Test coupon is small, yet critically important, panels fabricated alongside your printed circuit boards (PCBs) to validate the manufacturing process without damaging the actual product. This article provides a comprehensive guide to understanding, designing, and utilizing test coupons, specifically for high-frequency and HDI PCBs, to ensure ultimate reliability.

Without a proper test coupon strategy, many PCB issues—such as impedance errors, hidden lamination defects, inconsistent plating, unreliable vias, and registration problems—can remain undetected until it’s too late. Common Pain Points:

- Uncertain Impedance Control: Inability to accurately verify if the fabricated impedance matches the design specifications, leading to signal degradation.

- Hidden Lamination Defects: Lack of visibility into the quality of layer bonding, which can cause delamination under thermal stress.

- Inconsistent Plating Quality: Unknown thickness and uniformity of copper plating in vias and on layers, risking open or short circuits.

- Via Reliability Concerns: No data on the structural integrity of microvias and through-holes, making thermal cycling a gamble.

- Poor Registration Accuracy: Misalignment between layers in multilayer boards can affect performance and yield, but is difficult to confirm post-production.

Here’s how EBest Circuit (Best Technology) systematically eliminates these hidden PCB risks using dedicated test coupon validation methods:

- Precise Impedance Verification: We incorporate dedicated coupon test structures on the panel to measure impedance with a Time Domain Reflectometer (TDR), ensuring it meets your target values.

- Lamination Quality Assurance: Our test coupons include cross-section areas for microsection analysis, allowing us to inspect the resin fill, layer alignment, and bond quality.

- Plating Thickness Monitoring: Using test coupons, we perform non-destructive XRF measurements to confirm copper and surface finish thickness adheres to your requirements.

- Via Integrity Testing: We subject coupons to rigorous thermal shock and IST (Interconnect Stress Test) cycles to simulate aging and uncover any via barrel cracks or failures.

- Registration Accuracy Check: Features within the test coupon allow us to precisely measure and verify the alignment accuracy of all PCB layers.

At EBest Circuit (Best Technology), we specialize in manufacturing advanced PCBs, including heavy copper, high-frequency and HDI types. Our state-of-the-art facility is equipped with advanced coupon test stations and inspection equipment, ensuring that every board we ship meets the highest standards of quality and reliability. For your next project, pls feel free to contact us at sales@bestpcbs.com.

What is a Test Coupon?

A test coupon is a dedicated section on a PCB panel that contains various patterns and structures designed to represent the critical properties of the actual production boards. It is fabricated at the same time as the main PCB, using the same materials and the same processes, but it is not a “product PCB” — it is a PCB piece made exclusively for testing. Because it experiences identical manufacturing conditions, the coupon provides a reliable way to validate whether the production process meets the required specifications.

Purpose

- The primary purpose of a test coupon is to provide a non-destructive and destructive testing platform for quality control.

- Instead of cutting into a functional PCB, manufacturers perform all required evaluations—electrical, mechanical, or structural—on the coupon.

Location

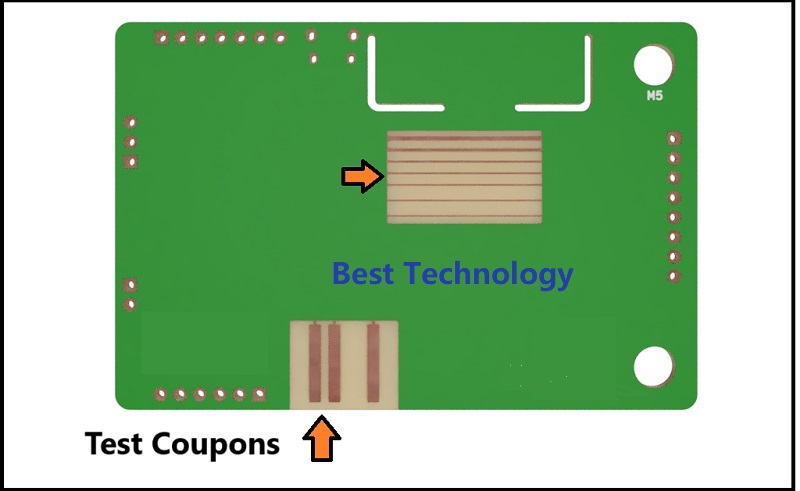

- Test coupons are typically placed in routing tabs, panel edges, or other unused areas of the PCB manufacturing panel. Their placement ensures they undergo the same lamination, drilling, plating, etching, and finishing processes as the actual boards.

Representation

A well-engineered test coupon accurately reflects key characteristics of the production PCB, such as:

- Trace width and spacing

- Layer stack-up structure

- Via types (microvias, blind vias, buried vias, through-holes)

- Controlled impedance lines

- Copper thickness and plating performance

By mirroring these features, the coupon serves as a reliable quality indicator for the entire batch of boards.

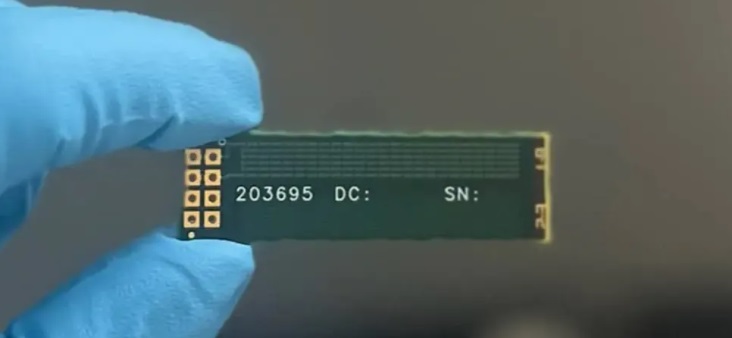

A PCB test coupon typically appears as a small rectangular or strip-shaped PCB segment, designed purely for test and analysis. It usually includes:

- Controlled-impedance trace patterns

- Daisy-chain via networks for via reliability testing

- Microsection (cross-section) targets

- Plating measurement pads for XRF analysis

- Registration and alignment markers

- Solder mask or surface finish evaluation areas

In appearance, a test coupon is more “pattern-dense” and more “structured” than a functional PCB.

It contains no ICs, no functional circuitry, and no components—only test structures arranged in a highly organized format. Most test coupons are designed for easy separation from the manufacturing panel and are visually identifiable by the repeated line patterns, via chains, and measurement pads.

In summary, test coupons act as a quality control proxy, allowing for comprehensive verification without compromising the integrity of the final product.

What is a Coupon Test Station in PCB?

A coupon test station is a dedicated area or setup within a PCB factory where these test coupons are evaluated. It comprises various instruments used to perform specific quality checks.

- TDR Station: Used for impedance measurement. A TDR probe makes contact with the coupon’s transmission lines to measure the characteristic impedance.

- XRF (X-Ray Fluorescence) Station: A non-destructive tool for measuring the thickness of metallic coatings, such as gold, nickel, or copper plating.

- Microsection (Cross-Section) Station: This involves cutting, potting, polishing, and examining the coupon under a microscope to inspect internal structures like layer alignment, plating thickness in vias, and lamination quality.

- IST/Thermal Shock Chamber: Specialized equipment that electrically and thermally stresses the coupons to assess the long-term reliability of the interconnects.

The coupon test station is the frontline for quality data collection, providing quantifiable evidence that the manufacturing process is under control.

Why Are Test Coupons Essential in PCB Manufacturing?

Test coupons are indispensable because they are the only way to objectively verify that the complex interplay of materials and processes has yielded a PCB that meets all design and reliability criteria. This is especially critical for HDI and high-frequency PCBs where tolerances are extremely tight.

- Impedance Control: For high-speed designs, impedance is paramount. Test coupons provide the only accurate method for verifying that the dielectric thickness, copper weight, and trace geometry have combined to create the designed impedance.

- Plating Quality: They allow for direct measurement of electroplated copper thickness in holes, which is crucial for current carrying capacity and reliability.

- Lamination Integrity: Cross-sectioning a coupon reveals the quality of the bond between layers, the presence of voids, and the resin content, which affects the electrical and thermal performance.

- Via Reliability: The structural integrity of vias, including plating uniformity and copper cracking, can be thoroughly evaluated through coupon testing.

- Registration Accuracy: Features on the coupon allow manufacturers to measure the misalignment between layers, a key factor in the yield of fine-pitch BGAs and HDI designs.

Without test coupons, PCB manufacturing would be a leap of faith. They provide the hard data needed for quality assurance.

What Parameters Can a PCB Test Coupon Verify?

A comprehensive test coupon can verify a wide array of parameters, offering a complete health report of the manufacturing process.

- Impedance: Single-ended and differential impedance values.

- Copper Thickness: Base copper foil thickness and plated copper thickness in holes.

- Dielectric Thickness: Thickness of the prepeg and core layers between copper.

- Solder Mask Thickness: Thickness and coverage of the solder mask.

- Surface Finish Thickness: Thickness of finishes like ENIG, Immersion Silver, or HASL.

- Via Integrity: Plating quality of microvias, blind vias, and through-holes via cross-section.

- Layer-to-Layer Registration: Precision of alignment between different layers.

- Solderability: The ability of pads to be wet by solder.

- Electrical Continuity: Presence of open or short circuits on test networks.

In essence, a test coupon serves as the “health report” of the PCB manufacturing process.

How to Design a Test Coupon for High-Frequency or HDI PCBs?

Designing a test coupon for advanced PCBs requires careful consideration to mirror the board’s most challenging features.

- For High-Frequency PCBs:

- Include Coupon Test Structures for All Critical Impedances: Have separate transmission lines for each controlled impedance value (e.g., 50Ω single-ended, 100Ω differential).

- Use Correct Stack-up: The test coupon must be built on the exact same stack-up as the main board, including the same high-frequency laminate material (e.g., Rogers, Taconic).

- Account for Surface Roughness: As roughness affects loss, the coupon should use the same copper type (e.g., HVLP copper).

- For HDI PCBs:

- Feature Microvias: The coupon must include structures with stacked and staggered microvias for reliability testing.

- Represent Fine Features: Include patterns with the smallest trace width and space used on the actual PCB.

- Test Buried/Blind Via Structures: Have dedicated sections for cross-sectioning complex via structures unique to HDI designs.

- Check Registration: Incorporate specific patterns to measure the alignment accuracy between sequential lamination cycles.

A well-designed test coupon is a miniature replica of your PCB’s most critical aspects.

Coupon Testing Methods Used in PCB Quality Control?

Several standardized coupon testing methods are employed to extract quality data.

- Time Domain Reflectometry (TDR): The primary method for impedance measurement. It sends a signal down a trace and analyzes the reflections.

- X-Ray Fluorescence (XRF): A non-destructive method to measure the thickness of surface finishes and platings.

- Microsection Analysis: A destructive test where the coupon is sliced, polished, and examined under a microscope to inspect internal details.

- Interconnect Stress Test (IST): Subjects a coupon with a daisy-chain via pattern to controlled electrical current and thermal cycling to failure, quantifying the thermal reliability of the plated through-holes.

- Thermal Shock: Exposes the coupon to extreme temperature cycles to assess the robustness of the materials and plated vias.

These methods provide clear, data-driven evidence to support PCB quality validation.

How Test Coupons Improve PCB Reliability and Reduce Production Risks?

Test coupons are a proactive risk management tool. They improve reliability by catching defects beforeboards are shipped.

- Early Defect Detection: They identify process drift (e.g., plating thinning, impedance shift) early, allowing for corrective action before an entire panel is scrapped.

- Yield Control: By providing data on process capability, they help manufacturers fine-tune their processes for higher yields, which ultimately benefits the customer through cost stability.

- Enhanced Reliability: Reliability tests like IST on coupons provide confidence that the boards will survive the intended lifecycle in the field, preventing costly field failures.

- Data-Driven Decisions: They replace guesswork with hard data, facilitating better communication and trust between the manufacturer and the designer.

Why Choose EBest Circuit (Best Technology) for High-Frequency PCBs?

When working with HDI and high-frequency PCBs, choosing a manufacturer that truly understands test coupon design, fabrication, and validation is crucial. At EBest Circuit (Best Technology), we combine advanced PCB manufacturing capabilities with professional coupon testing expertise to guarantee stable, high-frequency performance and long-term reliability.

1. Deep Expertise in High-Frequency & HDI Stack-Ups

High-frequency PCBs require precise control over dielectric thickness, copper roughness, and lamination quality. Our engineering team designs stack-ups that pair perfectly with the test coupon structures, ensuring impedance stability and consistent RF behavior across the entire panel.

2. Professional Test Coupon Fabrication

Because your project depends on accurate impedance and layer registration, every high-frequency PCB from EBest Circuit (Best Technology) includes a carefully designed test coupon built on the same materials, the same process, and the same stack-up as your product boards.

This allows us to validate:

- controlled impedance lines

- microvia reliability

- plating thickness

- lamination integrity

- layer-to-layer registration

Your high-frequency PCB performance is verified before the boards ever reach assembly.

3. Advanced Impedance & Plating Verification

Using TDR test coupon analysis, we ensure that every 50 Ω, 75 Ω, or 100 Ω line meets its target value.

Meanwhile, XRF testing on test coupons confirms that copper plating and surface finish thickness remain within tight tolerances—critical for RF loss performance and HDI via reliability.

4. Superior Reliability Testing for HDI Vias

For HDI designs, via integrity is everything.

Our coupon-based IST testing subjects daisy-chain via structures to electrical and thermal cycling, detecting micro-cracks or plating weaknesses before they become field failures.

5. Accurate Lamination and Registration Control

EBest Circuit (Best Technology) uses microsection analysis on the test coupon to inspect resin flow, layer bonding, and alignment accuracy. This is especially important for mmWave boards, RF front-end modules, and multi-lamination HDI structures.

6. One-Stop PCB + PCBA Manufacturing

Beyond fabricating high-frequency PCBs, we provide full assembly services—including RF module assembly, antenna assembly, selective soldering, and functional testing.

Your test coupon data flows directly into our PCBA quality process, ensuring end-to-end reliability.

7. Proven Expertise Across RF Industries

EBest Circuit (Best Technology) supplies high-frequency and HDI PCBs for applications such as:

- wireless communication modules

- radar systems

- 5G RF boards

- IoT devices

- automotive radar and sensors

- aerospace communication systems

Our long-term success with RF customers reflects our ability to produce PCBs that perform flawlessly at high frequencies.

8. Process Validation Through Dedicated Test Coupons

Many PCB suppliers treat test coupons as optional. At EBest Circuit (Best Technology), test coupon analysis is an integrated part of our high-frequency PCB quality system, ensuring:

- predictable signal integrity

- stable impedance

- reliable HDI vias

- low loss performance

- consistent production from batch to batch

By choosing us, you gain a partner that verifies every critical parameter before your boards enter assembly. For advanced high-frequency or HDI PCB projects, feel free to contact us at sales@bestpcbs.com.

In closing, Test coupons are the unsung heroes of PCB manufacturing, providing the critical data needed to ensure performance and reliability. This guide has detailed their role, design, and testing, particularly for demanding HDI and high-frequency applications. At EBest Circuit (Best Technology), we leverage state-of-the-art coupon test stations and deep manufacturing expertise to guarantee that your PCBs meet the highest standards. For reliable, high-performance PCBs backed by rigorous testing, pls feel free to contact our team at sales@bestpcbs.com.

Tags: Coupon Testing, Test Coupon, Test Coupons