An IATF 16949 certified PCB supplier is a manufacturer approved to produce automotive PCBs under strict quality, traceability, and risk-control systems required by global OEMs.

This certification confirms that PCB processes are controlled, repeatable, and audited for defect prevention rather than post-inspection.

For automotive buyers, choosing an IATF 16949 certified PCB supplier directly reduces recall risk, audit pressure, and long-term field failures.

What Is an IATF 16949 Certified PCB Supplier?

An IATF 16949 certified PCB supplier is a PCB manufacturer that complies with the global automotive quality management standard issued by the International Automotive Task Force.

This standard requires:

- Full process traceability

- Preventive quality planning (APQP, FMEA)

- Continuous improvement and corrective action systems

- Controlled production from prototype to mass volume

Unlike general certifications, IATF 16949 applies only to automotive supply chains.

What Is an IATF 16949 Certified PCB Supplier?

Why Do Automotive OEMs Require IATF 16949 PCB Suppliers?

Automotive OEMs require IATF 16949 because PCB failures can trigger recalls, safety risks, and regulatory penalties.

This certification ensures:

- Stable PCB manufacturing processes

- Early risk identification

- Consistent quality across production lots

- Audit-ready documentation for OEM and Tier-1 reviews

For safety-critical electronics, uncertified suppliers introduce unacceptable risk.

Which Automotive PCBs Must Come from an IATF 16949 Certified Factory?

Automotive PCBs that typically require IATF 16949 certification include:

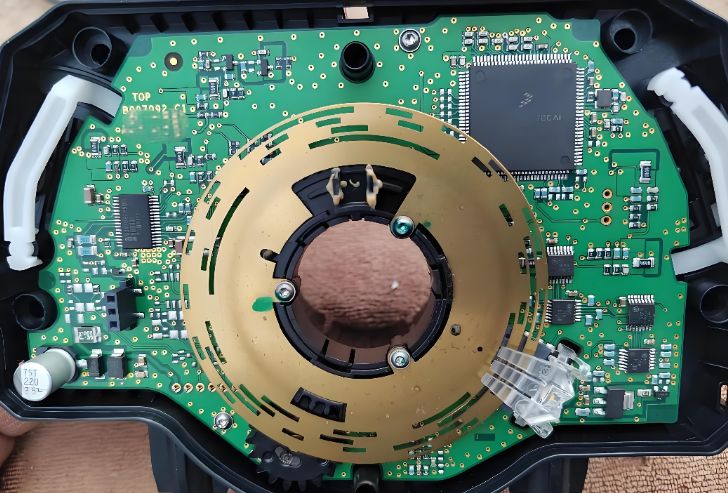

- Engine control units (ECU)

- ADAS and camera modules

- Radar and RF automotive PCBs

- Battery management systems (BMS)

- Power inverter and motor control boards

- Safety and braking control electronics

If a PCB affects vehicle safety, emissions, or power control, certification is expected.

IATF 16949 vs ISO 9001 for PCB Manufacturing

ISO 9001 focuses on general quality procedures across industries. IATF 16949 focuses on automotive risk prevention and process stability.

Key differences for PCB buyers:

- IATF 16949 requires FMEA and PPAP

- ISO 9001 allows broader process variation

- IATF 16949 enforces corrective action with data

- ISO 9001 emphasizes documentation, not automotive reliability

ISO 9001 alone is not sufficient for automotive PCBs.

Core Capabilities Required from an IATF 16949 PCB Supplier

An automotive-qualified PCB supplier must demonstrate both engineering and process discipline.

This includes impedance-controlled stackups, material consistency, SPC monitoring, and documented change control.

Below is a technical capability table automotive buyers often request.

| Capability Category | Automotive PCB Requirement | Typical Specification Range |

| PCB Layer Count | Multilayer & HDI | 2ÔÇô20 layers |

| Controlled Impedance | Mandatory for high-speed / RF | ┬▒5% to ┬▒10% |

| Copper Thickness | Power and signal balance | 0.5ÔÇô6 oz |

| Minimum Trace / Space | Dense automotive layouts | 3/3 mil |

| Via Technology | Reliability under vibration | Through, blind, buried, microvia |

| Laminate Materials | Thermal and electrical stability | High-Tg FR-4, Rogers, hybrid stackups |

| Surface Finish | Automotive solderability | ENIG, ENEPIG, OSP |

| Operating Temperature | Harsh environment tolerance | Ôłĺ40┬░C to +125┬░C |

| Traceability System | Mandatory under IATF 16949 | Lot-level MES tracking |

| Quality Documentation | OEM audit compliance | PPAP, FMEA, Control Plan, SPC |

| Production Volume | Prototype to mass production | NPI Ôćĺ high volume |

| Reliability Testing | Automotive qualification | Thermal cycling, cross-section |

How Traceability Works in IATF 16949 PCB Manufacturing?

In IATF 16949 certified PCB manufacturing, traceability links each PCB lot to materials, processes, inspections, and operators.

Traceability systems typically record:

- Laminate batch numbers

- Inner layer imaging data

- Lamination cycles

- Plating and surface finish parameters

- Final inspection results

This allows fast containment if field issues occur.

What Quality Risks Exist Without an IATF 16949 PCB Supplier?

Choosing a non-certified PCB supplier increases:

- Process variation

- Incomplete documentation

- Poor root-cause analysis

- Audit failures during OEM reviews

These risks often surface only after volume production begins.

What Documents Should an IATF 16949 PCB Supplier Provide?

Automotive buyers should expect:

- PPAP documentation

- PFMEA and Control Plans

- Material certifications

- SPC and inspection reports

- Change management records

Missing documents usually indicate limited automotive readiness.

Prototype vs Mass Production: What Buyers Often Overlook

IATF 16949 applies from the prototype stage, not only mass production.

Controlled materials, documented changes, and engineering approvals must begin early.

Skipping these steps creates instability during ramp-up.

Automotive-ready PCB suppliers treat prototypes as production-intent builds.

Why Automotive Buyers Choose EBest Circuit (Best Technology) as Their IATF 16949 Certified PCB Supplier?

EBest Circuit (Best Technology) supports automotive PCB projects under IATF 16949, ISO 9001, and ISO 13485, AS9100D systems.

Our company delivers:

- Automotive-grade multilayer and HDI PCBs

- Controlled impedance and high-frequency designs

- MES-based traceability

- Structured documentation for OEM audits

- Smooth transition from prototype to mass production

This combination reduces buyer risk and accelerates project approval.

FAQs

1. Is IATF 16949 mandatory for automotive PCBs?

Yes, for OEM and safety-critical automotive electronics.

2. Does IATF 16949 cover PCB prototypes?

Yes. Process control applies from early builds.

3. Can ISO 9001 replace IATF 16949?

No. ISO 9001 alone does not meet automotive standards.

4. How can buyers verify IATF 16949 certification?

Check the certificate scope, issuing body, and audit validity.

5. Why is traceability critical in automotive PCBs?

It enables fast containment and root-cause analysis during failures.

Tags: automotive pcb supplier, iatf 16949 certified pcb, iatf 16949 certified pcb supplier, iatf 16949 pcb, iatf 16949 pcb supplier