Are these PCB material challenges slowing down your projects?

- Does your current substrate overheat and shorten the lifespan of your high-power components?

- Are you losing signal quality in RF or microwave designs because the dielectric constant isn’t stable enough?

- Do harsh environments cause your boards to warp, crack, or fail over time?

At EBest Circuit (Best Technology), we work with engineers facing these exact problems every day.

- Our alumina ceramic substrates provide the thermal stability, electrical performance, and mechanical strength needed for demanding applications.

- With grades from 96% to 99.6% purity, thicknesses tailored to your design, and precision machining for complex layouts, we help you create PCBs that run cooler, last longer, and perform more reliably — even under extreme conditions.

If you’ve ever wondered about alumina ceramic substrate datasheet specs, dielectric constant, thickness, pricing, or how they compare to other materials, you’re in the right place. This guide answers the most common questions engineers and buyers ask — with clear, practical insights.

What Is Alumina Ceramic Substrate?

An alumina ceramic substrate is a flat base material made from aluminum oxide (Al₂O₃), sintered at high temperatures. It offers a rigid, thermally stable foundation for mounting electronic circuits.

The most common grades are 96% alumina and 99.6% alumina, where the number reflects the material’s purity. Higher purity improves electrical insulation and reduces dielectric loss, making it suitable for sensitive or high-frequency designs.

Engineers prefer alumina substrates because they:

- Withstand extreme heat without distortion.

- Resist wear, corrosion, and electrical breakdown.

- Match the thermal expansion of semiconductor materials, reducing mechanical stress during thermal cycling.

From LED modules to aerospace systems, alumina substrates protect circuits in environments where other materials would fail.

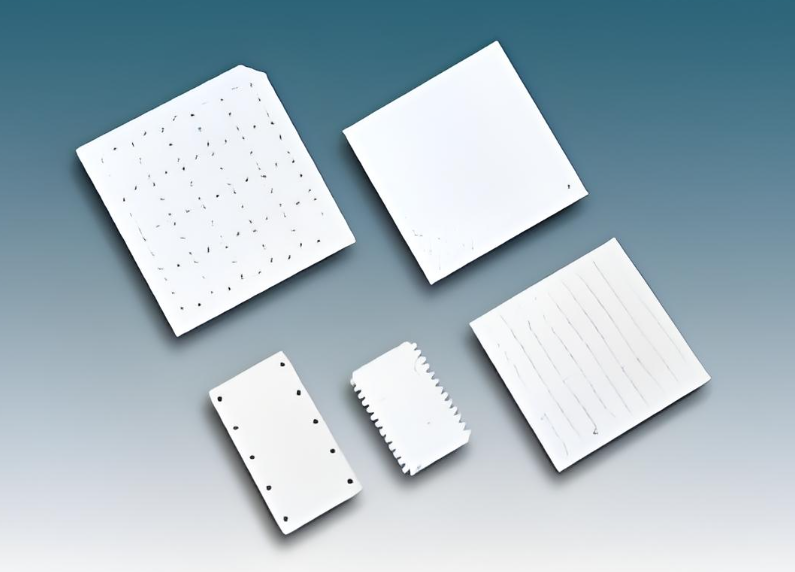

Types of Alumina Substrates

Although alumina substrates share the same base material, they come in different forms to suit different needs:

- 96% Alumina Substrates – The industry standard for general electronics. Balanced thermal conductivity (~20–25 W/m·K) and dielectric properties.

- 99.6% Alumina Substrates – Higher purity for RF, microwave, and high-precision devices.

- Metallized Alumina Substrates – Pre-coated with conductive layers like gold, silver, or copper using thick or thin film processes.

- Custom-Shaped Alumina Substrates – Produced by laser cutting or grinding for specialized layouts.

The choice depends on your performance requirements, assembly method, and budget.

Common Alumina Substrate Thickness Options

Thickness plays a critical role in mechanical stability, thermal transfer, and dielectric strength.

Standard options include:

- 0.25 mm – Excellent for compact modules with high heat transfer needs.

- 0.38 mm – Balanced option for strength and thermal performance.

- 0.5 mm – Common in LED boards and power modules.

- mm – Used in high-load or mechanically stressed environments.

Thinner substrates dissipate heat faster but are more fragile. Thicker substrates provide rigidity but may slow thermal transfer. The selection depends on your device’s heat output and durability requirements.

Alumina Substrate Dielectric Constant and Its Impact

The dielectric constant (εr) measures a material’s ability to store electrical energy in an electric field. For alumina substrates, it typically ranges from 9.4 to 10.2 at 1 MHz.

A stable dielectric constant is essential for maintaining signal integrity in RF and microwave circuits. If the dielectric constant is too high or unstable, signals can slow down or distort, especially in high-speed data paths.

Designers choose alumina when they need:

- Low signal loss in high-frequency designs.

- Stable electrical performance over temperature changes.

- Reliable insulation in compact multilayer packages.

Alumina Substrate Datasheet

When selecting an alumina ceramic substrate, having a clear reference to its mechanical, thermal, and electrical parameters ensures your design meets performance and safety requirements. Below is a consolidated datasheet for standard 96% and 99.6% alumina substrates.

| Property | 96% Alumina | 99.6% Alumina | Unit / Test Method |

| Al₂O₃ Content | ≥ 96% | ≥ 99.6% | XRF Analysis |

| Color | White / Ivory | White | Visual |

| Density | 3.70 – 3.75 | 3.90 – 3.92 | g/cm³ (ASTM C20) |

| Flexural Strength | ≥ 350 | ≥ 380 | MPa (ASTM C1161) |

| Thermal Conductivity | 20 – 25 | 28 – 32 | W/m·K (ASTM E1461) |

| Coefficient of Thermal Expansion (CTE) | 7.1 – 7.5 | 7.0 – 7.4 | ppm/°C (25–300°C, ASTM E831) |

| Dielectric Constant (εr) | 9.4 – 9.8 | 9.8 – 10.2 | @ 1 MHz (ASTM D150) |

| Dielectric Strength | 15 – 18 | 18 – 20 | kV/mm (ASTM D149) |

| Loss Tangent (tan δ) | ≤ 0.0015 | ≤ 0.0005 | @ 1 MHz |

| Maximum Operating Temperature | ~1500 | ~1700 | °C (Inert/Vacuum) |

| Water Absorption | 0 | 0 | % (ASTM C373) |

Key Takeaway:

- 96% alumina is cost-effective for general high-reliability electronics.

- 99.6% alumina is ideal for RF, microwave, and precision optical systems where dielectric performance and purity are critical.

Popular Alumina Ceramic Uses

Alumina ceramics are used in industries where heat, reliability, and precision are non-negotiable.

Applications include:

- LED Lighting: Improves heat dissipation, extending LED life.

- Power Electronics: Handles high voltage and heat in converters, inverters, and motor drives.

- Medical Devices: Offers biocompatibility and electrical stability for implants and diagnostic equipment.

- Aerospace: Withstands extreme thermal cycling and mechanical stress.

- Automotive Electronics: Reliable for ECU boards and EV power systems.

- RF & Microwave: Stable dielectric constant supports high-frequency communications.

Alumina Ceramic Substrates Price

Alumina ceramic substrate doesn’t have a specific price, it varies based on:

- Material Purity: 99.6% alumina costs more than 96%.

- Thickness: Thicker substrates use more material and require longer processing.

- Size and Shape: Custom cuts increase machining cost.

- Metallization: Gold or silver layers add cost.

- Order Quantity: Larger runs reduce per-unit price.

As a general guide, simple standard substrates may cost a few dollars, while large, high-purity, custom shapes can reach $20–$50+ per piece. For the alumina ceramic PCB, the price is much high, and should depends on the specific requirements, like metallization method, shapes, via holes, single side or double side or multi-layer.

Alumina Substrate vs. Silicon Nitride Substrate: How to Choose?

Both alumina substrate and silicone nitride substrate are the good material base for ceramic PCB. Each of them has its properties and advantages. When choosing between alumina and silicon nitride comes down to performance priorities — thermal conductivity, mechanical strength, and cost. Here’s a side-by-side comparison:

| Property | Alumina Ceramic Substrate | Silicon Nitride (Si₃N₄) Substrate |

| Thermal Conductivity | 20 – 32 W/m·K | 70 – 90 W/m·K |

| Flexural Strength | 350 – 400 MPa | 800 – 1000 MPa |

| Fracture Toughness | 3 – 4 MPa·m½ | 6 – 8 MPa·m½ |

| CTE (ppm/°C) | ~7.1 – 7.4 | ~2.8 – 3.2 |

| Dielectric Constant (εr) | 9.4 – 10.2 | 8.0 – 9.0 |

| Loss Tangent | ≤ 0.0015 (96%) / 0.0005 (99.6%) | ≤ 0.002 |

| Maximum Operating Temp. | ~1500 – 1700°C | ~1200°C |

| Cost Level | Low to Medium | High |

| Typical Applications | LEDs, RF boards, medical sensors, aerospace PCBs | EV inverters, IGBT modules, heavy-duty industrial electronics |

In Summary:

- Choose alumina when you need high dielectric performance, good thermal conductivity, and economical cost.

- Choose silicon nitride when your priority is extreme thermal cycling resistance, very high mechanical strength, or ultra-high-power module cooling.

Why Choose EBest Circuit (Best Technology) for Alumina Ceramic Substrates?

EBest Circuit (Best Technology) manufactures alumina ceramic substrates to meet strict industry requirements. We are certified to ISO9001, ISO13485, IATF16949, and AS9100D, covering industrial, medical, automotive, and aerospace applications.

We use MES systems to ensure traceability from raw material to finished product. Our engineering team works closely with customers to select the right grade, thickness, and metallization for optimal results. Competitive pricing, precise machining, and reliable delivery make us the trusted choice for customers worldwide.

FAQs

1. What is the maximum operating temperature of alumina substrates?

Up to 1500°C in inert or vacuum environments; metallization layers may limit this.

2. Can you machine alumina ceramic without damaging it?

Yes, using diamond grinding, laser cutting, or ultrasonic machining.

3. Are alumina substrates better for RF circuits than FR4?

Yes, because of stable dielectric constant and lower signal loss.

4. How do I choose the right thickness?

Match thermal load, mechanical requirements, and assembly constraints.

5. What is the standard lead time?

Around 3–5 weeks depending on complexity and order size.

Tags: alumina ceramic substrates, alumina ceramic substrates price, alumina substrate dielectric constant, alumina substrate thickness