How to choose copper busbar material? Let’s discover its material datasheet, material grades and properties, material selection guide, difference between T1 and T2 busbar material through this blog.

Are you worried about these problems?

- How to balance insufficient current-carrying capacity with cost?

- How to ensure lifespan under high-current conditions?

- Can non-standard designs be delivered quickly?

EBest Circuit (Best Technology) can provide solutions:

- High-Conductivity Copper: +15% conductivity with thinner design for cost reduction.

- Durable Protection: Tin/silver plating + passivation layer, 720h salt spray test.

- Agile Production: 3-day prototype delivery, supports 0.1mm precision adjustments.

Welcome to contact us if you have any request for copper busbar: sales@bestpcbs.com.

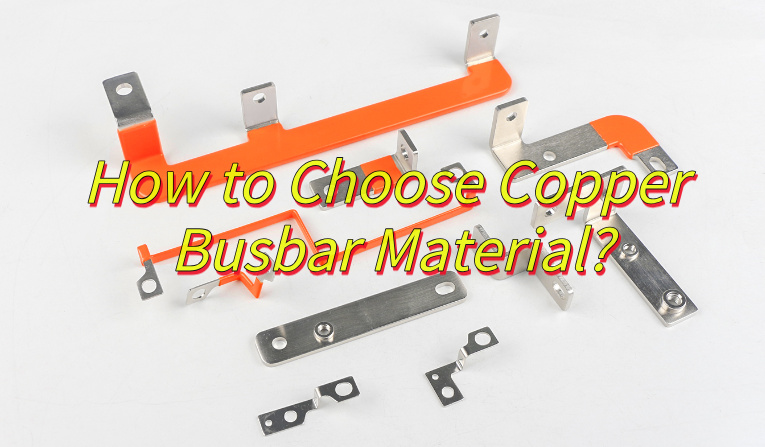

What is Copper Busbar?

Copper Busbar is a rectangular, circular, or tubular copper conductor used in power systems for high-current transmission. As a core component in busbar trunks and grounding systems, it directly carries large currents. Its advantages include high conductivity (superior to aluminum), thermal conductivity, corrosion resistance, and mechanical strength, supporting complex installation needs. Surfaces are often tin/silver-plated for enhanced durability.

Copper Busbar Material Datasheet

| Parameter Category | T1/TU1 (Oxygen-Free Copper) | T2 (Grade 2 Copper) | T3 (Grade 3 Copper) | TMY (Hard-State Copper) | Tin-Plated Copper (T2 Base) | Silver-Plated Copper (T2 Base) |

| Conductivity (%IACS) | ≥101 | ≥100 | ≥98 | ≥97 | ≥98 | ≥99 |

| Tensile Strength (MPa) | 200–250 | 220–280 | 240–300 | 350–450 | 220–280 | 220–280 |

| Elongation (%) | ≥40 | ≥35 | ≥30 | 6–15 | ≥35 | ≥35 |

| Hardness (HV) | 40–60 | 45–65 | 50–70 | 100–120 | 45–65 | 45–65 |

| Density (g/cm³) | 8.94 | 8.89 | 8.85 | 8.89 | 8.89 | 8.89 |

| Softening Temperature (°C) | 200 | 190 | 180 | 150 | 190 | 190 |

| Typical Standard | ASTM B152 | GB/T 5585 | GB/T 5231 | IEC 60439 | ASTM B33 | ASTM B298 |

Common Copper Busbar Material Grade & Properties

T1 (Grade 1 Copper) / TU1 (Oxygen-Free Copper)

- Properties: Ultra-high purity (≥99.95%), optimal conductivity/thermal conductivity, excellent plasticity (easy to bend/stretch), but low strength/hardness.

- Applications: Ultra-precision electrical instruments, high-frequency circuits, vacuum devices, superconducting equipment supports.

T2 (Grade 2 Copper)

- Properties: High purity (≥99.90%), good conductivity/thermal conductivity, excellent processability; contains trace oxygen (lower cost than T1).

- Applications: Most common copper busbar material. Used in power distribution systems (switchgear, transformers), high-current conductors, and busbar connections.

T3 (Grade 3 Copper)

- Properties: Purity ≥99.70%, slightly lower conductivity/thermal conductivity than T2, higher strength/hardness, good plasticity, lower cost.

- Applications: Cost-sensitive or moderate strength needs (e.g., general-purpose electrical connections).

TMY (Hard-State Copper Busbar)

- Properties: Typically T2 in hard (R) state. Cold-worked (rolled/drawn) for high strength/hardness, but reduced plasticity/conductivity.

- Applications: Structural supports, rigid connections, vibration-resistant components (common in distribution cabinets).

Soft Copper (O-State Copper)

- Properties: Annealed T2/TU1 in fully soft (O) state. Extremely pliable, highest conductivity (near-theoretical), but lowest strength.

- Applications: Flexible connections, complex-shaped components (e.g., jumpers, internal device soft links).

Tin-Plated Copper

- Properties: T2 copper with tin coating. Enhanced oxidation/corrosion resistance, improved solderability, stable contact resistance.

- Applications: Marine/outdoor equipment, high-humidity environments, tin-soldered connections.

Silver-Plated Copper

- Properties: Silver-coated copper. Superior conductivity (silver is best conductor), low/stable contact resistance, high corrosion/wear resistance.

- Applications: High-current/high-frequency contacts (e.g., HV switchgear, radar systems), sulfur-rich environments.

Special Copper Alloys (e.g., Cd, Zr, Cr-Zr)

- Properties: Copper with trace alloying elements (Cd, Zr, Cr). Slight conductivity loss for high strength/hardness, wear resistance, and elevated-temperature stability.

- Applications: High-stress/high-heat components (e.g., switch contacts, welding electrodes, furnace busbars).

How to Choose Copper Busbar Material?

Below are selection guide to copper busbar material:

1. Material Type and Conductivity

High-purity copper as the foundation:

- Electrolytic Tough Pitch (ETP) copper (purity ≥99.9%) is the industry standard, offering ≥98% IACS conductivity for minimal energy loss.

- Oxygen-Free Electronic (OFE) copper (purity ≥99.99%) is ideal for high-frequency applications (e.g., RF systems) due to its ultra-low oxygen content (<0.0005%), preventing oxide formation at joints.

Alloy avoidance:

- Unless mechanical strength is critical (e.g., seismic zones), skip brass or copper alloys, as even 0.5% alloy addition can reduce conductivity by 5–10%.

2. Surface Treatment and Corrosion Resistance

Plating strategies:

- Silver plating (2–5µm): Best for low-resistance contacts in high-current switches (e.g., circuit breakers), but requires laminating films to prevent scratching during installation.

- Tin plating (5–10µm): Cost-effective for general-purpose use, offering sacrificial protection against oxidation. Avoid in acidic environments (pH <6).

- Nickel plating (3–15µm): Resists sulfur-rich atmospheres (e.g., chemical plants) but increases contact resistance by 10–15%.

Edge finishing:

- Deburr all edges with a 1.5mm radius minimum; use CNC machining for precision. Chamfer angles >45° reduce electric field concentration.

3. Sizing and Current-Carrying Capacity

Cross-sectional design:

- Calculate using the formula: A = I × √(t) / (K × ΔT)

(Where A = area (mm²), I = current (A), t = time (s), K = material constant (0.049 for copper), ΔT = temp rise (°C)). - Example: For 1000A over 1s with ΔT=30°C, A ≈ 1000 × 1 / (0.049 × 30) ≈ 680mm² (use 700mm² for safety).

Shape optimization:

- Flat bars: Best for natural convection cooling (e.g., busbar trunks).

- Hollow tubes: Reduce weight by 40% while maintaining 85% conductivity (ideal for aerospace).

4. Fabrication and Installation

Precision processing:

- Use laser cutting for holes <3mm to avoid deformation. For bending, maintain a bend radius ≥2× thickness to prevent cracking.

- Clean surfaces with isopropyl alcohol after machining to remove oil residues.

Connection best practices:

- Copper-to-copper: Use friction welding for permanent joints (shear strength >200MPa).

- Copper-to-aluminum: Apply zinc-based dielectric coating (e.g., Dow 17) before bolting to mitigate galvanic corrosion.

Insulation requirements:

- Use silicone rubber (Class H, 180°C) for high-temp zones. For outdoor use, add UV-resistant coating.

5. System Compatibility and Standards

Standard alignment:

- IEC 60439-1: Mandates busbar temperature rise ≤70°C under full load.

- UL 758: Requires flammability rating V-0 for insulation materials.

Future-proofing:

- Pre-drill M6/M8 holes with 10mm spacing for future branch connections.

- Use modular busbar systems (e.g., plug-in units) for easy capacity upgrades.

6. Quality Assurance & Brand Trust

Inspection checklist:

- Visual: No discoloration (blue/green patches indicate oxidation).

- Dimensional: Use calipers to verify tolerance (±0.1mm for critical dimensions).

- Electrical: Conduct 4-wire resistance tests (≤0.00001Ω accuracy).

Certifications:

- Demand ISO 9001 (quality management) and IEC 62560 (safety for low-voltage systems).

7. Cost Optimization and Alternatives

Copper vs. aluminum:

- Aluminum costs 30% less but requires 1.6× larger area. Use only in dry, low-vibration environments (e.g., solar farms).

Sustainable options:

- Recycled copper (95% purity) reduces carbon footprint by 65% but requires rigorous testing for impurities (e.g., lead <0.001%).

Difference between T1 and T2 Copper Busbar Material

| Property | T1 Copper | T2 Copper |

| Purity | ≥99.95% Cu | ≥99.90% Cu |

| Conductivity | ~100% IACS | ~97% IACS |

| Tensile Strength | ≥275 MPa | ≥195 MPa |

| Impurity Control | Total impurities ≤0.05% (minimal P) | Total impurities ≤0.1% (trace P allowed) |

| Applications | High-precision instruments, vacuum devices | Power distribution, general electrical connections |

| Cost | Higher | Lower |

| Corrosion Resistance | Superior (ideal for harsh environments) | Good (avoid high-temp reducing atmospheres) |

| Workability | Avoid high-temp processing (prevent hydrogen embrittlement) | Excellent for mass production |

Why Choose EBest Circuit (Best Technology) as Copper Busbar PCB Supplier?

Reasons why choose us as copper busbar PCB supplier:

- Global Certifications: ISO 9001 (quality), ISO 14001 (environmental), and UL (flame/current safety) compliant.

- Cost Efficiency: 15-20% savings via direct factory pricing, no middlemen.

- Rapid Delivery: 24-hour prototype turnaround; 98% on-time delivery for bulk orders (500+ units).

- Premium Materials: 99.9% pure T2-grade copper with third-party certifications.

- Advanced PCBA Integration: In-house SMT lines handle 0201 components and 0.3mm BGA pitch.

- One Stop Solution: Design→ Prototyping → Mass Production → Assembly.

- Rigorous Quality Inspection: 4-stage checks (material → process → electrical → aging tests).

- Custom Flexibility: Multi-layer busbars (up to 6 layers), complex geometries, no MOQ (10+ units).

- Free Engineering Support: DFM analysis for cost-performance balance; 24/7 technical assistance.

Our Busbar PCB Capabilities

| Parameter | Value/Description |

| Copper Bar Spacing | 0.8-1.0mm |

| Copper Thickness | 1.0mm-3.0mm |

| Current Carrying Capacity | 50-300A |

| Bendability | Customizable bending upon request |

| Surface Finishing Options | ENIG (Electroless Nickel Immersion Gold), Immersion Silver, Gold Plating |

| Board Thickness | 3.0-6.0mm |

| Hole Wall Thickness | ≥25μm |

| Aspect Ratio | 1:6 or 1:7 (for 1.0mm copper thickness with minimum 0.7mm hole diameter) |

| Layer Count | Typical 3-4 layers; additional layers require design evaluation |

| Maximum Dimensions | Standard: 600×400mm; Double-sided: 900×600mm |

| Lead Time | 3-4 layers: 13-15 days; add 3 days per layer beyond 4 layers |

How to Get a Quote for Busbar PCB Project?

Below is a busbar PCB project quote required materials list:

1. Technical Specs:

- Dimensions/shape (include drawings or CAD files).

- Copper base material (T1/T2/alloy) and surface finish (tin/silver/nickel plating).

- Performance requirements (strength, conductivity, temperature resistance).

2. Project Details:

- Quantity/delivery timeline (e.g., 500pcs, 3 weeks).

- Certification needs (UL/RoHS/IEC).

- Testing requirements (e.g., salt spray test).

3. Commercial Terms:

- Budget range (optional).

- Packaging/shipping preferences (anti-static/moisture-proof).

Welcome to contact us if you have any request for busbar PCB: sales@bestpcbs.com.

Tags: copper busbar material