rogers or Taconic. For example, EBest Circuit (Best Technology) uses Rogers RO4350B for tight tolerance jobs. Our etching accuracy, within ±8%, helps avoid signal reflection, especially in boards operating above 3GHz.

Who is the Best Manufacturer of RF PCB in China?

While many factories claim experience, few consistently handle advanced RF designs. EBest Circuit (Best Technology) leads here with our integrated solution. Engineers often struggle with mismatched impedance or rough copper surfaces. Bestâs ENIG finish ensures Ra < 0.5ÎŒm, critical for 5G and radar systems. Moreover, our 24-hour prototype option gives designers a 40% faster verification cycle.

Who is the Largest RF PCB Manufacturer in China?

In volume, large-scale manufacturers such as Wus, Suntak, or Kinwong dominate. But for complex RF jobs, size isnât everything. Flexibility, fast response, and real-time feedback matter more. EBest Circuit (Best Technology) focuses on low-to-medium batches but with strong engineering support. We communicate closely with your design team, reducing miscommunicationâa common issue that slows product launch.

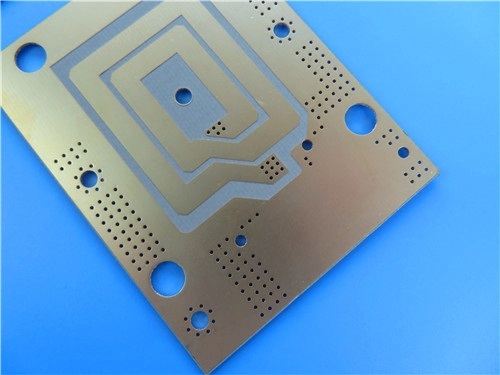

What is the Best Material for PCB RF?

Choosing the right RF PCB material means evaluating Dk, Df, thermal stability, and consistency. Rogers RO4003C and RO4350B are industry staples due to stable Dk and low loss. Meanwhile, PTFE-based materials work well at frequencies above 10GHz. EBest Circuit (Best Technology) helps clients match stackups and laminates, considering your frequency, dielectric tolerance, and thermal needs.

What is the Frequency Range of RF PCB?

Most RF PCBs operate from 500 MHz up to 77 GHz. Applications like GPS and Wi-Fi sit at the lower end, while automotive radar and satellite use the high end. EBest Circuit (Best Technology) supports a wide range of projectsâfrom 2.4GHz IoT modules to 60GHz millimeter-wave antennasâoffering layout, stackup guidance, and lab testing.

What is the Difference Between RF PCB and Traditional PCB?

Traditional PCBs focus on digital or low-speed analog. RF PCBs must deal with signal phase, impedance, and skin effect. Materials differ tooâFR4 isnât stable at high frequencies. RF printed circuit boards use materials like Teflon or ceramic-filled laminates. Etching tolerances are tighter, and return loss is a key metric. EBest Circuit (Best Technology) uses impedance simulation and X-ray alignment tools to ensure trace quality and layer consistency.

Which PCBs Should Be Recommended for High Frequency RF Devices?

For 5G, radar, or satellite use, you need PCBs with low Df, consistent Dk, and high peel strength. Multi-layer mixed dielectric stackups are often used. Rogers + FR4 or hybrid boards reduce costs while meeting RF needs. EBest Circuit (Best Technology) advises when to go pure PTFE, and when to mix to save cost without harming performance.

How to Choose an RF PCB Manufacturer in China?

Hereâs a checklist:

- Material Mastery:Â Can they handle Rogers, Arlon, or Taconic?

- Fast Prototyping:Â Do they offer 24h turnaround?

- Signal Expertise:Â Do they control impedance within 10% deviation?

- Stackup Support:Â Can they advise layout and Dk matching?

- Clear Communication:Â Is engineering feedback fast?

EBest Circuit (Best Technology) meets all these points. Our company invests in new advanced manufacturing machine, materials, and smarter planning. Whether you’re designing a mmWave radar or wearable sensor, weâve got you covered.

Why EBest Circuit (Best Technology) Is a Reliable RF PCB Manufacturer in China?

EBest Circuit (Best Technology) isnât the biggest name in China, but our high repeat rate says a lot. Hereâs why:

- Signal Control:Â Controlled impedance, Ra < 0.5ÎŒm, and ENIG uniformity stop signal loss.

- Quick Turn Samples:Â 24-hour prototype service accelerates validation.

- Material Readiness:Â Rogers, PTFE, Isola stocked for faster scheduling.

- Engineering Help:Â DFM reviews and impedance simulations provided upfront.

- Flex Options:Â Flex and rigid-flex available for compact RF modules.

- Small to Medium Batches:Â Fits R&D and early production without MOQ pressure.

In conclusion, finding the right RF PCB manufacturer in China can shape your entire project timeline and performance. Donât settle for mass producers who miss the details. Work with a team that understands your signal, your needs, and your timeline. EBest Circuit (Best Technology) bridges the gap between innovation and manufacturingâsolving RF signal issues, accelerating prototype cycles, and supporting your design with real engineers, not just order takers. Your RF project deserves more than average. It deserves precision, speed, and partnership. If you have any new inquiries or suggestions, please email us at sales@bestpcbs.com.

Tags: RF PCB Manufacturer In China, RF PCB Manufacturer In China for Rapid Prototyping