Designing electronics for high vibration and shock is a critical engineering discipline focused on ensuring electronic systems maintain functionality and integrity in physically demanding environments. This article explores the core principles, design strategies, and manufacturing essentials for creating robust electronics that can withstand extreme mechanical stress.

Is your electronic product failing unexpectedly in the field? Vibration and shock are silent killers of electronics, leading to premature failures, costly recalls, and damaged reputations. Designers and engineers often face these core challenges:

- Intermittent Failures & Broken Connections:‚Äč Solder joints crack, connectors loosen, and traces fracture under cyclic stress, causing hard-to-diagnose, intermittent faults.

- Component Damage & Detachment:‚Äč Heavy or loosely mounted components like large capacitors, connectors, or unsecured ICs can physically break off or become damaged from impact.

- Signal Integrity Degradation:‚Äč In high-frequency circuits, vibration can alter parasitic capacitance and inductance, causing signal noise, timing errors, and EMI issues.

- Structural Resonance & Fatigue:‚Äč The PCB assembly itself can resonate at certain frequencies, amplifying stress and leading to rapid material fatigue and catastrophic failure.

- Thermal Management Compromise:‚Äč Necessary mechanical reinforcements like stiffeners or potting can impede airflow, leading to overheating of critical components.

Overcoming these challenges requires a holistic approach from design to manufacturing. The following solutions are fundamental to success:

- Enhanced Mechanical Mounting & Support:‚Äč Utilize strategic anchoring, conformal coatings, staking adhesives, and PCB stiffeners to secure components and dampen board resonance.

- Advanced Soldering & Assembly Techniques:‚Äč Implement robust processes like underfilling for BGAs, using high-strength solder alloys, and ensuring optimal fillet geometry to combat joint fatigue.

- Strategic PCB Layout & Stackup Design:‚Äč Adopt compact layouts, symmetric stacking, and avoid placing heavy parts in board centers. Use rounded corners and via-in-pad with caution to reduce stress concentration points.

- Component Selection & Derating:‚Äč Choose components rated for high mechanical stress (e.g., solid capacitors, ruggedized connectors) and apply significant derating to electrical and thermal parameters.

- Integrated Thermal-Mechanical Design:‚Äč Employ thermal vias and carefully selected potting compounds or heatsinks that manage heat without overly restricting the board’s natural flexibility or adding excessive mass.

At BEST Technology, we specialize in manufacturing and assembling high-reliability PCBs and PCBAs built to survive harsh environments. While many Chinese PCB manufacturers are caught up in a rat race of competing on cost alone, BEST Technology focuses on cultivating a unique, sharp competitive edge. Our great technological expertise lies in selecting the right materials, applying stringent process controls, and offering design for manufacturability (DFM) feedback tailored for high vibration and shock applications. For a partnership that prioritizes durability, pls feel free to contact us at sales@bestpcbs.com.

What Does Designing Electronics for High Vibration and Shock Require in Modern Engineering?

Modern engineering for high-vibration environments demands an interdisciplinary approach that merges electrical, mechanical, and materials science. It’s about proactively designing electronics that work not just on a bench, but under continuous duress.

- Material Science:‚Äč Selection of substrates with high glass transition temperature (Tg), strong flexural strength, and compatible CTE (e.g., FR-4 High Tg, Polyimide, or metal-core boards).

- Mechanical Analysis:‚Äč Use of Finite Element Analysis (FEA) to model and predict board resonances, stress points, and fatigue life under expected vibration profiles.

- System-Level Integration:‚Äč Considering how the PCB mounts within the enclosure, using appropriate damping materials, and ensuring connectors are strain-relieved.

- Environmental Sealing:‚Äč Application of conformal coatings, potting, or encapsulation to protect against contaminants while adding structural rigidity.

- Validation & Testing:‚Äč Adhering to stringent testing standards (e.g., MIL-STD-810, IEC 60068-2) for shock and vibration to validate design robustness.

In essence, it requires shifting from a purely electrical design mindset to a holistic electromechanical reliability mindset from the very first schematic.

How Do Core Principles of Designing Electronics That Work Improve Durability in Harsh Environments?

The core philosophy of designing electronics that work‚Äč is about foresight and simplicity. In harsh environments, this translates to prioritizing reliability over unnecessary complexity and building in margins of safety.

- Simplify the Circuit:‚Äč Reduce component count where possible. Fewer parts mean fewer potential failure points from shock or vibration.

- Derate Aggressively:‚Äč Operate components well below their rated maximums for voltage, current, temperature, and power. A capacitor at 50% of its voltage rating is far less likely to fail from stress-induced micro-cracks.

- Implement Protective Architectures:‚Äč Use redundant circuits for critical functions and protective features like TVS diodes for transient suppression caused by sudden shocks.

- Prioritize Proven, Ruggedized Components:‚Äč Specify components with a proven track record in automotive, aerospace, or industrial applications, which often have higher mechanical endurance ratings.

- Design for Testability (DVT):‚Äč Include test points and functional blocks that allow for easy verification of performance after exposure to stress tests.

By adhering to these principles, engineers create a foundation of inherent durability, making the subsequent fight against PCB shock and vibration‚Äč more manageable.

How Does PCB Shock and Vibration Impact Long-Term Performance of Mission-Critical Devices?

PCB shock and vibration‚Äč are primary drivers of long-term performance degradation and field failures. Their impact is cumulative and often leads to sudden, catastrophic system breakdown.

| Failure Mode | Cause (Vibration/Shock) | Long-Term Effect |

|---|---|---|

| Solder Joint Fatigue‚Äč | Cyclic bending stresses the joint. | Cracks propagate, increasing resistance until an open circuit occurs. |

| Trace Cracking‚Äč | Board flexure concentrates stress. | Intermittent or permanent opens, especially at trace bends or via holes. |

| Conductor Debonding‚Äč | Repetitive stress at copper-substrate interface. | Lifted pads or broken traces, disrupting signals or power. |

| Connector Fretting‚Äč | Micromotion between mated contacts. | Increased contact resistance, oxidation, and signal loss. |

| Component Fracture‚Äč | High-G impact or resonance. | Immediate and total failure of the component (e.g., ceramic capacitors). |

The result is not just a failure, but a loss of trust in mission-critical systems in automotive, defense, or industrial automation, where downtime is unacceptable. This reality makes mastering pcb design for high vibration‚Äč non-negotiable.

What Layout and Structural Methods Define Effective PCB Design for High Vibration?

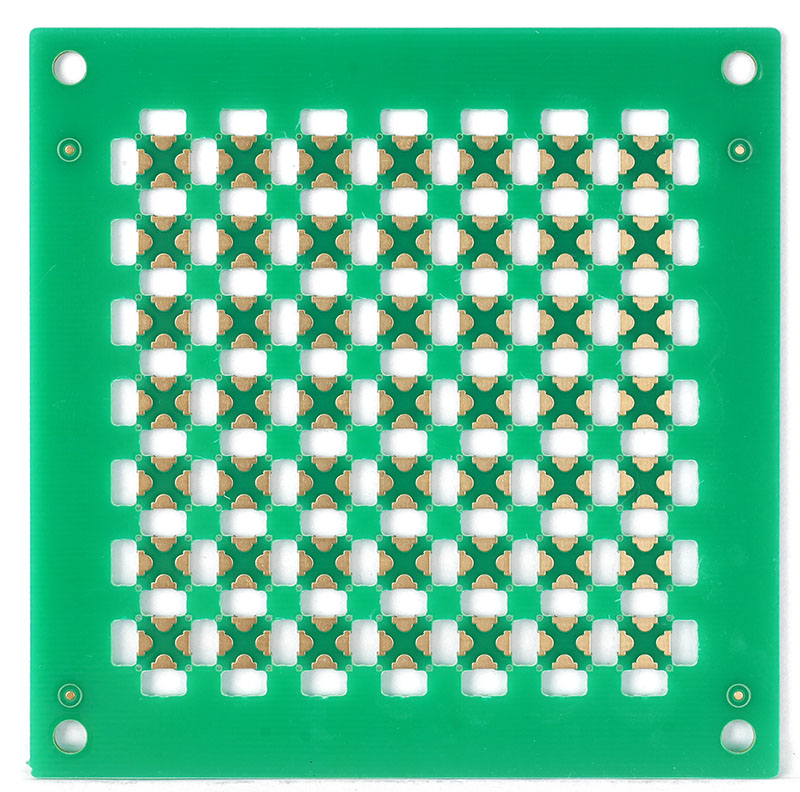

Effective pcb design for high vibration‚Äč employs specific layout and structural techniques to distribute and mitigate mechanical stress before manufacturing begins.

- Balanced, Symmetric Stack-up:‚Äč A symmetrical copper and dielectric layer stack around the central plane prevents warping and balances torsional forces.

- Strategic Component Placement:

- Place heavy, large, or tall components near board supports and away from the center or corners.

- Orient similar components in the same direction to evenly distribute stress.

- Reinforcement Structures:

- Stiffeners:‚Äč Aluminum or stainless-steel bars glued to areas prone to flex.

- Potting/Conformal Coating:‚Äč Epoxy or silicone materials that dampen vibration and protect components.

- Standoffs & Metal Braces:‚Äč Provide additional anchoring points between the PCB and chassis.

- Trace and Via Layout:

- Use curved traces instead of 90-degree angles to avoid stress concentrators.

- Avoid placing vias in high-stress BGA pads; use filled vias if necessary.

- Widen power/ground traces for added strength.

- Enhanced Mounting:

- Use multiple, strategically placed mounting holes with generous copper keep-outs.

- Employ shoulder washers or nylon washers to allow for slight movement without transferring full chassis stress to the board.

This mechanical-focused layout is a cornerstone of successfully designing electronic circuits‚Äč for harsh environments.

How Should Engineers Approach Designing Electronic Circuits to Reduce Failure Under Continuous Movement?

When designing electronic circuits‚Äč for continuous movement, the approach must be defensive and conservative, focusing on minimizing the forces acting on electrical elements.

- Component Form Factor Selection:‚Äč Prefer smaller, lighter surface-mount devices (SMDs) over larger through-hole parts. Chip-scale packages and 0402/0201 resistors/capacitors withstand vibration better.

- Circuit Simplification & Integration:‚Äč Use a highly integrated ASIC or FPGA instead of dozens of discrete logic chips. Fewer solder joints directly increase reliability.

- Secure Connection Strategies:‚Äč Specify connectors with positive locking mechanisms and use wire harnessing/strain relief for all cable attachments to the PCB.

- Redundancy for Critical Paths:‚Äč For absolutely vital signals or power rails, consider parallel components or pathways so a single point of mechanical failure does not down the system.

- Strain Relief on Board-Level Components:‚Äč Apply epoxy staking or corner bonds to large components like transformers, connectors, and heatsinks to anchor them to the board.

This approach ensures the electrical design actively contributes to mechanical survival.

Why Is Designing for Stability in High Frequency Circuits Essential When Vibration Cannot Be Avoided?

Designing for stability in high frequency circuits‚Äč is paramount because vibration can dynamically alter the physical geometry of the circuit, directly impacting its electrical performance in ways that can cause functional failure.

- Variable Parasitics:‚Äč Physical movement changes the distance between conductors, modulating parasitic capacitance and inductance, which can detune filters, oscillators, and impedance-matched lines.

- Microphonic Effects:‚Äč Certain components, like some inductors or crystals, can generate spurious electrical signals when vibrated, injecting noise.

- Impedance Discontinuities:‚Äč Flexing can cause minute cracks or delamination in transmission lines, creating impedance mismatches that cause signal reflections and loss in high-speed digital or RF circuits.

- Mitigation Strategies:

- Use rigid, high-Tg laminate materials with stable Dk (dielectric constant) over frequency and temperature.

- Employ robust shielding cans over sensitive RF sections to minimize the influence of external field changes.

- Implement differential signaling for critical high-speed data paths, as it is more immune to common-mode noise induced by vibration.

Without this focus on stability, a circuit can pass bench tests but fail in the field due to vibration-induced electrical instability.

Why High-Reliability PCB and PCBA Manufacturing Is Vital When Designing Electronics for High Vibration and Shock?

Electronics used in aerospace, automotive safety, and industrial automation must survive constant mechanical stress. Standard PCB builds often fail under these conditions, while high-reliability (Hi-Rel) manufacturing provides the structural strength and electrical stability needed for long-term performance.

1. Solder Joint Fatigue Prevention

High-frequency vibration causes repetitive micro-movement at solder joints, leading to metal fatigue.

Risks:

- Cracked joints

- Open circuits

- Intermittent failures in safety-critical systems

Hi-Rel Solutions:

- Enhanced reflow profiles

- Reinforced solder joints

- Underfill for heavy or vibration-prone components

2. Signal Integrity Protection Under Vibration

Mechanical stress can disrupt electrical behavior‚ÄĒnot only structural stability.

Risks:

- Impedance drift

- Copper trace micro-cracking

- RF and high-speed data distortion

- Increased EMI issues

Hi-Rel Solutions:

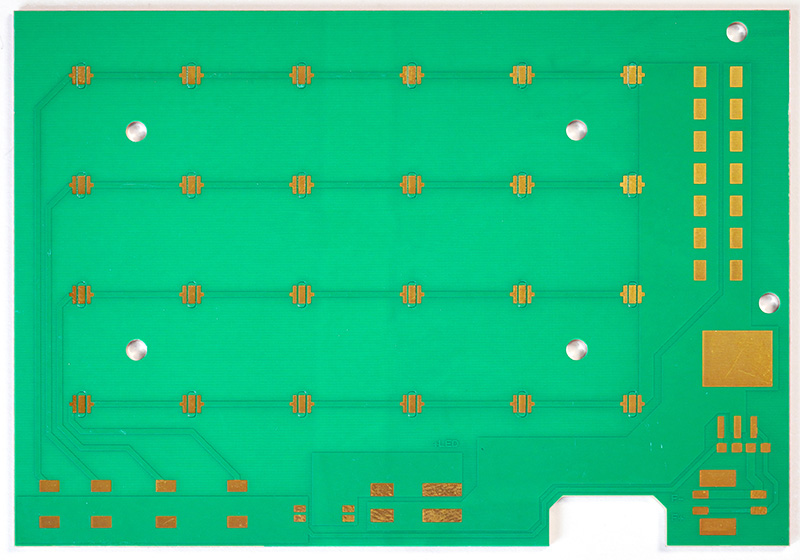

- Rigorous DFM/DFR reviews

- Stable routing geometry

- Controlled impedance stackups

3. Structural Reinforcement for Vibration Survival

Hi-Rel PCB builds integrate multiple protective mechanisms to withstand demanding environments:

- Material Reinforcement:

Thicker FR-4, polyimide, or rigid-flex substrates reduce bending and trace fractures. - Mechanical Stiffening:

Brackets, staking, adhesives, and press-fit support minimize stress transfer to solder joints. - FEA Simulation:

Predicts vibration modes, identifies stress concentrations, and optimizes layout to avoid resonance.

Standard PCB vs. High-Reliability PCB (Hi-Rel)

| Aspect | Standard PCB | High-Reliability PCB |

|---|---|---|

| Substrate | 1.6 mm FR-4 | 2.0 mm+ FR-4, Polyimide, or Rigid-Flex |

| Soldering | Basic reflow | Enhanced profile + underfill |

| Testing | Visual check only | ESS, vibration, shock testing |

| Durability | Fails under ~50 m/s² | Withstands rocket-level acceleration and long-term vibration |

Sectors such as aerospace, autonomous driving, robotics, and heavy industrial machinery increasingly require PCBs that can survive harsh mechanical environments. Hi-Rel PCB and PCBA manufacturing is now an essential extension of engineering design‚ÄĒnot an optional upgrade‚ÄĒwhen performance in vibration and shock conditions is mission-critical.

Why Choose EBest Circuit (Best Technology) to Manufacture PCBs and PCBA for Electronics Designed for High Vibration and Shock?

EBest Circuit (Best Technology) is engineered for reliability. We don’t just assemble boards; we build durable PCB and SMT assembly solutions designed to withstand the toughest conditions. Our specific process controls and capabilities directly address the challenges of high-vibration and shock environments.

- Superior Materials for Extreme Conditions:

- We utilize High-Tg (170-180¬įC) FR4 materials‚Äč (e.g., IT180A, S1170) to prevent delamination and maintain structural integrity under high thermal and mechanical stress.

- Our Metal Core PCBs (MCPCBs)‚Äč feature a thermal conductivity of up to 12 W/m.k, efficiently dissipating heat to prevent thermal cycling failures that weaken solder joints.

- Access to high-frequency materials (Rogers, Taconic) ensures signal integrity is maintained under stress.

- Precision Manufacturing for Unshakable Integrity:

- Exceptional layer-to-layer registration (¬Ī0.13mm)‚Äč ensures a stable, robust multilayer structure, preventing internal fractures.

- Advanced drilling capabilities allow for a high aspect ratio of 25:1, guaranteeing reliable plating integrity in every via, even in thick boards.

- We support heavy copper up to 28oz (outer layer)‚Äč and 20oz (inner layer), providing immense mechanical strength and current-carry capacity to resist flexing and vibration.

- Rigorous Quality Control & Certifications:

- Our assembly process is backed by state-of-the-art inspection: 3D SPI, AOI, and X-Ray‚Äč systems eliminate defects like weak solder joints that are prone to failure.

- We adhere to the most stringent industry standards, including IATF 16949 (Automotive)‚Äč and ISO 13485 (Medical), which mandate rigorous process controls for reliability and traceability.

- Our 97% on-time delivery rate‚Äč is a testament to a controlled and reliable production flow.

- Proven Experience and Turnkey Support:

- With 19 years of technical expertise‚Äč and a monthly capacity of 28,900 sq. meters, we have the scale and knowledge to handle complex, high-reliability projects from design (PCB layout) to full box-build assembly.

EBest Circuit (Best Technology) delivers the resilience your mission-critical applications require. With over 19 years of experience‚Äč and a monthly capacity of over 28,900 square meters, we have the relevant expertise and scale to not only manufacture your PCB and SMT design but also provide the engineering solutions for the high vibration and shock‚Äďcritical PCB and PCBA projects. Our 97% on-time delivery rate‚Äč ensures your demanding schedule is met.

To sum up, designing electronics for high vibration and shock‚Äč is a multifaceted challenge that demands expertise spanning design, material science, and precision manufacturing. This guide has outlined the essential strategies, from circuit design principles to PCB layout and the non-negotiable need for stable high-frequency performance. BEST Technology possesses the specialized knowledge and manufacturing rigor to transform your robust designs into reliable, durable products. Pls feel free to contact our engineering team at sales@bestpcbs.com‚Äč to discuss your high-vibration PCB or assembly application.

Tags: designing electronic circuits, Designing Electronics for High Vibration and Shock, designing electronics that work, designing for stability in high frequency circuits, pcb design for high vibration, PCB shock and vibration