MCPCB manufacturer is the term every engineer and procurement manager is searching for when LED performance and heat dissipation matter. The growing demand for high-brightness lighting and power electronics has made MCPCBs the go-to option for many industries. From LED lighting and automotive to telecom and industrial applications, these boards serve as reliable heat spreaders and signal carriers. As the market grows, so does the need for professional suppliers who understand the challenges of thermal management and efficient layouts.

EBest Circuit (Best Technology) implements a high-efficiency order-solving process and implements a 2-3 weeks lead time policy from the top down. We are an honest business. We prefer to lose face instead of losing customers, and we prefer to lose interest instead of the market. You can always trust EBest Circuit (Best Technology) for the diverse specifications of MCPCB, high quality, customizable design solutions, small quantity manufacturing, quick turn-around, and professional after-sales support. Share your request with us at sales@bestpcbs.com.

How is the MCPCB manufacturing process?

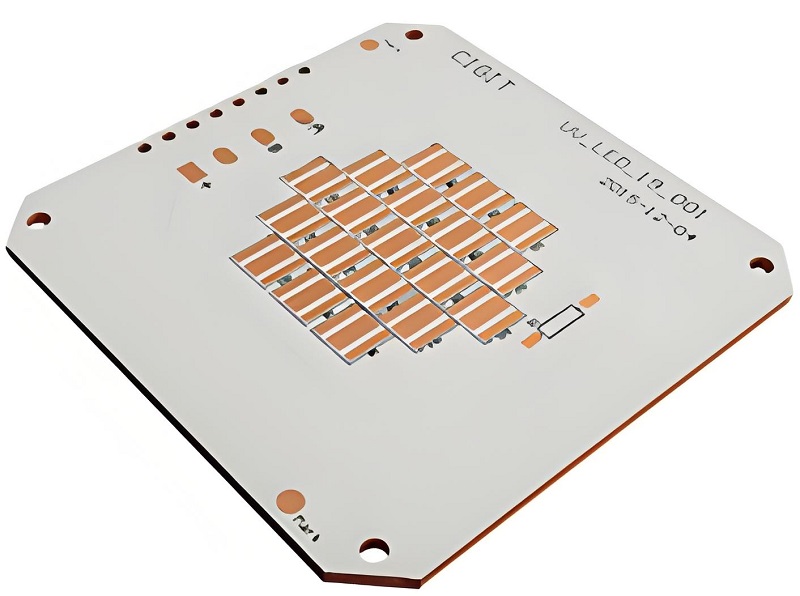

MCPCB manufacturer workflows vary based on product types, but for single-sided thermoelectric separation copper-based boards, the process is more refined and specialized. This kind of MCPCB is engineered to offer excellent thermal performance and reliability, especially in high-power LED and power module applications. To understand the build quality behind a reliable MCPCB, it’s important to look closely at how both the panel and the base board are made. From raw material preparation to surface finish and final testing, every step is monitored to ensure performance and consistency. Letâs walk through the real process behind these boards.

Panel Manufacturing Process:

- Cutting: The raw material is cut to the required size.

- Baking: Pre-baking removes internal moisture.

- Circuit Imaging: Patterns are transferred using photoresist.

- QC Inspection: Visual check for imaging defects.

- Etching: Unwanted copper is etched off to reveal the circuit.

- Etching QC: Visual, AOI (Automated Optical Inspection), and intermediate testing are done.

- Laminating PP: Pure resin prepreg is added between layers.

- Drilling/Target Hole: Drilling aligns layers and creates through-holes.

- Milling Slots: Grooves and stand positions are machined.

- Waiting for Lamination: Prepared for pressing with the base.

Substrate Manufacturing Process:

- Cutting: Substrate base is trimmed.

- High Temp Film Application: A protective high-temperature film is added unless already present.

- Grinding: Surface is cleaned and prepared.

- Circuit Tower Processing: Using dry or wet film, circuit elevations are formed.

- Etching: Refines the copper features.

- Pressing: The panel and substrate are laminated.

- Stripping Film): Film is removed after bonding.

- Target Hole Drilling: Ensures precise alignment.

- Grinding Again: Ensures cleanliness.

- Solder Mask: Includes resting, baking, exposure, and developing.

- Solder Mask QC: Inspected for uniformity.

- Silkscreen Text: Characters or labels are printed.

- Baking Curing: Sets the ink and layers.

- Surface Finish: Options include OSP, ENIG, ENEPIG, or lead-free HASL.

- Shaping: Final machining with drilling, V-CUT, or routing.

- Testing: Electrical tests ensure performance.

- FQC/FQA: Final Quality Control & Final Quality Assurance.

- Vacuum Packing: Boards are sealed to prevent moisture.

- Warehousing & Shipping: Ready for delivery.

The MCPCB manufacturing processâespecially for single-sided thermoelectric separation boardsâis both detailed and deliberate. From panel preparation to surface treatment and precision testing, each step plays a role in heat management and structural durability. When choosing an MCPCB manufacturer, itâs not just about the end product but also about the reliability of the process behind it. A transparent and tightly controlled manufacturing workflow often reflects the quality and performance of the final board.

PCB Manufacturers in Mexico

Mexico has become a hotspot for reliable PCB manufacturing due to its geographic advantage and increasing electronics demand. Here are three noteworthy manufacturers:

- JAV Electro: They offer quick-turn PCB prototyping and mid-volume production. Their local facility allows faster lead times and tight quality control.

- Bittele Mexico: A branch of Bittele Electronics, they provide full PCB services including assembly and component sourcing.

- PCBCart Mexico: Though based in China, PCBCartâs Mexican logistics support ensures rapid delivery and regional support for North American clients.

Mexico’s PCB sector is gaining traction thanks to responsive service and proximity to the U.S. electronics market.

MCPCB Manufacturers USA

The U.S. is home to many well-known MCPCB manufacturers offering high-reliability boards for LED, automotive, and aerospace applications.

- Advanced Circuits: Located in Colorado, they provide MCPCBs with same-day prototyping and certification for aerospace and medical industries.

- Rush PCB Inc.: This California-based company offers metal-core PCBs with excellent thermal design support and fast prototyping.

- Bay Area Circuits: They specialize in custom thermal management boards and short production cycles for startups and innovators.

U.S. manufacturers prioritize precision and turnaround, making them dependable for time-critical and high-end projects.

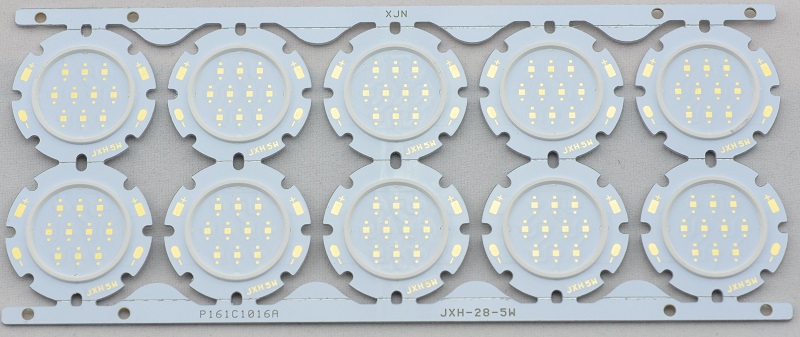

LED MCPCB Manufacturers China

China leads the world in LED MCPCB production. Competitive pricing and scalable production define the market.

- EBest Circuit (Best Technology) Co., Limited: Known for its rapid MCPCB prototyping, especially for aluminum LED applications.

- Shenzhen JDB Technology: They focus on custom LED MCPCBs, offering high thermal conductivity and RoHS compliance.

- Kinwong Electronic: One of the top 100 PCB companies in China, they provide large-scale LED MCPCB solutions.

If you need volume and cost-efficiency, Chinaâs LED MCPCB makers deliver both, without compromising quality.

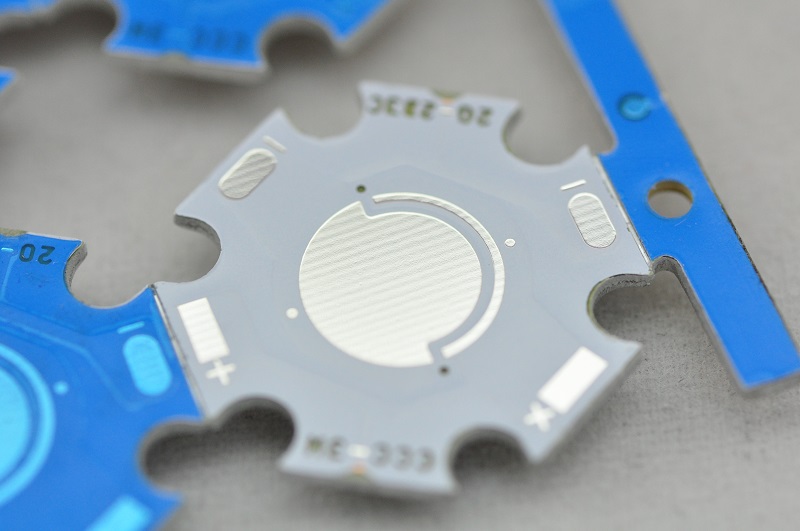

Projector MCPCB Manufacturer

MCPCBs used in projectors must offer strong thermal dissipation and precise alignment for consistent light output.

- EBest Circuit (Best Technology): Our projector MCPCBs come with customized thickness and metal base options.

- Thermaltronics: Specializes in heat-resistant MCPCBs for high-lumen projection systems.

- Ventec International Group: While known for laminates, they partner with MCPCB producers to supply materials specific for projection use.

Projector MCPCB makers tailor their products for optical clarity and heat resistance, enhancing device life and performance.

Berquist MCPCB Manufacturers

Berquist materials are considered premium for thermal conductivity. Here are manufacturers known to work with or specialize in Berquist-based MCPCBs.

- EBest Circuit (Best Technology) Co., Limited: EBest Circuit (Best Technology) uses Berquist substrates for top-tier thermal performance in LED and automotive MCPCBs. We offer standard and Berquist-based MCPCBs with 2-3 weeks lead time and ISO ISO9001, ISO13485, IATF16949, AS9100D, and UL certifications.

- Amitron Corporation: Based in Illinois, Amitron specializes in thermal management PCBs and often uses Berquist laminates for industrial clients.

Manufacturers using Berquist base materials produce MCPCBs with exceptional heat transfer properties, ideal for high-load applications.

Why Should You Choose EBest Circuit (Best Technology) as Your MCPCB Manufacturer?

EBest Circuit (Best Technology) is not just a name. Itâs a promise. Hereâs why customers from over 40 countries choose us:

- Full Customization â Whether you need a single-sided aluminum board, a complex multilayer MCPCB or a customized Aluminum PCB, we tailor the stackup to your project.

- Experienced Team â With 18+ years in MCPCB production, weâve tackled nearly every application type.

- In-House Testing â Thermal imaging, impedance checks, and continuity testing are standard.

- Material Options â We offer aluminum, copper, and even stainless steel bases, depending on your needs.

- Rapid Prototyping â Get samples in days, not weeks. For specific lead time information, just feel free to get in touch with us at any time.

- Global customer distribution  â From Asia to the USA and across Europe, our market share continues to soar rapidly.

We understand what makes a board reliable under heat and current. EBest Circuit (Best Technology) never stops fostering professional talents. Most of our account managers, sales managers, procurement, and R&D engineers have the experience over 10 years. From the top down in EBest Circuit (Best Technology), we believe maintaining consistency in quality and service is the key to getting the trust of our potential and regular customers. We believe understanding the customer’s needs and tackling their problems helps establish a long-term relationship and create a win-win situation.

To put it simply, finding the right MCPCB manufacturer is about more than specs and cost. Itâs about working with a team that listens, understands thermal design, and helps turn your idea into reality. Whether you’re looking for a led MCPCB manufacturer in India, MCPCB manufacturer in China, or a custom MCPCB solution, EBest Circuit (Best Technology) provides experience, flexibility, and speed. Our aluminum PCBs, projector MCPCBs, and Berquist-compatible builds are already powering devices worldwide. Get in touch with us at sales@bestpcbs.com for any questions or doubts.