Printed circuit board assembly PCBAÂ is a vital step between your design and a working electronic product. At EBest Circuit (Best Technology), we understand how much timing and quality matter. Our short delivery services, expert support, and cost-effective solutions have helped many clients get their innovations to market faster.

EBest Circuit (Best Technology) is an original factory offering printed circuit board assembly PCBA for the global market. We perceive that quality is our lifeline and the anchor that we gaining the trust of customers. Our facility is certified by ISO 9001, ISO 13485, IATF 16949, and AS9100D. You feel assured that we provide high-quality PCBA with short delivery. For any projects, kindly contact us at sales@bestpcbs.com at all times.

What is a Printed Circuit Board Assembly PCBA?

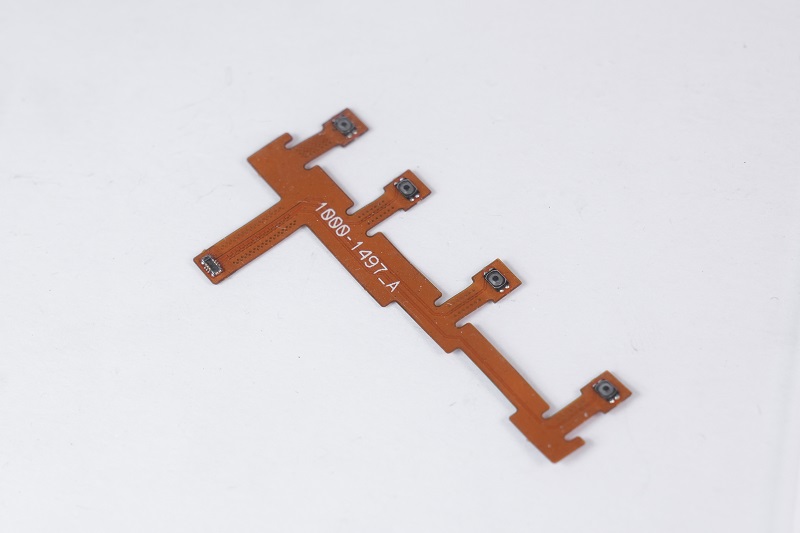

A printed circuit board assembly, or PCBA, refers to a finished circuit board after all the electronic components are mounted. This includes resistors, ICs, capacitors, and connectors. The PCBA stage transforms a bare PCB into a functional board ready to be used in devices.

What is the Difference Between PCB and Printed Circuit Board Assembly PCBA?

PCB is the blank board made of layers of insulating material and copper traces. It serves as the backbone of electronics. A PCBA, on the other hand, is that same board but fully populated with components. Simply put, PCBA = PCB + Assembly Process.

How Does a Printed Circuit Board Assembly PCBA Work?

The process begins with placing solder paste on pads, then mounting components using SMT or manual insertion. After that, boards are passed through a reflow or wave soldering process. Testing and cleaning ensure quality before packaging. At EBest Circuit (Best Technology), this process is handled quickly, even within 24â72 hours.

What is Circuit Board Board Assembly Process?

The board assembly process includes these steps:

- Solder paste printing

- Component placement (SMT or DIP)

- Reflow soldering or wave soldering

- Inspection (AOI, X-ray, ICT)

- Function testing

- Cleaning and final packaging

We make each step efficient with top equipment and skilled operators, helping reduce delays and rework.

What is Printed Circuit Board Assembly HS Code?

The HS code for printed circuit board assemblies is typically 8538900000. This classification helps with customs documentation and international shipping. Our team supports you with clear labeling and smooth logistics across borders.

How to Choose the Right Printed Circuit Board Assembly PCBA Partner for Your Product?

Choosing the right partner affects both product success and delivery time. Hereâs what to consider:

- Turnaround speed:Â Can they deliver in 24â72 hours?

- Engineering support:Â Do they help with design and DFM analysis?

- Cost control:Â Do they provide cost-saving options?

- Testing capability:Â Can they handle RF and EMC testing?

- Experience:Â Have they managed complex builds?

EBest Circuit (Best Technology) checks all the above boxes. We donât just build boards â we help optimize them too.

Why Should You Choose EBest Circuit (Best Technology) as One of Your Printed Circuit Board Assembly Companies?

Customers working with EBest Circuit (Best Technology) often face pressure with delivery, design complexity, or rising costs. Here’s how we solve those issues:

1. Fast Turnaround in 24â72 Hours

We understand your time matters. Thatâs why we offer rapid PCBA services that can be completed within one to three days. This helps speed up prototyping, testing, and full-scale launches.

2. Full Technical Support

From layout reviews to material selection, our engineers are here to help. We work closely with your team to spot problems early and recommend smart improvements.

3. Smart Cost Control

We combine advanced manufacturing with strong supply chain management. That way, you save money without sacrificing quality.

4. RF and High-Frequency PCB Expertise

Many clients trust us for high-speed, high-frequency builds. We resolve signal loss, EMI, and impedance issues using techniques like:

- 45-degree routing

- Proper grounding and shielding

- Differential pair control

- Optimized PCB stackup

5. Simulation and Testing Support

Donât wait until the final product fails. We offer signal integrity simulation and full EMC testing with equipment like TDR, VNA, and spectrum analyzers. This reduces rework and speeds up certification.

6. Advanced Manufacturing Capabilities

Our facility handles complex needs like:

- Impedance-controlled multilayers

- Blind/buried vias

- Ultra-fine trace and spacing (±5μm precision)

- Microvia laser drilling

All are supported by ISO 9001, ISO 13485, IATF 16949, and AS9100D certifications.

7. One-Stop Service

Whether you need bare boards, component sourcing, or final testing â we handle it all. This simplifies communication and cuts handover time.

In summary, when choosing a printed circuit board assembly PCBA supplier, donât settle for average. You need a partner who understands urgency, accuracy, and innovation. EBest Circuit (Best Technology) is that partner.

With short lead times, expert design support, and cost-effective options, we help you move faster â and smarter. Our customers trust us because we solve problems before they appear. And we back that up with top-notch production and reliable delivery. Contact EBest Circuit (Best Technology) at sales@bestpcbs.com for a custom quote or consultation. Weâre ready to help you build better, faster.