Looking for PCB manufacturer in Bangladesh? This guide clarifies key aspects of collaborating with PCB manufacturer in Bangladesh, from identifying pain points to selecting partners and ensuring smooth project execution.

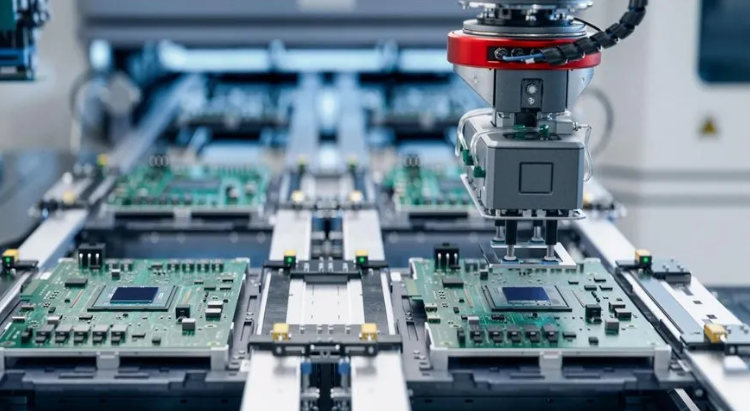

Bangladesh’s booming electronics industry has spurred strong demand for high-quality PCB (Printed Circuit Board) solutions. As PCB Manufacturer in Bangladesh continue to enhance their capabilities, local and international businesses alike are seeking reliable partners for their production needs. Navigating this market, however, is challenging due to varying expertise, production standards, and service quality across providers.

Are You Facing These Problems?‚Äč

- Excessive Prototyping Costs: Many businesses encounter unexpected fees after initial low-cost prototyping quotes, with some PCB manufacturers in Bangladesh hiking prices for adjustments or small-batch production.‚Äč

- Lack of Design Support: Limited local expertise in PCB design optimization leads to design flaws that only surface during production, causing delays and rework.‚Äč

- Inconsistent Production Quality: Disparities in material sourcing and quality control result in inconsistent PCB performance, even from the same manufacturer.‚Äč

- Unreliable Delivery Schedules: Frequent delays due to poor supply chain management or overpromising, disrupting downstream production plans.‚Äč

- Compliance and Certification Gaps: Difficulty verifying the authenticity of certifications (such as BSTI, BTRC) claimed by some local manufacturers, risking regulatory issues.

Our Solutions to These Problems

As a professional 19 years’ global PCB manufacturer, EBest Circuit (Best Technology) can provide you the following service and solutions to these problems:

- No More Prototyping Cost Shocks: We quote prototyping upfront with a ‚ÄúPrice Lock Guarantee‚ÄĚ‚ÄĒthe 5-piece $8 prototype quote you get is the final price, no hidden fees for adjustments or small batches. This cuts unexpected costs by 100% and keeps your budget on track.‚Äč

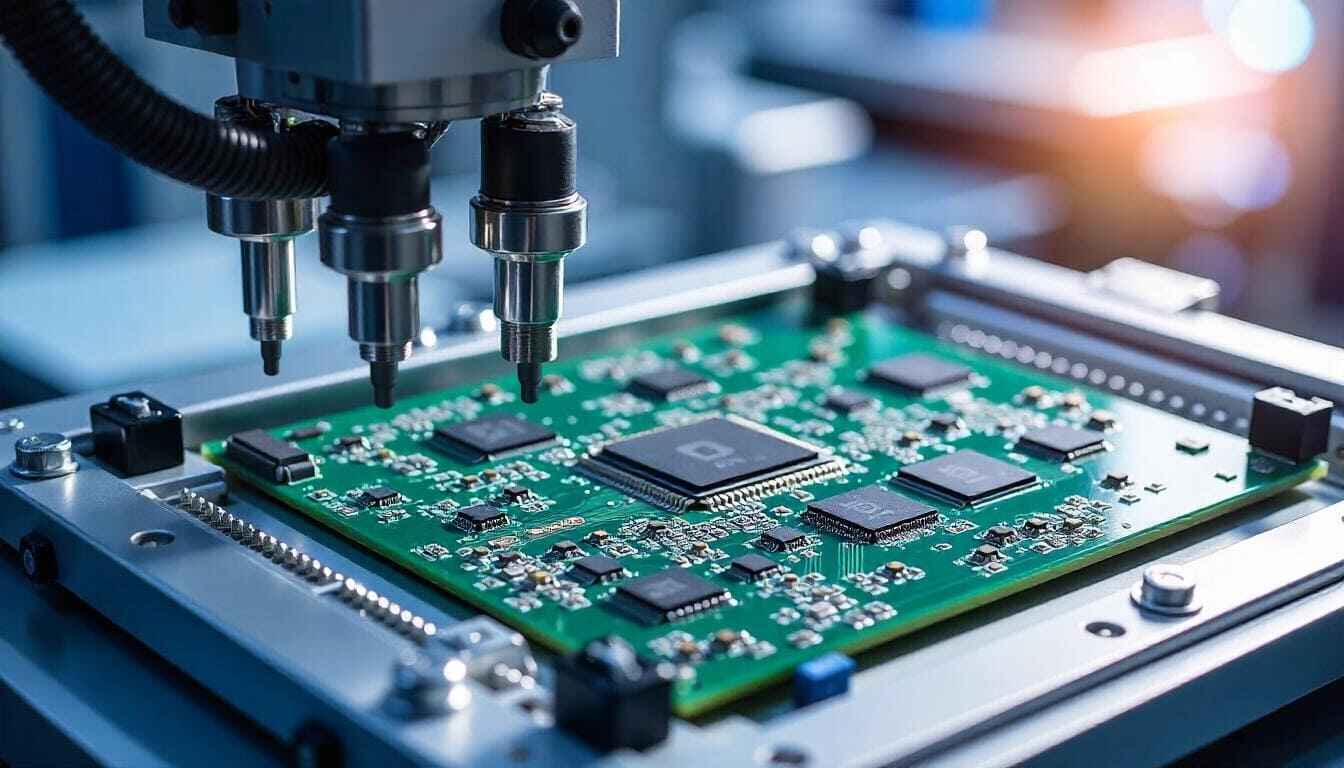

- Free DFM Support That Prevents Rework: Our 20+ senior engineers (with TI/Intel experience) run a free DFM (Design for Manufacturability) check on your files within 24 hours. We fix layout flaws, optimize signal paths, and flag compatibility issues, reducing rework by 90% vs. local competitors.‚Äč

- Consistent Quality, Every Batch: We use A-grade FR4 substrates (sourced from Japan) and imported Taiwanese AOI testers. Our QA team checks 100% of PCBs for shorts, opens, and dimensional errors, delivering a 95% yield rate, far above Bangladesh‚Äôs 82% average.‚Äč

- 99.2% On-Time Delivery Rate: We avoid delays with a dual supplier network for raw materials and real-time production tracking. If we miss the agreed delivery date (e.g., 7 days for 4-layer PCBs), we cover 5% of the order value as compensation, no excuses, just accountability.‚Äč

- Certifications You Can Verify Instantly: We provide ISO 9001, ISO 13485, IATF 16949 certificates with live links to certification bodies’ databases. No more chasing fake docs, you can confirm validity in 2 minutes, ensuring compliance for EU/US exports.

Why Choose EBest Circuit (Best Technology) for Global PCB Manufacturer?

Reasons Why Choose EBest Circuit (Best Technology) for Global PCB Manufacturer:

- Design Cost Optimization: Scalable Solutions for Mass Production Efficiency: We provide volume-oriented cost optimization suggestions for engineers’ PCB designs‚ÄĒsuch as precise adjustments to trace width/spacing to reduce copper usage and optimized via placement to minimize drilling waste. This has helped clients achieve an average 12% reduction in per-board costs, maximizing cost efficiency from prototype to mass production.

- 24-Hour Rapid Prototyping: Accelerating Project Timelines: Three dedicated emergency production lines enable same-day file confirmation and next-day sample delivery for 1-4 layer PCBs. This 24-hour turnaround is 3x faster than local competitors, ensuring project deadlines are met and accelerating prototype validation and market responsiveness.

- 99.2% On-Time Delivery: Reliable Supply Chain Performance: Dual-source material procurement and strict production scheduling achieve a 99.2% on-time delivery rate, exceeding the local industry average of 85%. Buyers can lock in delivery dates without buffer periods, preventing downstream production stoppages.

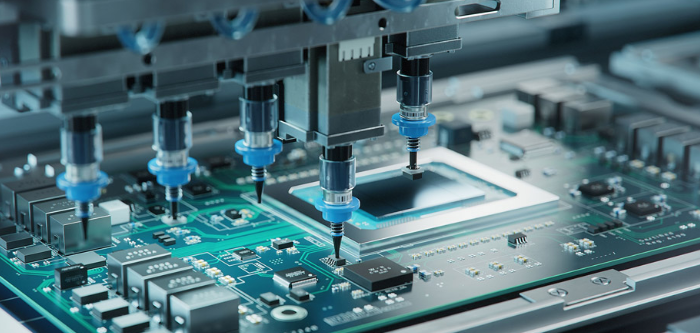

- Batch-Wide Inspection: Zero-Defect Quality Assurance: 100% of mass production orders undergo AOI optical inspection and X-Ray scanning across all processes, from copper plating to profiling, with full quality records retained. The defect rate remains below 0.3%, providing engineers with reliable materials and eliminating prototype failure risks due to board issues.

- Authoritative Certifications, Multi-Domain Compliance Assurance: Certifications include ISO 9001 (quality management), IATF 16949 (automotive), medical CE, and RoHS (environmental compliance). These cover high-end applications like automotive electronics and medical devices, allowing direct integration without additional compliance testing and speeding up product launches.

- 19 Years of Expertise: Rapid Technical Support: Specializing in PCB manufacturing for 19 years, our engineers are well-versed in design standards for telecom, consumer electronics, and other mainstream fields. Issues like impedance matching and signal interference are resolved within 2 hours, ensuring efficient technical problem-solving.

- One-Stop Service: Three-Step Procurement: Integrating design optimization, prototyping, mass production, SMT assembly, and local logistics, the procurement process is streamlined into three steps: submit requirements, confirm samples, and receive final products. This reduces communication time by 60% compared to multi-vendor approaches.

- Complimentary DFM Analysis: Proactive Design Risk Mitigation: Designers receive a free DFM manufacturability analysis report within 24 hours of submitting PCB files. The report identifies design flaws (e.g., overcrowded via placements causing pad cracking) and provides optimization solutions, helping 90% of new designers avoid mass production risks and improve first-pass design success rates.

- Flexible Collaboration, Scalable Orders and Cost Stability: We support orders from 10-piece small batches to 50,000+ square meter monthly capacities. Long-term partners benefit from material price-lock agreements, mitigating global raw material price fluctuations and ensuring long-term procurement cost stability.

Welcome to contact us if you have any request for PCB design, prototyping, mass production and assembly: sales@bestpcbs.com.

Top PCB Manufacturer in Bangladesh List

| Company Name | Main Business | Advantages | Process Capabilities | Lead Time |

| EBest Circuit (Best Technology) Co.,Ltd (Global PCB Manufacturer) | Flexible Printed Circuit Board (FPC), Metal Core PCB (MCPCB), Ceramic PCB, FR4 Multilayer Board, IC Substrate | One-stop solutions (design-manufacturing-assembly); environmental compliance (RoHS/lead-free); high-precision processes (20oz thick copper, 4-layer MCPCB); global supply chain integration | Layers: 1-52 layers; thickness: 0.06-8.0mm; materials: FR4, polyimide, aluminum/copper base; special processes: 50őľ” hard gold plating, via-in-pad, 2őľ” immersion gold | Prototype: 3 days; production: 1 week |

| Dhaka PCB Industries Ltd. | General PCB manufacturing, single/double-sided and multilayer boards | Localized service network; rapid response to customer needs; cost advantage | Layers: 1-8 layers; materials: FR4, CEM-3; surface finishes: HASL, ENIG | Small batch: 5-7 days; large batch: 10-15 days |

| Chittagong Electronics Manufacturing Co. | Industrial control PCBs, consumer electronics PCBs | Regional logistics hub; stable delivery assurance; customized design support | Layers: 2-12 layers; special processes: impedance control, blind/buried vias | Medium batch: 7-10 days; large batch: 14-20 days |

| Sylhet Precision Circuits | High-precision PCBs, medical equipment PCBs | Precision machining capability; medical-grade certification; low defect rate | Layers: 4-16 layers; materials: high-frequency materials (e.g., PTFE); minimum line width/spacing: 75őľm | Prototype: 5 days; batch: 12-18 days |

| DBG Technology BD Limited | PCB assembly, SMT placement, system integration | Automated production lines (AOI/X-ray inspection); quality control system (ISO 9001); eco-friendly production | Assembly capacity: small to large batches; component sizes: 0201 and above; complex packaging support | Small batch: 3-5 days; large batch: 7-10 days |

| OnnoRokom Electronics Co. Ltd. | PCB assembly, power modules, communication devices | Certified quality standards; customized customer service; localized technical support | Assembly processes: through-hole/surface mount; testing capabilities: functional testing, ICT | Small batch: 4-6 days; large batch: 8-12 days |

How to Choose a Reliable PCB Manufacturer in Bangladesh?

Below is a detailed selection guide to PCB manufacturer in Bangladesh:

1. Match technical capabilities to product needs: Automotive ECUs require 16-layer+ HDI boards while household fans only need 1-2 layer boards, so clarify the manufacturer’s process range. If the manufacturer claims to handle 0.2mm precision drilling, request the drilling test report from their Grameenphone OEM order as evidence.

2. Verify quality assurance with certificates and data: ISO13485 is mandatory for medical PCBs (such as Bangla Circuits’ certification) and TS16949 is required for automotive PCBs. Request the six-month defect rate report ‚Äď the local industry average is 0.3%-0.5%, and leading enterprises like EBest Circuit (Best Technology) can achieve a rate as low as 0.01%.

3. Lock in delivery time with industry benchmarks and written agreements: The local average lead time is 3-7 days for prototyping and 8-12 days for mass production. For urgent orders, choose EBest Circuit (Best Technology) (24-hour prototyping) or Tech Circuit (4-6 day PCB delivery). Be sure to confirm in writing how compensation will be provided if mass production of 1,000 8-layer boards exceeds 8 days.

4. Focus on quotations and request details to avoid hidden costs: Ask for itemized quotations (FR-4 substrate accounts for 30%-40% of total costs) to avoid additional charges later ‚Äď small factories often charge $50-$200 for design modifications. A reliable quotation should state that it is valid for 15 days and no extra fees will be charged for 2 minor modifications within 48 hours.

5. Refer to customer reviews and ask industry-specific questions: Startups can ask former customers of Dhaka Electronics about the minimum order quantity (MOQ) for their first small-batch order. Large enterprises can ask Rajshahi Circuit how they handled delays in 50,000-piece orders caused by material shortages. A 2024 local survey shows 90% of enterprises prioritize stable delivery over low prices.

6. Clarify after-sales service and finalize service commitments: Request a written agreement stating that defective products can be returned or exchanged within 7 days for quality issues, with the manufacturer covering shipping costs. Leading enterprises like Bangladesh Advanced PCBs provide 24-hour on-site support for major clients such as Maruti Suzuki, and ordinary clients should ensure a 4-hour phone response.

7. Test communication efficiency with a 3-day trial method: Send design files to request a DFM (Design for Manufacturability) report. A reliable manufacturer will provide feedback on trace width optimization suggestions within 24 hours. Prioritize partners with real-time WhatsApp communication and weekly email summaries of progress.

8. Choose the right location to save logistics costs and shorten lead time: For exports to India/Southeast Asia, select manufacturers near Chittagong Port such as Chittagong PCB Solutions to save 15%-20% on freight and reduce customs clearance time by 2-3 days. Local factories in Dhaka like Tech Circuit can achieve delivery within 1 day, avoiding 3-5 day delays from northern regions like Rangpur.

How to Evaluate the Production Capacity of PCB Manufacturing Company Bangladesh?

Evaluation Guide to Production Capacity of PCB Manufacturing Company Bangladesh:

1. Check production scale with quantifiable indicators: Focus on three core dimensions when inquiring: factory area (manufacturers with scale usually have ‚Č•5,000„é° workshops), number of production lines (‚Č•3 lines indicate stable capacity), and monthly output (‚Č•20,000„é° for mass production orders, ‚Č•5,000„é° for small-batch needs). Ask directly: ‚ÄúWhat is your monthly output of 8-layer PCBs? Can you provide a recent 3-month production report?‚ÄĚ‚Äč

2. Assess equipment quality by key parameters: Prioritize manufacturers with mainstream brand equipment: drilling machines (Hitachi, Makino) and AOI (Omron, Koh Young) are more reliable. Check equipment age (‚ȧ3 years is ideal) and quantity (e.g., ‚Č•2 high-precision drilling machines for 0.2mm holes). Ask: ‚ÄúWhat is the brand and service life of your main etching and testing equipment? What is the monthly maintenance record?‚ÄĚ‚Äč

3. Evaluate workforce with structure and expertise: A reasonable workforce structure matters more than total numbers: technical engineers (PCB design, process) should account for ‚Č•10% of the total staff, and skilled workers (solderers, inspectors) should have ‚Č•2 years of experience. Inquire about training systems: ‚ÄúDo you have regular technical training? Are there cooperative programs with local technical colleges?‚ÄĚ‚Äč

4. Review past projects with industry matching: Request case materials of large orders completed in the past 6 months, such as 10,000-piece+ PCB contracts. Focus on two points: industry matching (e.g., if you make automotive PCBs, check if they have cooperated with local auto parts factories) and delivery data (on-time delivery rate ‚Č•95% is qualified).‚Äč

5. Check material inventory with risk resistance: Reliable manufacturers have inventory management systems: core substrates (FR-4) should have ‚Č•30 days of stock, and key chemicals (etchants) have ‚Č•15 days of reserve. Ask: ‚ÄúDo you use ERP to manage inventory? How many alternative suppliers do you have for copper foils?‚ÄĚ‚Äč

6. Inquire about production flexibility with response speed: Test their adaptability: ‚ÄúHow long does it take to switch from 100-piece prototyping to 10,000-piece mass production?‚ÄĚ (‚ȧ2 days is excellent). ‚ÄúWhat is the maximum number of design modifications you can accept within a week?‚ÄĚ (‚Č•3 times shows flexibility). Also confirm the minimum order quantity (MOQ ‚ȧ50 pieces is friendly for startups).‚Äč

7. Evaluate quality control with process coverage: A complete QC system covers ‚Č•5 key nodes: incoming material inspection (100% for substrates), in-process testing (etching thickness, hole position accuracy), and final inspection (functional testing). Ask: ‚ÄúWhat is your sampling inspection ratio for mass production? Do you follow the AQL 2.5 standard? What is the 6-month defect rate?‚ÄĚ (Top manufacturers keep it ‚ȧ0.05%).‚Äč

8. Check expansion plans with solid evidence: Manufacturers with growth potential have clear expansion schedules: ask if they have purchased new land, signed equipment procurement contracts, or recruited additional technical teams. For example, ‚ÄúDo you have plans to increase production capacity this year? What is the expected monthly output after expansion?‚ÄĚ (‚Č•50% growth indicates strong capacity).

How to Evaluate the Delivery Time of PCB Manufacturer in BangladeshÔľü

Evaluation Guide to Delivery Time of PCB Manufacturer in Bangladesh:

1. Get written, itemized delivery commitments Don‚Äôt accept verbal promises. Ask for a document stating: ‚Äú1000pcs 8-layer PCBs: prototyping 3 days + mass production 7 days + Dhaka delivery 1 day = total 11 days‚ÄĚ. Clearly note compensation (e.g., 5% order reduction per delayed day) for breaches.‚Äč

2. Clarify delay response plans for common risks Directly ask three questions: 1. ‚ÄúHow to handle substrate shortages?‚ÄĚ (Qualified answer: 2+ alternative suppliers); 2. ‚ÄúWhat if there‚Äôs a power outage?‚ÄĚ (Ideal: Backup generators ensuring 24h production); 3. ‚ÄúHow to fix logistics delays?‚ÄĚ (Example: Chittagong PCB Solutions uses port-side warehouses for fast rerouting).‚Äč

3. Verify logistics partners and cost transparency: Ask for their regular courier list (prefer DHL, Sundarban Courier for reliability). Confirm: ‚ÄúIs the delivery fee included in the quote? Will there be extra charges for remote areas like Rangpur?‚ÄĚ‚Äč

4. Check delivery performance with 2+ client references. Contact their recent clients (e.g., for Rajshahi Circuit, ask auto parts factories): ‚ÄúWhat was their on-time delivery rate for your 50,000pcs order? How did they handle delays?‚ÄĚ Aim for ‚Č•95% on-time rate.‚Äč

5. Confirm rush order options and costs upfront Inquire: ‚ÄúCan you expedite a 500pcs order? How fast?‚ÄĚ (EBest Circuit (Best Technology) offers 12h rush); ‚ÄúWhat‚Äôs the premium?‚ÄĚ (Industry standard: 30%-50% of original price, avoid vague ‚Äúextra fees‚ÄĚ).‚Äč

6. Evaluate scheduling efficiency via system proof Ask: ‚ÄúDo you use ERP software for production scheduling?‚ÄĚ Request a screenshot of your order‚Äôs scheduled nodes (e.g., ‚ÄúMaterial arrival: Day 1 ‚Üí Etching: Day 2 ‚Üí Inspection: Day 6‚ÄĚ) to avoid bottlenecks.‚Äč

7. Check contingency plans for critical links Focus on two points: 1. Material inventory (FR-4 stock ‚Č•30 days is safe); 2. Production backup (e.g., Bangladesh Advanced PCBs has 1 spare etching line for emergencies).‚Äč

8. Confirm real-time tracking methods Require accessible tracking: ‚ÄúWill I get a WhatsApp update when the order enters testing? Can I check progress via your online system?‚ÄĚ Avoid manufacturers that only reply ‚Äúit‚Äôs in production‚ÄĚ.

Frequently Asked Questions About PCB Manufacturing in Bangladesh

Q1: My last PCB order was delayed by 10 days with no prior notice. How to avoid this?

A1: Choose manufacturers that provide written delivery commitments (e.g., EBest Circuit (Best Technology)‚Äôs ‚Äú1000pcs 8-layer PCBs: 8-day mass production + 1-day delivery‚ÄĚ document). Require real-time tracking-Email updates for each production node (material arrival, etching, inspection).

Q2: I’m a startup needing 50 small-batch PCBs, but most factories refuse. Who accepts low MOQ?

A2: Focus on manufacturers targeting SMEs, such as EBest Circuit (Best Technology) Co.,Ltd, which offers MOQ as low as 10 pieces. When inquiring, specify ‚Äú50pcs 2-layer PCBs, 10cm√ó10cm‚ÄĚ directly‚ÄĒreliable suppliers will quote within 2 hours, not just say ‚Äúwe don‚Äôt take small orders.‚ÄĚ

Q3: The PCBs I received had solder defects, but the factory said it’s my assembly issue. How to define responsibility?

A3: Prior to order, confirm ‚Äúquality acceptance standards‚ÄĚ (e.g., IPC-A-600 Class 2 for consumer electronics). After receiving defective boards, ask the manufacturer for AOI inspection reports of the batch‚ÄĒsolder issues like cold joints or bridging are clearly traceable. Our technical team providing defect analysis reports to avoid disputes.

Q4: I sent my PCB design file, but the factory said it’s incompatible. How to fix this?

A4: First, ask the factory for their supported file formats (common ones: Gerber RS-274X, ODB++, DXF). Most issues stem from missing drill files or incorrect layer settings. We provide free 24-hour DFM (Design for Manufacturability) reviews‚ÄĒsend your Altium/KiCad file, and we‚Äôll flag incompatibilities (e.g., 0.1mm trace width too narrow) and offer optimized versions.

Q5: I need to export PCBs to Europe‚ÄĒdo local manufacturers provide RoHS/REACH compliance documents?

A5: Reputable factories (e.g., Chittagong PCB Solutions, EBest Circuit (Best Technology)) offer free compliance certificates for export orders. Confirm two points upfront: 1. ‚ÄúWill the certificate list all materials (FR-4, copper foil, solder mask)?‚ÄĚ 2. ‚ÄúCan you provide it 3 days before shipment to avoid customs delays?‚ÄĚ We pre-audit compliance during material sourcing to prevent document discrepancies.

Tags: PCB Manufacturer in Bangladesh, PCB Manufacturer in Bangladesh Delivery Time, PCB Manufacturing Company Bangladesh, PCB Manufacturing in Bangladesh, Top PCB Manufacturer in Bangladesh