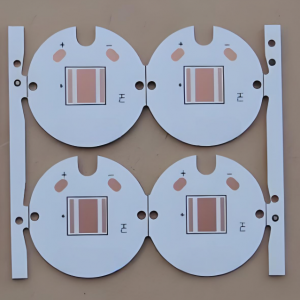

1. What is the SinkPAD Board?

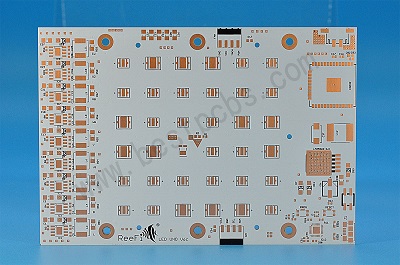

Sink Pad¬†Board, also called Heat Sink or¬†DTP (direct thermal path),¬†it’s an alternative PCB technology to the conventional¬†metal core PCB¬†providing direct thermal path¬†solutions for high power LED.¬†

The thermal conductive PAD is convexity area of copper core/pedestal, so that the thermal PAD of LED can touch the convexity area of metal core directly, and then the heat of LED will be dissipated into the air much faster and more efficient than conventional MCPCB.

2. If only the LED pad can be made as SinkPAD?

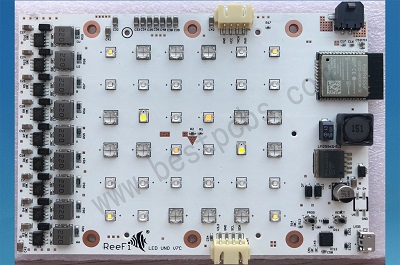

Of course no, the pads of other chips or components also can be designed as Sink PAD, one of the most common is the IC pad. In some designs, IC needs to pass through the large current and it will emit a lot of heat, it would be best to design its pad as a thermal conductive pad at this time.

3. What is the thermal conductivity of a SinkPAD ?

The thermal conductivity could be 235 W/m.k to 400 W/m.k.

4. Can we use SinkPAD technology for any LED packages?

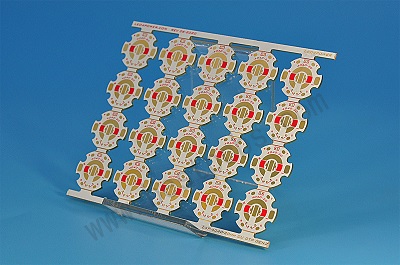

No, it’s designed to be used with the LEDs which has electrically neutral thermal pad. Such as Cree XPL/XML/XHP/XPG/XPE/XPC/XTE/XBD, Luxeon Rebel & Luxeon M from Philips Lumiled, Oslon SSL & Oslon square from Osram, Nichia N219, Seoul Semiconductor Z5P / Z5M, Samsung 3535, Bridgelux SM4, etc.

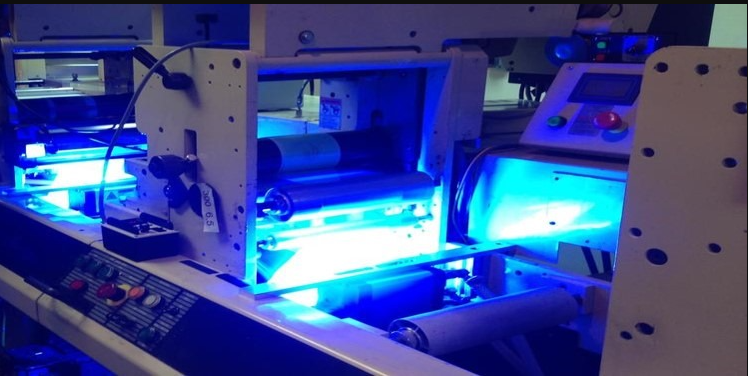

5. What is the Manufacturing Process for the SinkPAD Board?

Manufacturing process is the same as conventional MCPCB, please click here to see the manufacturing process status.

6. How does SinkPAD Board compare to Conventional MCPCB?

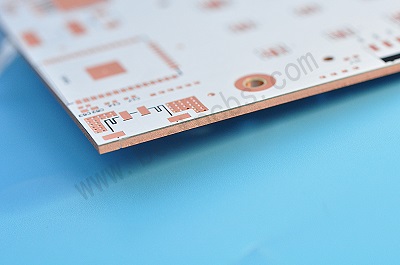

Conventional MCPCB uses a thermally conductive dielectric layer to bond circuit layer with base metal (Aluminum or Copper) layer. The key to thermal performance of MCPCB lies in its dielectric layer. Even¬†though thermally conductive dielectric has higher thermal performance compared to normal FR4,¬†it’s still a weakest link in the conduction thermal path.

SinkPAD¬†Board¬†approach overcomes this limitation, which provides “Direct¬†thermal¬†path”, the LED Chip can directly¬†contact the copper substrate,¬†there’s no¬†dielectric between LED thermal pads and the metal base, then the thermal resistance is very small.

7. Can the aluminum be made as the base of Heat Sink?

Actually yes, however, regarding of current technical conditions, since aluminum or aluminum alloy cannot directly react with acid, the reaction process is too complex and difficult to control, which will increase the difficulty of etching the LED pad platform.

Considering the scrap rate, the process of etching LED pad platform with aluminum is more complex and the overall cost is higher, and the copper also dissipates heat much better than aluminum, so copper is generally used as the substrate for Heat Sink in our company.

8. Does SinkPAD Board require special PCB design?

No, we can use your existing MCPCB Gerber data.

Welcome to contact us if you have other questions about Sink Pad Board.