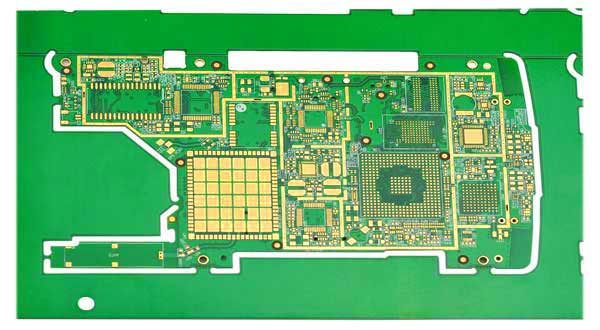

As the name implies, multi-layer PCB is that has multiple layers on one single board. It is like single or double-layer printed circuit board but in multi-layer PCB, the layers are substrate and copper coating over two layers.

Compared with the ordinary PCBs, the multi-layer PCBs are more difficult to fabricate. As it has multi layers that will make the manufacturing procedures getting complicated. Moreover, the fabrication process will be stricter. In order to provide the most satisfying service for customers, Best Technology continues to improve and develop more new products those meet the market needs. Currently, we can produce 20L-32L FR4 printed circuit board.

Since manufacturing the multi-layer PCBs are not easy, then what are the difficult points to make the 14L IT180 PCB? There are three reasons as below for you reference:

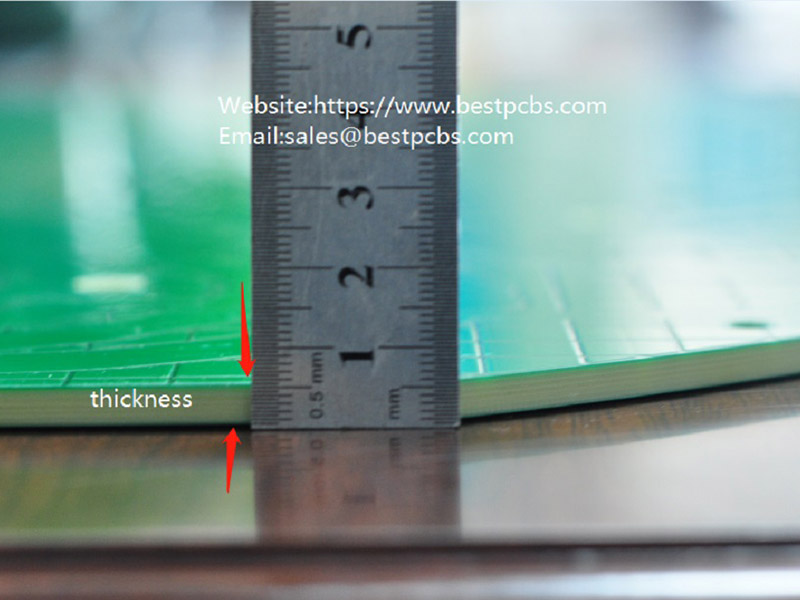

1.      It is pretty thick

The thickness of it is more than 5mm. What’s more, the copper inside and outside are different, both of them are over 5OZ. Generally speaking, the thickness of ordinary PCBs is 1-2OZ. If the thickness is greater than and equal to 4OZ, it is called heavy copper PCBs. The copper thickness is related to the width and the line space. The line space is too narrow to etch and may cause short circuit.

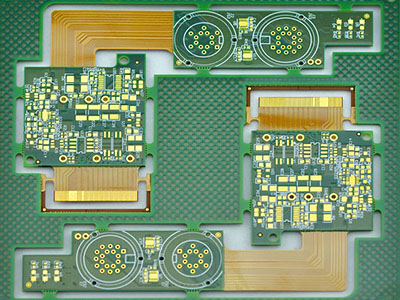

2.      It has a certain difficulty to make coil board

This 14L IT180 heavy copper PCB belongs to coil board, so it has a certain difficulty to make. The coil board refers to a circuit board in which the wiring pattern is mainly winding, and the circuit board is replaced by an etched circuit instead of the conventional copper wire. If it is not a coil board, it is easier to etch the straight line on the board, but if it is a coil board, there is a certain requirement for the factory technology, because the surrounding shape of the coil needs to be carefully carved.

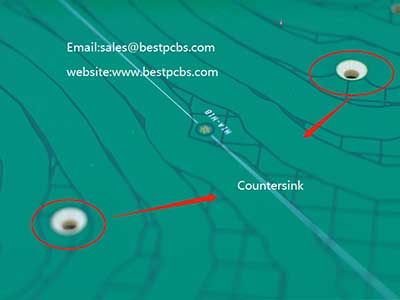

3.      It has countersink

Because the countersink has certain requirements for angle and depth in the manufacturing process. In general, the countersink is easier to make if the angle is the multiple of 5. For example, the 90 degree angle is easier to make than the 85 degree angle.

This 14L IT180 heavy copper PCB possess a variety of advantages, so do not hesitate to send your orders if you would like to order multi-layer PCB and heavy copper PCB.

For more details about this 14L IT180 heavy PCB, please click here to know: https://www.bestpcbs.com/index.htm

Â